Professional Documents

Culture Documents

Batch Controller (Spec)

Batch Controller (Spec)

Uploaded by

Tung Bui HuyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Batch Controller (Spec)

Batch Controller (Spec)

Uploaded by

Tung Bui HuyCopyright:

Available Formats

Explosionproof Type

BATCH CONTROLLER

MODEL EL7200

GENERAL SPECIFICATION

GS.No.GEB503E-1

s GENERAL

Designed to be used in conjunction with a flowmeter and a shutoff valve, the batch controller measures the process flow by controlling the valve in batches of a preset quantity. Built around a microprocessor, this multifunction allweather controller in a flameproof enclosure can be installed in Division 1 and 2 hazardous locations. It streamlines the blending or dosing processes, transfer between tanks, shipping control of the process material to save time and effort in chemical, food, paint, and many other industries.

s FEATURES

1. Easy to operate: Flameproof enclosure (Exd II BT4) permits installation in hazardous locations (Division 1 and 2). 2. Easy to operate: The controller responds to batch setup, start, stop, and reset commands - all at the touch of front-panel pushbuttons. 3. Accurate batch control: Thanks to the output of status valve operate signals (2 points) and 4/20mA PID control signal, applicationspecific accurate valve control and accurate batch measurement can be achieved. 4. Simplifies system configuration: Can start, stop, and reset the controller with remote signals. Provides a batch end output. All these simplify building a system to be interlocked with other control systems. 5. Increased process safety: 1) The valve opens and closes in two stages (controlled initial flow toward the full flow and then controlled final flow before closure). This arrangement prevents static electricity buildup in the piping assembly or in the tank at startups of operation and eliminates water hammer that could otherwise give destructive forces of hydraulic shock to the piping assembly at valve shutdowns. 2) Upon detection of an erratic condition, such as interrupted pulses during the batch process, or an overmeasurement that has exceeded the preset quantity of a batch, the controller can be so configured as to produce an alarm signal.

6. Communication interface as standard feature: Has communication capabilities to communicate with the host computer. Interface: RS-485 (standard) RS232C (option) Protocol: Modbus RTU Baud rate: 1200, 2400, 4800, 9600, 19200 bps 7. Improved reliability and easy maintenance: 1) All major circuits are modularized on printed circuit boards for increased reliability and serviceability. 2) In power cycling or in the event of power failure, a built-in EEPROM storage retains variables and parameters.

http://www.oval.co.jp

Head Office (Tokyo): Phone. 81-3-3360-5121. Fax. 81-3-3365-8605 Beijing Office: Phone. 86-10-5867-4711. Fax. 86-10-5867-4713 Overseas Branch Offices: Seoul, Singapore and Taipei

BATCH CONTROLLER MODELEL7200

GEB503E-1

s GENERAL SPECIFICATIONS

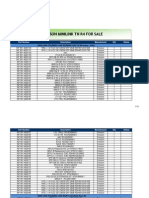

Item Principle of operation Display Description Pulse addition Backlit LCD 19264 dots Grand total (9-digit) Target batch 6-digit, standard (9-digit max.) Instant rate (corrected) SV, MV, PU, END, ALARM, com. status Measurement units, trend graphic representation of on-going batch Alarm identification Temp., press., density, volume conv. factor, grand total (9-digit), total before temp. corr. (9-digit) Can accepts 2 inputs (one channel is a pulse input to verify pulse input variation.) Power to generator: 12VDC, 24VDC (Max. current: 60mA with 1 input; 30mA with 2 inputs) Input pulse: Contact-closure, current, voltage, or open collector pulse 200Hz Max. 2kHz (when hardware input freq. scaling is enabled.) 0.2ms Capacity 24VDC, 5mA max. Start, reset: Formacontact ContactONduration: 30ms min. (instant make) Stop: Formbcontact ContactOFFduration: 30ms min. (instant break) Secure at least a 0.5 sec interval between signals. InterlockNormally shortinput (Formacontact ) 3-wire Pt100 Transmission length: 300 meters (loop DC resistance 5 max. with CVVS 1.25 sq. mm or equiv.) or 4 to 20mA (internal load resist.: 250) or 1 to 5V 4 to 20mA (internal load resist.: 250) or 1 to 5V 24VDC10% Max.: 80mA Significand: 0.0001 to 9.9999 Exponent part: -5 to +5 JIS K2249-1995 Crude Oil and Petroleum Product JIS K2240-1991LPG Correction accuracy: Other liquids (Correction formula using a quadratic approximation) 0.075%0.004%/ -20 to +160 Yes (Can set up temp. to start correction.) Option Any setting or selectable from three preset values (standard prese1000, 2000, 4000 counts) 0 to 9999 counts (default: 80 couns) 0 to 9999 counts (default: 80 couns) 0 to 99 counts (default: 2 couns) 0 to 99 counts (default: 2 couns) 0 to 9999 sec (default: 30 sec) 0 to 15 pulses (default: 0 pulse) 0 to 99 sec (default: 5 sec) Invalid for 5 sec after startup Instant flowrate 1 to 99999 Holds from the start of a batch until end of a batch. Voltage signal which is the same as supply voltage, or Formacontact (250VAC, 1A) Holds from the end of initial controlled flow until the start of final controlled flow. Voltage signal which is the same as supply voltage, or Formacontact (250VAC, 1A) 4 to 20mA (Max. load resistance 750) Holds from the start of a batch until end of a batch + timer setting a Form contact or bcontact (250VAC, 1A) Photo MOS relay (250V AC/DC, 0.15A) Photo MOS relay (250V AC/DC, 0.15A) Photo MOS relay (250V AC/DC, 0.15A) 1 to 99 ms selectable in 1 ms steps One kilometer max. with CVVS 1.25sq. mm or equiv. RS-485 (standard) or RS-232C (option) Modbus RTU 1200, 2400, 4800, 9600, 19200 bps RS-485: 1.2 kilometers max. Parameter read/write, total and other variables read I/O check except for pulse, temp., press. input, PID output Front-panel pushbuttons (available only part of parameters) 1 Evacuates critical data in EEPROM. 100/110/115VAC, 200/220/230VAC 50/60Hz AC230V51VA, AC115V40VA AC220V48VA, AC110V38VA AC200V43VA, AC100V34VA 10 to 50

Information shown Input signal Correction

3

Shown at all times

Scrolling variables Flowrate Frequency response Min. pulse width

Remote control input

Temperature Pressure (option)

Power to transmitter (temp. and press.)

Meter factor setting Temperature Temperature range

Pressure Target batch Initial value Final value Predicted overshoot Overshoot Pump timer Pulse variation Missing pulse Excessive flowrate Valve operate signals PID Pump

Alarms

Batch setting

Status

SV (controlled flow signal)

MV (full flow signal)

Output

Communication

End Alarm

Pulse

Pulse width Transmission length Interface Protocol Baud rate Transmission length Contents Operation check functions Parameter configuration Power failure backup Power supply Max. power consumption (apparent power)

Ambient temperature Insulation resistance Explosionproof rating Installation Finish Weight Electromagnetic compatibility

Because of surge suppressors installed, insulation resistance and dielectric tests are unacceptable.

Flameproof enclosure ExdBT4 2 Stanchion or wall mount type Munsell 2.5PB5/8, glossy Stanchion type: 50 kg approx. (stanchion incl.) or wall mount type: 25 kg approx. EMS EN55011 EN61000-6-2

1Initial velocity, magnitude of shift, predicted overshoot, overshoot, missing pulse intervals, target batch selectable only with front-panel pushbuttons. 2Pressure-resistant packings are options. Specify the quantity desired when you order the controller.

BATCH CONTROLLER MODELEL7200

GEB503E-1

s OPERATION TIME CHART

Description of Operation (where two-stage open shutoff valve is used.) Upon depression of START button (point A), the valve opens to Valve Operating Signal ON a predetermined position (initial controlled flowrate). When a Limit Signal predetermined quantity (from point A to point B) is delivered, the OFF ON (1st stage open) Soft timer valve opens fully; when metering reaches point C, the valve Upper Limit Flowrate Signal 0 to 9999 sec. automatically throttles the flow and maintains a predetermined (Full open) ON OFF valve position (final controlled flowrate). At point D, a closure Ongoing output OFF signal is generated. However, due to a time lag in valve signal (pump control) END in the display actuation inherent to the type of valve used, the valve actually Full-flow open closes at point E. Here, since the quantity delivered from point D MV in the display to point E is an overshoot that can be anticipated, we can Reset button Controlled-flow open determine the target setpoint with this overshoot corrected.While cancels END SV in the display the time required for the valve to shut off may remain constant, Full Flowrate variables, such as line pressure variation, cause the closure C point to deviate more or less from point E. By taking into account Start signal Stop Signal this overshoot from point E, we can arbitrarily select the magnitude of overshoot. If an overshoot, or overmeasurement, Initial Flowrate Final Flowrate exceeds a predetermined quantity, the controller can be so B D configured as to produces an alarm. In the event an alarm is Batch End issued, the next measurement is prevented. Safe and accurate measurement is thus achieved. As a matter of A E F Predicted Time course, valve positions from AB and CD must be adjusted overshoot B Initial controlled flow beforehand on the part of the valve. Overshoot initial setpoint Controlled flow functions Final controlled

Flowrate

Target batch

batch setpoint

flow A final setpoint AB

PID control to match the instantaneous flowrate to the flow program setting. Proportional band P to 9999 0 Integral timeI 0.01 to 99.99 sec. Derivative timeD 0.00 to 99.99 sec. Settings .. Initial flowrate, full flowrate, final flowrate

s MODEL CODE NUMBER

Item Model Product Code E L 7 2 0 0 1 2

Supplementary Code

100VAC 200VAC 50/60Hz 50/60Hz 50/60Hz 50/60Hz

Description

Explosionproof Type Batch Controller

Power Supply

3 4 9 2 3 4 5 6 9 1

110/115VAC 220/230VAC

Other than above

Contact-closure pulse (PG20, etc.) 12V, 3-wire voltage pulse (PG30, etc.) 24V, 2-wire 4/20mA current pulse 12V, 2-wire current pulse (PG30S) Open collector

Flowrate input

Other than above (2 inputs inclusive)

Any 6-digit setting 1-2-4k remote input Other than above 0 Less temperature input (no correction for temperature) Pt 100 1 to 5VDC voltage input 4 to 20mA current input Other than above 1 2 The same voltage as supply voltage (status signal) Contact-closure output (status signal) For controlled flow PID 4 to 20mA For controlled flow (term 1 + term 3) 1 2 3 9 2 9

Programming

Temperature input

Valve output

3 4 9 1 2 1

Other than above

Wall mount type Stanchion type

Installation

Finish

Standard communication interfaceRS-485 Options (stated in special note) Pressure input (corrected for pressure) Communication interfaceRS-232C

Munsell 2.5PB5/8, glossy

BATCH CONTROLLER MODELEL7200

GEB503E-1

s PART NAMES AND FUNCTIONS

Hex boltM10, a total of 8)

Front Panel Display

Sunshade

Pushbuttons

Pushbutton white Pushbutton ROT. red Pushbutton green

ROT.

Pushbutton STOP red

STOP

RESET

START

Pushbutton START green

Pushbutton RESET white

Front

panel Display and Controls

Functions Shows grand total in a range 0 to 999,999,999. Shows preset value in a range 0 to 999,999 (standard)Max.999,999,999 Shows NET, GROSS, TEMP, PRESS, DENSITY, and k. Shows gross total in a range 0 to 999,999,999. Shows measured temperature to 1st decimal place in a range between low and high limit. Shows measured pressure to 2nd decimal place in a range between low and high limit. Shows measured density to 2nd decimal place. Shows volume conversion factor to 4 th decimal place. Shows total net in a range 0 to 999,999,999. Shows instant rate in a range 0 to 9,999,999 in a batch process (temporary interruption incl.). Beyond this range,Flow overappears. In standby and END stateappears.

Shows RUN COM , ,and operation status. RUN blinks at all times; COM appears only during communication. , , , Operation statusesSTARTSTOPEND or ALARMlights corresponding to the current state.

Display item Total counter Preset window Scrolling window GROSS TEMP PRESS DENSITY k NET Instant rate window Status window Chart window of batch

Pushbutton

Shows a chart representation of on-going batch process

Functions

Functions Scrolls available variables in the scrolling window. Pressing for 5 seconds moves modes to simple parameter setup mode. Pressing for 5 seconds moves modes to parameter setup mode with ten-key (ten-key mode). Pressing for 5 seconds moves modes to setup mode (param. and variable setup mode).

Pushbutton symbol ROT

STOP RESET START

Interrupts batch process temporarily. Also silences alarm buzzer or clears alarm condition

(depending on the type of alarm). Resets batch process; resets pulse input prior to startup, or cancels alarm condition. Starts or restart batch process.

Short Open detector detector 30V Option 24V Switch board Reed switch 16 MHz CPU 5V Photocoupler Photocoupler Scaler 1/1, 1/10 24V Buzzer Relay board Relay 32-bit microprocessor MOS-FET Com. 5V RS-485 RS-232C 3.684MHz SRAM EEPROM EPROM Communication 7, 8, 9, /10, 11, 12 24-bit A/D converter 8-bit microprocessor 1/1, 1/10 Front panel pushbuttons Start, stop, reset, scroll, , LCD Ten key unit 19264 dots Display board

Power to generator SUP 1

Flow input 1

S1

Generator select board

Flow input 2

S2 4

Generator select board

s CONTROLLER BLOCK DIAGRAM

BATCH CONTROLLER MODELEL7200

0V 3

12V

Const. current B 2mA

Remote inputs Start, stop, reset 25-28, 27-28, 26-28 Target batch select1-2-4k 37-40, 38-40, 39-40 Interlock 29-30

14

b 15

MV, SV, pump output 34-35, 36-35, 44-45 Pulse, end, alarm output 21-22, 23-24, 32-33

Pt 100

A 13

24V

Power to transmitter

MAX.80mA

20

4 to 20mA/1 to 5V select

Analog input 1 temp. 5-6 Analog input 2 press. 17-18 Communication

24V

5V

41 12-bit A/D converter

PID output 4 to 20mA

I/O flow input. contact-closure 15V input, relay output

Power unit Power unit

Noise filter AC power 46-47

42

Microprocessor, logic

5V Analog in/out, Pt100 12V

GEB503E-1

BATCH CONTROLLER MODELEL7200

GEB503E-1

s TERMINAL IDENTIFICATION

Term. No. 1 Label SUP Description

SUP 3-wire generator

Flow signal input

2 3 4

SIG1 0V SIG2

FLOW SIGNAL IN

2-wire generator SIG1 Generator 1 Generator 2 SIG1 Generator 1 Generator 2

0V

0V

SIG2

SIG2

Temp. transmitter

5 6 7

Rx

TEMP IN

4 to 20mAinternal load resistance250or 1 to 5V A parameter selects current input or voltage input.

Rx Rx SG Tx Tx SG Rx SG Tx RXD

8 9 10 11 12 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 13

Communication

Rx SG Tx Tx SG A B b (option terminal) (option terminal) G SUP SA RE ST COM2 LOCK COM2 G MV COM1 SV 1k 2k 4k COM2 PID OUT G GND terminal PUMP OUT REMOTE IN VALVE OUT INTER LOCK GND terminal ALM OUT TC OUT END OUT . REMOTE CONTROL PRESS IN Pt100 COMMUNICATION

or RS-485 std.

GND TXD

RS-232 option

If RS-485 is selected, terminals 7-10 and 8-11 are internally connected. With multidrop wiring, etc., either of these terminal pairs may be used as a tie-point. Terminals 9-12 are internally connected.

Resistance bulbs

A B b

Input terminals for resistance bulbs. G terminalGND

1 G

Pressure transmitter

4 to 20mAinternal load resistance250or 1 to 5V A parameter selects current input or voltage input. G terminalGNDearth ground SUPPower to transmitterfor temp. and/or press. 24VDC Pulse output terminals Photo MOS relay 250V AC/DC, 0.15A END output terminals Photo MOS relay 250V AC/DC, 0.15A

START RESET STOP COM2

Pulse output END output

Contact-closure input

Start, reset: Formacontact ContactONduration: 30ms min. (instant make) Stop: Formbcontact ContactOFFduration: 30ms min. (instant break)

Capacity 24VDC, 5mA max. Secure at least a 0.5 sec interval between signals.

Interlock terminalNormally shortinput (Formacontact ) Earth grounding input signal, etc. Earth ground terminal Alarm output terminal Photo MOS relay 250V AC/DC, 0.15A Control valve Control output signal 2-stage shutoff valve MVHolds from the end of initial controlled flow until the start of final controlled flow. SV Holds from the start of a batch until the end of a batch. Voltage signal the level of which is the same as supply voltage, or Form acontact 250VAC, 1A Remote input terminals for target batch selection. (Standard 1K1000, 2K2000, 4K4000)

Alarm output

Valve operate signal

Contactclosure signal

Valve operate signals

PID output terminals for valve control 4 to 20mA outputmax. load resistance 750

Earth ground terminal

Output terminals for pump Holds from the start of batch until batch end time setting Form aor Form bcontact 250VAC, 1A

Pump output

H N G

Power input

POWER VAC

100/110/115 VAC, 50/60Hz or 200/220/230 VAC, 50/60Hz G terminalGNDearth ground terminal

1Connect temperature input to temperature transmitter terminals (Nos. 5-6) or resistance thermometer terminals (Nos. 13 to 16). A parameter selects temperature transmitter or resistance thermometer.

BATCH CONTROLLER MODELEL7200

GEB503E-1

s OUTLINE DIMENSIONSUnit in mm

Wall Mount TypeEL7200-11

Approx. Weight 25kg

332.4 274 240

259.5 200 160 40

441.5 360

STOP ROT.

RESET

START

Perssure-resistant packingoption

390

230

210

Close-up plug

41 40 40 41

Stanchion TypeEL7200-21

360.5

80

46 34

Approx. Weight 50kg

Bracket U-bolt

STOP ROT. RESET START

option Stanchion

299.5 2B 50A SGP pipe

GND screw, M6

340

P.C.D.300 4 places equally spaced Anchor bolt holes 415

1500

Perssure-resistant packing

BATCH CONTROLLER MODELEL7200

GEB503E-1

s When making inquiries, please advise the following: (Fill in the blanks or check with mark.)

1. Product model 2. Application 3. Companion flowmeter type Metered process fluid 4. Flow range Min. flowrate Max. flowrate EL 11. Temperature input specifications Pt100Resistance thermometer type 4 to 20mA 1 to 5VDC to Temperature range 13. Tag No., instrument No., etc. 14. Pressure-resistant packing quantity desired Yes No Unit

12. Companion valve type, model, specifications

5. Pulse generator type or converter type 6. Input (pulse generator) pulse units Resolution of total counter reading 7. Supply voltage VAC Hz

15. System block diagram and a sketch of installation location 16. Interface with the host CPU NOTE This controller has obtained an explosionproof certificate, including pressure-resistant packings. If you plan to use it in an explosionproof application, pressure-resistant packings dedicated to this controller are required separately. So do not

8. Companion receiving instrument type, model, and specifications for batch end output, remote output to totalizer, and alarm output 9. Remote command input (start, stop, reset, interlock) types 10. Factory- or user-defined parameters Standard Specified Item (Example) Initial setting Specified setting 100 counts

forget to specify the quantity of pressure-resistant packings desired. When you use pressure-resistant packings, use cables 16.0 to 20.0mm in outside diameter and never route signal cables in the same conduit with power cable.

The specification as of March, 2009 is stated in this GS Sheet. Specifications and design are subject to change without notice.

Sales Representative:

GS.No.GEB503E 09.3 06.10

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MRL E-Pack Assay Instructions For Tests and VerificationsDocument35 pagesMRL E-Pack Assay Instructions For Tests and VerificationsLe Huynh LongNo ratings yet

- Nie 2206 Embedded SystemsDocument4 pagesNie 2206 Embedded Systemslynx101No ratings yet

- Radwin Idu-S: Layer 2 Indoor SwitchDocument4 pagesRadwin Idu-S: Layer 2 Indoor Switchcephas01No ratings yet

- MB Manual Ga-Z (H) 270n-Wifi eDocument48 pagesMB Manual Ga-Z (H) 270n-Wifi eRACHMAWATI BELLINo ratings yet

- Datasheet of iDS-7600NXI-I2 P'8F - DeepinMind NVR - V4.1.60 20190716Document6 pagesDatasheet of iDS-7600NXI-I2 P'8F - DeepinMind NVR - V4.1.60 20190716Nathalia Andrea Jaramillo GilNo ratings yet

- Installation Guide - Tecnomen NGM 5.1.3 - IG - 6000700 - 11Document110 pagesInstallation Guide - Tecnomen NGM 5.1.3 - IG - 6000700 - 11fahad01No ratings yet

- EWS Switch c1.6.x: User ManualDocument67 pagesEWS Switch c1.6.x: User Manualashokj1984No ratings yet

- SimCoder User ManualDocument84 pagesSimCoder User ManualAlArpeggios AzAzel NaFisNo ratings yet

- Lte Questions and AnswersDocument2 pagesLte Questions and AnswersRaj RanjanNo ratings yet

- 2019 Chrysler Dodge Jeep Ram SRT ManualDocument202 pages2019 Chrysler Dodge Jeep Ram SRT ManualRadiocode24No ratings yet

- Varistor Productcatalog Sep07Document41 pagesVaristor Productcatalog Sep07rushbrNo ratings yet

- Comincashin Scania ProblemsDocument10 pagesComincashin Scania ProblemsHani SweetieNo ratings yet

- Ba Eng Pico+xxxuiDocument2 pagesBa Eng Pico+xxxuipecf VOLTESTNo ratings yet

- Common-Base ConfigurationDocument10 pagesCommon-Base ConfigurationRakin Mohammad SifullahNo ratings yet

- Touch Screen With Haptic Feedback (TI Design)Document34 pagesTouch Screen With Haptic Feedback (TI Design)Jm SunNo ratings yet

- Ericsson Minilink TN R4Document15 pagesEricsson Minilink TN R4Ebenezer AnnanNo ratings yet

- SP791 Data SheetsDocument19 pagesSP791 Data SheetstarpinoNo ratings yet

- OmniVision OP02220 PDFDocument2 pagesOmniVision OP02220 PDFMaikel WilkeNo ratings yet

- Encoder Error-The Encoder of Motor Doesn't Send Proper SignalsDocument1 pageEncoder Error-The Encoder of Motor Doesn't Send Proper SignalsjhfbtyNo ratings yet

- Axi Timer V2.0: Logicore Ip Product GuideDocument36 pagesAxi Timer V2.0: Logicore Ip Product GuideMounira TarhouniNo ratings yet

- PC-EE-504-Module 5 Power Electronics: InvertersDocument39 pagesPC-EE-504-Module 5 Power Electronics: InvertersSanjoy PathakNo ratings yet

- ST-901 User ManualDocument10 pagesST-901 User ManualEugenio100% (1)

- AN 1059 High CMR Isolation Amplifier For Current SensingDocument9 pagesAN 1059 High CMR Isolation Amplifier For Current Sensing조용규No ratings yet

- MV Gateway PDFDocument2 pagesMV Gateway PDFAndrea QuadriNo ratings yet

- Locoloc® #1-Sc Hand Swager WR/04149 WR/04140 WR/04139 9560133940Document1 pageLocoloc® #1-Sc Hand Swager WR/04149 WR/04140 WR/04139 9560133940Manish JhaNo ratings yet

- LG LTV Pricelist (March 2019)Document3 pagesLG LTV Pricelist (March 2019)galura gizeldaNo ratings yet

- Chapter 3: Receiver: Ground Power1 Power2 COM Emerg.-Stop COM UP COM Down 2A 5ADocument4 pagesChapter 3: Receiver: Ground Power1 Power2 COM Emerg.-Stop COM UP COM Down 2A 5APhongTrầnNo ratings yet

- I B.tech II Semester (MR15 Regulations) II Mid Examination - ECAS (EEE)Document13 pagesI B.tech II Semester (MR15 Regulations) II Mid Examination - ECAS (EEE)arunkumarmurugesan88No ratings yet

- Versamax Nano and Micro: New Expansion UnitsDocument6 pagesVersamax Nano and Micro: New Expansion UnitsOvidiu GavrilasNo ratings yet

- 05 Differential ProtectionDocument21 pages05 Differential ProtectionArliel John GarboNo ratings yet