Professional Documents

Culture Documents

RDBALAN Full en Metric A4

RDBALAN Full en Metric A4

Uploaded by

David AltarribaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RDBALAN Full en Metric A4

RDBALAN Full en Metric A4

Uploaded by

David AltarribaCopyright:

Available Formats

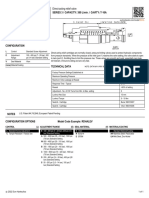

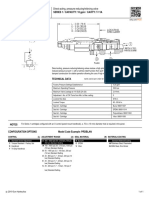

MODEL Direct-acting relief valve

RDBA CAPACITY: 45 L/min. / CAVITY: T-162A

snhy.com/RDBA

CONFIGURATION

Direct-acting relief cartridges are normally closed, pressure-limiting valves used to protect hydraulic components

L Control Standard Screw Adjustment

from pressure transients. When the pressure at the inlet (port 1) reaches the valve setting, the valve starts to open

A Adjustment 500 - 3000 psi (35 - 210 bar), to tank (port 2), throttling flow to limit the pressure rise. These valves are smooth and quiet, essentially zero leak,

Range 1000 psi (70 bar) Standard dirt tolerant, immune to silting and are very fast.

Setting

N Seal Material Buna-N TECHNICAL DATA NOTE: DATA MAY VARY BY CONFIGURATION. SEE CONFIGURATION SECTION.

(none) Material/Coating Standard Material/Coating

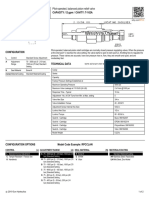

Cavity T-162A

Series 0

Capacity 45 L/min.

Factory Pressure Settings Established at 15 L/min.

Maximum Operating Pressure 350 bar

Maximum Valve Leakage at Reseat 0,7 cc/min.

Response Time - Typical 2 ms

Reseat >85% of setting

Adjustment - No. of CW Turns from Min. to Max. setting 6

Valve Hex Size 19,1 mm

Valve Installation Torque 27 - 33 Nm

Adjustment Screw Internal Hex Size 4 mm

Locknut Hex Size 12,7 mm

Locknut Torque 9 - 10 Nm

Seal kit - Cartridge Buna: 990162007

Seal kit - Cartridge EPDM: 990162014

Seal kit - Cartridge Polyurethane: 990162002

Seal kit - Cartridge Viton: 990162006

Model Weight 0.10 kg.

NOTES U.S. Patent #4,742,846; European Patent Pending

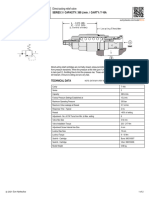

CONFIGURATION OPTIONS Model Code Example: RDBALAN

CONTROL (L) ADJUSTMENT RANGE (A) SEAL MATERIAL (N) MATERIAL/COATING

L Standard Screw Adjustment A 500 - 3000 psi (35 - 210 bar), 1000 psi N Buna-N Standard Material/Coating

C Tamper Resistant - Factory Set (70 bar) Standard Setting E EPDM /AP Stainless Steel, Passivated

K Handknob W 800 - 4500 psi (55 - 315 bar), 1000 psi V Viton /LH Mild Steel, Zinc-Nickel

(70 bar) Standard Setting

B 300 - 1500 psi (20 - 105 bar), 1000 psi

(70 bar) Standard Setting

C 1000 - 6000 psi (70 - 420 bar), 1000 psi

(70 bar) Standard Setting

D 200 - 800 psi (14 - 55 bar), 400 psi (28

bar) Standard Setting

E 100 - 400 psi (7 - 28 bar), 200 psi (14

bar) Standard Setting

S 50 - 200 psi (3,5 - 14 bar), 100 psi (7

bar) Standard Setting

c 2019 Sun Hydraulics

1 of 2

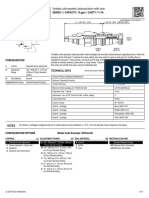

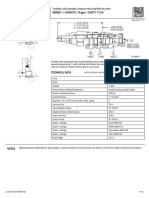

TECHNICAL FEATURES

All 2-port relief cartridges (except pilot reliefs) are physically and functionally interchangeable (same flow path, same cavity for a given frame size).

Will accept maximum pressure at port 2; suitable for use in cross port relief circuits.

The seals on the adjust screw are exposed to system pressure which means this valve can only be adjusted when the pressure is removed. The setting procedure

is; check the setting, remove the pressure, adjust the valve, check the new setting.

Valve is relatively insensitive to varying oil temperatures and oil borne contamination.

Select a spring range where the desired relief setting is approximately mid-range to high between the minimum and maximum pressure to ensure maximum valve

repeatability.

Suitable for use in load holding applications.

Back pressure on the tank port (port 2) is directly additive to the valve setting at a 1:1 ratio.

Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage

the seals.

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge

machining variations.

PERFORMANCE CURVES

c 2019 Sun Hydraulics

2 of 2

You might also like

- The Complete Field Guide For Solar Sales Leaders - SPOTIODocument29 pagesThe Complete Field Guide For Solar Sales Leaders - SPOTIOrenewenergymanNo ratings yet

- RDBALAN Full Es Metric A4Document2 pagesRDBALAN Full Es Metric A4Willam Hugo Luna PonteNo ratings yet

- RDDALDN Full en Us A4Document3 pagesRDDALDN Full en Us A4clark jonesNo ratings yet

- Sun Hydraulics RDDA-LCNDocument3 pagesSun Hydraulics RDDA-LCNJustinNo ratings yet

- RDDALAN Es Metric LetterDocument1 pageRDDALAN Es Metric Lettersebastian.vegaNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADocument1 pageModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTENo ratings yet

- RPCCLAN Full en Us LetterDocument2 pagesRPCCLAN Full en Us Lettera safaieNo ratings yet

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- Model Direct-Acting Relief Valve: CAPACITY: 12 GPM / CAVITY: T-162ADocument1 pageModel Direct-Acting Relief Valve: CAPACITY: 12 GPM / CAVITY: T-162AmhasansharifiNo ratings yet

- RDDA Es Metric A4Document1 pageRDDA Es Metric A4Daniel GómezNo ratings yet

- RDJA Full en Us A4Document3 pagesRDJA Full en Us A4GERALD SIMONNo ratings yet

- Modelo Acción-Directa Alivio Válvula: Series 1 / Capacidad: 25 GPM / Cavidad: T-10ADocument1 pageModelo Acción-Directa Alivio Válvula: Series 1 / Capacidad: 25 GPM / Cavidad: T-10AErasmo LimaNo ratings yet

- Model Direct-Acting Relief Valve: Series 2 / Capacity: 50 GPM / Cavity: T-3ADocument2 pagesModel Direct-Acting Relief Valve: Series 2 / Capacity: 50 GPM / Cavity: T-3AJustinNo ratings yet

- Relife Valve Rpeclnn - Pilot OperatedDocument2 pagesRelife Valve Rpeclnn - Pilot OperatedHassan KhattabNo ratings yet

- Relief Valve VENTABLE RVCALAN - T11A RV1Document1 pageRelief Valve VENTABLE RVCALAN - T11A RV1Hassan KhattabNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- CCCALBN Full en Us LetterDocument2 pagesCCCALBN Full en Us Letterisaiahsamsonm_948069No ratings yet

- Model Ventable, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Poppet Relief ValveGamal El Deen KamalNo ratings yet

- RPECOAN Full Es Metric LetterDocument2 pagesRPECOAN Full Es Metric Letteralfredo lopez regaladoNo ratings yet

- RVCALCN Full en Us A4Document2 pagesRVCALCN Full en Us A4Felipe DiazNo ratings yet

- Model Ventable, Pilot-Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Piston Relief ValveGamal El Deen KamalNo ratings yet

- SUN RPGC-JCN (Relief Valve)Document3 pagesSUN RPGC-JCN (Relief Valve)ful islamNo ratings yet

- Model Ventable, Pilot Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot Operated, Balanced Piston Relief ValveErasmo LimaNo ratings yet

- SUN RPGC-LAN (Relief Valve)Document3 pagesSUN RPGC-LAN (Relief Valve)ful islamNo ratings yet

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument2 pagesModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- CBEWLJN Full en Metric A4Document2 pagesCBEWLJN Full en Metric A4Ηρακλης ΤσαπραζηςNo ratings yet

- CCCALBN en Us LetterDocument1 pageCCCALBN en Us Letterisaiahsamsonm_948069No ratings yet

- Relife Valve Low Flow Rbac - T10aDocument1 pageRelife Valve Low Flow Rbac - T10aHassan KhattabNo ratings yet

- DRBCLBN Full Es Us A4Document2 pagesDRBCLBN Full Es Us A4Erasmo LimaNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveANDRESNo ratings yet

- Modelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument1 pageModelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AJonathanDavidDeLosSantosAdornoNo ratings yet

- PRDBOEN Full en Us LetterDocument3 pagesPRDBOEN Full en Us LetterPartagon PowNo ratings yet

- CBGGLJN Es Metric LetterDocument1 pageCBGGLJN Es Metric LetterjesusNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2AleosignareNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveLennyn Mamani VenturaNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11AmhasansharifiNo ratings yet

- Model Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveJustinNo ratings yet

- PPDB en Us A4Document1 pagePPDB en Us A4Felipe DiazNo ratings yet

- Sun Hydraulics MWEB-LJN Technical SpecificationsDocument1 pageSun Hydraulics MWEB-LJN Technical SpecificationsJustinNo ratings yet

- Model Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10ADocument2 pagesModel Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10AHassan KhattabNo ratings yet

- PVDB Full en Us LetterDocument2 pagesPVDB Full en Us LetterIsrael RuizNo ratings yet

- RDDA - Direct-Acting Relief ValveDocument3 pagesRDDA - Direct-Acting Relief ValveD ŠpokauskasNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveRobertoNo ratings yet

- Direct-Acting Relief Valve: DownloadDocument2 pagesDirect-Acting Relief Valve: Downloadaristi51No ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveRonildo - HydraparNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CBEALBN Full en Us LetterDocument2 pagesCBEALBN Full en Us Letterangelo.araza0913No ratings yet

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CBGH Full en Us LetterDocument2 pagesCBGH Full en Us LetterPrakash VasudevanNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance Valveதமிழன் இராமசாமிNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Model 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveDocument1 pageModel 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveRinaldo BompieriNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- PPDBLAN Es Metric LetterDocument1 pagePPDBLAN Es Metric Lettersebastian.vegaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Modelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaDocument1 pageModelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaErasmo LimaNo ratings yet

- Modelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Document1 pageModelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Erasmo LimaNo ratings yet

- Aa11vlo250drg 10R-NSD62N00 - R909606604Document20 pagesAa11vlo250drg 10R-NSD62N00 - R909606604David AltarribaNo ratings yet

- A4VG56DA1D7 32R-NZC02F023SH-S R902088328 - en - 20201001Document35 pagesA4VG56DA1D7 32R-NZC02F023SH-S R902088328 - en - 20201001David AltarribaNo ratings yet

- VD10A - VD12A - Technical CatalogueDocument34 pagesVD10A - VD12A - Technical CatalogueDavid AltarribaNo ratings yet

- Load Sensing Directional Control Valve: 1 DescriptionDocument14 pagesLoad Sensing Directional Control Valve: 1 DescriptionDavid AltarribaNo ratings yet

- WSP22 3 - 400 P 120801 enDocument4 pagesWSP22 3 - 400 P 120801 enDavid AltarribaNo ratings yet

- A4VG90DA2D2 32R-NSF02F071DC-S R902076835 - en - 20200114Document14 pagesA4VG90DA2D2 32R-NSF02F071DC-S R902076835 - en - 20200114David AltarribaNo ratings yet

- APL3001Document1 pageAPL3001David AltarribaNo ratings yet

- IR Sensor MLX90247 PDFDocument9 pagesIR Sensor MLX90247 PDFMuskan BhargavaNo ratings yet

- ĐỀ CƯƠNG ÔN TẬP HKII LOP 8Document5 pagesĐỀ CƯƠNG ÔN TẬP HKII LOP 8CHUPI FFNo ratings yet

- XCSD70CDocument2 pagesXCSD70CDiego FernandesNo ratings yet

- OSPF Part2 - Study Notes CheatSheet - (Waqas Karim) WK v2Document1 pageOSPF Part2 - Study Notes CheatSheet - (Waqas Karim) WK v2Sivaraman AlagappanNo ratings yet

- EA-Archi-Adi WDocument38 pagesEA-Archi-Adi WBytecode AvNo ratings yet

- Bs-En 1080-2013. InglesDocument24 pagesBs-En 1080-2013. InglesDaniela Serna PulgarinNo ratings yet

- Managerial Computing (MC), PGP I: 2017-18, Term I: Material On Electronic Medium Is The Supplementary Reading MaterialDocument6 pagesManagerial Computing (MC), PGP I: 2017-18, Term I: Material On Electronic Medium Is The Supplementary Reading MaterialvijetaNo ratings yet

- Boiler Interlock and ProtectionDocument25 pagesBoiler Interlock and Protectioncaptainrajneesh87% (15)

- IoTWorX - MQTT Broker ConnectivityDocument2 pagesIoTWorX - MQTT Broker ConnectivityJirawat JumpathongNo ratings yet

- Roldan, Regin Pio 71, Bayani Street, Barangay 37, Caloocan City, Metro Manila, PhilippinesDocument1 pageRoldan, Regin Pio 71, Bayani Street, Barangay 37, Caloocan City, Metro Manila, Philippinesregin pioNo ratings yet

- MIS MCQsDocument10 pagesMIS MCQsSalman ShaikhNo ratings yet

- Definitions of The Turing MachineDocument10 pagesDefinitions of The Turing Machinemaki ababiNo ratings yet

- CSE252Document87 pagesCSE252abhaNo ratings yet

- Department of Education: y LogDocument3 pagesDepartment of Education: y LogBraham Codizar LptNo ratings yet

- 14-Nm Finfet Technology For Analog and RF ApplicationsDocument7 pages14-Nm Finfet Technology For Analog and RF ApplicationsTwinkle BhardwajNo ratings yet

- Priti KumariDocument138 pagesPriti KumariinfoNo ratings yet

- P2-Python ProgramsDocument5 pagesP2-Python ProgramsSagar AbhiNo ratings yet

- Manual Testing NotesDocument60 pagesManual Testing NotesAlpha0% (1)

- RP 70 K 39 RFns QLZD UDocument2 pagesRP 70 K 39 RFns QLZD Ushivam raiNo ratings yet

- 2nd MIDTERM MATH 10Document3 pages2nd MIDTERM MATH 10Mard A. MacNo ratings yet

- Lego-Brand-Audit Final MbanfieldDocument14 pagesLego-Brand-Audit Final MbanfieldSauransh GuptaNo ratings yet

- RWTP GB Mne Msa 000151Document90 pagesRWTP GB Mne Msa 000151slayerzzz22No ratings yet

- Vehari Shops DataDocument9 pagesVehari Shops DataJoiya_loveNo ratings yet

- GN TD04301 I Pendant CustomizationDocument16 pagesGN TD04301 I Pendant CustomizationKristal NewtonNo ratings yet

- Experiment No.5: Rogramming M21E-20SPP-195 For Scientists LabDocument6 pagesExperiment No.5: Rogramming M21E-20SPP-195 For Scientists LabHarwinder SinghNo ratings yet

- Unit-5 SoftComputingDocument5 pagesUnit-5 SoftComputingTusheet Pal SinghNo ratings yet

- Ashtech Solutions ManualDocument186 pagesAshtech Solutions ManualDerzsi Elthes AndrasNo ratings yet

- ALAVES BOMBA SCHMALS - en-ENDocument2 pagesALAVES BOMBA SCHMALS - en-ENEdmundo SánchezNo ratings yet

- Automotive R and D Transformation Optimizing Gen Ais Potential ValueDocument7 pagesAutomotive R and D Transformation Optimizing Gen Ais Potential Valuekellymeinhold327No ratings yet