Professional Documents

Culture Documents

No-59-Pedestal-Drill SÜTÜUNLU MATKAPA RİSK

No-59-Pedestal-Drill SÜTÜUNLU MATKAPA RİSK

Uploaded by

Yeni BulutlarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

No-59-Pedestal-Drill SÜTÜUNLU MATKAPA RİSK

No-59-Pedestal-Drill SÜTÜUNLU MATKAPA RİSK

Uploaded by

Yeni BulutlarCopyright:

Available Formats

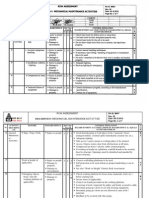

Technologies - No.

59 Pedestal Drill (Metal Work) (List additional hazards, risks and controls particular to your school using the blank template no.69)

Hazards Is the What is the Risk rating Controls Is this Action/to do list/outstanding controls Person Signature

hazard risk? H = High control responsible and date

present? M = Medium (When all controls are in place risk in *Risk rating applies to outstanding completed

L = Low controls outlined in this column

Y/N will be reduced). place?

Contact Entanglement H Drive mechanism appropriately

with drive guarded. Guard removable only

mechanism Severe hand with the use of a tool or alternatively

injury be fitted with an interlocking guard

mechanism

Contact Entanglement, H Safe operational areas should be

by persons pinching, marked out clearly around machines

other than amputation of

the operator body parts

with moving

machine

Contact with Entanglement H The spindle and drill bit is guarded.

spindle and (An adjustable spindle/twist drill guard

drill bit Severe hand so that the spindle and twist drill (to

injury the bit) are guarded to the greatest

extent possible)

H Chuck appropriately guarded

H Ensure drill bit is clamped and chuck

key is removed

H Spindle guard in place before the drill

is operated

Direct Injuries H Before use a visual check should be

contact with causing carried out to ensure where applicable

moving parts laceration, all guards and covers are fitted, in

amputation, good order and there are no visible

bruising, faults

fracture or

burns H Tools are used in compliance with

manufacturers instructions

M Operators manual is available where

required

H Dangling jewellery prohibited

H Long hair is tied back

187

© All Rights Reserved

188

Technologies - No.59 Pedestal Drill (Metal Work) cont’d. (List additional hazards, risks and controls particular to your school using the blank template no.69)

Hazards Is the What is the Risk rating Controls Is this Action/to do list/outstanding controls Person Signature

hazard risk? H = High control responsible and date

present? M = Medium (When all controls are in place risk will be in *Risk rating applies to outstanding completed

Y/N L = Low reduced). place? controls outlined in this column

Contact with Entanglement H The stop control is more prominent than

pedestal drill the start control to facilitate ease and speed

Severe hand of access when it is necessary to turn off the

injury machine.

H Where applicable machine is fitted with an

emergency stop control (usually red domed

mushroom type head on yellow housing) in an

appropriate location, which is easily accessible in

an emergency. A foot operated emergency stop

would be appropriate on a pedestal drill

H The flap type emergency stop control (flap-

stop is a normal start and stop contact, which is

equipped with a yellow flap and red mushroom-

type push buttons, covering both the start and

stop contacts) is not acceptable where there is a

need for an emergency stop

H Foot operated emergency stop is operational

H In the event of power supply interruption,

automatic restart is prevented after restoration

of the power supply

Unsupervised Unsupervised H Pupils are prohibited from using certain

use of use leading to machinery

machines injury

H Pupils are supervised by teacher when using any

machine

H Pupils are instructed by teacher before using any

machine

H Machinery to be used by teachers only should be

clearly identified

© All Rights Reserved

Technologies - No.59 Pedestal Drill (Metal Work) cont’d. (List additional hazards, risks and controls particular to your school using the blank template no.69)

Hazards Is the What is the risk? Risk rating Controls Is this Action/to do list/outstanding controls Person Signature

hazard H = High control responsible and date

present? M = Medium (When all controls are in place risk in *Risk rating applies to outstanding completed

L = Low controls outlined in this column

Y/N will be reduced). place?

Electric shock, Electric shock/fire/ H Visual check carried out prior to use

electrocution, burns

burns, death

H Machines are serviced by a competent

person and service records kept as part

of the maintenance schedule

H Defective electrical equipment shall

be clearly identified, labelled as out of

use. Ensure all faults are recorded in

log book. Ensure any previous faults

have recieved attention. Report defects

to person in control of workplace

to ensure all items are repaired or

replaced

H The operation of the RCD is checked

by pressing the test button regularly

and the RCD is tested periodically by

a competent person to ensure that it

operates at correct leakage current

(leakage current not exceeding 30

mA in a time of not more than 0.3

seconds). Applicable to plug & sockets

arrangements

H Ensure cables are free from damage,

do not have any non-standard joints or

show any signs of overheating

H Ensure equipment is disconnected or

isolated when not in use

Unsecured Movement of H Machine securely fixed to the floor

machine / machine leading or bench and appropriate clamps in

unsecured to injury during place to ensure that work pieces are

work piece use secured, where applicable

189

© All Rights Reserved

190

Technologies - No.59 Pedestal Drill (Metal Work) cont’d. (List additional hazards, risks and controls particular to your school using the blank template no.69)

Hazards Is the What is the Risk rating Controls Is this Action/to do list/outstanding controls Person Signature

hazard risk? H = High control responsible and date

present? M = Medium (When all controls are in place risk in *Risk rating applies to outstanding completed

L = Low controls outlined in this column

Y/N will be reduced). place?

Inadequate Inadequate M Warning signs are prominently located

signage information and maintained in good condition

and warnings

leading to

unsafe use of

machine and

injury

Flying Eye/facial H Appropriate eye protection is worn

fragments injury

H Pay particular attention to spring

loaded chuck key

Contact with Eye irritation H See No.56 Hazardous Substances

swarf or metal

working fluids Skin irritation H Suitable implements should be used to

remove swarf (dustpan and brush). No

swarf to be removed whilst machine is

in motion

Ingestion of Poisoning or M Food and drink are prohibited in

contaminated ill health working area

material

Contact with Exposure to M Personal hygiene is promoted (washing

hazardous hazardous of hands, use of barrier creams etc.)

materials materials

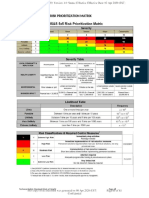

If there is one or more High Risk (H) actions needed, then the risk of injury could be high and immediate action should be taken.

Medium Risk (M) actions should be dealt with as soon as possible. Low Risk (L) actions should be dealt with as soon as practicable.

Risk Assessment carried out by: Date: / / © All Rights Reserved

You might also like

- Jha For Chipping and Drilling Concrete Step Step Discription Hazards Hazard ControlDocument7 pagesJha For Chipping and Drilling Concrete Step Step Discription Hazards Hazard Controlmark alexies herreraNo ratings yet

- Risk Assessment - Mounting Equipment and Installing Network Devices - SYBYLDocument2 pagesRisk Assessment - Mounting Equipment and Installing Network Devices - SYBYLJOHN IGA100% (1)

- JSA DrillingDocument4 pagesJSA DrillingAmalNo ratings yet

- Swms For Glass Partition FixingDocument6 pagesSwms For Glass Partition FixingSiddharth PNo ratings yet

- Crushing/ Amputation of Limbs: Maintenance - No.51 Waste Compactor And/or BalerDocument2 pagesCrushing/ Amputation of Limbs: Maintenance - No.51 Waste Compactor And/or Balersuriya karthikeyanNo ratings yet

- Mechanical Maintenance ActivitesDocument7 pagesMechanical Maintenance ActivitesJhun Aquino50% (2)

- Risk Assessment Band SawDocument5 pagesRisk Assessment Band SawybuluckNo ratings yet

- Technologies - Milling Machine - No 60Document4 pagesTechnologies - Milling Machine - No 60Malayalam musical CollectionNo ratings yet

- Technologies - Metal Working Centre Lathe - Manually Operated - No 56Document5 pagesTechnologies - Metal Working Centre Lathe - Manually Operated - No 56Matthew LeeNo ratings yet

- Technologies - Bench Pedestal Grinder - No 58Document4 pagesTechnologies - Bench Pedestal Grinder - No 58janel norbeNo ratings yet

- No 50 Powered Hand ToolsDocument3 pagesNo 50 Powered Hand ToolsAliNo ratings yet

- No-52-Electric-Ovens RaDocument2 pagesNo-52-Electric-Ovens RaSRAAVAN BNo ratings yet

- Generic Risk Assessment - General Lathe Use v.1Document7 pagesGeneric Risk Assessment - General Lathe Use v.1Darus YasunNo ratings yet

- CMS100 Hazard EvaluationDocument4 pagesCMS100 Hazard EvaluationRamon ArruaNo ratings yet

- Maintenance - Grass Cutting Ride On Mower - No 41Document2 pagesMaintenance - Grass Cutting Ride On Mower - No 41Kaiser CarloNo ratings yet

- JSA HEMP Well Services Pg36-40Document5 pagesJSA HEMP Well Services Pg36-40Ashok Suresh100% (1)

- Jha 01Document3 pagesJha 01samfesfeNo ratings yet

- Hydraulic Press Risk MG T FormDocument10 pagesHydraulic Press Risk MG T FormAndrei VNo ratings yet

- Use of Woodworking MachineryDocument2 pagesUse of Woodworking MachineryKate CarterNo ratings yet

- TRA Safe Ops of Rig TongsDocument3 pagesTRA Safe Ops of Rig Tongselfakeh90No ratings yet

- MACHINE GUARDING BY Fci 1Document34 pagesMACHINE GUARDING BY Fci 1RUFFALYN FINCALERONo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- Risk Assess T-17 - Using Portable Hand ToolsDocument4 pagesRisk Assess T-17 - Using Portable Hand ToolsMAB AliNo ratings yet

- Earth WorksDocument4 pagesEarth WorksLawrence adeleke OmisakinNo ratings yet

- No 32 Home Economics Room General ConsiderationsDocument2 pagesNo 32 Home Economics Room General ConsiderationsmeryllNo ratings yet

- Department of Chemical and Polymer Engineering - Risk AssessmentDocument4 pagesDepartment of Chemical and Polymer Engineering - Risk AssessmentmjunaidNo ratings yet

- AHA-002, Geotechnical WorkDocument5 pagesAHA-002, Geotechnical WorkBuddhikaNo ratings yet

- Risk Assessment For Grinding Work: Classic Builders and DevelopersDocument3 pagesRisk Assessment For Grinding Work: Classic Builders and DevelopersradeepNo ratings yet

- Risk Assessment No. 35 USING GRINDER Rev 0Document2 pagesRisk Assessment No. 35 USING GRINDER Rev 0Lalit ChoudharyNo ratings yet

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument11 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralAlejandro Campomar100% (1)

- JSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurgingDocument2 pagesJSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurginggolusinghdataNo ratings yet

- 22-Ra Work With Hand Held Portable MachinesDocument3 pages22-Ra Work With Hand Held Portable MachinesAsad AyazNo ratings yet

- Concrete Works AHADocument9 pagesConcrete Works AHALawrence adeleke OmisakinNo ratings yet

- Hewlett: PackaroDocument379 pagesHewlett: PackaroStephieNo ratings yet

- Basics of Equipment Guarding: Mining and Petroleum Training ServiceDocument51 pagesBasics of Equipment Guarding: Mining and Petroleum Training ServiceKim Lien TrinhNo ratings yet

- HILTI - TE 7 Rotary HammerDocument18 pagesHILTI - TE 7 Rotary HammerSasidharan Kattisseril GovindanNo ratings yet

- Mechanical SafetyDocument10 pagesMechanical SafetyChristian MeanaNo ratings yet

- Structural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDocument2 pagesStructural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDarseen RNo ratings yet

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- Electrical and Telecom WorksDocument7 pagesElectrical and Telecom WorksLawrence adeleke OmisakinNo ratings yet

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document1 pageRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo RajanNo ratings yet

- Print Only JhaDocument9 pagesPrint Only JhaZul IrmanNo ratings yet

- 3-Jaw Chuck Safety ChecklistDocument3 pages3-Jaw Chuck Safety ChecklistMakrem CherifNo ratings yet

- HEI JHA Leakage RectificationDocument7 pagesHEI JHA Leakage RectificationJavid AaqibNo ratings yet

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- Donghwa Tanabe H SeriesDocument95 pagesDonghwa Tanabe H Seriesjohn smith0% (1)

- AHA-003, ExcavationDocument5 pagesAHA-003, ExcavationBuddhika100% (2)

- DWCE-RA-106 Use of Pneumatic ToolsDocument1 pageDWCE-RA-106 Use of Pneumatic ToolsghughesNo ratings yet

- JSA - Chop Off Machine For Cutting.Document6 pagesJSA - Chop Off Machine For Cutting.RajuNo ratings yet

- Plant and Equipment Risk Assessment Fgoc - NewDocument12 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- Use of 110v Tools B 05Document1 pageUse of 110v Tools B 05cardyNo ratings yet

- Risk Assessment Form - CompletedDocument3 pagesRisk Assessment Form - CompletedPeter GoldNo ratings yet

- Accident PreventionDocument31 pagesAccident PreventionRonald RobertNo ratings yet

- Concrete BreakingDocument2 pagesConcrete BreakingRodrigo CohitmingaoNo ratings yet

- DCH 300 ManualDocument24 pagesDCH 300 Manualeduflo92No ratings yet

- JSA For Height WorkDocument6 pagesJSA For Height WorkMithilesh KumarNo ratings yet

- Casting ConcretDocument2 pagesCasting ConcretMohammed AdnanNo ratings yet

- Fall PreventionsDocument16 pagesFall PreventionsRajesh gp100% (1)

- Jha For Monitoring, Troubleshooting, of Instrument For Startup Assistance.Document5 pagesJha For Monitoring, Troubleshooting, of Instrument For Startup Assistance.Chinedu AchilikeNo ratings yet

- 2018 Safety Manual CompressedDocument376 pages2018 Safety Manual CompressedYeni BulutlarNo ratings yet

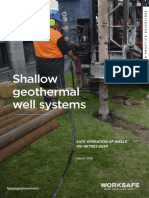

- 56WKS-4-geothermal-shallow-Geothermal-Well-GPGSığ Jeotermal Kuyu SistemleriDocument40 pages56WKS-4-geothermal-shallow-Geothermal-Well-GPGSığ Jeotermal Kuyu SistemleriYeni BulutlarNo ratings yet

- WKS-8-technical-bulletin-drill-rigs SONDAJ MAKİNELERİDocument2 pagesWKS-8-technical-bulletin-drill-rigs SONDAJ MAKİNELERİYeni BulutlarNo ratings yet

- No 21 StressDocument1 pageNo 21 StressYeni BulutlarNo ratings yet

- No 22 Aggressive Threatening Behaviour Towards A Staff MemberDocument1 pageNo 22 Aggressive Threatening Behaviour Towards A Staff MemberYeni BulutlarNo ratings yet