Professional Documents

Culture Documents

Question Bank Format - HMT Unit 3

Question Bank Format - HMT Unit 3

Uploaded by

Excel Conference0 ratings0% found this document useful (0 votes)

8 views2 pages1) The document contains questions from the question bank for the subject Heat and Mass Transfer from the Mechanical Engineering department.

2) It includes 20 multiple choice questions in Part A and 10 numerical problems in Part B related to concepts like boiling, condensation, heat exchangers and their analysis and design.

3) The questions assess various concepts of phase change heat transfer and heat exchangers like boiling curves, heat transfer coefficients, LMTD method, effectiveness-NTU method and design of different heat exchangers.

Original Description:

HMT BP

Original Title

Question Bank Format_ HMT unit 3

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document contains questions from the question bank for the subject Heat and Mass Transfer from the Mechanical Engineering department.

2) It includes 20 multiple choice questions in Part A and 10 numerical problems in Part B related to concepts like boiling, condensation, heat exchangers and their analysis and design.

3) The questions assess various concepts of phase change heat transfer and heat exchangers like boiling curves, heat transfer coefficients, LMTD method, effectiveness-NTU method and design of different heat exchangers.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

8 views2 pagesQuestion Bank Format - HMT Unit 3

Question Bank Format - HMT Unit 3

Uploaded by

Excel Conference1) The document contains questions from the question bank for the subject Heat and Mass Transfer from the Mechanical Engineering department.

2) It includes 20 multiple choice questions in Part A and 10 numerical problems in Part B related to concepts like boiling, condensation, heat exchangers and their analysis and design.

3) The questions assess various concepts of phase change heat transfer and heat exchangers like boiling curves, heat transfer coefficients, LMTD method, effectiveness-NTU method and design of different heat exchangers.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

EXCEL ENGINEERING COLLEGE

(Autonomous)

DEPARTMENT OF MECHANICAL ENGINEERING

VI Semester

ME8693- HEAT AND MASS TRANSFER

Regulations 2017

Question Bank

UNIT – III PHASE CHANGE HEAT TRANSFER AND HEAT EXCHANGER

PART- A

Q.No Questions Marks CO BL

1 Define boiling? 2 CO3 R

2 Mention the process in condensation. 2 CO3 U

3 What is meant by pool boiling? 2 CO3 R

4 List the factors affecting the overall heat transfer coefficient. 2 CO3 U

5 Draw different regions of boiling process. 2 CO3 R

6 Give the merits of condensation? 2 CO3 R

7 Classify the various types of heat exchangers. 2 CO3 R

8 What is meant by dropwise condensation? 2 CO3 R

9 Define heat exchanger. 2 CO3 R

10 Distinguish between parallel and counter flow heat exchanger. 2 CO3 U

11 Compare the direct and indirect contact heat exchanger? 2 CO3 U

12 What is regenerator? 2 CO3 R

13 Write the importance of shell and tube heat exchanger? 2 CO3 R

14 Define Biot number? 2 CO3 R

15 What is meant by LMTD? 2 CO3 R

16 What is meant by fouling factor? 2 CO3 R

17 What is meant by effectiveness? 2 CO3 R

18 Give an example of pool boiling and flow boiling. 2 CO3 R

19 Discuss the advantage of NTU method over the LMTD method. 2 CO3 U

Sketch the temperature variations in parallel flow and counter flow heat 2 CO3 U

20

exchangers.

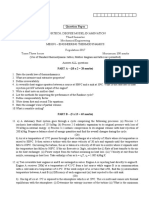

PART- B

Q.No Questions Marks CO BL

1 Discuss the various regimes of pool boiling heat transfer. 16 CO1 U

2 It is desired to boil water at atmospheric pressure on a copper surface

which is electrically heated. Estimate the heat flux from the surface of 16 CO1 U

water, if the surface is maintained at 110°C and also the peak heat flux.

3 (i) Derive the rate of heat transfer equation of parallel flow heat exchanger for

LMTD analysis.

8+8 CO1 U

(ii) Derive the rate of heat transfer equation of counter flow heat exchanger for

effectiveness-NTU analysis.

4 Water is to be boiled at atmospheric pressure in a polished copper pan by

means of an electric heater. The diameter of the pan is 0.38m and is kept at

16 CO1 AP

115°C. Calculate the following, 1. Power required boiling the water, 2.

Rate of evaporation, 3. Critical heat flux.

5 Water is boiled at the rate of 24 kg/h in a polished copper pan, 300mm in

diameter at atmospheric pressure. Assuming nucleate boiling conditions, 16 CO1 AP

calculate the temperature of the bottom surface of the pan.

6 A horizontal tube of outer diameter 2.2 cm is exposed to dry steam at 100

°C. The pipe surface is maintained at 62°C by circulating water through it. 16 CO1 AP

Calculate the rate of formation of condensate per metre length of the pipe.

7 In a counter flow double pipe heat exchanger, water is heated from 25°C to

65°C by an oil with a specific heat of 1.45 kJ/kg K and mass flow rate of

0.9 kg/s. The oil is cooled from 230°C to 160°C. If the overall heat transfer

16 CO1 AP

coefficient is 420 W/m2K, calculate the following, 1. The rate of heat

transfer, 2. The mass flow rate of water, 3. The surface area of the heat

exchanger.

8 In a double pipe counter flow heat exchanger 10000 kg/h of an oil having a

specific heat of 2095 J/kgK is cooled from 80°C to 50°C by 8000 kg/h of

16 CO1 AP

water entering at 25°C. Determine the heat exchangers area for an overall

heat transfer coefficient of 300 W/m2K. Take Cp for water as 4180 J/kg K.

9 A counter flow concentric tube heat exchanger is used to cool engine oil

(Cp= 2130 J /kg K) from 160°C to 60°C with water available at 25°C as

the cooling medium. The flow rate of cooling water through the inner tube

16 CO1 AP

of 0.5m is 2 kg/s while the flow rate of oil through the outer annulus OD =

0.7 m is also 2 kg/s. If ‘h’ is 250 W/m2K, how long must the heat

exchanger be to meet its cooling requirement?

10 A parallel flow heat exchanger has hot and cold water stream running

through it, the flow rates are 10 and 25 kg/min respectively. Inlet

temperatures are 75°C and 25°C on hot and cold sides. The exit

16 CO1 AP

temperature on the hot side should not exceed 50°C. Assume hi=ho= 600

W/m2K. Calculate the area of heat exchanger using Effectiveness- NTU

approach.

Subject In charge Course Coordinator HOD IQAC

(Name & Signature) (Name & Signature)

You might also like

- Ammonia Refrigeration Room Ventillation Rev1Document5 pagesAmmonia Refrigeration Room Ventillation Rev1dilin sharafNo ratings yet

- 2 Psychormetrics AnalysisDocument108 pages2 Psychormetrics Analysishasan bishNo ratings yet

- Question Bank - HMT Unit 2Document2 pagesQuestion Bank - HMT Unit 2Excel ConferenceNo ratings yet

- HX qp1Document3 pagesHX qp1Delinda DimpleNo ratings yet

- Btech Thermodynamics - 2021Document2 pagesBtech Thermodynamics - 2021Shailesh Singh SuryavanshiNo ratings yet

- NTK/KW/15/7829Document4 pagesNTK/KW/15/7829Anurag TalwekarNo ratings yet

- Bethlahem Institute of Engineering Karungal - 629 157: Internal Assessment Exam - 1Document6 pagesBethlahem Institute of Engineering Karungal - 629 157: Internal Assessment Exam - 1COMMANDER ALANNo ratings yet

- Bbbdnitm, Lko Mechanical Department Subject-Heat and Mass Transfer UNIT-5 Assignment-5 Section-A Short Questions: (2 Marks)Document2 pagesBbbdnitm, Lko Mechanical Department Subject-Heat and Mass Transfer UNIT-5 Assignment-5 Section-A Short Questions: (2 Marks)Hoài ThươngNo ratings yet

- Question Paper HMT - CO Mapping - SampleDocument6 pagesQuestion Paper HMT - CO Mapping - SamplejayanthikrishnanNo ratings yet

- Heat Transfer Paper - IV: B.Tech. Fifth Semester (Chemical Engineering) (C.B.S.)Document2 pagesHeat Transfer Paper - IV: B.Tech. Fifth Semester (Chemical Engineering) (C.B.S.)Anurag TalwekarNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityBala DuttNo ratings yet

- Tutorial 3 - Revised SolutionDocument11 pagesTutorial 3 - Revised Solutionngoc.nguyenlamNo ratings yet

- Tutorial 3 SolutionDocument5 pagesTutorial 3 Solutionngoc.nguyennhuNo ratings yet

- HMT 113401 Anna UnivDocument5 pagesHMT 113401 Anna Univsathiya_ramNo ratings yet

- 2021 July CHT204-ADocument4 pages2021 July CHT204-ANikhilNo ratings yet

- New-Problems-Chapter-16 Heat ExchangersDocument2 pagesNew-Problems-Chapter-16 Heat ExchangersKhanh NhiNo ratings yet

- HMT IMP Questions NewDocument3 pagesHMT IMP Questions NewRavi PatilNo ratings yet

- Question Bank On Unit 6Document5 pagesQuestion Bank On Unit 6dongaNo ratings yet

- Internal Test II-21.03.2013Document1 pageInternal Test II-21.03.2013vsureshkannanmsecNo ratings yet

- SE - 2019 Engineering ThermodynamicsDocument4 pagesSE - 2019 Engineering ThermodynamicsYash PawarNo ratings yet

- T.Y.B.tech Mech Sem VDocument24 pagesT.Y.B.tech Mech Sem VChirag JainNo ratings yet

- Answer Key CIA IIIDocument7 pagesAnswer Key CIA IIISUBRAMANI NANJANNo ratings yet

- Icam (Lille) - Heat Exchanger Course Icam 2 - Autumn 2003 Heat Exchanger Examples - Sheet 2Document3 pagesIcam (Lille) - Heat Exchanger Course Icam 2 - Autumn 2003 Heat Exchanger Examples - Sheet 2FahmiRamdanNo ratings yet

- Ae 1201 - Aero Engineering ThermodynamicsDocument4 pagesAe 1201 - Aero Engineering ThermodynamicsRameez FaroukNo ratings yet

- Heat Exchanger Design: ME 310 Thermo-Fluid System DesignDocument24 pagesHeat Exchanger Design: ME 310 Thermo-Fluid System DesignprishaNo ratings yet

- Glasgow College of Nautical Studies Engineering DepartmentDocument2 pagesGlasgow College of Nautical Studies Engineering DepartmentMullah FassudinNo ratings yet

- 18 Me 42Document2 pages18 Me 42Zeeshan SiddiqueNo ratings yet

- Heat TransferDocument2 pagesHeat TransferSMIT CHRISTIANNo ratings yet

- Assignment 5Document2 pagesAssignment 5pradeep.kumarNo ratings yet

- IES-CONV-Mechanical Engineering-2002Document8 pagesIES-CONV-Mechanical Engineering-2002aditya_kumar_meNo ratings yet

- Question 1. During An Experiment Conducted in A Room at 25Document11 pagesQuestion 1. During An Experiment Conducted in A Room at 25fivos_rgNo ratings yet

- Heat Transfer: B.Tech. (Chemical Engineering) Fifth Semester (C.B.S.)Document2 pagesHeat Transfer: B.Tech. (Chemical Engineering) Fifth Semester (C.B.S.)Anurag TalwekarNo ratings yet

- Lecture 3-1 - Heat Exchanger CalculationsDocument50 pagesLecture 3-1 - Heat Exchanger CalculationsBilal AhmedNo ratings yet

- 13A03506 Heat TransferDocument2 pages13A03506 Heat TransferKRISHNA YADAVNo ratings yet

- 5TH SEM - 5ME4-02 Heat Transfer - QPDocument2 pages5TH SEM - 5ME4-02 Heat Transfer - QPChitranjan KumarNo ratings yet

- STUCOR - ME8595-TJ (1) - WatermarkDocument14 pagesSTUCOR - ME8595-TJ (1) - WatermarkMr PerfectNo ratings yet

- BME MSE QP-January-2022Document1 pageBME MSE QP-January-2022Dewang Mitesh ShawNo ratings yet

- IES CONV Mechanical Engineering 1991Document7 pagesIES CONV Mechanical Engineering 1991GURURAJ CNo ratings yet

- Multipass Heat ExchangersDocument21 pagesMultipass Heat ExchangersBrando_BalagonNo ratings yet

- Heat Transfer May2004 NR 310803Document8 pagesHeat Transfer May2004 NR 310803Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Che0405 Ped Lecture 1Document25 pagesChe0405 Ped Lecture 1miraNo ratings yet

- ME Subjective Paper IESDocument8 pagesME Subjective Paper IESizharul haqueNo ratings yet

- Visvesvaraya National Institute of TechnologyDocument5 pagesVisvesvaraya National Institute of TechnologyAbhishekRajeshDhobeNo ratings yet

- Analysis of A Counter Flow Parallel-Plate Heat ExchangerDocument5 pagesAnalysis of A Counter Flow Parallel-Plate Heat ExchangerJohn Manuel BautistaNo ratings yet

- Assignment 1 - 14-09-2021Document2 pagesAssignment 1 - 14-09-2021Abhishek GuptaNo ratings yet

- CH 224 Assignment Test-IIDocument1 pageCH 224 Assignment Test-IIBathula KasiNo ratings yet

- Power Lab #3 (Surface Condenser)Document4 pagesPower Lab #3 (Surface Condenser)Mahmud L. MusaNo ratings yet

- RA 9A23501 Heat Transfer in BioprocessesDocument2 pagesRA 9A23501 Heat Transfer in BioprocessessivabharathamurthyNo ratings yet

- Me8693 Heat and Mass Transfer - QBDocument5 pagesMe8693 Heat and Mass Transfer - QBmeckup123No ratings yet

- 13A03302122016Document2 pages13A03302122016EhteshTubeNo ratings yet

- Me8391 - EtdDocument3 pagesMe8391 - Etdsyed1188No ratings yet

- Instructions:: Gujarat Technological UniversityDocument2 pagesInstructions:: Gujarat Technological UniversityKislay ChoudharyNo ratings yet

- Basic Design MethodologyDocument4 pagesBasic Design MethodologySatya SuryaNo ratings yet

- Guess QuestionsDocument4 pagesGuess QuestionsumarNo ratings yet

- 7.QP-Special Coaching Test 3Document1 page7.QP-Special Coaching Test 3vsureshkannanmsecNo ratings yet

- 10 Numerical 10Document1 page10 Numerical 10Aakash AgarwalNo ratings yet

- Lecture 6 - Heat Transfer EquipmentDocument72 pagesLecture 6 - Heat Transfer EquipmentLouie GresulaNo ratings yet

- Answer - Ert 216 Midterm2Document5 pagesAnswer - Ert 216 Midterm2norsiahNo ratings yet

- Mid-Term Exam (2022-2023)Document5 pagesMid-Term Exam (2022-2023)alhussenyNo ratings yet

- Ejercicios Topico 3 Moreta HenryDocument6 pagesEjercicios Topico 3 Moreta HenrystearimofyNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- HMT-2 9Document4 pagesHMT-2 9Excel ConferenceNo ratings yet

- HMT-2 2Document10 pagesHMT-2 2Excel ConferenceNo ratings yet

- Excel Engineering College (Autonomous)Document21 pagesExcel Engineering College (Autonomous)Excel ConferenceNo ratings yet

- Unit 1Document66 pagesUnit 1Excel ConferenceNo ratings yet

- Question Bank - HMT Unit 2Document2 pagesQuestion Bank - HMT Unit 2Excel ConferenceNo ratings yet

- Excel Engineering College (Autonomous)Document3 pagesExcel Engineering College (Autonomous)Excel ConferenceNo ratings yet

- Excel Engineering College (Autonomous)Document4 pagesExcel Engineering College (Autonomous)Excel ConferenceNo ratings yet

- IES Mechanical Engineering 2011 PDFDocument40 pagesIES Mechanical Engineering 2011 PDFExcel ConferenceNo ratings yet

- Excel Engineering College (Autonomous)Document9 pagesExcel Engineering College (Autonomous)Excel ConferenceNo ratings yet

- Air Cooling Effect of Fins in MotorcycleDocument7 pagesAir Cooling Effect of Fins in Motorcyclestorage spaceNo ratings yet

- WCH04 01 Que 20180111 PDFDocument24 pagesWCH04 01 Que 20180111 PDFMuhammad FarhanNo ratings yet

- Acid-Base ConceptsDocument7 pagesAcid-Base ConceptsMaia Lee BaysaNo ratings yet

- Bronsted-Lowry Acid and BaseDocument27 pagesBronsted-Lowry Acid and BaseKemuel LegaspiNo ratings yet

- S o L U T I o N o F U P S C P A P e R S O F B A S I C A N D A P P L I e D T H e R M o D y N A M I C S F I R S T L A W o F T H e R M o D y N A M I C SDocument18 pagesS o L U T I o N o F U P S C P A P e R S O F B A S I C A N D A P P L I e D T H e R M o D y N A M I C S F I R S T L A W o F T H e R M o D y N A M I C SHimanshu Chauhan50% (2)

- Chapter 3.4Document9 pagesChapter 3.4Jhon Barzola PalominoNo ratings yet

- 9518-109-Pvm-B-235-02-Cat IDocument49 pages9518-109-Pvm-B-235-02-Cat IAshok reddyNo ratings yet

- Chemical Equilibrium FinalDocument49 pagesChemical Equilibrium FinalJagmohan SinghNo ratings yet

- Melting Boiling Condensation SolidificationDocument12 pagesMelting Boiling Condensation Solidificationsalmanismart123No ratings yet

- Q2 A AnsDocument10 pagesQ2 A AnsKai Faha LukumNo ratings yet

- Lab Report Physics Exp 8Document20 pagesLab Report Physics Exp 8irdinaNo ratings yet

- 11 HeatDocument11 pages11 Heatapi-185034533No ratings yet

- Met Ques Temp Press Density NoDocument6 pagesMet Ques Temp Press Density NoSuleiman MusaNo ratings yet

- 12.thermal Properties of MatterDocument26 pages12.thermal Properties of Mattersridevi73No ratings yet

- P18 - Practice Question AnswersDocument3 pagesP18 - Practice Question AnswersdenisNo ratings yet

- Use of Superposition To Describe Heat TransferDocument59 pagesUse of Superposition To Describe Heat TransferHezekiah AntonanoNo ratings yet

- Heat Transfer ACEDocument122 pagesHeat Transfer ACERamnarayan MeenaNo ratings yet

- Chapter 18 Silberberg AnswersDocument51 pagesChapter 18 Silberberg AnswersKevin DashNo ratings yet

- Thermodynamics: 02 Properties IDocument9 pagesThermodynamics: 02 Properties IZoya MargochikNo ratings yet

- Prinsip Le Chatelier Dan KatalisisDocument19 pagesPrinsip Le Chatelier Dan KatalisisLestari zaiNo ratings yet

- Tugas Termodinamika Kelompok 1Document8 pagesTugas Termodinamika Kelompok 1Jasmine AprilNo ratings yet

- Catalogo Tarifa Hisense 2016Document37 pagesCatalogo Tarifa Hisense 2016David GarciaNo ratings yet

- Natural and Force Convection Lab ReportDocument43 pagesNatural and Force Convection Lab Reportloqmannazli100% (1)

- Hvac Rpoblems NewDocument20 pagesHvac Rpoblems NewGrace Joy CariNo ratings yet

- Lesson - 1 PDFDocument5 pagesLesson - 1 PDFVikas Kumar ThakurNo ratings yet

- College of Medical Technology Center For Medical and Allied Health ScienceDocument15 pagesCollege of Medical Technology Center For Medical and Allied Health ScienceGlomelyn Rose Ortiz TañedoNo ratings yet

- Air Conditioning TermsDocument15 pagesAir Conditioning TermsBaby DarylNo ratings yet

- Termo 1 6.20 6.21Document3 pagesTermo 1 6.20 6.21Achmad WidiyatmokoNo ratings yet