Professional Documents

Culture Documents

PPS 000606

PPS 000606

Uploaded by

Javier MartinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PPS 000606

PPS 000606

Uploaded by

Javier MartinCopyright:

Available Formats

Crimson Publishers Research Article

Wings to the Research

Production of Hythane by Stepped

Pyrolysis of Biomass

Amrit Anand, Dipika Das and Shalini Gautam*

ISSN: 2637-8035

Department of Fuel Minerals and Metallurgical Engineering, Indian Institute of Technology (ISM),

Dhanbad, India

Abstract

The transportation industry mainly uses conventional fuel like petrol and diesel, which produces

greenhouse gases and cause serious environmental concerns. A clean, sustainable renewable fuel

is needed to minimize the high carbon footprint and emissions. This study focuses on producing

Hythane(mainly a mixture of hydrogen and methane) from biomass through the pyrolysis route. Sawdust

and groundnut shell is slowly pyrolyzed in the vertical reactor to produce hythane gas. The weight loss

profile was studied through a thermogravimetric analyzer, and the effect of temperature on hythane

gas composition was analyzed by gas chromatography. The hythane gas contains almost 40%-45% of

hydrogen and 12 to 25% methane along with oxides of carbon, which depends upon temperature and

feedstock types.

*Corresponding author: Shalini

Gautam, Department of Fuel Minerals Keywords: Hydrogen; Methane; Ultimate analysis; TGA; Gas chromatography; Hythane gas; Gas

and Metallurgical Engineering, Indian chromatography

Institute of Technology (ISM), Dhanbad,

Jharkhand-826004, India

Introduction

Submission: February10, 2023

Energy is the backbone of any country, and its demand is increasing tremendously yearly

Published: March 21, 2023

[1]. Fossil fuels fulfill most of the huge energy demand [2-4], but these conventional fuels

Volume 5 - Issue 2 leave a huge carbon footprint. The interconnected problems for sustainable energy and the

environment are very challenging, which can be minimized by alternate renewable fuel.

How to cite this article: Amrit Anand,

Dipika Das and Shalini Gautam*.

The thermochemical conversion route is an excellent solution to use biomass energy in the

Production of Hythane by Stepped technical application [5] and to overcome environmental pollution due to the exhaust of

Pyrolysis of Biomass. Progress Petrochem Internal Combustion (I.C.) engines and industries; the immediate replacement of fossil fuel

Sci. 5(1). PPS. 000606. 2023. systems with a pure hydrogen system is a gigantic task and must be attained in a stepwise

DOI: 10.31031/PPS.2023.05.000606

manner in the near future. So, the technology is approaching for CNG and hythane (a mixture

Copyright@ Shalini Gautam, This of hydrogen and methane) [6]. Agricultural and forestry wastes are potential renewable

article is distributed under the terms of sources of energy. Biomass is carbon neutral fuel and is abundantly available in India. The

the Creative Commons Attribution 4.0 total biomass production is around 750MT, out of which the surplus availability is 230MT

International License, which permits

unrestricted use and redistribution

[7]. Many conventional and established ways exist to obtain H2 and CH4 mixture, but they

provided that the original author and can only be environmentally friendly if extracted from renewable energy sources like

source are credited. biomass other than fossil fuels. Thermo-chemical and biochemical processes are the two

main routes to producing biomass hythane. Hydrogen can be obtained from syngas, alkane

steam reforming, electrosynthesis, and dark fermentation processes whose main gaseous

component is hydrogen [6-8] Gasification is a process where hydrocarbons undergo partial

combustion, and the main product is synthesis gas. Slow pyrolysis is a process in which bio-

organic materials undergo thermal degradation in a completely oxygen-free atmosphere. At

the end of biomass pyrolysis, one can get solid (biochar), liquid (bio-oil), and biogas [a mixture

of H2, CO, CH4, CO2, and lower hydrocarbon of (C1-C3) [9]. Biomass structures also define the

proportion of different pyrolytic products and the composition of the gaseous product. The

heating rate also changes the composition of different pyrolytic products [10]. As lignin is

responsible for high H2 and CH4 formation, hemicellulose is accountable for the increased CO2

emission, and cellulose is responsible for high C.O. production [11]. The hydrogen content

Progress in Petrochemical Science 483

PPS.000606. 5(2).2023 484

(H2) depends on the pyrolysis temperature and increases as the reactor setup consists of a quartz reactor sample holder holding

latter increases [6,12]. In Earlier studies, the syngas was produced the sample inside the heating zone and a furnace with a PID

from biomass through the gasification route and enrichment of controller. A water condenser condenses the condensable gases

hydrogen through steam and methane reforming, water gas shift and separates them from non-condensable gases in the liquid gas

reaction [13]. The current study aims to produce the hythane from separator. Further, the product gases passed through a scrubber to

biomass through the pyrolysis route, the effect of temperature on clean the gas. Non condensable gas is collected in a gas collector,

product gas, and its utilization prospects in an internal combustion and intermediate gas sampling was done to analyze the product gas

engine and iron ore reduction. composition with respect to temperature by Gas Chromatography

(G.C.) (MM TECH, M 2012) equipped with a Thermal Conductivity

Materials and Methods

Detector (TCD). The analysis was carried out using (N 2000)

Sample collection and preparation software attached to the instrument. The biomass samples of <2

The biomass sample used in this Study Includes Saw Dust inches size is fed into the reactor during this process. N2 gas was

(SD) and Groundnut Shell (GS). Both samples were collected from purged (1lpm) to maintain an inert environment inside the reactor.

the Dhanbad region, Jharkhand. All samples were appropriately The heating rate was maintained at 15 ˚C/minute. Initially, Nitrogen

cleaned to remove dust and contamination. Approximately 200g of (@5 liter/min) is purged in the reactor, up to 150 ˚C, to remove

the samples were chopped and dried at 105 °C using the oven-dry the moisture. Further, the nitrogen was purged(1 liter/min) to

technique ASTM D-3173-87. The samples were shredded to-1mm maintain the inert atmosphere and uniform heating zone, with a

and pulverized to-212μm for further compositional, structural, and heating rate of 25 ˚C/minute. The intermediate sampling was done

thermal analysis. at temperatures of 400 ˚C, 500 ˚C, 600 ˚C, 700 ˚C, and 800 ˚C. The

overall sampling was done from the gaseous chamber, where the

Experimental procedure

total non-condensable gas was collected to determine the overall

Proximate and ultimate analyses and calorific value composition of gases.

determination: Proximate analysis (ash, moisture, Volatile Matter

(V.M.), and Fixed Carbon (F.C.) contents) of biomass samples

and their chars was performed following the standard methods

(ASTM E871-82, E1755-01, and E872-82) [14,15].The difference

determined the F.C. content. Ultimate analysis (EL III, Vario) of

the biomass samples was carried out following ASTM E777, E778,

and E775 standard methods for determining C,H,N, and S content.

The oxygen content (%) was calculated by difference. The calorific

value was determined using a Bomb Calorimeter (AC-350; LECO);

the standard test method ASTM D5865-13 was followed for

determining the calorific value of biomass samples [16,17].

Structural analysis of biomass samples: For structural

analysis, the samples were prepared as per ASTM Standard Practice

E 1757-01 [18]; further, for determining the extractive, the ethanol

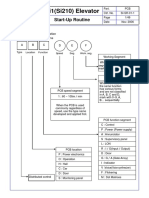

solvent extraction method was used in which all the extractives Figure 1: Flow chart of the pyrolysis process.

get dissolved [19], and the structural component of extractive free

Result and Discussion

biomass samples was determined by ASTM E1758-01[7,19].

Proximate and ultimate analysis and GCV of biomass

TGA and DTG analysis: The ASTM E1131-03 standard method

samples

was followed for T.G. analysis (STA 449F3 Jupiter; NETZCH), in

which about 15mg of biomass sample (-212μ) was used. The Tables 1 & 2 shows the chemical characterization of biomass

heating and nitrogen gas flow rates in the TGA analyzer were 10 and their chars and calorific value. The volatile matter (V.M.) is

°C/min and 60ml/min, respectively. very high (3.5 times) compared to conventional fuels like coal [20],

which is desirable for the current study. In the case of char majority

Reactor setup and procedure: The designed pyrolysis reactor

of V.M. gets evaluated at 800 ˚C. So, the higher content of V.M. will

shown in Figure 1 was performed under anaerobic conditions. The

contribute to a higher yield of product hythane gas [21].

Table 1: Proximate and ultimate analysis and GCV of biomass and char (dry basis).

Samples F.C.(%) VM(%) A(%) C(%) H(%) N(%) S(%) O(%) GCV(%)

SD 19.83 74.99 5.18 47 6.34 0.18 0.1 38.3 19.1

GS 20.54 73.93 5.53 47.15 6.59 0.48 0.16 35.46 19.42

SDC 72.3 16.34 11.36 77.38 1.65 0.12 0.07 7.56 23.07

GSC 74.71 15.17 10.12 76.9 1.77 0.57 0.13 6.82 24.03

Progress Petrochem Sci Copyright © Shalini Gautam

PPS.000606. 5(2).2023 485

Table 2: Structural analysis of biomass.

Biomass Extractives Hemicellulose Cellulose

Lignin (%) L/C ratio L/H ratio L/E ratio Type

sample (%) (%) (%)

C>L>H

SD 8.28 20.01 36.85 26.5 0.719 1.324 3.2

(36.8520.01%)

C>H>L

WH 13.4 21.2 34.78 18.1 0.52 0.854 1.35

(34.7818.1%)

Carbon & hydrogen content: Table 1 shows that the carbon and the amount of sulfur present in the range of (0.10%-0.16%)

content in raw biomass samples lies around 47% and in char and 0.07%-0.13% respectively. The low S&N-containing biomass

around 77%. It is the primary component that contributes to the consider a good fuel because there will be a low formation of

product gas. The higher the carbon content, the higher the product sulfur and nitrogen oxides during the thermochemical conversion

gas yield [22]. The hydrogen content in studied raw samples lies process [8,25]. The High sulfur-containing fuel is not suitable for

in the range of (6.34%-6.59%) and char (1.65%-1.77%). Hydrogen internal combustion engines as well for power production. The

is the most important element in this investigation that will be sulfur-containing fuel adversely affects the metal quality due to its

responsible for hydrogen production and methane production. corrosive nature towards metal; sulfur-containing fuels are not fit

Higher the hydrogen content, the better the product gas. Hydrogen for I.C. engines [24]. Therefore, the biomass used in this work can

is mainly generated from the condensation of aromatics or alkyl reduce the corrosion severity impact on the equipment use and

aromatization reaction during pyrolysis at a temperature beyond maintenance cost.

400 °C [23]. Thus, these plants can act as a good source of hydrogen. Oxygen content: From (Table 3), the amount of oxygen present

The difference between hydrogen in raw and char after pyrolysis in raw samples and their char is 35.46%-38.30% and 6.82%-

processing shows the extent of hydrogen evolution, mainly in 7.56%, respectively. Oxygen is mainly responsible for forming

hydrogen and methane [24]. carbon monoxide and Carbon dioxide, which exist in the molecular

Nitrogen and sulfur content: From (Table 1), it can be observed structure of biomass [26]. Thus, the oxygen content should be less

that nitrogen content in raw biomass samples and their char; for quality product yield fuel.

lies in the range of 0.18%-0.48% and 0.12%-0.57%, respectively,

Table 3: Thermal characteristics of sawdust and groundnut shell.

Hemicellulose Peak Cellulose peak

Material Tonset(°C) Toffset(°C) Tbo(°C)

(dm/dt)sh Tsh(°C) (dm/dt)peak Tpeak(°C)

SD 182 5.74 281 8.65 307 678 353

GS 161 2.13 240 6.14 312 581 364

Calorific value: The calorific value of raw samples and their and methane in the gaseous yield of S.D. were higher than GS (Table

char lies in the range of 19.10MJ/kg- 19.42MJ/kg and 23.07MJ/ 4).

kg-24.03MJ/kg, respectively well-represented in 1. Hydrogen and Table 4: Volumetric composition of produced gas during

carbon are the main contributors to GCV, and hydrogen plays a vital the slow pyrolysis process of sawdust.

role as its calorific value is four times higher than the GCV of coal.

Volume %

So higher hydrogen content is desirable in fuel [27]. Temperature

H2 CH4 CO CO2

Structural analysis

600 ˚C 23.14 5.29 35.20 34.41

Biomass comprises three major structural components, 700 ˚C 31.42 22.93 22.87 20.81

hemicellulose, cellulose, and lignin, which play a significant role

800 ˚C 50.29 22.58 12.37 12.79

in their growth period and provide strength; their concentration

*Overall 51.50 25.15 4.34 17.05

varies substantially as per the location, species to species, and

growth conditions. This three-component, along with extractives, Thermogravimetric analysis

is the main contributor to all products obtained during the Thermogravimetric Analysis (TGA) and Differential

thermochemical conversion of biomass. From (Table 2), it can be Thermogravimetric Analysis (DTG) of biomass were done to

seen that the structural components, extractives (E), hemicellulose understand the decomposition characteristics of biomass with

(H), cellulose (C), and lignin (L) are in the range of 8.28-13.4, 20.01- respect to temperature and time shown in Figure 2 and Table 3. From

21.2, 34.78-36.85, 18.1-26.5 respectively. The L/C, L/H, and L/E (Figure 2), the thermal characteristics table has been made, which

ratios are more dominant in sawdust than in groundnut shells. describes the respective temperatures and rate of decomposition

As per [11], lignin is responsible for high H2 and CH4 formation, of structural components based upon peaks obtained in the DTG

hemicellulose is responsible for increased CO2 emissions, and profile. Thermal characteristics [28,29] of the SD and GS is shown

cellulose is responsible for high C.O. production. So, the hydrogen in (Table 3).

Progress Petrochem Sci Copyright © Shalini Gautam

PPS.000606. 5(2).2023 486

Figure 2: TGA and DTG analysis of sawdust and groundnut shell.

Where; CO2. The overall composition of H2 is about 51.50%, CH4 nearly

a. Tonset: The extrapolated onset temperature is calculated 25.15%, C.O. is about 4.34%, and CO2 is approximately 17.05%.

from the partial peak resulting from the decomposition of the From the 5, At lower pyrolysis temperatures, the concentration of

hemicellulose component. H2CH4 is significant, i.e.,27% and 43%, respectively, whereas for

C.O. and CO2, it is 12% and 15%, respectively, at 600 ˚C. Further,

b. (dm/dt)sh: The overall maximum of the hemicellulose with the temperature rise, only hydrogen concentration increases

decomposition rate. significantly, and the trend is reversed for other gases. In view of

c. Tsh: The temperature corresponding to the overall the overall composition of gases, sawdust pyrolytic hythane gas has

maximum of the hemicellulose decomposition rate. better quality than G.S. pyrolytic gas due to a higher percentage of

d. (dm/dt)peak: The overall maximum of the cellulose hydrogen and methane. So, the perspective of the I.C. engine, the

decomposition rate. hythane produced from sawdust will perform better.

Table 5: Volumetric composition of produced gas during

e. Tpeak: The temperature corresponding to the overall

the slow pyrolysis process of groundnut shell.

maximum of the cellulose decomposition rate.

Volume %

f. Toffset: The extrapolated offset temperature of the dm/ Temperature

dt curves. This value describes the end of the cellulose H2 CH4 CO CO2

decomposition. Decomposition of the structural component 600 ˚C 27.35 42.75 12.55 15.39

varies in diverse temperature regions; hemicelluloses and 700 ˚C 65.72 16.18 2.44 13.71

cellulose usually occur around 220-315 °C and 305-400 °C, 800 ˚C 76.38 13.04 2.12 6.50

respectively, with the maximum mass losses at 268-355 °C, *Overall 49.3 19.51 9.78 19.44

whereas lignin decomposes in a wide range of 180-900 °C

[1,30]. In the case of SD, the decomposition of extractives

Mass balance

starts at a higher temperature (182 °C) compared to G.S. (161 a. Wt. % of Bio-char=W1 (Measured)

°C). A similar observation was in the case of hemicellulose, b. Wt. % of Bio-oil=W2 (Measured)

cellulose, and lignin and decomposition rate component. Due

c. Wt. % of Gas=W3=(100-W1-W2)

to the higher content of lignin in S.D., offset temperature is

higher for S.D. than G.S., whereas the burnout temperature (Tbo d. CVo and CVG=calorific value of oil and gas.

, mass loss rate<1%) is lower in the case of S.D. due to higher (Table 6) Hythane obtained from sawdust has better hythane

decomposition rate. yield, quality and calorific value, so it will perform better than GS.

Gas chromatographic analysis On the other hand, hydrogen and methane are strong reducing

agents that can utilize for iron ore reduction [6,30].

Analysis of the produced gas was done through Gas

Chromatography (G.C.); results of G.C. for each of the selected Table 6: Mass balance of feed and product (wt%) CV of gas

and oil.

biomass samples are shown in Tables 4 & 5. Table 4 shows that the

composition of H2, CO, and CO2 is significant at 600 ˚C, which is CVo CVG

Sample

about 23.14%, 35.20%, and 34.41%, whereas CH4 concentration Biomass W1 W2 W3 (cal/ (cal/

name

gm) gm)

is significantly less than about 5% at this temperature. As the

temperature rises, the H2 and CH4 concentration increases SD 100 38.59 37.26 24.15 1865 5884

significantly, while the trend is reversed in the case of C.O. and GS 100 37.66 40.77 21.57 2472 4758

Progress Petrochem Sci Copyright © Shalini Gautam

PPS.000606. 5(2).2023 487

Conclusion 11. Hlavsová A, Corsar A, Raclavská H, Juchelková D, Škrobánková H (2014)

Syngas production from pyrolysis of nine composts obtained from

Hythane was produced from sawdust and groundnut shells nonhybrid and hybrid perennial grasses. Sci World J.

during stepped pyrolysis. It can be concluded that hydrogen and 12. Neves D, Thunman H, Matos A, Tarelho L, Gómez-BA (2011)

methane production was directly relative to temperature; however, Characterization and prediction of biomass pyrolysis products. Prog

higher temperature ranges contributed more towards hydrogen Energy Combust Sci 37(5): 611-630.

and methane production due to higher lignin and cellulose content. 13. Mishra A, Gautam S, Sharma T (2018) Effect of operating parameters on

coal gasification. Int J Coal Sci Technol 5: 113-125.

Typically, noncondensable Biogases contain 49%-51% hydrogen

14. Das D, Anand A, Gautam S, Rajak VK (2022) Assessment of utilization

and 19%-25% methane along with 4%-9% carbon monoxide

potential of biomass volatiles and biochar as a reducing agent for iron

and 19%-21% carbon dioxide depending on different biomass ore pellets. J Env Tech pp. 1-26.

samples. As the samples were pyrolyzed in a stepped (temperature- 15. Demirbas A (2004) Effects of temperature and particle size on bio-char

wise) manner, the oxygen functionality evolved in the initial yield from pyrolysis of agricultural residues. J Anal Appl Pyrolysis 72(2):

stages, reducing the concentration of CO and CO2 in the product 243-248.

gas. Eventually, the concentration of Hydrogen and Methane in 16. Das D, Anand A, Gautam S (2022) Effect of rice husk volatiles in iron

ore reduction and its kinetic study. Energy Sources, Part A Recover. Util

the product gases increases. The structural component, mainly

Environ Eff 44(3): 6321-6333.

cellulose and lignin, dominates over the groundnut shell, which

17. Ohliger A, Förster M, Kneer R (2013) Torrefaction of beechwood: A

leads to richer hydrogen and methane concentration in hythane parametric study including heat of reaction and grindability. Fuel 104:

at higher temperatures. The potential utilization of hythane gas as 607-613.

hydrogen-rich fuel in I.C. engines can be done. 18. Hames B, Ruiz R, Scarlata C, Sluiter A, Sluiter J (2008) Preparation of

samples for compositional analysis: Laboratory analytical procedure

Acknowledgment (LAP).

The authors are thankful to the Dept. of FMME, Indian Institute 19. Sluiter JB, Ruiz RO, Scarlata CJ, Sluiter AD, Templeton DW (2010)

of Technology (ISM) DHANBAD, for providing the research facility Compositional analysis of lignocellulosic feedstocks. 1 Review and

description of methods. J Agric Food Chem 58: 9043-9053.

to carry out this experimental work.

20. Gautam S (2017) Effect of washing and stamping on coke making of a

References low-grade Indian coal: Correlation between various properties. Ironmak

1. Paswan DK, Anand A, Nandi BK, Gautam S (2022) Drying characteristics Steelmak 44(7): 505-512.

and kinetics behavior of Indian coal slurries using natural draft tray 21. Nunes L, Matias JCDO, Catalao JPDS (2018) Torrefaction of biomass for

dryer. Int J coal Prep Util. energy applications. Elsevier

2. Shalini G (2017) Assessment of low-volatile poor caking Indian coal for 22. Mazzotti M, Carlos J, Allam RJ, Lackner KS, Meunier F, et al. (2005)

coke making. Int J Coal Prep Util 37(1): 33-43. Mineral carbonation and industrial uses of carbon dioxide. IPCC Spec

3. Petrović M, Fiket Ž (2022) Environmental damage caused by coal Rep Carbon dioxide Capture Storage pp. 319-338.

combustion residue disposal: A critical review of risk assessment 23. Liu P, Wang Y, Zhou Z, Yuan H, Zheng T, et al. (2020) Effect of carbon

methodologies. Chemosphere 299: 134410. structure on hydrogen release derived from different biomass pyrolysis.

4. Pudasainee D, Kurian V, Gupta R (2020) Coal: Past, present, and future Fuel 271.

sustainable use. Future Energy Improv Sustain Clean Options Our Planet 24. Loison R, Foch P, Boyer A (1989) Coke quality and production.

pp. 21-48. Butterworth & CO.

5. Chen G, Andries J, Luo Z, Spliethoff H (2003) Biomass pyrolysis/ 25. Suman S, Gautam S (2017) A comparative study between time,

gasification for product gas production: 0054he overall investigation of temperature, and fixed carbon using different biochar reductants as an

parametric effects, Energy Conversion and Management 44(11): 1875- alternate source of energy. Energy Sources Part A Recover Util Environ

1884. Eff 39(10): 1029-1035.

6. Prajapati BK, Anand A, Gautam S, Singh P (2022) Production of hydrogen- 26. Nunes LJR, Matias JCDO, Catalão JPDS (2018) Introduction, in:

and methane-rich gas by stepped pyrolysis of biomass and its utilization Torrefaction of biomass for energy applications. Elsevier pp.1-43.

in IC engines. Clean Technol Environ Policy 24: 1375-1388

27. Anand A, Gautam S, Ram LC (2023) Feedstock and pyrolysis conditions

7. Anand A, Gautam S, Chand Ram LC (2023) A characteristic-based affect suitability of biochar for various sustainable energy and

decision tree approach for sustainable energy applications of biomass environmental applications. J Anal Appl Pyrolysis 170: 105881.

residues from two major classes. Fuel 339: 127483.

28. El-Sayed SA, Mostafa ME (2014) Pyrolysis characteristics and kinetic

8. Rahimi Z, Anand A, Gautam S (2022) An overview on thermochemical parameters determination of biomass fuel powders by differential

conversion and potential evaluation of biofuels derived from agricultural thermal gravimetric analysis (TGA/DTG). Energy Convers Manag 85:

wastes. Energy Nexus 7: 100125. 165-172.

9. Karagöz S (2009) Energy production from the pyrolysis of waste 29. Wilson L, Yang W, Blasiak W, John GR, Mhilu CF (2011) Thermal

biomasses. Int J Energy Res 33(6): 576-581. characterization of tropical biomass feedstocks. Energy Convers. Manag

10. Debdoubi A, Amarti A, Colacio E, Blesa MJ, Hajjaj LH (2006) The effect 52(1): 191-198.

of heating rate on yields and compositions of oil products from esparto 30. Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of

pyrolysis. Int J Energy Res 30(15): 1243-1250. hemicellulose, cellulose and lignin pyrolysis. Fuel 86(12-13): 1781-

1788.

Progress Petrochem Sci Copyright © Shalini Gautam

You might also like

- Eff 7Document10 pagesEff 7Kalil BashaNo ratings yet

- Y.cao, y Bai and J. DuDocument10 pagesY.cao, y Bai and J. DuBilal KazmiNo ratings yet

- Hydrogen Production From Biomass Combining Pyrolysis and The Secondary DecompositionDocument6 pagesHydrogen Production From Biomass Combining Pyrolysis and The Secondary DecompositionBiruk GetachewNo ratings yet

- Biomass and Bioenergy: Research PaperDocument11 pagesBiomass and Bioenergy: Research PaperSamuel AnandNo ratings yet

- A Novel Process Simulation Model For Hydrogen Production Via Reforming of Biomass Gasification TarDocument10 pagesA Novel Process Simulation Model For Hydrogen Production Via Reforming of Biomass Gasification TarHassane AmadouNo ratings yet

- M. Singh Et AlDocument9 pagesM. Singh Et AlBilal KazmiNo ratings yet

- Process Overview For The Production of Hydrogen by Natural Gas Pyrolysis - Schneider - 2020Document28 pagesProcess Overview For The Production of Hydrogen by Natural Gas Pyrolysis - Schneider - 2020c675jjNo ratings yet

- High Temperature Steam Gasification of Corn StrawDocument10 pagesHigh Temperature Steam Gasification of Corn Straw63011273No ratings yet

- 2019-Process Simulation of Hydrogen Rich Gas Production From Producer Gasusing HTS CatalysisDocument11 pages2019-Process Simulation of Hydrogen Rich Gas Production From Producer Gasusing HTS CatalysisChantelleNo ratings yet

- 1 s2.0 S1876610214025302 MainDocument9 pages1 s2.0 S1876610214025302 MainAhmad HarisNo ratings yet

- International Journal of Greenhouse Gas Control: Liyuan Deng, May-Britt Ha GGDocument9 pagesInternational Journal of Greenhouse Gas Control: Liyuan Deng, May-Britt Ha GGMiguel RibeiroNo ratings yet

- JASEM ISSN 1119-8362: Keywords: Cobalt Greenhouse Gases Hydrogen Reforming Neodymium (III) OxideDocument6 pagesJASEM ISSN 1119-8362: Keywords: Cobalt Greenhouse Gases Hydrogen Reforming Neodymium (III) OxideOsariemen Angela EdokpayiNo ratings yet

- Pyrolysis Kinetics and Characteristics of Waste Tyres - Products Distribution and Optimization Via TG-FTIR-MS and Rapid Infrared Heating TechniquesDocument16 pagesPyrolysis Kinetics and Characteristics of Waste Tyres - Products Distribution and Optimization Via TG-FTIR-MS and Rapid Infrared Heating TechniquesTENGKU NUR SYAFIKA TENGKU SHAFIENo ratings yet

- Applied Thermal Engineering: Research PaperDocument6 pagesApplied Thermal Engineering: Research Paperanang darunnajaNo ratings yet

- Catalytic Pyrolysis of Biomass-Plastic Wastes in The Presence of MgO and MgCO3 For Hydrocarbon-Rich Oils ProductionDocument6 pagesCatalytic Pyrolysis of Biomass-Plastic Wastes in The Presence of MgO and MgCO3 For Hydrocarbon-Rich Oils Productionbambang_teknikkimiaNo ratings yet

- Methanol Production From Natural Gas Reforming and CO2 CapturingDocument12 pagesMethanol Production From Natural Gas Reforming and CO2 Capturingguigoal2010No ratings yet

- Hydrogen Production From Pruning WasteDocument9 pagesHydrogen Production From Pruning Wastethe scorpion 2500No ratings yet

- Karakteristik HydrocharDocument22 pagesKarakteristik Hydrocharrio cristianoNo ratings yet

- Journal of Cleaner Production: Mohammad Hasan Khademi, Mohammad Lotfi-VarnoosfaderaniDocument16 pagesJournal of Cleaner Production: Mohammad Hasan Khademi, Mohammad Lotfi-VarnoosfaderaniCinthia Sierra LgarsNo ratings yet

- Renewable EnergyDocument12 pagesRenewable EnergySaadNo ratings yet

- Sheth 2010Document8 pagesSheth 2010Tomás Pessoa Londe CamargosNo ratings yet

- Jae Hac Ko, Jingchen Wang, Qiyong Xu: Full Length ArticleDocument9 pagesJae Hac Ko, Jingchen Wang, Qiyong Xu: Full Length ArticleCarlos AlvarezNo ratings yet

- Plastic Waste (PET) To SyngasDocument9 pagesPlastic Waste (PET) To Syngaswaseemkhan49No ratings yet

- Process Design and Comprehensive 3E Analysis of Low Carbon Diol Production With and Without Heat IntegrationDocument11 pagesProcess Design and Comprehensive 3E Analysis of Low Carbon Diol Production With and Without Heat IntegrationIntan SyahirahNo ratings yet

- 1 s2.0 S0016236120321396 Main - CompressedDocument13 pages1 s2.0 S0016236120321396 Main - CompressedAlly HerreraNo ratings yet

- 1 s2.0 S0959652622025173 MainDocument11 pages1 s2.0 S0959652622025173 MainMay PassarapornNo ratings yet

- Fuel Processing Technology: Ahmad Tavasoli, Masoumeh G. Ahangari, Chirayu Soni, Ajay K. DalaiDocument11 pagesFuel Processing Technology: Ahmad Tavasoli, Masoumeh G. Ahangari, Chirayu Soni, Ajay K. DalaiJaydeep PatelNo ratings yet

- Design & Development of 5 KW Downdraft Biomass GasifierDocument7 pagesDesign & Development of 5 KW Downdraft Biomass GasifierAksaralangit BudiyartoNo ratings yet

- Thermodynamics and Economic Feasibility of Acetone Production From Syngas Using The Thermophilic Production Host Moorella ThermoaceticaDocument18 pagesThermodynamics and Economic Feasibility of Acetone Production From Syngas Using The Thermophilic Production Host Moorella Thermoaceticaهنگامه ذولعلیNo ratings yet

- Energies 14 08457Document9 pagesEnergies 14 08457Gargee YadavNo ratings yet

- Vipppp4 BicakovaDocument14 pagesVipppp4 Bicakovahafeez khanNo ratings yet

- Process Safety and Environmental Protection: S.M. Al-SalemDocument9 pagesProcess Safety and Environmental Protection: S.M. Al-SalemHEMANT BALSORANo ratings yet

- Journal of The Taiwan Institute of Chemical EngineersDocument8 pagesJournal of The Taiwan Institute of Chemical EngineersJonathan SoeNo ratings yet

- Bioethanol Production Through Syngas Fermentation in A Tar Free Bioreactor Using Clostridium ButyricumDocument8 pagesBioethanol Production Through Syngas Fermentation in A Tar Free Bioreactor Using Clostridium Butyricumoki trisnaNo ratings yet

- 2018, CO2 Capture and Electro-Conversion Into Valuable Organic Products A Batch and Continuous StudyDocument13 pages2018, CO2 Capture and Electro-Conversion Into Valuable Organic Products A Batch and Continuous StudyRitesh PatidarNo ratings yet

- Get FileDocument9 pagesGet FileAzza M. ElnenaeyNo ratings yet

- Assessment of Natural Gashydrogen Blends As AnDocument15 pagesAssessment of Natural Gashydrogen Blends As AnRaulNo ratings yet

- Referencia 65Document5 pagesReferencia 65Marcelo L. H. FilhoNo ratings yet

- Enhancement of Catalytic Performance of Porous Membrane Reactor With Ni Catalyst For Combined Steam and Carbon Dioxide Reforming of Methane ReactionDocument6 pagesEnhancement of Catalytic Performance of Porous Membrane Reactor With Ni Catalyst For Combined Steam and Carbon Dioxide Reforming of Methane ReactionWassachol SumarasinghaNo ratings yet

- Date Palm Waste Gasification in Downdraft GasifierDocument7 pagesDate Palm Waste Gasification in Downdraft GasifiersumitrochakrabortiNo ratings yet

- Novel Energy Efficient Process For Acetic AcidDocument12 pagesNovel Energy Efficient Process For Acetic AcidainNo ratings yet

- Yang Xiao, Shengbin Wu, Hantao Xia, Jinyuan Zhang, Lingling Ding, Xiaolong Bao, Yi Tang, Yongjie QiDocument16 pagesYang Xiao, Shengbin Wu, Hantao Xia, Jinyuan Zhang, Lingling Ding, Xiaolong Bao, Yi Tang, Yongjie Qihossein nezhadiNo ratings yet

- Bio-Oil Production Via Co-Pyrolysis of Almond Shell As Biomass and HighDocument7 pagesBio-Oil Production Via Co-Pyrolysis of Almond Shell As Biomass and HighhammadahmedNo ratings yet

- Renewable and Sustainable Energy ReviewsDocument14 pagesRenewable and Sustainable Energy ReviewsAnonymous x0QRgPNo ratings yet

- Yan2020 Article BiocharAndPyrolyticGasPropertiDocument10 pagesYan2020 Article BiocharAndPyrolyticGasPropertiRonei de AlmeidaNo ratings yet

- Slow Pyrolysis of Low-Density Poly-Ethylene (LDPE) A Batch Experiment and Thermodynamic AnalysisDocument13 pagesSlow Pyrolysis of Low-Density Poly-Ethylene (LDPE) A Batch Experiment and Thermodynamic AnalysisPICHE MME SecretaryNo ratings yet

- Artigo 2Document19 pagesArtigo 2Tiffany RansdorfNo ratings yet

- Kinetic Modeling of Biomass Steam Gasification System For Hydrogen Production With CO AdsorptionDocument7 pagesKinetic Modeling of Biomass Steam Gasification System For Hydrogen Production With CO Adsorptionprash_13No ratings yet

- Plant Design and Economics ProjectDocument43 pagesPlant Design and Economics Projectetayhailu100% (5)

- J Fuel 2020 117534Document10 pagesJ Fuel 2020 117534Shafira RiskinaNo ratings yet

- Characteristics of Biomass Charcoal Briquetttes and Pollutant Emission Reduction For Sulfur and Nitrogen During CombustionDocument10 pagesCharacteristics of Biomass Charcoal Briquetttes and Pollutant Emission Reduction For Sulfur and Nitrogen During Combustiongabrielpio654No ratings yet

- Hydrothermal Co-CarbonizationDocument13 pagesHydrothermal Co-CarbonizationcemilNo ratings yet

- Processes 10 01879 v2Document21 pagesProcesses 10 01879 v2Imran AriffNo ratings yet

- Material and Energy Balance Analysis For Urea Production From Biomass Via Methane Steam ReformingDocument11 pagesMaterial and Energy Balance Analysis For Urea Production From Biomass Via Methane Steam ReformingIJAERS JOURNALNo ratings yet

- Bioresource Technology: Qiangu Yan, Fei Yu, Jian Liu, Jason Street, Jinsen Gao, Zhiyong Cai, Jilei ZhangDocument10 pagesBioresource Technology: Qiangu Yan, Fei Yu, Jian Liu, Jason Street, Jinsen Gao, Zhiyong Cai, Jilei ZhangMuhammad IrwandaNo ratings yet

- Biomass and Bioenergy: Deepak Kumar Singh, J.V. TirkeyDocument12 pagesBiomass and Bioenergy: Deepak Kumar Singh, J.V. Tirkeyazhar KhanNo ratings yet

- Environmental and Economic Benefits of Hydrogen Fuel Production From Heavy Fuel Oil in NigeriaDocument11 pagesEnvironmental and Economic Benefits of Hydrogen Fuel Production From Heavy Fuel Oil in NigeriaKolawole OsafehintiNo ratings yet

- A Novel Process Simulation Model For Hydrogen Production Via Reforming of Biomass Gasification TarDocument10 pagesA Novel Process Simulation Model For Hydrogen Production Via Reforming of Biomass Gasification TarSirikul BoontermNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Effectiveness ESWT in Lower Limb Tendinopathy Syst. Rev. Mani-Babu 2014Document10 pagesEffectiveness ESWT in Lower Limb Tendinopathy Syst. Rev. Mani-Babu 2014Javier MartinNo ratings yet

- Rai S. 2023. Intralesional Steroid Inj Vs ESWT in Plantar Fasciitis. Comparative, Prospective, Case Series Study.Document10 pagesRai S. 2023. Intralesional Steroid Inj Vs ESWT in Plantar Fasciitis. Comparative, Prospective, Case Series Study.Javier MartinNo ratings yet

- Yasin A. 2022. Advances in HA For Biomed Applications.Document12 pagesYasin A. 2022. Advances in HA For Biomed Applications.Javier MartinNo ratings yet

- Sprott H. 2023. HA in RheumatologyDocument18 pagesSprott H. 2023. HA in RheumatologyJavier MartinNo ratings yet

- Violante IR. 2023. Non-Invasive TI Electrical Stimulation Human Hippocampus.Document24 pagesViolante IR. 2023. Non-Invasive TI Electrical Stimulation Human Hippocampus.Javier MartinNo ratings yet

- Burke 2019 Neurophysiological Clinical Appl.Document20 pagesBurke 2019 Neurophysiological Clinical Appl.Javier MartinNo ratings yet

- Gulle H. 2023. Prediciting Outcome Plantar Heel Pain. Systematic Review Prognostic FactorsDocument13 pagesGulle H. 2023. Prediciting Outcome Plantar Heel Pain. Systematic Review Prognostic FactorsJavier MartinNo ratings yet

- Eaes 000746Document3 pagesEaes 000746Javier MartinNo ratings yet

- Lota KS. 2023. Rapid ESWT Coccydinia - Prospective Study 14 PatientsDocument6 pagesLota KS. 2023. Rapid ESWT Coccydinia - Prospective Study 14 PatientsJavier MartinNo ratings yet

- Düregger K. 2016. Influence Storage Conditions of The Release of GF in Platelet Rich Blood Derivatives.Document4 pagesDüregger K. 2016. Influence Storage Conditions of The Release of GF in Platelet Rich Blood Derivatives.Javier MartinNo ratings yet

- Balius R. 2021. HFPS Beyond Acute Plantar Fasciitis.Document32 pagesBalius R. 2021. HFPS Beyond Acute Plantar Fasciitis.Javier MartinNo ratings yet

- Mcda 000794Document2 pagesMcda 000794Javier MartinNo ratings yet

- Amms 000756Document10 pagesAmms 000756Javier MartinNo ratings yet

- GMR 000665Document14 pagesGMR 000665Javier MartinNo ratings yet

- NTNF 000652Document6 pagesNTNF 000652Javier MartinNo ratings yet

- Tteh 000578Document8 pagesTteh 000578Javier MartinNo ratings yet

- Rmes 000734Document8 pagesRmes 000734Javier MartinNo ratings yet

- RPN 000665Document5 pagesRPN 000665Javier MartinNo ratings yet

- SBB 000629Document15 pagesSBB 000629Javier MartinNo ratings yet

- Mapp 000557Document4 pagesMapp 000557Javier MartinNo ratings yet

- Acam 000668Document5 pagesAcam 000668Javier MartinNo ratings yet

- Tteft 000685Document9 pagesTteft 000685Javier MartinNo ratings yet

- Icp 000562Document2 pagesIcp 000562Javier MartinNo ratings yet

- Mcda 000793Document2 pagesMcda 000793Javier MartinNo ratings yet

- Mcda 000789Document3 pagesMcda 000789Javier MartinNo ratings yet

- Mcda 000790Document2 pagesMcda 000790Javier MartinNo ratings yet

- Fsar 000635Document7 pagesFsar 000635Javier MartinNo ratings yet

- Mcda 000757Document3 pagesMcda 000757Javier MartinNo ratings yet

- Epmr 000580Document3 pagesEpmr 000580Javier MartinNo ratings yet

- Ajhs 000540Document2 pagesAjhs 000540Javier MartinNo ratings yet

- Design of Powertrain Model For An Electric Vehicle Using MATLAB SimulinkDocument8 pagesDesign of Powertrain Model For An Electric Vehicle Using MATLAB Simulinksatish moupuriNo ratings yet

- Tail Gas Treating CatalystsDocument4 pagesTail Gas Treating CatalystsAhmed SaidNo ratings yet

- 8thchapter 210501 180648Document3 pages8thchapter 210501 180648Parvesh KumarNo ratings yet

- Eaton SWBD Quick Conn Design Guide Dg015007enDocument15 pagesEaton SWBD Quick Conn Design Guide Dg015007entammamshNo ratings yet

- Sigma Lg-Otis Di1 (Si210) PCBDocument49 pagesSigma Lg-Otis Di1 (Si210) PCBVilla Robert RamoaNo ratings yet

- Oil LevelDocument2 pagesOil LevelAndres AlejandroNo ratings yet

- 0625 Thermal Properties and Temperature - P1 - QPDocument6 pages0625 Thermal Properties and Temperature - P1 - QPapdrenlNo ratings yet

- Landfill Gas Energy Project Development Handbook (EPA)Document143 pagesLandfill Gas Energy Project Development Handbook (EPA)ChrisMurilloNo ratings yet

- Fundamentals of Heat Engines 1St Edition Jamil Ghojel Full ChapterDocument51 pagesFundamentals of Heat Engines 1St Edition Jamil Ghojel Full Chapterdavid.brown418100% (14)

- Company Profile PT ProEnergiDocument8 pagesCompany Profile PT ProEnergiOnome EmefekeNo ratings yet

- QTT Spare Part Deutz TCD Dan BF6MDocument2 pagesQTT Spare Part Deutz TCD Dan BF6MvirtualakunifnuNo ratings yet

- Value Engineering List - MEPDocument1 pageValue Engineering List - MEPAshraf ElmagdoubNo ratings yet

- AC CircuitsDocument14 pagesAC CircuitsShiva Sankar BeharaNo ratings yet

- 4.3 Electric Circuits & Electrical SafetyDocument10 pages4.3 Electric Circuits & Electrical SafetyAyana AkjolovaNo ratings yet

- Passos Et Al. - 2017 - Towards Energy Neutral Microalgae-Based Wastewater Treatment PlantsDocument9 pagesPassos Et Al. - 2017 - Towards Energy Neutral Microalgae-Based Wastewater Treatment PlantsfvassisNo ratings yet

- 2023 Eng1503 - Question PaperDocument6 pages2023 Eng1503 - Question PaperAnelka AshleyNo ratings yet

- 7 Copra Dryer TechnologiesDocument28 pages7 Copra Dryer TechnologiesVanNo ratings yet

- SJ4 CatalogDocument5 pagesSJ4 CatalogLê Anh TuấnNo ratings yet

- Channel Flow Behind CasingDocument2 pagesChannel Flow Behind Casingحسين رامي كريم A 12No ratings yet

- PV Romania 65 MW 1.0Document10 pagesPV Romania 65 MW 1.0Adriana PitigoiNo ratings yet

- Crude-to-Chemicals (CTC) : A Straight-Forward Route For A Strategic TurnDocument29 pagesCrude-to-Chemicals (CTC) : A Straight-Forward Route For A Strategic TurnrahulNo ratings yet

- Sperre - XA250Document7 pagesSperre - XA250Mechanical DeptNo ratings yet

- 70ACRJDocument28 pages70ACRJsugianto barusNo ratings yet

- Bobcat S750 Service Manual Skid Steer Loader 6990249enUSDocument1,262 pagesBobcat S750 Service Manual Skid Steer Loader 6990249enUSАндрей ОвчаренкоNo ratings yet

- Generac Ficha TecnicaDocument2 pagesGenerac Ficha TecnicaPercyNo ratings yet

- Motor SiemensDocument4 pagesMotor SiemensAlejandro SotoNo ratings yet

- Wood Mackenzie Venezuela Plataforma Deltana Block 4Document7 pagesWood Mackenzie Venezuela Plataforma Deltana Block 4rubenpeNo ratings yet

- AD 1+Tension+PackerDocument2 pagesAD 1+Tension+PackerHamid Reza BabaeiNo ratings yet

- RELAY2Document3 pagesRELAY2Ritesh KumarNo ratings yet

- Hydrogen Storage in Porous Silicon - A ReviewDocument12 pagesHydrogen Storage in Porous Silicon - A Reviewgabriela plaiasuNo ratings yet