Professional Documents

Culture Documents

802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A of Civil Construction and Infrastructure Works, Stage 2

802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A of Civil Construction and Infrastructure Works, Stage 2

Uploaded by

Agus SupriadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A of Civil Construction and Infrastructure Works, Stage 2

802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A of Civil Construction and Infrastructure Works, Stage 2

Uploaded by

Agus SupriadiCopyright:

Available Formats

Contract High Technology Steam field Civil Construction and Infrastructure Works Stage 2 Date : 01 Nov 2018

Tittle Lifting Procedure Author Sutan Adlan Sakti

Location SAE Baturaden Area, Central Java Status High Priority

Client PT. Sejahtera Alam Energi

802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A

OF CIVIL CONSTRUCTION AND INFRASTRUCTURE WORKS, STAGE 2

HISTORICAL DOCUMENT APPROVAL

REV DATE INITIATED REVIEWED VERIFIED APPROVED DESCRIPTION

BY BY BY BY

A 011118 SAS AMS AMS RP/TAL

TABLE OF CONTENTS

MAP OF SITE LAYOUT PLAN 3 of 11

1 INTRODUCTION………. ................................................................................................................. 4 of 11

2 DESCRIPTION ................................................................................................................................ 4 of 11

3 SCOPE............................................................................................................................................. 4 of 11

4 PURPOSE........................................................................................................................................ 4 of 11

5 ROLES AND RESPONSIBILITY………………..………………………………………………………… 5 of 11

6 LIMITATION OF PROCEDURE………………..…………………………………………………………. 6 of 11

7 TOOLS AND EQUIPMENT………………………………………………………………………………... 8 of 11

8 LIFTING RADIUS AND LOAD CALCULATION…………………………………………………………. 10 of 11

9 LIFTING PROCEDURE AND EXECUTION……………………………………………………………... 10 of 11

10 HOUSEKEEPING………………………………………………………………………………………...... 11 of 11

11 REFERENCES………………………………………………………………………………………………. 11 of 11

Prepared by:

PT. CIPTA BANGUN NUSANTARA

EPC, Consultants & Project Managers

Jl. M.T. Haryono, Kav. 15

Jakarta 12810, Indonesia

Contract High Technology Steam field Civil Construction and Infrastructure Works Stage 2 Date : 01 Nov 2018

Tittle Lifting Procedure Author Sutan Adlan Sakti

Location SAE Baturaden Area, Central Java Status High Priority

Client PT. Sejahtera Alam Energi

802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A

OF CIVIL CONSTRUCTION AND INFRASTRUCTURE WORKS, STAGE 2

PT. Cipta Bangun Nusantara EPC,

Consultants & Project Managers Graha

Pratama Building 18th Floor

Jl. MT. Haryono, Kav. 15

Jakarta 12810

Tel: +62 21 8379 3811

Fax: +61 21 8379 3627

Web: www.cbn-cepm.com

COPYRIGHT: The concepts and information contained in this document are the property of PT. Cipta Bangun

Nusantara. Use or copying of this document in whole or in part without the written permission of PT. Cipta Bangun

Nusantara constitutes an infringement of copyright.

LIMITATION: This report has been prepared on behalf of and for the exclusive use of PT. Cipta Bangun

Nusantara’s Client, and is subject to and issued in connection with the provisions of the agreement between

PT. Cipta Bangun Nusantara and its Client. PT. Cipta Bangun Nusantara accepts no liability or responsibility

whatsoever for or in respect of any use of or reliance upon this document by any third party.

Project Execution Plan – Baturraden Geothermal Project Page 2 of 11

Contract High Technology Steam field Civil Construction and Infrastructure Works Stage 2 Date : 01 Nov 2018

Tittle Lifting Procedure Author Sutan Adlan Sakti

Location SAE Baturaden Area, Central Java Status High Priority

Client PT. Sejahtera Alam Energi

MAP OF SITE LAYOUT PLAN

Contract High Technology Steam field Civil Construction and Infrastructure Works Stage 2 Date : 01 Nov 2018

Tittle Lifting Procedure Author Sutan Adlan Sakti

Location SAE Baturaden Area, Central Java Status High Priority

Client PT. Sejahtera Alam Energi

1. INTRODUCTION

Landslides has been occurred at the Access Road to Well Pad F on October 27th, 2018 which is resulted in the Water

Distribution System (WDS) pipe is being displaced from its position. The contractor has the responsibility to repair the

WDS pipe by means of lifting the displaced pipe. The contractor will use and excavator to lift the pipes with calculation

and lifting procedures that will describe in this Standard Operational Procedure.

2. DESCRIPTION

Stability is one of the most important measures of good design machine and lift capacity is its consequence. Stability

is the final outcome of how total weight of machine is distributed over an excavator. Since undercarriage of an excavator

is never a square and tilt lines distances from slew center differ between front and side, lift capacity rating over side is

often lower and so is a considered a measure of functional stability. Lift capacity chart guides an operator and engineer

on safe lifting loads at various distances from the slew center (reference standard ISO 10567 and SAE J1097). When

loads are lifted close to the machine, the maximum lift capacity is no longer limited by machine tipping limit but by the

cylinder pressures generated by the load. When the cylinder pressure exceeds the hydraulic cylinder, relief setting the

load is not sustainable and constitutes the hydraulic limit. Both tipping and hydraulic limits are measured simultaneously

and lower of these values are considered for rating purposes. For reporting, rated lift capacity values, test values are

reduced by 25% if machine hit the tipping limit first and by 13% if hydraulic limit is lower than tipping limit. The above

figure uses SAEJ1097 which was superseded by ISO 10567 in 2008.

3. SCOPE

The procedure described below checks pair-wise accuracy of “stability limited” rating values published in Lift Capacity

Rating Charts of manufacturers per ISO 10567 for hydraulic excavators.

4. PURPOSE

The purpose of this Procedure is to describe and determine the processes and techniques to be implemented and to

ensure that lifting activities comply with standard and safety. This procedure also details the techniques and practices

for the subsequent of lifting activities to comply with the requirements of the Project's Quality, Health & Safety and

Environmental Plans, and the statutory legislation and regulations applicable to the contract. Job Safety Analysis (JSA)

will be carried out to identify any specific hazards that may not be addressed in this Procedure, and control measures

will be established to mitigate any risks identified. This document shall be issued to Company (PT. Sejahtera Alam

Energi or PT. SAE) for review and approval.

Project Execution Plan – Baturraden Geothermal Project Page 4 of 11

Contract High Technology Steam field Civil Construction and Infrastructure Works Stage 2 Date : 01 Nov 2018

Tittle Lifting Procedure Author Sutan Adlan Sakti

Location SAE Baturaden Area, Central Java Status High Priority

Client PT. Sejahtera Alam Energi

5. ROLE AND RESPONSIBILITIES

Roles and responsibilities shall be in accordance with the PT. SAE and PT. CBN, Health, Safety and Environmental

(HSE) Procedures and those defined in the Project-Specific Quality, Health, Safety and Environmental Management

Plans. Lifting activities will be good result if there is a responsible person in accordance with the position and job title.

The responsibility personnel are:

1. Project Manager

Overall responsibility for all activities, insofar as projects are concerned, Project Management represents Contractor’s

Senior Management and hence, assumes overall responsibility for concrete repair result and safety during filed

activities. Project Manager is accountable to the Project Director for all survey activities under the scope of this contract.

2. Site Manager and Site Coordinator

SM and SC is ensuring Engineer planners, Implementers and the workers who do the right work, according to the initial

plan, the technical specifications, on schedule, budget, and quality.

3. Heavy Equipment (HE) Coordinator

HE coordinator prepare work lifting procedure, material type and specification, cost estimates for the above-mentioned

work, work schedules and coordinate with the executive team on the field,

4. Construction Supervisor

Construction supervisor supervises all the work and make sure that the work following to the Procedure, material type

and specifications, quality, schedule and budget. Construction supervisor also conduct to coordination or tool box

meeting and ensure that all the workforce use PPE and comply with safety requirement.

5. Safety Officer/Safety Man

Safety officer can make JSA and MSDS (Material Safety Data Sheet) for concrete material repair before start the work.

It aims to anticipate and mitigate the risk and hazardous in the field. He also helps supervisor to ensure that all the

workforce use PPE and all the work in the safe condition. He can explain HSE regulation in the coordination or tool

box meeting.

6. Operator Heavy Equipment

Operator is the person, who works in the safe condition and comply with the HSE requirement. He also dutiful to HE

Coordinator.

7. Workforce or labor

Workforce or labor will perform the work in the field and dutiful to foreman, HE Coordinator and supervisor in order to

good result. Workforces also are complying with regulation and HSE requirement.

Project Execution Plan – Baturraden Geothermal Project Page 5 of 11

Contract High Technology Steam field Civil Construction and Infrastructure Works Stage 2 Date : 01 Nov 2018

Tittle Lifting Procedure Author Sutan Adlan Sakti

Location SAE Baturaden Area, Central Java Status High Priority

Client PT. Sejahtera Alam Energi

6. LIMITATION OF THE PROCEDURE

• Pair-wise values mean = a pair of (Rating over front, Rating over side) values for same Load Point Radius (LPR).

This procedure does not calculate individual lift capacity values.

• For hydraulic limited lift capacity rating, formula below defines only an upper limit for pair-wise consistency.

• The procedure is limited to hydraulic excavators without dozer blade. In machines equipped with dozer blade most

of the ratings are hydraulic limited and this procedure cannot be applied directly.

• Key Assumptions:

o Center Gravity (CG) of Undercarriage is assumed to be collinear with the Axis of rotation (AR). This

procedure is still valid if the distance between Undercarriage CG and AR is very small compared to the

total distance between Rear and Front Tipping lines.

o Symmetric undercarriage is a reasonable assumption. Since ISO requires that if the undercarriage is

unsymmetrical, the machine should be positioned in the least stable position for tipping limit calculations;

our assumption of symmetry should give a conservative value.

Variable names (Refer fig below)

Figure 1. Excavator for Lifting Procedure

Project Execution Plan – Baturraden Geothermal Project Page 6 of 11

Contract High Technology Steam field Civil Construction and Infrastructure Works Stage 2 Date : 01 Nov 2018

Tittle Lifting Procedure Author Sutan Adlan Sakti

Location SAE Baturaden Area, Central Java Status High Priority

Client PT. Sejahtera Alam Energi

Front and Side tipping conditions for same LPR are super-imposed. The hatched areas are tracks in side tipping

condition.

1. Wf = (Front Lift capacity Rating / 0.75) (known)

2. Ws = (Side Lift capacity rating / 0.75) (known)

3. LPR = Load Point Radius (front) = Load Point radius (side) (known)

4. a = Distance between FTL and RTL

5. b = Distance between STL

• Calculating ‘a’:

o a is the distance between FTL (front tipping line) and RTL (rear tipping line). For track type

undercarriage, per ISO 10567, the line joining the centers of support idlers is FTL and

o centerline of sprockets is RTL. Since we are assuming the undercarriage to be symmetrical,

o FTL and RTL are equidistant from the slew center and a = Distance between tumblers (distance

between sprocket and idler centers)

• Calculating ‘b’:

o ISO 10567 for track type undercarriages gives the side tipping lines (TL) for balance point calculations

as below:

o For right-extreme track scheme, assuming ‘b’ to be equal to Track Gauge (distance between left and

right track center lines) wouldn’t give very wrong results. For other two track chain configurations, use

the table below for calculating ‘b’.

o b=Track Gauge + (A or B)

• Now with a and b calculated Wf, Ws and LPR from published lift capacity data; one can calculate the

following values:

o m = Wf. (LPR - a/2) where Wf = (Front published rating / 0.75)

o n = Ws. (LPR - b/2) where Ws = (Side published rating / 0.75)

o k = [(a– b)/2]

o Wc = [(m– n)/k]

Now check if Wc≤ Wp where Wc is calculated Operating weight and Wp is Published Operating Weight of machine

(see below sample lift chart). If Wc and Wp are within±5% of each other as set out by ISO standard, then we have

a valid pair-wise accurate stability rating. Let’s look at a sample of excavator manufacturer’s stability data and see

how they fare with our accuracy check. While data is from real machines, all the model names have been changed.

Project Execution Plan – Baturraden Geothermal Project Page 7 of 11

Contract High Technology Steam field Civil Construction and Infrastructure Works Stage 2 Date : 01 Nov 2018

Tittle Lifting Procedure Author Sutan Adlan Sakti

Location SAE Baturaden Area, Central Java Status High Priority

Client PT. Sejahtera Alam Energi

For other pairs of data that are hydraulic limit rating values, including those that have one of the pair stability

limited, Wc should be definitely less than Wp. If it is not then, one or both the published lift capacity values are

wrong. Engineers measuring lift capacity can use this equation to estimate side tipping limit if front is already

tested accurately.

Table 1. Load Data for lifting Pipe

Material Weight Contingency Design load Unit

Carbon Steel Pipe 1,750 10.00% 1,925.00 kg

Shackle 50.00 20.00% 60.00 kg

Sling 30.00 20.00% 36.00 kg

Snatch blok 150.00 20.00% 180.00 kg

Bucket 635.00 10.00% 698.50 kg

Sub total 2,615.00 2,899.50 kg

a. Load contingency value is determined as follow:

b. Load data from estimation: 20%

c. Load data from calculation with estimated data: 20%

d. Load data from calculation with exact data: 10%

e. Load data from weighed: 3%

7. TOOLS AND EQUIPMENT

From the load and estimated working radius, hydraulic excavator PC-200 or equivalent is selected.

a. One unit, PC-200 or equivalent

b. One unit, snatch block (10 ton)

c. 2 each, nylon webbing sling (4 inch and 6 inch- 4 ton and 6 ton)

d. 4 each, forged shackles ¾ (4 ¾ ton)

e. 2 each, hand chain hoist (6 ton)

f. 1 each, tifor - camlong (10 ton)

g. 2 each tag line

Project Execution Plan – Baturraden Geothermal Project Page 8 of 11

Contract High Technology Steam field Civil Construction and Infrastructure Works Stage 2 Date : 01 Nov 2018

Tittle Lifting Procedure Author Sutan Adlan Sakti

Location SAE Baturaden Area, Central Java Status High Priority

Client PT. Sejahtera Alam Energi

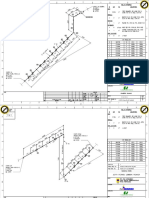

Figure 2. Sample of the lifting

8. LIFTING RADIUS AND LOAD CALCULATION

From the planned lay out, the boom length and working radius are as follow:

1. Excavator : PC-200

2. Bucket hook height : 6 meter

3. Maximum Working Radius : 6 meter

Based on Excavator lifting chart, the SWL for this plan is 5950 kg/5.95ton (see load chart on the last page of this

document) Check

Lifted load = 2,899.5 kg

SWL = 5,950 kg

Safety factor = 2,053→OK

9. LIFTING PROCEDURE/EXCECUTION

1. Pre-Execution

a. Conduct safety meeting involving supervisor, operator and riggers.

b. Ensure work permit is approved

c. Define clearly which persons shall be in charge

d. Construction Supervisor and Safety Officer shall check and ensure the lifting equipment to be used for

lifting process, in a good working condition. Also, lifting tool, such as shackles, wire sling, should be

checked by Heavy Equipment inspector and Safety Officer to ensure all tools in a good condition.

Project Execution Plan – Baturraden Geothermal Project Page 9 of 11

Contract High Technology Steam field Civil Construction and Infrastructure Works Stage 2 Date : 01 Nov 2018

Tittle Lifting Procedure Author Sutan Adlan Sakti

Location SAE Baturaden Area, Central Java Status High Priority

Client PT. Sejahtera Alam Energi

2. Preparation and Set Up

a. Revise this procedure on-site if the weight will be > 4 ton.

b. Check actual working radius with measure tape or other tools.

c. Prepare the area to provide secure bearing for undercarriage of excavator.

d. Ensure no power cable around the lifting and swinging area

3. Execution Lifting Pipe 36-inch STD 8" Std Carbon Steel Pipe

a. Locate the excavator rating over front position.

b. Position of the excavator shall be arranged so that maximum working radius is 6 m from CG of excavator

to center of pipe to be install.

c. Hitch arrangement of pipe by webbing sling and shackle.

d. Set the snatch block below the lifting point of bucket excavator.

e. Set the excavator on standby position and turn on knob of low gear (turtle picture knob, no rabbit picture

knob).

f. Set the tifor-camlong at pipe support existing.

g. Install shackle and sling min at 2 lifting points at pipe, Install tag line, minimum 2 ea at opposite corners

of the pipe.

h. Pulling the tifor for lift up the pipe slowly.

i. Excavator operator shall be position on cabin.

j. Rigger to check the radius on-site with measure tape then check the compliance with excavator load

chart.

k. Ensure rigger double check rigging sequence and center of gravity and marking.

l. Ensure no worker under working radius.

m. Start to lift to elevation of approximately 20 cm

n. Hold the load for 2 minutes

o. Observe the undercarriage of excavator and stabilization of machine.

p. If the soil cannot hold undercarriage, cancel the lifting, compact the soil, and repeat above procedure.

q. If the soil is good, continue lift up slowly and pay more attention when the pipe starts to rise.

r. Watch the pipe movement and anticipate the reaction

s. Use tagline to control unexpected movement of pipe during the lifting

t. Lower pipe smoothly once it is right base of existing pipe support.

Project Execution Plan – Baturraden Geothermal Project Page 10 of 11

Contract High Technology Steam field Civil Construction and Infrastructure Works Stage 2 Date : 01 Nov 2018

Tittle Lifting Procedure Author Sutan Adlan Sakti

Location SAE Baturaden Area, Central Java Status High Priority

Client PT. Sejahtera Alam Energi

u. Disconnect all shackles and job completed.

v. Heavy equipment inspector will be on site during works.

10. HOUSEKEEPING

1. Clean for all work area;

2. Provide trash bin;

3. Separate all the type of waste;

4. Cleaned and laid all the equipment after be used.

11. REFERENCES

a. ISO 10567 – 2008 standard.

b. SAE J 1097 standard.

c. Construction Equipment Guide, second edition: David A. Day, Neal B.H. Benjamin

d. Lifting and Rigging Chevron Standard.

e. Komatsu Lifting capacity.

This work method does not properly describe the lift sequence. The pipe in question is 200

meters long. Your sketch only shows a short 12 meter section of pipe.

..

Since you do not mention cutting and welding, I assume the WDS line will not be cut into

sections as we do not want to disrupt the water supply to the drilling rig. If this is so, then the

work method needs to reflect the fact that you will lift one section of pipe onto the supports.

Then you will secure that pipe onto the supports so it does not move, while you reposition

the excavator and tifor to lift the next section of pipe. I estimate you will have to reposition

and lift about 12-15 times.

..

There should be stress calculations produced to show what is the maximum allowable bend

from lifting the pipe while each end will still be in contact with ground or a support.

I also do not recommend using tag lines on the pipe while attempting to reposition it onto

supports. If the pipe was cut and both ends were free, I agree with tag lines. If only one end

is cut or no cutting at all is performed, then putting a tag line on the pipe will only endanger

the workers. There is also no way they can physically control the pipe with a tag line with

pipe in the uncut condition.

..

There is no mention of how you will rectify the bench and sleepers in those spots where the

bench is damaged.

Project Execution Plan – Baturraden Geothermal Project Page 11 of 11

You might also like

- Math Preparedness WorkbookDocument26 pagesMath Preparedness WorkbookAnonymous czkmnf100% (2)

- Kajian Teknis Temporary JettyDocument103 pagesKajian Teknis Temporary JettyBayu Putra0% (1)

- Technical & Commercial Proposal For Geological Asssessment at Kenyir DamDocument33 pagesTechnical & Commercial Proposal For Geological Asssessment at Kenyir DamFaridah HanomNo ratings yet

- Material Requisition For Butterfly ValvesDocument11 pagesMaterial Requisition For Butterfly Valvesengr_umer_01100% (3)

- Desktop Review Kertawira Sera Lestari, PTDocument14 pagesDesktop Review Kertawira Sera Lestari, PTis mailNo ratings yet

- Foundation Method Statement: Uganda Electricity Transmission Corporation Limited. UETCLDocument20 pagesFoundation Method Statement: Uganda Electricity Transmission Corporation Limited. UETCLAnonymous CPEha1db7UNo ratings yet

- Soil Stabilization ProjectDocument53 pagesSoil Stabilization Projectrohit attri100% (2)

- Annexure W - Commissioning Management PlanDocument38 pagesAnnexure W - Commissioning Management Plansimbamike100% (3)

- Projects-ESIA Aek Sibundong EnergyDocument231 pagesProjects-ESIA Aek Sibundong EnergyIrman Ahadian100% (2)

- Millard HouseDocument20 pagesMillard HouseMadiha Rehmath100% (1)

- 802-CBN-00-PR-CE-LIFTING PROCEDURE-049-B of Civil Construction and Infrastructure Works, Stage 2Document12 pages802-CBN-00-PR-CE-LIFTING PROCEDURE-049-B of Civil Construction and Infrastructure Works, Stage 2Agus SupriadiNo ratings yet

- 2015-05-25 LESA-2 CT Cement Squeeze Contaminant Rev 0.0Document28 pages2015-05-25 LESA-2 CT Cement Squeeze Contaminant Rev 0.0Pratama RuliandryNo ratings yet

- LAST EHS - KTCO Reviewed - 05062018Document54 pagesLAST EHS - KTCO Reviewed - 05062018Cyprian AendeNo ratings yet

- 2973 - Method Statement For Cable LayingDocument13 pages2973 - Method Statement For Cable LayingMuhammad SajjadNo ratings yet

- Method Statementfor Mechanical Works Underground Rain Water Sewer Drainage SystemDocument19 pagesMethod Statementfor Mechanical Works Underground Rain Water Sewer Drainage Systemammarsleman356No ratings yet

- MR For Ball ValvesDocument12 pagesMR For Ball Valvesengr_umer_01100% (1)

- Proposal Infrastruktur Jaringan Komunikasi Telepon, Data Dan Data Center PT. Tunas Financindo Sarana Plaza BBD - JakartaDocument31 pagesProposal Infrastruktur Jaringan Komunikasi Telepon, Data Dan Data Center PT. Tunas Financindo Sarana Plaza BBD - JakartayuanNo ratings yet

- 338-2434 Tharaldson Compressor Station, Casselton, NDDocument49 pages338-2434 Tharaldson Compressor Station, Casselton, NDharishNo ratings yet

- Field Work Practice Report Electrical Installation System Lighting at Pt. Gedong Karya TeknikaDocument55 pagesField Work Practice Report Electrical Installation System Lighting at Pt. Gedong Karya TeknikaM Yoni AndriyanaNo ratings yet

- Achmad Zainullah: ProjectsDocument13 pagesAchmad Zainullah: ProjectsArie RitongaNo ratings yet

- Consultancy Services ForDocument360 pagesConsultancy Services ForView Computer EngineeringNo ratings yet

- Part02gsDocument171 pagesPart02gsAman SrivastavaNo ratings yet

- Modified DPR Part 1Document336 pagesModified DPR Part 1Bhuvan BajajNo ratings yet

- Technical Specifications of Kuraz Road Final HG1Document37 pagesTechnical Specifications of Kuraz Road Final HG1ABAMELANo ratings yet

- Laporan KP Fadil Fix BangetDocument96 pagesLaporan KP Fadil Fix BangetRaditya RamdaniNo ratings yet

- Paew Aiec 1 2017 PQP DraftDocument45 pagesPaew Aiec 1 2017 PQP DraftPopescu OctavianNo ratings yet

- Solar Power Solar Heating Systems Designing and Installation Services Rs. 4.71 Million May-2021Document37 pagesSolar Power Solar Heating Systems Designing and Installation Services Rs. 4.71 Million May-2021Jawad AnsariNo ratings yet

- Construction Plan For The Earthwork Test Section of The Standard Gauge Railway Line 6 On The Central LineDocument36 pagesConstruction Plan For The Earthwork Test Section of The Standard Gauge Railway Line 6 On The Central Linejoseph mtalemwaNo ratings yet

- Sample Testing & Commissioning MSRA (Complete)Document18 pagesSample Testing & Commissioning MSRA (Complete)Dihar RaviNo ratings yet

- Volume I - Main ReportDocument600 pagesVolume I - Main Reportमयंक भारद्वाज100% (1)

- EIADocument262 pagesEIAmikefara100% (1)

- Project Qa QCDocument27 pagesProject Qa QCOctora Perdani100% (4)

- Hjkalmnupojkitasrstu BvhajkilmnaopDocument150 pagesHjkalmnupojkitasrstu BvhajkilmnaopKurnia AryadiNo ratings yet

- Design Basis Report - 22 Sep08Document26 pagesDesign Basis Report - 22 Sep08Bejil ShresthaNo ratings yet

- Final Project ALAPAN - Nabigh Nabiyl (25515305)Document50 pagesFinal Project ALAPAN - Nabigh Nabiyl (25515305)Nabigh NabiylNo ratings yet

- Tech SpecDocument16 pagesTech SpecArga LinggaNo ratings yet

- PDS Abbah King Cement CorporationDocument25 pagesPDS Abbah King Cement CorporationHerwin NavarreteNo ratings yet

- Projek Penswastaan Lebuhraya Bertingkat Sungai Besi - Ulu Kelang (Suke)Document18 pagesProjek Penswastaan Lebuhraya Bertingkat Sungai Besi - Ulu Kelang (Suke)fendi azizNo ratings yet

- JKT05-C-REP-00-0 - Civil Works Technical SpecificationDocument74 pagesJKT05-C-REP-00-0 - Civil Works Technical SpecificationAhmad Rifqi syauqieNo ratings yet

- Natan Teknik Mandiri Performance Budget Mechanical & Electrical Hm. Sampoerna Project - PandaanDocument11 pagesNatan Teknik Mandiri Performance Budget Mechanical & Electrical Hm. Sampoerna Project - PandaanMangatas MarbunNo ratings yet

- Twjo 1 TCD St1 0004 Rev ADocument407 pagesTwjo 1 TCD St1 0004 Rev AAnang AprizalNo ratings yet

- Software Requirements Specifications: Online Social Networking SystemDocument18 pagesSoftware Requirements Specifications: Online Social Networking SystemArunava BiswasNo ratings yet

- Wog-2013-Stp-Ptpli-Be-103 R6 Basic Engineering Package (Sbme-Vdt-700-2978 Stat - A) (Stamp)Document29 pagesWog-2013-Stp-Ptpli-Be-103 R6 Basic Engineering Package (Sbme-Vdt-700-2978 Stat - A) (Stamp)Rentu PhiliposeNo ratings yet

- 1737 r0 NR PT - III Section 3 LallcoDocument116 pages1737 r0 NR PT - III Section 3 LallcoVikas GoelNo ratings yet

- UNFOUND Draw 26070-203-V14-CG00-J9328-00BDocument22 pagesUNFOUND Draw 26070-203-V14-CG00-J9328-00Bsafaruddin KSNo ratings yet

- Twjo 1 TCD St1 0004 Rev C (Rev)Document401 pagesTwjo 1 TCD St1 0004 Rev C (Rev)Anang AprizalNo ratings yet

- Standar Operational Procedure (Civil)Document7 pagesStandar Operational Procedure (Civil)sefinaNo ratings yet

- Geotechnical ReportDocument239 pagesGeotechnical ReportpanikarickyNo ratings yet

- Esia Report Hema Hard Coal Mine Project 1Document199 pagesEsia Report Hema Hard Coal Mine Project 1Bo RoNo ratings yet

- 22031-C-Rep-Tec-2-001 Shatale Water Works Upgrade Updated DDR 2Document99 pages22031-C-Rep-Tec-2-001 Shatale Water Works Upgrade Updated DDR 2Clement TakavarashaNo ratings yet

- Compro Amsak.Document21 pagesCompro Amsak.natannababan5No ratings yet

- ARL07008 IIW Design Report (Rev 01)Document72 pagesARL07008 IIW Design Report (Rev 01)Fareed KhanNo ratings yet

- IC Contractor Scope of Work 11498 WORDDocument13 pagesIC Contractor Scope of Work 11498 WORDalanNo ratings yet

- For Bid Understanding Project Area Final Construction Report CompleteDocument415 pagesFor Bid Understanding Project Area Final Construction Report CompleteAbudi KasahunNo ratings yet

- Oxygen Gas Producing Plant PDFDocument29 pagesOxygen Gas Producing Plant PDFMuhammad UmaishNo ratings yet

- FWR TECBM#P 01 - P Is OKDocument29 pagesFWR TECBM#P 01 - P Is OKtolstoy potemkinNo ratings yet

- MQ SP B 4916Document14 pagesMQ SP B 4916jaseel kNo ratings yet

- KNT 02 RP W 0021 - B1Document110 pagesKNT 02 RP W 0021 - B1Trong VuNo ratings yet

- UNFOUND Draw 26070-203-V14-CG00-J9327-00BDocument60 pagesUNFOUND Draw 26070-203-V14-CG00-J9327-00Bsafaruddin KSNo ratings yet

- South Africa’s Renewable Energy IPP Procurement ProgramFrom EverandSouth Africa’s Renewable Energy IPP Procurement ProgramNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. ADocument6 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. AAgus SupriadiNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. ADocument19 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. AAgus SupriadiNo ratings yet

- Soil StiffnessDocument1 pageSoil StiffnessAgus SupriadiNo ratings yet

- Globe Rev. A SHT 1Document1 pageGlobe Rev. A SHT 1Agus SupriadiNo ratings yet

- Globe Rev. A SHT 2Document1 pageGlobe Rev. A SHT 2Agus SupriadiNo ratings yet

- Specification For Piping MaterialDocument9 pagesSpecification For Piping MaterialAgus SupriadiNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. A CoverDocument5 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. A CoverAgus SupriadiNo ratings yet

- General Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Document20 pagesGeneral Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Agus SupriadiNo ratings yet

- Specification For Piping Thermal InsulationDocument14 pagesSpecification For Piping Thermal InsulationAgus SupriadiNo ratings yet

- SPECIFICATION FOR PIPING FABRICATION, WELDING, INSPECTION AND TESTING Rev. ADocument15 pagesSPECIFICATION FOR PIPING FABRICATION, WELDING, INSPECTION AND TESTING Rev. AAgus SupriadiNo ratings yet

- 802-CBN-00-PR-CE-LIFTING PROCEDURE-049-B of Civil Construction and Infrastructure Works, Stage 2Document12 pages802-CBN-00-PR-CE-LIFTING PROCEDURE-049-B of Civil Construction and Infrastructure Works, Stage 2Agus SupriadiNo ratings yet

- UntitledDocument3 pagesUntitledAgus SupriadiNo ratings yet

- Estimasi Harga Material Perpipaan Nike Project No Quantity Size (Inch)Document4 pagesEstimasi Harga Material Perpipaan Nike Project No Quantity Size (Inch)Agus SupriadiNo ratings yet

- Exh B2Document163 pagesExh B2Agus SupriadiNo ratings yet

- Attachment 1 Pipe Bend ModellingDocument1 pageAttachment 1 Pipe Bend ModellingAgus SupriadiNo ratings yet

- ISO 9001 Auditing Practices Group Guidance On:: The Need For A 2 Stage Approach To AuditingDocument2 pagesISO 9001 Auditing Practices Group Guidance On:: The Need For A 2 Stage Approach To AuditingAgus SupriadiNo ratings yet

- 6-HG-1000-G (Sheet 1 - 11)Document11 pages6-HG-1000-G (Sheet 1 - 11)Agus SupriadiNo ratings yet

- GRSM 00 Cons PL 015 Rev.2 Pipeline Tie in ProcedureDocument7 pagesGRSM 00 Cons PL 015 Rev.2 Pipeline Tie in ProcedureAgus SupriadiNo ratings yet

- Contractor'S Reply To Company'S Comments: (Ref. No.) SubjectDocument1 pageContractor'S Reply To Company'S Comments: (Ref. No.) SubjectAgus SupriadiNo ratings yet

- Sarulla Geotermal Power ProjectDocument1 pageSarulla Geotermal Power ProjectAgus SupriadiNo ratings yet

- Branch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangDocument6 pagesBranch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangAgus SupriadiNo ratings yet

- Branch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangDocument6 pagesBranch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangAgus SupriadiNo ratings yet

- Load Hot TapDocument1 pageLoad Hot TapAgus SupriadiNo ratings yet

- Ode and NameDocument670 pagesOde and Namenavneetkpatil8409No ratings yet

- Sample Treatment Plan Form - Coun755Document2 pagesSample Treatment Plan Form - Coun755api-310813184No ratings yet

- Tabel Usia Teknis Peralatan MedisDocument12 pagesTabel Usia Teknis Peralatan MedisAditya PuteraNo ratings yet

- Secrets of A Millionaire Magician DeluxeDocument480 pagesSecrets of A Millionaire Magician DeluxelautaroNo ratings yet

- Efm Cip UfDocument6 pagesEfm Cip UfDaneAoneNo ratings yet

- Unit Planner 2021 4b enDocument15 pagesUnit Planner 2021 4b enAineeNo ratings yet

- 20 Must-Know Rocks Licks: Shuffle Lick 5Document3 pages20 Must-Know Rocks Licks: Shuffle Lick 5julyfriska100% (1)

- Foreign Technology DivisionDocument467 pagesForeign Technology DivisionArashNo ratings yet

- 555 TimerDocument48 pages555 TimeracidreignNo ratings yet

- Textbook A World of Three Cultures Honor Achievement and Joy 1St Edition Miguel E Basanez Ebook All Chapter PDFDocument53 pagesTextbook A World of Three Cultures Honor Achievement and Joy 1St Edition Miguel E Basanez Ebook All Chapter PDFkatie.martinez610100% (23)

- Radio Host/Teacher: GreetingsDocument4 pagesRadio Host/Teacher: GreetingsAlleigh Krizylle GetuabanNo ratings yet

- Characteristics of LDCsDocument22 pagesCharacteristics of LDCstinsaeres100% (2)

- Understanding The Self Syllabus 2nd Sem 2021-22Document7 pagesUnderstanding The Self Syllabus 2nd Sem 2021-22Mary Crisza RentoriaNo ratings yet

- Ford MotorsDocument4 pagesFord Motorssalman sheikhNo ratings yet

- CGR1 Text ModeDocument11 pagesCGR1 Text ModeRaj SuraseNo ratings yet

- ALUMINIUMTECHNOLOGIES Week1 PDFDocument141 pagesALUMINIUMTECHNOLOGIES Week1 PDFNasional GotongroyongNo ratings yet

- Codelco Guia Graduado 2018Document120 pagesCodelco Guia Graduado 2018Wilson Campos RojasNo ratings yet

- Final Reflection Essay Outline 1Document8 pagesFinal Reflection Essay Outline 1api-643387955No ratings yet

- Here Is The MoonDocument2 pagesHere Is The MoonDeepakNo ratings yet

- Ec 604 HW 3 PDFDocument3 pagesEc 604 HW 3 PDFgattino gattinoNo ratings yet

- NIPER - Raebareli: Candidate Application-Non TeachingDocument6 pagesNIPER - Raebareli: Candidate Application-Non TeachingAnand Kumar ChauhanNo ratings yet

- (V2224G-OP) Leaflet EN 130125 V1Document2 pages(V2224G-OP) Leaflet EN 130125 V1nmc79No ratings yet

- Jane Eyre Bertha Mason Teachers Notes UpdatedDocument4 pagesJane Eyre Bertha Mason Teachers Notes Updated04. Phan Thi Huyen Trang K17 HLNo ratings yet

- Industrial Waste Management Rules and RegulationsDocument69 pagesIndustrial Waste Management Rules and RegulationsE MoneyNo ratings yet

- Transition Planning: For Students With Disabilities & Their ParentsDocument7 pagesTransition Planning: For Students With Disabilities & Their ParentsawriezNo ratings yet

- Why Is Omkar Called As Pranav MantraDocument6 pagesWhy Is Omkar Called As Pranav Mantraami1577No ratings yet

- ABB - Motor-StartersDocument10 pagesABB - Motor-StartersMac WaseemNo ratings yet

- English Essay Bros Before HosDocument5 pagesEnglish Essay Bros Before HosAndrés I. Rivera33% (3)