Professional Documents

Culture Documents

Value Chain For Fan Industry: Illustrated Product Is Deluxe Model Ceiling Fan

Value Chain For Fan Industry: Illustrated Product Is Deluxe Model Ceiling Fan

Uploaded by

Kamran Mustafa0 ratings0% found this document useful (0 votes)

19 views1 pageOriginal Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

19 views1 pageValue Chain For Fan Industry: Illustrated Product Is Deluxe Model Ceiling Fan

Value Chain For Fan Industry: Illustrated Product Is Deluxe Model Ceiling Fan

Uploaded by

Kamran MustafaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Value Chain for Fan Industry: Illustrated Product is Deluxe Model Ceiling Fan

Backward Forward Linkage in

Linkage in VC Total Cost: Rs 1,776 VC

1. Body Turning – 0.5%

Value Added 2. Body Drilling – 0.3% Value Added Value Added

21% 3. Axle Turner & Winding – 1.2% 23% Rs 485 27% Rs 575

4. Fitter – 0.3% Major cost in

5. Painting – 1.1% this

6. Testing & Packaging – 0.3% component

1. Aluminium – 12.4% Casting and aluminium die-casting ISSUES

process is not energy efficient.

is electricity

2. Aluminium Rod 3.2 1. The Body turning is currently Value addition is low due to lack

3. Blades - 13.2% 95% of the costs are electricity which is

done using simple Lathe Machine of designing, product innovation,

4. Electric Sheet – 24% consumption. – If technology is upgraded to non-

5. Winding Wire - 18.9& competitive high input costs, and compliance

CNC Machines productivity will

6. Bearing - 2.4% Uncompetitive electricity pricing and issues restricting entry into high

increase by a minimum of 4X.

7. Paint- 4.9% policy This will reduce the costs inconsistent income markets.

8. Other Parts – 21.8% 1. Pakistan: $0.14/Kwh significantly. The quality will also

ISSUES 2. S. Africa: $0.06/Kwh improve and a reduction in

1. 50% of the materials are 3. China: $0.09/Kwh wastage of 5-10% wastage will be

imported including electric 4. Taiwan: $0.09/Kwh possible. The current marketing costs include wall International importers are

sheet, winding wire, bearing

and paint and some other Electricity unreliable and writing, newspaper and internet. The adding more value than the

2. Body drilling is currently done

small parts. Value Addition is generators are needed to run the by single drill – multi drills will

sector does not have a clear marketing manufacturers. The inability of

not possible. operation – cost of running the improve the productivity 4X. strategy for export. Branding local manufacturers to develop

generator is even more expensive internationally is nonexistent. sale points abroad means the

2. Where local materials are – around $0.28/Kwh. 3. Painting is predominantly done foreign agents are taking bigger

used (aluminum and steel On average 40 electricity in the industry using wet paint chunk of the value added. In

sheet) quality is not outages/month is experienced and spray gun. This results in

affecting performance

comparison India and China

consistent. Fans are not around 40% wastage – shift to

energy efficient when have much more on ground

powder coating will reduce loses

compared with competition. significantly. presence in their export target

countries.

4. Shortage of skilled workers

TRTA Pakistan Copyright

You might also like

- Bergerac Systems: The Challenge of Backward IntegrationDocument5 pagesBergerac Systems: The Challenge of Backward IntegrationSanthosh Selvam100% (2)

- Quiet Title Complaint Template Sample Example FormDocument5 pagesQuiet Title Complaint Template Sample Example FormZionNo ratings yet

- Operations Strategy at BYD of China, Electrifying The World's Automotive MarketDocument13 pagesOperations Strategy at BYD of China, Electrifying The World's Automotive MarketJessica InaNo ratings yet

- RFT in Reactive DyeingDocument24 pagesRFT in Reactive DyeingRezaul Karim Tutul100% (10)

- Forward Integration or Horizontal Expansion Rev TheoDocument32 pagesForward Integration or Horizontal Expansion Rev TheoJawad FarisiNo ratings yet

- Cutlery VCDocument1 pageCutlery VCBurhan UddinNo ratings yet

- Disposable Diaper Industry - Group 9Document8 pagesDisposable Diaper Industry - Group 9Kartik NarayanaNo ratings yet

- Cost & Expense: Muhamad Rizal Muhamad Rico P F Nabila Hanifah Nisa Sajiah N Nur Kamilatus Solihah Rendy JinalihDocument6 pagesCost & Expense: Muhamad Rizal Muhamad Rico P F Nabila Hanifah Nisa Sajiah N Nur Kamilatus Solihah Rendy JinalihNabila HanifahNo ratings yet

- Inventory - Driven CostsDocument9 pagesInventory - Driven CostsShubham RathiNo ratings yet

- Roland Berger - The Lithium-Ion Battery Market and Supply Chain - 2022 - FinalDocument38 pagesRoland Berger - The Lithium-Ion Battery Market and Supply Chain - 2022 - FinalRodrigo LuisNo ratings yet

- U.S. Solar Photovoltaic System Cost Benchmark: Q1 2017Document66 pagesU.S. Solar Photovoltaic System Cost Benchmark: Q1 2017Francisco Cano MarínNo ratings yet

- Ingles - PDF HarvardDocument10 pagesIngles - PDF HarvardComic Matute LanzaNo ratings yet

- Power Quality Solutions - V3 - 01 - 22Document10 pagesPower Quality Solutions - V3 - 01 - 22vratolomacNo ratings yet

- Ensuring California Manufacturing Stays CompetitiveDocument16 pagesEnsuring California Manufacturing Stays CompetitiveJonathan WenNo ratings yet

- Group 12 - American Connector Company Case SolutionDocument7 pagesGroup 12 - American Connector Company Case Solutionpeeyushjain2020No ratings yet

- Final PPT Aluminium IndustryDocument36 pagesFinal PPT Aluminium IndustryDanish Memon50% (2)

- Project 4 Final PaperDocument30 pagesProject 4 Final Paperrtk5025No ratings yet

- Dolf Gielen Keynote 231113Document36 pagesDolf Gielen Keynote 231113LelosPinelos123No ratings yet

- WP SiPV Manufacturing 0Document9 pagesWP SiPV Manufacturing 0Mohammad RazaNo ratings yet

- Power Sector ChallemgesDocument28 pagesPower Sector Challemgesadepaul62No ratings yet

- Lect 1512Document6 pagesLect 1512filmon dissanNo ratings yet

- Clean & Green Energy Project (USD) CSBDocument10 pagesClean & Green Energy Project (USD) CSBTESTERPERSONNo ratings yet

- BentoniteDocument10 pagesBentoniteKunal ArjariyaNo ratings yet

- Airborne Teaching NoteDocument17 pagesAirborne Teaching NotePEDRO LOLINo ratings yet

- Teaching Note PDFDocument17 pagesTeaching Note PDFPEDRO LOLINo ratings yet

- Solar O&M Cost ReductionDocument27 pagesSolar O&M Cost Reductionsce jggppNo ratings yet

- Hydro Powered Turbine: Executive SummaryDocument24 pagesHydro Powered Turbine: Executive Summaryrtk5025No ratings yet

- Augmented Reality: Reducing Scrap ReworkDocument5 pagesAugmented Reality: Reducing Scrap Reworkmakdeep2012No ratings yet

- Cost Calculation Program For Productivity in WeldingDocument20 pagesCost Calculation Program For Productivity in WeldingiyigunNo ratings yet

- Analysis of The Indian PaperDocument7 pagesAnalysis of The Indian PaperAshutosh kumarNo ratings yet

- Mr. Bhishma Pandit - NepalDocument38 pagesMr. Bhishma Pandit - NepalMajid KhanNo ratings yet

- Wind Turbines CaseDocument4 pagesWind Turbines CaseEster SusantoNo ratings yet

- Case-American Connector CompanyDocument9 pagesCase-American Connector CompanyDIVYAM BHADORIANo ratings yet

- American Connector CompanyDocument15 pagesAmerican Connector CompanyUjjval YadavNo ratings yet

- Company-Havells India LimitedDocument11 pagesCompany-Havells India LimitedSurbhi SabharwalNo ratings yet

- Materials Matter™: Solar Panel Reliability and Impact On Financial Returns Dupont Photovoltaic SolutionsDocument31 pagesMaterials Matter™: Solar Panel Reliability and Impact On Financial Returns Dupont Photovoltaic SolutionssnairmNo ratings yet

- Imc-Br004 - En-E V IMPDocument12 pagesImc-Br004 - En-E V IMPSubramanyam Arehalli MuniswariahNo ratings yet

- American Connector CompanyDocument9 pagesAmerican Connector CompanyAntariksha GangulyNo ratings yet

- Oversizing Whitepaper: Maximum Freedom When OversizingDocument8 pagesOversizing Whitepaper: Maximum Freedom When OversizingEduardus PandikNo ratings yet

- S.No Issues Under Consideration Desired Information Available Information Gap Possible Sources of InformationDocument1 pageS.No Issues Under Consideration Desired Information Available Information Gap Possible Sources of InformationSUALI RAVEENDRA NAIKNo ratings yet

- Generac Industrial Power Whitepaper Total Cost of Ownership Diesel V Natural GasDocument5 pagesGenerac Industrial Power Whitepaper Total Cost of Ownership Diesel V Natural GasShazmaniaNo ratings yet

- IMR Solution For Offshore Wind FarmDocument28 pagesIMR Solution For Offshore Wind Farmaslamajec123No ratings yet

- Flexible Operation NTPC'S Approach: Presented by A.K.Sinha, NTPC LTD, IndiaDocument18 pagesFlexible Operation NTPC'S Approach: Presented by A.K.Sinha, NTPC LTD, Indiamag_ktps20021520No ratings yet

- Working Together: To Prevent Cable DamageDocument16 pagesWorking Together: To Prevent Cable DamageinnNo ratings yet

- Designing Global Supply Chain NetworksDocument8 pagesDesigning Global Supply Chain NetworksaasthaNo ratings yet

- Power Economics in Liberalised Electricity MarketsDocument23 pagesPower Economics in Liberalised Electricity MarketsCarlos Fabian GallardoNo ratings yet

- Ricoh IM C3000 Marketing PlanDocument16 pagesRicoh IM C3000 Marketing PlanAhmed HadadNo ratings yet

- Assignment Topic:: Decision Making AnalysisDocument10 pagesAssignment Topic:: Decision Making AnalysisJu Naid MalikNo ratings yet

- Electric Vehicles Pb-0124ADocument28 pagesElectric Vehicles Pb-0124Aindraneel pNo ratings yet

- ResultDocument1 pageResultRachel McDonnellNo ratings yet

- Reaching Higher Standards With Cell and Module InnovationDocument52 pagesReaching Higher Standards With Cell and Module InnovationJose SifuentesNo ratings yet

- kwt2001 01Document12 pageskwt2001 01Ahmad ShaheenNo ratings yet

- At 03383 WP Refinery ProfitsDocument18 pagesAt 03383 WP Refinery Profitszubair1951100% (1)

- Production Departments Direct Labor Rate Manufacturing Overhead Application RatesDocument10 pagesProduction Departments Direct Labor Rate Manufacturing Overhead Application RatesSano ManjiroNo ratings yet

- Eliminating Hidden Material CostsDocument19 pagesEliminating Hidden Material CostsMarcos Antonio RossiNo ratings yet

- PQ Case Studies Manas KunduDocument58 pagesPQ Case Studies Manas KunduSuresh Kumar RajagopalNo ratings yet

- 5-3 LDC PoA Case Study - RLDocument13 pages5-3 LDC PoA Case Study - RLNofutureNo ratings yet

- Chapter 2 Cost ClassificationsDocument18 pagesChapter 2 Cost Classificationsmarizemeyer2No ratings yet

- Siemens VFD HandbookDocument4 pagesSiemens VFD Handbookshanks263No ratings yet

- Operations Management: Case Write-UpDocument6 pagesOperations Management: Case Write-Upankit_dadesiNo ratings yet

- Innovation and Inequality: How Does Technical Progress Affect Workers?From EverandInnovation and Inequality: How Does Technical Progress Affect Workers?No ratings yet

- 7 Sellout Offer Feb 24 - 040133Document1 page7 Sellout Offer Feb 24 - 040133Kamran MustafaNo ratings yet

- Electric Fan Manufacturing Sector: PakistanDocument8 pagesElectric Fan Manufacturing Sector: PakistanKamran MustafaNo ratings yet

- 5-PEL Price List 5 W.E.F 25th MarDocument3 pages5-PEL Price List 5 W.E.F 25th MarKamran MustafaNo ratings yet

- How To Calculate Force Is Equal To MaDocument1 pageHow To Calculate Force Is Equal To MaKamran MustafaNo ratings yet

- MPLUN-DSC User ManualDocument5 pagesMPLUN-DSC User ManualAccounts DepartmentNo ratings yet

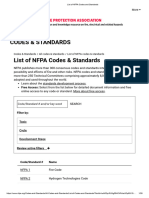

- List of NFPA Codes and StandardsDocument28 pagesList of NFPA Codes and StandardsjteranlavillaNo ratings yet

- AHIST 1401-01 - AY2022-T4 - Web Resources For Art History ResearchDocument3 pagesAHIST 1401-01 - AY2022-T4 - Web Resources For Art History ResearchAhmed Al-BetarNo ratings yet

- Lis Pendens NoticeDocument2 pagesLis Pendens Noticemarc47No ratings yet

- REMEDIAL-WPS OfficeDocument7 pagesREMEDIAL-WPS OfficeEJ OstanNo ratings yet

- Guarantee LetterDocument1 pageGuarantee LetterWizcarmelo ParcellanoNo ratings yet

- Daftar Pustaka Lutfi AmaliaDocument3 pagesDaftar Pustaka Lutfi AmaliaLutfi amaliaNo ratings yet

- 2012 The GLOCK ReportDocument76 pages2012 The GLOCK Reportshopper9990% (1)

- Have To Dont Have To BingoDocument17 pagesHave To Dont Have To BingoYazmin HermidaNo ratings yet

- Bevel Gears - PPT (Revised) PDFDocument47 pagesBevel Gears - PPT (Revised) PDFsidguru chinchole50% (2)

- D FM Cost User GuideDocument135 pagesD FM Cost User GuideUdaya RangaNaikNo ratings yet

- World Economic Forum - Annual Report 2000/2001Document20 pagesWorld Economic Forum - Annual Report 2000/2001World Economic Forum100% (2)

- FIRST SUMMATIVE TEST IN MEDIA First QuarterDocument2 pagesFIRST SUMMATIVE TEST IN MEDIA First QuarterRhaieyee ElNo ratings yet

- Glossarium Graeco Barbarum PDFDocument741 pagesGlossarium Graeco Barbarum PDFdrfitti1978No ratings yet

- Oim552-Lean Manufacturing Question BankDocument6 pagesOim552-Lean Manufacturing Question BankRaagul SNo ratings yet

- CV TemplateDocument1 pageCV TemplateLiza Fitri SyarselaNo ratings yet

- KPM V TrajanoDocument2 pagesKPM V Trajanojodelle11No ratings yet

- SB98 2Document6 pagesSB98 2Luis LeonNo ratings yet

- BDA PresentationsDocument26 pagesBDA PresentationsTejaswiniNo ratings yet

- Entrance Form 2023 24Document1 pageEntrance Form 2023 24Goodwell Mzembe100% (1)

- Guwahati Smart GirlDocument5 pagesGuwahati Smart GirlManKapNo ratings yet

- Sri Lanka Desk Calendar &: Grow More For Nations ProsperityDocument1 pageSri Lanka Desk Calendar &: Grow More For Nations ProsperitySanaka LogesNo ratings yet

- ZomatoDocument3 pagesZomato2305112130010No ratings yet

- Titrimetric Potentiometric Determination of Anionic and Cationic SurfactantsDocument13 pagesTitrimetric Potentiometric Determination of Anionic and Cationic SurfactantsJosué MedeirosNo ratings yet

- Case 4Document4 pagesCase 4cuong462003No ratings yet

- Collinear ReportDocument15 pagesCollinear ReportRemonIbrahimNo ratings yet

- FINAL - Presentations in Your OfficeDocument2 pagesFINAL - Presentations in Your OfficeSyed Mohammed AzharuddinNo ratings yet

- Practice Development Guide and Evaluation Rubric - Unit 3 - Phase 4 - Practical Component - Simulated PracticesDocument7 pagesPractice Development Guide and Evaluation Rubric - Unit 3 - Phase 4 - Practical Component - Simulated PracticesMaria Jose Ramos BarcoNo ratings yet

- A Project Report On Electricity Generation With Combination of Wind and Solar EnergyDocument33 pagesA Project Report On Electricity Generation With Combination of Wind and Solar EnergySantoch SriNo ratings yet