Professional Documents

Culture Documents

GMC2009 Load and Flow Control Devices

GMC2009 Load and Flow Control Devices

Uploaded by

cnrk777inOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GMC2009 Load and Flow Control Devices

GMC2009 Load and Flow Control Devices

Uploaded by

cnrk777inCopyright:

Available Formats

ACI Services, Inc.

Cambridge, Ohio USA

740.435.0240

www.ACIServicesInc.com

GMC 2009 – Atlanta, GA

Course Purpose

Provide course attendees with:

A fundamental review and understanding of the many types of

reciprocating compressor unloading and capacity control

devices,

Useful knowledge for evaluating and comparing individual

unloading and control devices,

Tools for identifying the best approach and devices for

optimizing current, reapplied and new compressor

performance relative to unique needs and budgets,

An objective method for selecting and economically justifying

optimum control devices.

GMC 2009 – Atlanta, GA 2

Course Scope

Quick-reference charts

Pressure-Volume diagrams

Diagrams, schematics and pictures

Relative advantages and disadvantages

Practical applicability

Performance considerations across full operating maps

Installation considerations

Maintenance issues

Operational limitations

Automation possibilities

Economic considerations and justification

GMC 2009 – Atlanta, GA 3

Compression Process

GMC 2009 – Atlanta, GA 4

Compressor Load

(Power Requirement)

Friction Loss

Valve

Loss Adiabatic Load

Indicated Load = Adiabatic Load + Valve Loss

(As Measured via Analyzer)

Total Cylinder Load = Indicated Load + Friction Loss

GMC 2009 – Atlanta, GA 5

Compressor Load

(Power Requirement)

Indicated Load per End =

Adiabatic + ValveLoss Suction + ValveLoss Discharge

Discharge Valve

Loss Load VL = f (RPM3)

PD

Thus,

80% Speed Î 51% VL

Pressure

Adiabatic

Load

PS

Suction Valve

Loss Load

Volume

GMC 2009 – Atlanta, GA 6

Compressor Flow

(Capacity)

Flow Rate or Capacity

Flow = f ( VES x PS x AP x S x RPM )

Suction

Pressure

Piston Displacement

Suction

AP = Piston Area

Volumetric

S = Piston Stroke

Efficiency

RPM = Speed

GMC 2009 – Atlanta, GA 7

Compressor Flow

(Capacity)

Volumetric Efficiency

Flow = f (VES)

PD

Inlet Volume

VES = %

Swept Volume

Inlet volume

PS

VMIN VMAX

Swept Volume

GMC 2009 – Atlanta, GA 8

Compressor Flow

(Capacity)

Crank

Fixed Clearance Volume

End

Head

Flow = f (VES)

(

VE S % ≈ 100% − Clr% R1/ K − 1)

Fixed Volume

Clr % = *100%

Swept Volume

Head End Head

R is Pressure Ratio

K is a Gas Property

GMC 2009 – Atlanta, GA 9

Reasons for Control of

Load and Flow

Reduce Load for Easier Startup

Gradual Loading After Startup

Avoid Driver Overload as Conditions Change

Deliver Required Flow Rate

Maximize Driver Load Utilization and Flow

Reduce the Number of Shut Downs and Start Ups

Automate Unit Control

Handle System Upsets without Shut Downs

Accommodate Wide Range of Conditions

(e.g. Storage/Withdrawal)

System Optimization

GMC 2009 – Atlanta, GA 10

Parameters Affecting

Load and Flow

Suction Pressure

Suction Temperature

Discharge Pressure

Gas Properties

Piston Stroke

Speed

Piston Area (bore size)

Cylinder Fixed Clearance Percent

Valve Size (effective area and resistance to flow)

Number of Cylinder Active Ends (front and rear ends)

GMC 2009 – Atlanta, GA 11

Means of Controlling

Load and Flow

9 Physical Hardware Changes

Manual Control with Manual Actuation

Manual Control with Automated Actuation

Automated Control with Automated Actuation

Examples:

Valve spacers.

Relining cylinders to change bore diameters.

GMC 2009 – Atlanta, GA 12

Means of Controlling

Load and Flow

Physical Hardware Changes

9 Manual Control with Manual Actuation

Manual Control with Automated Actuation

Automated Control with Automated Actuation

Example:

Manual front head variable volume clearance pocket

(VVCP).

GMC 2009 – Atlanta, GA 13

Means of Controlling

Load and Flow

Physical Hardware Changes

Manual Control with Manual Actuation

9 Manual Control with Automated Actuation

Automated Control with Automated Actuation

Examples:

Pneumatic, hydraulic and electric actuation devices

that are activated with manual valves or switches.

GMC 2009 – Atlanta, GA 14

Means of Controlling

Load and Flow

Physical Hardware Changes

Manual Control with Manual Actuation

Manual Control with Automated Actuation

9 Automated Control with Automated Actuation

Examples:

Pneumatic, hydraulic and electric actuation devices

that are controlled and activated by a Control Panel.

GMC 2009 – Atlanta, GA 15

Load and Flow

Methods & Devices

9 Variable Speed Control

Engine Speed Governor

Variable Frequency Motor Drive

Torque Controller

External Bypass

Startup Bypass

Capacity Control Bypass

Suction Pressure Control

Pressure Reducing Valve

Deactivate Cylinder End

Suction Valve Removal

Valve Unloaders (Plug-Type, Finger-Type, or Radial-Type)

Suction Valve Lifting

Internal Cylinder Body Bypass

Head End Bypass

GMC 2009 – Atlanta, GA 16

Load and Flow

Methods & Devices

Variable Speed Control

Engine Speed Governor

Variable Frequency Motor Drive

Torque Controller

9 External Bypass

Start Up Bypass

Capacity Control Bypass

Suction Pressure Control

Pressure Reducing Valve

Deactivate Cylinder End

Suction Valve Removal

Valve Unloaders (Plug-Type, Finger-Type, or Radial-Type)

Suction Valve Lifting

Internal Cylinder Body Bypass

Head End Bypass

GMC 2009 – Atlanta, GA 17

Load and Flow

Methods & Devices

Variable Speed Control

Engine Speed Governor

Variable Frequency Motor Drive

Torque Controller

External Bypass

Startup Bypass

Capacity Control Bypass

9 Suction Pressure Control

Pressure Reducing Valve

Deactivate Cylinder End

Suction Valve Removal

Valve Unloaders (Plug-Type, Finger-Type, or Radial-Type)

Suction Valve Lifting

Internal Cylinder Body Bypass

Head End Bypass

GMC 2009 – Atlanta, GA 18

Load and Flow

Methods & Devices

Variable Speed Control

Engine Speed Governor

Variable Frequency Motor Drive

Torque Controller

External Bypass

Startup Bypass

Capacity Control Bypass

Suction Pressure Control

Pressure Reducing Valve

9 Deactivate Cylinder End

Suction Valve Removal

Valve Unloaders (Plug-Type, Finger-Type, or Radial-Type)

Suction Valve Lifting

Internal Cylinder Body Bypass

Front Head Bypass

GMC 2009 – Atlanta, GA 19

Load and Flow

Methods & Devices

9 Displacement Changes

Changing Bore Diameter or Stroke

Fixed Clearance Changes

Removable Clearance Plugs (Head or Body)

Clearance Bottles

Internal Body Pockets

Valve Spacers

Front Head Spacers

Piston Changes

Head End Fixed Volume Clearance Pockets

Valve Cap Fixed Volume Clearance Pockets

Variable Volume Clearance Pockets

Adjustable Suction Valves

Timed Valve Closing

Infinite Step Unloaders (e.g. HydroCOM)

Combinations of the Above

GMC 2009 – Atlanta, GA 20

Load and Flow

Methods & Devices

Displacement Changes

Changing Bore Diameter or Stroke

9 Fixed Clearance Changes

Removable Clearance Plugs (Head or Body)

Clearance Bottles

Internal Body Pockets

Valve Spacers

Front Head Spacers

Piston Changes

Head End Fixed Volume Clearance Pockets

Valve Cap Fixed Volume Clearance Pockets

Variable Volume Clearance Pockets

Adjustable Suction Valves

Timed Valve Closing

Infinite Step Unloaders (e.g. HydroCOM)

Combinations of the Above

GMC 2009 – Atlanta, GA 21

Load and Flow

Methods & Devices

Displacement Changes

Changing Bore Diameter or Stroke

Fixed Clearance Changes

Removable Clearance Plugs (Head or Body)

Clearance Bottles

Internal Body Pockets

Valve Spacers

Front Head Spacers

Piston Changes

Head End Fixed Volume Clearance Pockets

Valve Cap Fixed Volume Clearance Pockets

Variable Volume Clearance Pockets

Adjustable Suction Valves

9 Timed Valve Closing

Infinite Step Unloaders (e.g. HydroCOM)

Combinations of the Above

GMC 2009 – Atlanta, GA 22

Load and Flow

Methods & Devices

Displacement Changes

Changing Bore Diameter or Stroke

Fixed Clearance Changes

Removable Clearance Plugs (Head or Body)

Clearance Bottles

Internal Body Pockets

Valve Spacers

Front Head Spacers

Piston Changes

Head End Fixed Volume Clearance Pockets

Valve Cap Fixed Volume Clearance Pockets

Variable Volume Clearance Pockets

Adjustable Suction Valves

Timed Valve Closing

Infinite Step Unloaders (e.g. HydroCOM)

9 Combinations of the Above

GMC 2009 – Atlanta, GA 23

P–V Diagram

The Pressure-Volume Diagram

Items to Watch

Efficiency

Load Changes

Flow Changes

Load/Flow Unit

GMC 2009 – Atlanta, GA 24

Ratings Criteria

INSTALLED COST

What is the relative initial capital investment cost of the device?

Low Initial Cost

Moderately Low Initial Cost

Medium Initial Cost

Moderately High Initial Cost

High Initial Cost

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 25

Ratings Criteria

EFFICIENCY

What is the relative effect of the device on isentropic efficiency

during use?

Greatly improves

Moderately improves

Little or no effect

Moderately reduces

Greatly reduces

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 26

Ratings Criteria

ADAPTABILITY

How easily is the device applied to, and installed on,

existing equipment?

Easy

Moderately Easy

Neither Easy or Difficult

Moderately Difficult

Difficult

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 27

Ratings Criteria

SIMPLICITY

How easy is the device to use?

Easy

Moderately Easy

Neither Easy or Difficult

Moderately Difficult

Difficult

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 28

Ratings Criteria

AUTOMATABLE

How easily can the device be automated?

Easy

Moderately Easy

Neither Easy or Difficult

Moderately Difficult

Difficult

Not Possible

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 29

Variable Speed Control

9 Variable Speed Control

Defined

Adjustment of the prime

Unit / Stage Bypass mover operating speed

Control system

Throttling of Operating Pressures evaluates a process

End Deactivation variable and adjusts

speed

Displacement Changes Affects the suction and

discharge events

Added Fixed Clearance Same adiabatic load per

Adjustable Head End Suction Valve revolution, just a change

in RPM

Added Variable Volume Clearance

Added Fixed Volume Clearance Devices Devices

Governor

Timed Valve Closing Fuel Control Valve

Variable Frequency

Drives

Torque Controllers

GMC 2009 – Atlanta, GA 30

Variable Speed Control Governors, VFD & Other Speed Control

What is it?

Fuel Control Valve; Mechanical

Governor; Torque Controller; Variable

Frequency Drive

What does the device do?

Decreases / Increases the prime mover

operating speed

How does it work?

Input variable from the operator via the

prime mover control system

Appropriate signals are generated and

the control device makes the necessary

adjustments

Image courtesy of Waukesha Engine Division

Where is it installed?

Designed as part of the prime mover

control system

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 31

Variable Speed Control P-V Diagram

Fixed Clearance Avg. 25%

Load Changes

750 RPM

800 RPM

900 RPM

Reduce RPM: 1000 RPM

Adiabatic Load Remains Same

Flow changes due to less RPM

Reduction in Valve Loss Load Flow Changes

GMC 2009 – Atlanta, GA 32

Unit / Stage Bypass

Variable Speed Control Defined

Start Up or Capacity

9 Unit / Stage Bypass

Control

Modulating Valves

Throttling of Operating Pressures

Commonly used for

End Deactivation Control Purposes

Startup: typically hot

Displacement Changes gas bypass (before

cooler)

Added Fixed Clearance Capacity Control:

Adjustable Head End Suction Valve typically cooler gas

bypass (after the cooler)

Added Variable Volume Clearance Gas piped back to the

suction scrubber

Added Fixed Volume Clearance Devices

Timed Valve Closing Devices

Piping system with

appropriate plug-type

throttling valves

GMC 2009 – Atlanta, GA 33

Unit / Stage Bypass External Piping Bypass

What is it?

Bypass Valve (Plug-type valve)

External piping from discharge piping to

suction piping (4 to 8 inch piping)

What does the device do?

Recycles gas - Allows compressed

discharge gas to expand and flow back to

the suction side of the compressor

How does it work?

Control overall output of the unit/station

Open the control valve to allow gas to

pass from the discharge to suction piping

Open suction valve – signal to bypass

valve to close (up to 20 seconds)

Where is it installed?

Image courtesy of Cameron Valves Photos courtesy of El Paso Corp.

Within the confines of the station piping;

* Station’s overall efficiency affected, not unit’s isentropic efficiency. between discharge and suction

INSTALLED COST EFFICIENCY*

Courtesy of ACI Services, Inc.

ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 34

Unit / Stage Bypass P-V Diagram

GMC 2009 – Atlanta, GA 35

Throttling of Operating Conditions

Defined

Variable Speed Control

Adjustment of the

Unit / Stage Bypass operating pressures to a

set value

9 Throttling of Operating Pressures

Typically suction pressure

control

End Deactivation Control system evaluates

Displacement Changes a process variable and

adjusts the suction

Added Fixed Clearance pressure

Accomplished through a

Adjustable Head End Suction Valve suction control valve

Added Variable Volume Clearance Affects the suction and

compression events

Added Fixed Volume Clearance Devices Changes adiabatic load

Timed Valve Closing Devices

Suction Pressure

Reducing Valve

GMC 2009 – Atlanta, GA 36

Throttling of Operating Pressures Suction Pressure Control Valves

What is it?

Plug-type Control Valve – (manual,

pneumatic or electric)

What does the device do?

Pinch back the suction pressure

How does it work?

Intake line is throttled towards off

No supply (or reduced) supply of gas to

compressor

The suction pressure will decline

Ultimate result is a reduction in

capacity

Where is it installed?

Within the suction piping prior to the

scrubber / pulsation bottle

Image Courtesy of Kimray

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 37

Throttling of Operating Pressures P-V Diagram

Fixed Clearance Avg. 25%

Load Changes

Suction Pressure

600 psig

Suction Pressure

650 psig

Reduce Ps:

Load may Increase OR Decrease!

Isentropic Efficiency Increases

Reduce Flow Flow Changes

GMC 2009 – Atlanta, GA 38

End Deactivation

Defined

Variable Speed Control

Means to allow gas to

Unit / Stage Bypass flow out of the cylinder

end during the

Throttling of Operating Pressures compression stroke

9 End Deactivation

Devices

Displacement Changes Internal Body Ports

Suction Valve Unloaders

Added Fixed Clearance (Finger and Plug-type)

Adjustable Head End Suction Valve Radial Valve Unloaders

Valve Assembly Lifter

Added Variable Volume Clearance Front Head Plug-type

Bypass

Added Fixed Volume Clearance Devices

Timed Valve Closing

GMC 2009 – Atlanta, GA 39

End Deactivation Internal Cylinder Body Ports

What is it?

Removable plug (manually removed)

Plug type actuator assembly

What does the device do?

Allows gas to flow back to inlet passage

Image Courtesy of Cameron

Compression Systems

How does it work?

Actuation medium supplied to actuation

cylinder

Actuation Pressure to load the cylinder

Vent actuation pressure – gas pressure

moves plug to open the volume allowing

gas to flow

Where is it installed?

Cavity cast into the cylinder

Head end or crank end

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 40

End Deactivation Finger-type Valve Unloaders

What is it?

Plunger with fingers attached

Fits into the seat of the valve

What does the device do?

Depresses the valve plates (deactivating

the cylinder end)

Allows gas to pass through the valves

during the compression event

Gas passes back onto the inlet passage

How does it work?

Fingers push and hold open the moving

element in the suction valve

Air pressure to unload

Where is it installed?

Image Courtesy of Hoerbiger Corp.

Over suction valves (head or crank end)

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 41

End Deactivation Plug-type Valve Unloaders

What is it?

Shaft with a plug attached

Partial valve with a hole in the center

What does the device do?

Deactivates the cylinder end

Allows gas to pass through the hole in the

valve during the compression event

Gas passes back into the inlet passage

How does it work?

Plug seals the hole during normal

operation - Air pressure to load

OPEN CLOSED Remove Air pressure – gas pressure

pushes the plug to the open position

Gas flows Gas flows

around valves through valves

Where is it installed?

Over suction valves (head or crank end)

Images Courtesy of ACI Services, Inc.

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 42

End Deactivation Radial Poppet Unloaders

What is it?

Poppet valve assembly

Guard which holds the poppets connected

to an actuator assembly

Cylindrical seat for poppets

What does the device do?

Deactivates the cylinder end

Allows gas to flow through seat

Gas flows back into inlet passage

How does it work?

Air pressure to load

Guard moves linearly up/down

Poppets move with guard

Images Courtesy of ACI Services, Inc.

Where is it installed?

Suction valves (head end or crank end)

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 43

End Deactivation Valve Assembly Lifter

What is it?

Valve attached to a lead screw

Lead screw is mounted in a yoke

assembly (valve cap)

What does the device do?

Deactivates the cylinder end

Lifts the suction valve from their seat

Image Courtesy of GPSA

How does it work?

Turn the lead screw (and valve assembly)

Moves the valve away from its seat

Allows gas to flow into the inlet passage

Where is it installed?

Over suction valves (head or crank end)

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 44

End Deactivation Front Head Plug-type Bypass

What is it?

Front end head with a bypass plug and

actuator assembly

External piping to inlet passageways

What does the device do?

Deactivates the cylinder end

Allows gas to flow through the bypass

plug to the bottle or suction valve

How does it work?

Images Courtesy of ACI Services, Inc.

Air pressure to seat the bypass plug

Remove pressure, cylinder pressure will

push the plug away from the seat

Gas flows around plug – deactivating end

Where is it installed?

Cylinder Head End Head

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 45

End Deactivation P-V Diagram

Fixed Clearance Avg. 25%

Load Changes

End Deactivated

GMC 2009 – Atlanta, GA 46

Displacement Changes

Defined

Variable Speed Control

Change of the cylinder

Unit / Stage Bypass bore diameter

Change of the stroke of

Throttling of Operating Pressures the compressor throw

End Deactivation

Devices

9 Displacement Changes

Piston and Liner Changes

Added Fixed Clearance Crankshaft Changes

Adjustable Head End Suction Valve

Added Variable Volume Clearance

Added Fixed Volume Clearance Devices

Timed Valve Closing

GMC 2009 – Atlanta, GA 47

Displacement Changes Liner Insertion (Cylinder Bore Change)

What is it?

Physical change to the cylinder bore size

Utilization of cylinder slip fit liners

What does the device do?

Reduces/increases the piston

displacement

Affects the cylinder fixed clearance

How does it work?

Change the piston diameter

Install the appropriate liner

Images Courtesy of Cameron Compression Systems

Where is it installed?

Cylinder bore area

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 48

Displacement Changes P-V Diagram

Cylinder Bore 7-inch

Fixed Clearance Avg. 25%

Load Changes

Cylinder Bore 6-inch

Fixed Clearance Avg. 35%

Decrease Cylinder Bore:

Load Reduction

Isentropic Efficiency Increases

Flow Reduction

GMC 2009 – Atlanta, GA 49

Added Fixed Clearance

Defined

Variable Speed Control

Increase of the cylinder

Unit / Stage Bypass fixed clearance volume

Once added, clearance is

Throttling of Operating Pressures always present

End Deactivation Physical change to the

compressor cylinder

Displacement Changes Affects the compression

and expansion events

9 Added Fixed Clearance

Adjustable Head End Suction Valve Devices

Clearance Plugs/Bottles

Added Variable Volume Clearance

Valve Spacers

Added Fixed Volume Clearance Devices Piston Modifications

Cylinder Head

Timed Valve Closing Modifications

Liner Changes

GMC 2009 – Atlanta, GA 50

Added Fixed Clearance Devices Clearance Plugs and Bottles

Internal Cylinder Designs

What is it?

Cylinder designed with plug ports

What does the device do?

Plug/Partial Plug – Fills a volume

Cap – Exposes designed volume

Bottle – Adds additional volume

How does it work?

Remove the plug for added clearance

Install a cap or bottle in place of the plug

Where is it installed?

In/over a cylinder body port

Images Courtesy of ACI Services, Inc.

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 51

Added Fixed Clearance Devices Clearance Plugs and Bottles

Retrofit Designs

What is it?

Retrofit of added port plugs

What does the device do?

Plug/Partial Plug – Fills a volume

Cap – Exposes designed volume

Bottle – Adds additional volume

How does it work?

Remove the plug for added clearance

Install a cap or bottle in place of the plug

Where is it installed?

Front Head End of Cylinder

Over a Valve (rare)

Image Courtesy of ACI Services, Inc.

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 52

Added Fixed Clearance Devices Valve Spacers

What is it?

Ring manufactured from bar stock or

tubing

Thickness ranges from 0.375” to 1.50”

What does the device do?

Moves the valves away from cylinder bore

Images Courtesy of Ariel Corporation Adds fixed clearance to the cylinder end

How does it work?

Valve seats on the spacer instead of the

cylinder port

Space under the valve - fixed clearance

Where is it installed?

Under the suction and/or discharge valves

On one, or both ends of the cylinder

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 53

Added Fixed Clearance Devices Piston Modifications

What is it?

Piston design that is reversible

Physical modification to existing piston

What does the device do?

Adds fixed clearance to the cylinder end

How does it work?

Minimum Clearance – installed one way

Added Clearance – Reverse the piston

end

Permanently add clearance – Machine

(shorten) the piston length

Image Courtesy of ACI Services, Inc.

Where is it installed?

Piston assembly of the cylinder

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 54

Added Fixed Clearance Devices Front Head Spacers

What is it?

Ring manufactured from bar stock

Thickness varies with desired effect

What does the device do?

Moves the head away from cylinder bore

Adds fixed clearance to the cylinder end

Front Head

How does it work?

Images Courtesy of ACI Services, Inc.

Spacer Ring

Remove cylinder front end head

Install a spacer ring

Install front end head with longer bolts

Where is it installed?

Cylinder front end head

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 55

Added Fixed Clearance Devices P-V Diagram

Fixed Clearance Avg. 25%

Load Changes

Fixed Clearance Avg. 35%

Increase Fixed Clearance:

Load Reduction

Small Isentropic Efficiency Change

Flow Reduction

GMC 2009 – Atlanta, GA 56

Adjustable Head End Suction Valve

Defined

Variable Speed Control

The suction valve’s

Unit / Stage Bypass position is adjustable

Valve can be screwed in

Throttling of Operating Pressures and out, changing fixed

clearance

End Deactivation Adjusted to fully

Displacement Changes deactivate the cylinder

end

Added Fixed Clearance Affects the compression

and expansion events

9 Adjustable Head End Suction Valve

Added Variable Volume Clearance Devices

Valve-In-Piston

Added Fixed Volume Clearance Devices Compressor Cylinder

Timed Valve Closing

GMC 2009 – Atlanta, GA 57

Adjustable Head End Suction Valve Valve-In-Piston Type Cylinder

What is it?

Suction valve installed on each end

Threaded lead screw attached to the H.E.

suction valve

What does the device do?

Moves the suction valve away from

cylinder bore

Image Courtesy of Dresser-Rand Corp. Adds fixed clearance to the cylinder end

Deactivates the Head End

How does it work?

As lead screw is screwed out, the suction

valve will move away from the piston

Where is it installed?

Cylinder head end head

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 58

Adjustable Head End Suction Valve P-V Diagram

Fixed Clearance Avg. 25%

Load Changes

Stepless Control within

The volume of the device

Fully Deactivate the end

Increase Fixed Clearance:

Load Reduction

Varying Change to Isentropic Efficiency

Flow Reduction

GMC 2009 – Atlanta, GA 59

Added Variable Volume Clearance

Defined

Variable Speed Control

Adjust clearance volumes

Unit / Stage Bypass within the design of the

device

Throttling of Operating Pressures Accomplished by Manual,

Hydraulic, or Gas Forces

End Deactivation

Displacement Changes

Added Fixed Clearance Devices

VVP – Manual Screw Type

Adjustable Head End Suction Valve VVP – Power Screw Type

9 Added Variable Volume Clearance VVP – Hydraulic Assisted

VVP – Gas Pressure

Added Fixed Volume Clearance Devices Controlled

Timed Valve Closing

GMC 2009 – Atlanta, GA 60

Added Variable Volume Clearance VVP (Manual Screw Type)

What is it?

Variable clearance device

Design as the head end head

Piston installed on a lead screw

What does the device do?

Moves the piston away from cylinder bore

Adds fixed clearance to the cylinder end

Fixed clearance is changed in increments

How does it work?

As lead screw is screwed out (manually),

the piston will move away from the piston

Where is it installed?

Cylinder head end head

Image Courtesy of Cameron Corporation

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 61

Added Variable Volume Clearance VVP (Hydraulic Assisted)

What is it?

Variable clearance device

Designed for the front head

What does the device do?

Moves the piston away from cylinder bore

Adds fixed clearance to the cylinder end

Fixed clearance is changed in smooth

increments

Image Courtesy of ACI Services, Inc.

How does it work?

Suction/discharge pressure is a driving

force to allow hydraulic fluid to flow in/out

of the actuation cylinder allowing the

piston to move back and forth

Where is it installed?

Image Courtesy of

Dresser-Rand Corp.

Cylinder’s front head

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 62

Added Variable Volume Clearance P-V Diagram

Fixed Clearance Avg. 25%

Load Changes

Stepless Control within

The volume of the device

Increase Fixed Clearance:

Load Reduction

Slight Change to Isentropic Efficiency

Flow Reduction

GMC 2009 – Atlanta, GA 63

Added Variable Volume Pocket Clearance VVP (Gas Pressure Controlled)

What is it?

Fixed Volume Pocket

Specially designed compressor valve

What does the device do?

Allows a fixed clearance to be added

Varies the effective clearance based on

the control pressure

How does it work?

Valve guard designed to use control gas

pressure on guard side of the elements

Opens when the cylinder pressure is

greater than the control pressure

Image Courtesy of Dresser-Rand Corp.

Closes when the cylinder pressure is less

than the control pressure

Where is it installed?

Compressor cylinder head or crank end

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 64

Added Variable Volume Pocket Clearance P-V Diagram

Fixed Clearance Avg. 25%

Load Changes

Balance Pressure of

1150 psig

Balance Pressure of

900 psig

Decrease Balance Pressure:

Balance Pressure 650

Load Reduction

Slight Change to Isentropic Efficiency

Flow Reduction

GMC 2009 – Atlanta, GA 65

Added Fixed Volume Clearance

Defined

Variable Speed Control

Adjust clearance

Unit / Stage Bypass volumes within the

design of the device

Throttling of Operating Pressures Accomplished by

Manual, Hydraulic, or

End Deactivation Pneumatic Forces

Displacement Changes

Devices

Added Fixed Clearance Front Head Volume

Adjustable Head End Suction Valve Pocket

Valve Cap Volume

Added Variable Volume Clearance Pocket

Internal Body Volume

9 Added Fixed Volume Clearance Devices

Pocket

Timed Valve Closing

GMC 2009 – Atlanta, GA 66

Added Fixed Volume Clearance Devices Front Head Volume Pockets

What is it?

Fixed clearance device

Designed for the front head

Actuator assembly

What does the device do?

Adds a predetermined amount of fixed

clearance to the cylinder end

How does it work?

Actuation medium supplied to actuation

Photo Courtesy of ACI Services, Inc. cylinder

Actuation Pressure to close off volume

Vent actuation pressure – gas pressure

moves plug to open the volume

Where is it installed?

Photo Courtesy of Ariel Corporation Cylinder head end head

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 67

Added Fixed Volume Clearance Devices Valve Cap Volume Pocket

What is it?

Fixed clearance device

Designed as part of the valve cap

Actuator assembly

What does the device do?

Adds a predetermined amount of fixed

clearance to the cylinder end

Photo Courtesy of Dominion Resources

Images Courtesy of ACI Services, Inc.

How does it work?

Air, gas, or manual power actuates device

Closed: Actuation pressure engaged

Open: Vent actuation pressure

Requires a special valve retainer

Where is it installed?

Over a suction or discharge valve on the

head or crank end of the cylinder

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 68

Added Fixed Volume Clearance Devices Internal Body Volume Pockets

What is it?

Fixed clearance device

Actuator assembly

What does the device do?

Adds a predetermined amount of fixed

clearance to the cylinder end

How does it work?

Actuation medium supplied to actuation

cylinder

Actuation Pressure to close of volume

Vent actuation pressure – gas pressure

moves plug to open the volume

Where is it installed?

Cavity casted into the cylinder

Photo Courtesy of Cameron Corporation Head end or crank end

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 69

Added Fixed Volume Clearance Devices P-V Diagram

Fixed Clearance Avg. 25%

Load Changes

Fixed Clearance Avg. 50%

Load and Flow Reduction

Fixed Clearance Avg. 75%

Load and Flow Reduction

Increase Fixed Clearance:

Load Reduction

Slight Change to Isentropic Efficiency

Flow Reduction

GMC 2009 – Atlanta, GA 70

Timed Valve Closing

Defined

Variable Speed Control Delay of the closing point

of the suction valves

Unit / Stage Bypass

Electronic, hydraulic,

Throttling of Operating Pressures pneumatic or mechanical

means

End Deactivation Delay reduces the net

piston displacement

Displacement Changes Delay increases the

effective fixed clearance

Added Fixed Clearance The net effect is a

reduction in capacity

Adjustable Head End Suction Valve Accomplished during the

Added Variable Volume Clearance compression event

Added Fixed Volume Clearance Devices Devices

Hydraulic / Electronic

9 Timed Valve Closing

controlled finger type

devices

Changes to Valve Flow Area

GMC 2009 – Atlanta, GA 71

Timed Valve Closing HydroCOM / Infinite Step

What is it?

Computer controlled, hydraulically activated,

finger unloader system

What does the device do?

Forces the suction valve to remain open

during the compression event

How does it work?

Re-expansion - the suction valve is closed

Image Courtesy of Dresser Rand Corp. (due to differential pressure)

Suction - the unloader forces the valve open

Compression - the unloader forces the valve

open (gas flows into suction plenum)

Compression - Suction valve is allowed to

close at a selected crank angle

Where is it installed?

Image Courtesy of Hoerbiger Corporation

Head end / Crank End Suction Valves

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 72

Timed Valve Closing P-V Diagram

Fixed Clearance Avg. 25%

Load Changes

Valve Timing 15 Deg.

Valve Timing 30 Deg.

Valve Timing 60 Deg.

Increase Valve Timing:

Load Reduction

End Deactivated

Decrease in Isentropic Efficiency

Flow Reduction

GMC 2009 – Atlanta, GA 73

Timed Valve Closing

Defined

Variable Speed Control Provide More Flow Area

Unit / Stage Bypass May Increase Fixed

Clearance

Throttling of Operating Pressures Manual Shut Down

Required

End Deactivation Application may Limit

Range of Valve Types to

Displacement Changes Consider

Added Fixed Clearance

Devices

Adjustable Head End Suction Valve Suction and/or Discharge

Valves

Added Variable Volume Clearance

Added Fixed Volume Clearance Devices

Timed Valve Closing

9 Changes to Valve Flow Area

GMC 2009 – Atlanta, GA 74

Adjustments to Valve Flow Areas Compressor Valves

What is it?

Efficient Compressor Valves

What does the device do?

Reduces Valve Losses

May Include Added Fixed Clearance

How does it work?

Increases Effective Flow Area

Minimizes Effort to Open/Close Valve

Where is it installed?

Compressor Valve Ports

Images Courtesy of ACI, Cook Manley, Dresser-Rand Corp., and Hoerbiger

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 75

Adjustments to Valve Flow Areas Valve-In-Piston Type Cylinder

What is it?

New Cylinder Design

What does the device do?

Moves Discharge Valves to Piston

Adds Fixed Clearance to Cylinder Ends

Doubles number of Suction Valves

How does it work?

Doubling of suction valves tends to

reduce suction valve losses by 75%

Image Courtesy of Dresser-Rand Corp.

Where is it installed?

Completely New Cylinder

INSTALLED COST EFFICIENCY ADAPTABILITY SIMPLICITY AUTOMATABLE

GMC 2009 – Atlanta, GA 76

Adjustments to Valve Flow Areas P-V Diagram

Original Flow Area

Increasing Flow Area Load Reduction

Increase in Isentropic Efficiency

Potential Flow Increases only if

Power Savings can be Utilized

GMC 2009 – Atlanta, GA 77

Selection Process

Photograph by China Newsphoto/Reuters/Corbis

Selecting the Appropriate Devices for a Specific Application

GMC 2009 – Atlanta, GA 78

Selection Process

Selecting the Appropriate Device(s) for a Specific Application

Load v. PS Load v. PS

End Deactivation Fixed Clearance Changes

Typically large load/flow changes Typically smaller load/flow changes

Load v. PS Load v. PS

Variable Clearance Changes Combinations - Best of each

Typically very smooth changes to load/flow Gives maximum coverage of operating ranges

GMC 2009 – Atlanta, GA 79

Selection Process

9 Determine the required range of operating conditions

Gas composition

Pressure and temperature ranges

Flows

Important operating points

Determine the timing of operating condition changes

Fluctuating, gradual, seasonal, random

Determine the physical properties of the compressor and driver

Driver load and speed ratings and ranges

Compressor frame and cylinder sizes and ratings

Include any existing load and flow devices

System cooling capacities, temperatures and pressure drops

GMC 2009 – Atlanta, GA 80

Selection Process

Determine the required range of operating conditions

Gas composition

Pressure and temperature ranges

Flows

Important operating points

9 Determine the timing of operating condition changes

Fluctuating, gradual, seasonal, random

Determine the physical properties of the compressor and driver

Driver load and speed ratings and ranges

Compressor frame and cylinder sizes and ratings

Include any existing load and flow devices

System cooling capacities, temperatures and pressure drops

GMC 2009 – Atlanta, GA 81

Selection Process

Determine the required range of operating conditions

Gas composition

Pressure and temperature ranges

Flows

Important operating points

Determine the timing of operating condition changes

Fluctuating, gradual, seasonal, random

9 Determine the physical properties of the compressor and driver

Driver load and speed ratings and ranges

Compressor frame and cylinder sizes and ratings

Include any existing load and flow devices

System cooling capacities, temperatures and pressure drops

GMC 2009 – Atlanta, GA 82

Selection Process

Model the compressor performance

Need a robust performance modeling approach

Determine how well the existing unit handles the range of conditions

Safe operating limits – Load, MAWP, Rod Load, PNR, Low VE, temperatures...

Identify gaps in unit capability

+ +

+

+

+

+

+ +

+

+

+

+

GMC 2009 – Atlanta, GA 83

Selection Process

Investigate alternatives for changing the unit performance

Review types of devices

Compare relative characteristics of devices with application requirements

Select tentative devices to be investigated

Effects of Added Clearance

90

60%

80

80%

Change in Capacity %

70

60

40%

50

40

30

20%

20

10

0

1.0 1.5 2.0 2.5 3.0 3.5

Pressure Ratio

GMC 2009 – Atlanta, GA 84

Selection Process

Change the compressor performance model

Change performance model to add tentative changes

(cylinder bore size, fixed clearances, deactivation, or combinations)

Evaluate the changes vs. the desired performance and flexibility

Tune the parameters to optimize the performance

Review Limits – Load, MAWP, Rod Load, PNR, Low VE, Temperatures...

Iterate as necessary until tentative hardware selection is complete

Finding an optimum

solution can be a

challenging

process!

GMC 2009 – Atlanta, GA 85

Justification Process

Justification – Types of Projects

Mandatory Projects

Contracted Flow Requirements

Equipment Replacement / Maintenance Requirements

HSE (Health-Safety-Environment) Related

Discretionary Projects

Maximize Capacity

Efficiency Improvements

Maintenance Savings

Automation

Equipment Protection

GMC 2009 – Atlanta, GA 86

Justification Process

Justification – Economic Considerations

Costs

Capital costs – hardware devices, control system, software

Installation cost, freight, taxes, misc.

Long term operating and maintenance costs

Potential Areas of Savings

Increased flow capacity (throughput)

Operation and maintenance labor savings

Operating efficiency improvement / energy savings

Increased reliability - maintenance savings, and downtime reduction

Favorable environmental impact

Maximize asset utilization – capital avoidance

Tax savings / incentives

Extend equipment useful life

Other

Typical Financial Hurdles

Percent Rate of Return on Investment

Months/Years to payback

GMC 2009 – Atlanta, GA 87

Justification Process

Financial Modeling Tools

GMC 2009 – Atlanta, GA 88

Justification Process

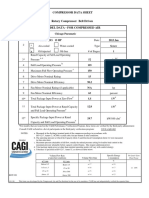

Financial Modeling Tools

Savings Spreadsheet

1. Fuel Savings

300 Number of days operating per year

24 Average number of hours operating per day

1200 Average Engine Load (BHP)

7600 Average Engine Fuel Consumption (BTU/BHP-hr)

950 Fuel Heating Value (BTU/CF)

$5.00 Fuel Gas Cost (US$/MCF)

5.0 Efficiency Gain (%)

$24,192 Savings Sub-total ($US/yr)

GMC 2009 – Atlanta, GA 89

We have provided:

9 A fundamental review of the many types of reciprocating

compressor unloading and capacity control devices,

9 Useful knowledge for evaluating and comparing individual

unloading and control devices,

9 Tools for identifying the best approach and devices for

optimizing current, reapplied and new compressor

performance relative to unique needs and budgets,

9 An objective method for selecting and economically

justifying optimum control devices

GMC 2009 – Atlanta, GA 90

Questions ?

GMC 2009 – Atlanta, GA 91

You might also like

- R5.5-A125 ManualDocument1 pageR5.5-A125 ManualDiiani AmayaNo ratings yet

- Hitachi ZAXIS 130W Wheeled Excavator Operator's Manual SN 001001 and Up PDFDocument12 pagesHitachi ZAXIS 130W Wheeled Excavator Operator's Manual SN 001001 and Up PDFfjkskemdmme50% (2)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- Compressor Data Sheet Rotary Compressor: Fixed Speed: Gardner DenverDocument1 pageCompressor Data Sheet Rotary Compressor: Fixed Speed: Gardner DenverRamon SanhuezaNo ratings yet

- Spillback CompressorDocument3 pagesSpillback CompressorpsaradaNo ratings yet

- Valve Ls LindeDocument24 pagesValve Ls Lindele100% (2)

- 30 Kva Manual (7598)Document2 pages30 Kva Manual (7598)Nijo Joseph0% (1)

- PCB Design Made Easy With EasyEDADocument36 pagesPCB Design Made Easy With EasyEDAcnrk777inNo ratings yet

- Compressor Data Sheet: Chicago PneumaticDocument1 pageCompressor Data Sheet: Chicago PneumaticAlex Daniel Nepomuceno JorgeNo ratings yet

- CAGI QRS 15 HP (125psi) tcm332 - 3524075 1272440482Document1 pageCAGI QRS 15 HP (125psi) tcm332 - 3524075 1272440482Alex Daniel Nepomuceno JorgeNo ratings yet

- Ga 250-125Document1 pageGa 250-125Gustavo RodriguesNo ratings yet

- CAGI Rotdata ISO1217 Annex CDocument1 pageCAGI Rotdata ISO1217 Annex Csvengoto9No ratings yet

- Up6s 30 125Document1 pageUp6s 30 125Eddie SantillánNo ratings yet

- Com - .Surge and Anti-Surge SystemDocument13 pagesCom - .Surge and Anti-Surge SystemBianco BoualemNo ratings yet

- Cagi Data Sheets 7509ps Ac 20080401Document1 pageCagi Data Sheets 7509ps Ac 20080401AllinUrbinaGoicocheaNo ratings yet

- 2 AerodynamicDocument1 page2 AerodynamicPooya ShayestehNo ratings yet

- Compresor Quincy QGV100Document1 pageCompresor Quincy QGV100Luis LoredoNo ratings yet

- Rs37i A200 PDFDocument1 pageRs37i A200 PDFMohammadAlAmeenNo ratings yet

- CAGI RS37i-A125Document1 pageCAGI RS37i-A125Marco ChablaNo ratings yet

- GA90-125 - 125 Psi 2020Document1 pageGA90-125 - 125 Psi 2020Eloy Armando Rodriguez PazNo ratings yet

- 102.1 Beam ComponentsDocument106 pages102.1 Beam ComponentsTh Suppachoknirun100% (3)

- Compressor Data Sheet Centrifugal Compressor: Model Data - For Compressed AirDocument1 pageCompressor Data Sheet Centrifugal Compressor: Model Data - For Compressed AiracildeNo ratings yet

- CAGI Data Sheet - 2209 PDFDocument1 pageCAGI Data Sheet - 2209 PDFShiro EmiyaNo ratings yet

- SAV-500 125 Psi EAY DATA SHEET UnloadDocument1 pageSAV-500 125 Psi EAY DATA SHEET UnloadricardoNo ratings yet

- TMP 21165-S220 Cagi 1001802177504Document1 pageTMP 21165-S220 Cagi 1001802177504John TheodorouNo ratings yet

- Events Oilgas 20051006 Methanerec PD Vru DehyDocument47 pagesEvents Oilgas 20051006 Methanerec PD Vru DehyLiêm Nguyễn HữuNo ratings yet

- GA 90plus - 75 Psi - Air Cooled - 2016Document1 pageGA 90plus - 75 Psi - Air Cooled - 2016SURYANo ratings yet

- Model: C60D6R (B3.3 Rental Product) Frequency: 60 HZ Fuel Type: DieselDocument3 pagesModel: C60D6R (B3.3 Rental Product) Frequency: 60 HZ Fuel Type: DieselMarco BernalNo ratings yet

- Procidia Control Solutions Compressor Surge Control: Application DataDocument3 pagesProcidia Control Solutions Compressor Surge Control: Application DataAto AnsoriNo ratings yet

- Rs160i A145Document1 pageRs160i A145gustavo rodriguesNo ratings yet

- RS37i A125Document1 pageRS37i A125Cay MartínezNo ratings yet

- RS11i A125Document1 pageRS11i A125rigoberto alvaNo ratings yet

- How To Achieve Higher Performance?: Analysis of Engine PerformanceDocument18 pagesHow To Achieve Higher Performance?: Analysis of Engine PerformanceBharat SharmaNo ratings yet

- Wheel Loader - Lonking CDM833Document2 pagesWheel Loader - Lonking CDM833Sonny SaputraNo ratings yet

- Lecture 10Document24 pagesLecture 10varshasdm1987No ratings yet

- RS30ie A110Document1 pageRS30ie A110Phil NorvalNo ratings yet

- Voith-IPS High-Pressure Internal Gear PumpDocument20 pagesVoith-IPS High-Pressure Internal Gear Pumpjuan camilo gutierrezNo ratings yet

- CAGI Data Sheet L250-340hp-125psi-Water 7-9-20Document1 pageCAGI Data Sheet L250-340hp-125psi-Water 7-9-20Heba MohamedNo ratings yet

- Up 6 50pe 125Document1 pageUp 6 50pe 125mahdiNo ratings yet

- (Lecture 7) Introduction To Fan, Pump and Energy Saving OpportunitiesDocument69 pages(Lecture 7) Introduction To Fan, Pump and Energy Saving OpportunitiesTân NguyễnNo ratings yet

- GA 132 - 125psig (8.6bar) - Air CooledDocument1 pageGA 132 - 125psig (8.6bar) - Air CooledGleidson AnteroNo ratings yet

- Hyd Basic ConceptDocument36 pagesHyd Basic ConceptAgus SujionoNo ratings yet

- 4 19750065518Document14 pages4 19750065518makbuleesrasircaNo ratings yet

- Hino RK-CNG IntroductionDocument15 pagesHino RK-CNG Introductionpriyo100% (3)

- Reading Material CH 12 Sucker Rod PumpingDocument22 pagesReading Material CH 12 Sucker Rod PumpingSagar DadhichNo ratings yet

- CAGI Data Sheet SAV-200hp-EAU-125psi-Water 6-26-20 PDFDocument1 pageCAGI Data Sheet SAV-200hp-EAU-125psi-Water 6-26-20 PDFCarlos MNo ratings yet

- RM 58Document5 pagesRM 58Jabita Aguilera CabreraNo ratings yet

- Up6 40 125Document1 pageUp6 40 125erickNo ratings yet

- Mixing Fundamentals Terminology and FormulasDocument24 pagesMixing Fundamentals Terminology and FormulasJorge DiAlvearNo ratings yet

- Series: CC CCT CCVS/CCVLDocument15 pagesSeries: CC CCT CCVS/CCVLxmen norNo ratings yet

- 25 Kva Diesel GeneratorDocument2 pages25 Kva Diesel Generatormsi36No ratings yet

- Hoja Cagi Ga 30-125 Psi Atlas CopcoDocument1 pageHoja Cagi Ga 30-125 Psi Atlas CopcoCarlos FerreraNo ratings yet

- Pump Performance: EAS 199A NotesDocument16 pagesPump Performance: EAS 199A Notesantopaul2No ratings yet

- BSD40 - 175 AC tcm9 21216Document1 pageBSD40 - 175 AC tcm9 21216ANDRESNo ratings yet

- External Gear Pump Series U: Overview of Contents FeaturesDocument28 pagesExternal Gear Pump Series U: Overview of Contents FeaturesDieselkNo ratings yet

- Pump Performance and Characteristic Curves TAB Journal 1997 SpringDocument8 pagesPump Performance and Characteristic Curves TAB Journal 1997 SpringMr humanNo ratings yet

- Nearly The Same As That of Pumps With Sign Changes On Loss TermsDocument23 pagesNearly The Same As That of Pumps With Sign Changes On Loss Termsvarshasdm1987No ratings yet

- Specsheet 30 PDFDocument2 pagesSpecsheet 30 PDFFaizi93No ratings yet

- CAGI-000048_01_4509B 60HP H ACDocument1 pageCAGI-000048_01_4509B 60HP H ACJuan SantiagoNo ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Mycom K-SeriesDocument2 pagesMycom K-Seriescnrk777inNo ratings yet

- HydroCOM Brochure EN A4Document4 pagesHydroCOM Brochure EN A4cnrk777inNo ratings yet

- BPCL Technical-DataSheet-a8a979Document13 pagesBPCL Technical-DataSheet-a8a979cnrk777inNo ratings yet

- Gea Gas Screw Compressor en - tcm26 45251Document12 pagesGea Gas Screw Compressor en - tcm26 45251cnrk777inNo ratings yet

- Video Measurement SystemDocument1 pageVideo Measurement Systemcnrk777inNo ratings yet

- MAN Screw-Compressors-EngDocument6 pagesMAN Screw-Compressors-Engcnrk777inNo ratings yet

- VisionhawkspecDocument2 pagesVisionhawkspeccnrk777inNo ratings yet

- WMH DatasheetDocument2 pagesWMH Datasheetcnrk777inNo ratings yet

- Wika ProdDocument291 pagesWika Prodcnrk777inNo ratings yet

- Helvarnet CrestronDocument46 pagesHelvarnet Crestroncnrk777inNo ratings yet

- Digidim Toolbox UserguideDocument271 pagesDigidim Toolbox Userguidecnrk777inNo ratings yet

- 8018 Deskphone Datasheet enDocument3 pages8018 Deskphone Datasheet encnrk777inNo ratings yet

- User Manual PolarisDocument64 pagesUser Manual Polariscnrk777inNo ratings yet

- EasyEDA-Tutorials v6.3.53Document256 pagesEasyEDA-Tutorials v6.3.53cnrk777inNo ratings yet

- Surge Stopper IC Simplifies Design of Intrinsic Safety Barrier For Electronics Destined For Hazardous EnvironmentsDocument7 pagesSurge Stopper IC Simplifies Design of Intrinsic Safety Barrier For Electronics Destined For Hazardous Environmentscnrk777inNo ratings yet

- Ten Ways To Design For Intrinsic Safety - Industry ArticlesDocument5 pagesTen Ways To Design For Intrinsic Safety - Industry Articlescnrk777inNo ratings yet

- Procell Battery Range Declaration To 2014/34/EU Explosive Atmospheres (ATEX Equipment) DirectiveDocument1 pageProcell Battery Range Declaration To 2014/34/EU Explosive Atmospheres (ATEX Equipment) Directivecnrk777inNo ratings yet

- 11 English Mixed Test Paper 02Document4 pages11 English Mixed Test Paper 02Robin AhujaNo ratings yet

- Kisi-Kisi Soal Pas Kelas XDocument14 pagesKisi-Kisi Soal Pas Kelas XRionaNo ratings yet

- EBS Period Close Analyzer-CompressedDocument29 pagesEBS Period Close Analyzer-CompressedRaoof AhmedNo ratings yet

- Motivational Case Study ExerciseDocument3 pagesMotivational Case Study ExerciseMelnicof DanyNo ratings yet

- 10 JMSCR PDFDocument5 pages10 JMSCR PDFSubi SureshNo ratings yet

- 1 Enterprise Lan Switching Cisco Ccna 200 125 200 105 m1 SlidesDocument65 pages1 Enterprise Lan Switching Cisco Ccna 200 125 200 105 m1 SlidesMiticuta SurubNo ratings yet

- Deploying C++Builder ApplicationsDocument11 pagesDeploying C++Builder ApplicationsalhadeedNo ratings yet

- Office of The RegistrarDocument3 pagesOffice of The RegistrarAdemolaNo ratings yet

- Host Reactions To BiomaterialsDocument40 pagesHost Reactions To BiomaterialsSidekkNo ratings yet

- Sarthak GuptaDocument10 pagesSarthak GuptasuyashguptaNo ratings yet

- LC1DS09-18 Ssap CN61441Document2 pagesLC1DS09-18 Ssap CN61441gogo.ilNo ratings yet

- KGH Series Bellows CouplingDocument1 pageKGH Series Bellows CouplingServo2GoNo ratings yet

- The Nano World and Gene TherapyDocument6 pagesThe Nano World and Gene TherapyEriel P. GamengNo ratings yet

- JA-100 EndUser Brochure EN PDFDocument5 pagesJA-100 EndUser Brochure EN PDFjanderclanderNo ratings yet

- Wearable 2D Ring Scanner: FeaturesDocument2 pagesWearable 2D Ring Scanner: FeaturesYesica SantamariaNo ratings yet

- Ch10 ForouzanDocument44 pagesCh10 Forouzanjohnmechanji0% (1)

- Installation Qualification For Informatic System ExampleDocument7 pagesInstallation Qualification For Informatic System ExampleCarlos SanchezNo ratings yet

- Chapter 10 - Concepts of Vat 7thDocument11 pagesChapter 10 - Concepts of Vat 7thEl Yang100% (3)

- 8 Settlement of Pile FoundationDocument16 pages8 Settlement of Pile FoundationSamirsinh ParmarNo ratings yet

- Sir Samuel CunardDocument1 pageSir Samuel CunardMarknel LasernaNo ratings yet

- Abhishek AnandDocument1 pageAbhishek AnandPritanshi AnandNo ratings yet

- BillInvoice 2Document2 pagesBillInvoice 2gopim888No ratings yet

- ISO ImageDocument3 pagesISO ImageNicolaescu NicuNo ratings yet

- Rock MechanicsDocument33 pagesRock MechanicsErnesto Oporto VergaraNo ratings yet

- SAP SD Consultant Sample ResumeDocument10 pagesSAP SD Consultant Sample ResumemarishaNo ratings yet

- Guidelines On The Evaluation of Organic Agriculture ProposalsDocument37 pagesGuidelines On The Evaluation of Organic Agriculture ProposalsJefferson RillortaNo ratings yet

- Earned Value Management TutorialDocument7 pagesEarned Value Management TutorialracmalufNo ratings yet

- 2019 Colloquium Draft March 12Document33 pages2019 Colloquium Draft March 12Jessica BrummelNo ratings yet

- (Claim Form 4) : PM AM AM PMDocument4 pages(Claim Form 4) : PM AM AM PMRuthCel TupazNo ratings yet