Professional Documents

Culture Documents

2145 I 28 Rev 3 EN

2145 I 28 Rev 3 EN

Uploaded by

Raymond ZamoraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2145 I 28 Rev 3 EN

2145 I 28 Rev 3 EN

Uploaded by

Raymond ZamoraCopyright:

Available Formats

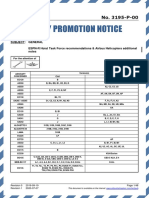

No.

2145-I-28

Information Notice

SUBJECT: FUEL

Fuel Quality

Cancels Safety Information Notice No. 2478-S-00

For the attention of

AIRCRAFT Version(s)

CONCERNED Civil Military

EC120 B

AS350 B, BA, BB, B1, B2, B3, D L1

AS550 A2, C2, C3, U2

AS355 E, F, F1, F2, N, NP

AS555 AF, AN, SN, UF, UN

EC130 B4, T2

SA365 / AS365 C, C1, C2, C3, N, N1, N2, N3 F, Fs, Fi, K, K2

AS565 AA, MA, MB, SA, SB, UB

SA366 G1 GA

EC155 B, B1

SA330 J Ba, Ca, Ea, L, Jm, S1, Sm

SA341 G B, C, D, E, F, H

SA342 J L, L1, M, M1, Ma

ALOUETTE II 313B, 3130, 318B, 318C, 3180, 3180B, 3180C

ALOUETTE III 316B, 316C, 3160, 319B

LAMA 315B

EC225 LP

EC725 AP

AS332 C, C1, L, L1, L2 B, B1, F1, M, M1

AS532 A2, U2, AC, AL, SC, UE, UL

EC175 B

Revision 0 2010-02-18 Page 1/4

Revision 3 2019-07-08 This document is available on the internet: www.airbushelicopters.com/techpub

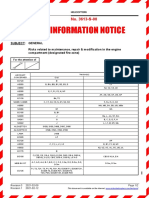

No. 2145-I-28

Airbus Helicopters is issuing this Information Notice to inform you of findings during engine overhaul, and of some

problems encountered in operation, in certain cases due to a drop in the quality of fuels.

The purpose of revision 3 is to highlight that it is necessary to refer to international standards ASTM D1655 and

DEF-STAN 91-9 for the FAME content and that special attention must be paid to the presence of SAP

(Superabsorbent polymer) in fuels.

To ensure normal helicopter operation, the instructions given in the documentation must be complied with

scrupulously.

This Information Notice supersedes Service Letter LS No. 1255-28-95 of December 21, 2006.

Consequences of fuel contamination:

Contamination can:

• Attack and destroy fuel system components such as the fuel tank skin, hoses and pipes.

• Impede fuel probe operation. This results in the erroneous display of fuel quantities.

• Obstruct the fuel filters.

• Obstruct all of the fuel system components, in particular the heat exchangers.

• Cause engine malfunctioning which can lead to a loss of power or engine flame-out.

Reminder of the instructions given in the maintenance documentation:

• Fuels:

o must comply with the standards specified in the Engine Maintenance Manual and Flight Manual.

o must not be contaminated, for example, by water, particles in suspension, micro-organisms such as bacteria,

fungi, actinomyces, EMAG/FAME, etc.

o must be tested:

1. for traces of water (for the method used and the interval, refer to MTC Work Card 20.07.03.412 - For the

EC120, refer to AMM 20-10-00, 3-39),

2. for fungi. The instructions for the detection and prevention of fungi, and the preparation of mixtures

against contamination by the formation of fungi are given on MTC Work Card 20.08.06.401 (For the

EC120, refer to AMM 20-10-00, 3-24),

3. for the detection of biocontamination (refer to MTC Work Card 20.08.06.403 - For the EC120, refer to

AMM 20-10-00, 3-38) if any particular smell is detected.

o must be treated with BIOBOR or KATHLON-FP-15 fungicide if they are used in hot and humid atmospheric

conditions (30 to 40°C) as a preventive measure (refer to MTC Work Card 20.08.06.401 - For the EC120,

refer to AMM 20-10-00, 3-24 - and to MTC Work Card 20.08.06.402 - being incorporated in the AMM for the

EC120).

• Bleeding (tanks and filters) must be carried out regularly in accordance with the Flight Manual and Maintenance

Manual: refer to "Daily Checks", "General Information" and "Check before the First Flight of the Day".

• Filter cartridges must be replaced or cleaned in accordance with the instructions given in the Maintenance

Programs (PRE or MSM).

Particular recommendations for the use of anti-icing additives:

Airbus Helicopters reminds you that in conditions where fuel anti-icing protection is required, the anti-icing additive

content shall be 0.10% to 0.15% by volume, in accordance with the Flight Manual (Chapter 2: Limitations).

If not required by the flight conditions, it is advisable not to add any anti-icing additive.

Furthermore, if possible, it is recommended to use fuels containing anti-icing additives premixed by the oil

company.

Revision 0 2010-02-18 Page 2/4

Revision 3 2019-07-08 This document is available on the internet: www.airbushelicopters.com/techpub

No. 2145-I-28

If the fuel used contains no additive, the best way to add the correct percentage of additive consists in using a

continuous-mixing nozzle connected to the helicopter refueling line (for example from a tanker).

If such equipment is not available, we recommend that you carry out the following operations:

• Fill the tank to approximately half the fuel quantity required for the next flight.

• Premix the required quantity of additive with 10 to 20 liters of fuel. Add this fuel containing the additive, to the

fuel in the fuel tank.

• Then replenish the tank to the level required for the next flight.

• The additive content shall be 0.10% to 0.15% by volume:

o Of the total fuel quantity required for the next flight if the residual fuel in the tank contains no additive.

o Or of the quantity of fuel replenished for the next flight if the residual fuel in the tank already contains an

additive.

You must avoid exceeding the dose of anti-icing additive. The recommended concentration is sufficient to

prevent fuel icing phenomena from occurring on a helicopter.

An excessive concentration of additive can rapidly cause helicopter fuel filter clogging.

If the additive content is too high, the additive no longer dissolves in the fuel and deposits on the bottom of the tank

and can then cause damage to the internal liner of the tank.

Particular recommendations for maintenance:

• If work is carried out on the fuel system, requiring a pipe or other components to be removed, do not forget to fit

protective blanks on the openings.

• Check the cleanliness of the pipes or other components before installation. No foreign bodies or large quantities

of talcum power residues.

• If any signs of contamination are detected, investigations must be carried out regarding fueling, the points of

distribution and the complete helicopter fuel system.

• If contamination of the helicopter fuel system is confirmed, the appropriate measures must be taken immediately

to ensure that clean fuel is used before the next flight of the day. Clean and flush the fuel system until there are

no more signs of contamination.

• A sample of fuel must be analyzed in order to determine the exact cause of the contamination. Inform the Airbus

Helicopters Technical Support department and the engine manufacturer.

Particular recommendations when EMAG/FAME is found:

In order to meet the environmental and governmental requirements concerning diesel fuel, an "EMAG/FAME" type

organic component is incorporated during the production of conventional diesel.

Note: FAME is the abbreviation for Fatty Acid Methyl Ester. The French translation of FAME is EMAG (Ester

Méthylique d’Acide Gras).

When this bio-diesel is transported via multi-product pipelines or by other conventional means (ship, road, train),

the bio-component "EMAG/FAME" adheres to the walls and may mix with the next product, which could be aviation

fuel, and thus contaminate it.

Standards ASTDM1655 and DEF-STAN 91.91 limit the maximum FAME content in fuels. Airbus Helicopters

recommends compliance with these standards.

We request you to report any unusual event related to the use of fuel with a FAME content that exceeds the

standard value.

Revision 0 2010-02-18 Page 3/4

Revision 3 2019-07-08 This document is available on the internet: www.airbushelicopters.com/techpub

No. 2145-I-28

Airbus Helicopters also informs you of several recently reported cases in which SAP (Superabsorbent Polymer)

was found inside fuel tanks.

This type of product is used in the filtering systems of fueling services to enable the trapping of any water. If this

filter is saturated, SAP can extrude and be transferred to the helicopter’s fuel tanks.

As specified in Safety Information Bulletin SIB 2018-10 issued by the EASA in July 2018, this type of contamination

can lead to engine power variations, and the monitoring of the condition of the filtering system is the responsibility

of the fuel supplier.

Revision 0 2010-02-18 Page 4/4

Revision 3 2019-07-08 This document is available on the internet: www.airbushelicopters.com/techpub

You might also like

- Kinsley David R Tantric Visions of The Divine Feminine 330p PDFDocument330 pagesKinsley David R Tantric Visions of The Divine Feminine 330p PDFvoiddoor94% (18)

- The Lean Product Design and Development Journey: Marcus Vinicius Pereira Pessôa Luís Gonzaga TrabassoDocument319 pagesThe Lean Product Design and Development Journey: Marcus Vinicius Pereira Pessôa Luís Gonzaga Trabassormfdiniz100% (2)

- A318/A319/A320/A321: Service BulletinDocument129 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Auto Pilot PDFDocument41 pagesAuto Pilot PDFharun2261No ratings yet

- RRLfor Gasoline StationDocument6 pagesRRLfor Gasoline StationWellan Joy Dela Fuerta100% (1)

- Information Notice: Subject: Fuel Fuel Quality (Was Previously Service Letter No. 1255-28-95)Document3 pagesInformation Notice: Subject: Fuel Fuel Quality (Was Previously Service Letter No. 1255-28-95)arun RajannaNo ratings yet

- 3349 S 25 Rev 0 ENDocument3 pages3349 S 25 Rev 0 ENMário MineiroNo ratings yet

- 3433 P 24 Rev 0 ENDocument3 pages3433 P 24 Rev 0 ENlacsmm982No ratings yet

- Information Notice: Subject: Occurrence ReportingDocument28 pagesInformation Notice: Subject: Occurrence ReportingMário MineiroNo ratings yet

- Safety Information Notice - Aumento de Incidentes Por Falha Na Rotina de ManutencaoDocument3 pagesSafety Information Notice - Aumento de Incidentes Por Falha Na Rotina de Manutencaoleonardo saraivaNo ratings yet

- Safety Information Notice: Subject: Parking and Mooring Helicopter Parking For An Extended Period of Time (Work Stoppage)Document2 pagesSafety Information Notice: Subject: Parking and Mooring Helicopter Parking For An Extended Period of Time (Work Stoppage)Ibrahim AsifNo ratings yet

- Ata 00 - 3686-I-00 - RN02Document3 pagesAta 00 - 3686-I-00 - RN02trinidad sordoNo ratings yet

- Airbus Winch DetailsDocument48 pagesAirbus Winch Detailszozi6030No ratings yet

- SIN3868S20RN0Document2 pagesSIN3868S20RN0Maurício LopesNo ratings yet

- 3947 S 00 Rev 0 ENDocument3 pages3947 S 00 Rev 0 ENReinaldo SouzaNo ratings yet

- SIN3613S00RN1Document2 pagesSIN3613S00RN1Maurício LopesNo ratings yet

- Information Notice: Subject: SERVICING - Disinfection of The Helicopter Interior and The External HandlesDocument3 pagesInformation Notice: Subject: SERVICING - Disinfection of The Helicopter Interior and The External HandlesrobbertmdNo ratings yet

- Safety Promotion Notice: Subject: Standard Practices Recommendations For Torquing OperationsDocument5 pagesSafety Promotion Notice: Subject: Standard Practices Recommendations For Torquing OperationsIbrahim AsifNo ratings yet

- SIN3704S25RN0Document3 pagesSIN3704S25RN0Maurício LopesNo ratings yet

- Safety Information Notice: Subject: Power Plant Inspection and Maintenance of The Engine Compartment SealsDocument2 pagesSafety Information Notice: Subject: Power Plant Inspection and Maintenance of The Engine Compartment SealsIbrahim AsifNo ratings yet

- 3700 S 24 Rev 1 ENDocument6 pages3700 S 24 Rev 1 ENConstantinescu DragosNo ratings yet

- SIN3786S62RN0ERRDocument2 pagesSIN3786S62RN0ERRMaurício LopesNo ratings yet

- 3157 S 63 Rev 0 ENDocument4 pages3157 S 63 Rev 0 ENHuda LestraNo ratings yet

- SIN3463S00RN2Document3 pagesSIN3463S00RN2Maurício LopesNo ratings yet

- 3293 P 00 Rev 1 ENDocument2 pages3293 P 00 Rev 1 ENWan Nabilah Farahin WawanpinkNo ratings yet

- 3821 P 00 Rev 1 ENDocument3 pages3821 P 00 Rev 1 ENButacu LucicaNo ratings yet

- Ata 25 - 3629-I-25 - RN00Document3 pagesAta 25 - 3629-I-25 - RN00trinidad sordoNo ratings yet

- Safety Information Notice: Subject: Equipment and Furnishings Measures To Be Taken If The Hoist Jams in OperationDocument2 pagesSafety Information Notice: Subject: Equipment and Furnishings Measures To Be Taken If The Hoist Jams in OperationIbrahim AsifNo ratings yet

- Safety Information Notice: Subject: Tail Rotor Reminder of The Dedicated Maintenance For The Tail Rotor Trailing Edge TabDocument2 pagesSafety Information Notice: Subject: Tail Rotor Reminder of The Dedicated Maintenance For The Tail Rotor Trailing Edge TabBruno Alonso PachecoNo ratings yet

- Airbus Landing SitesDocument7 pagesAirbus Landing SitesMarcvs LewisNo ratings yet

- 3754 S 34 Rev 0 ENDocument5 pages3754 S 34 Rev 0 ENM GhNo ratings yet

- Safety Promotion Notice: Subject: Standard Practices Recommendations For Visual Inspections - Human Factor ApproachDocument12 pagesSafety Promotion Notice: Subject: Standard Practices Recommendations For Visual Inspections - Human Factor ApproachAlejandro RagoNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument123 pagesA318/A319/A320/A321: Service BulletinPradeep K s100% (1)

- 3700 S 24 Rev 0 ENDocument3 pages3700 S 24 Rev 0 ENJoão CorrêaNo ratings yet

- Information Notice: Subject: Oil Information On The Locking of The Filler Cap of The Oil TankDocument2 pagesInformation Notice: Subject: Oil Information On The Locking of The Filler Cap of The Oil TankGiuseppeTrottaNo ratings yet

- Alert Service Bulletin: EmergencyDocument13 pagesAlert Service Bulletin: EmergencyRaymond ZamoraNo ratings yet

- 1E4 Rev 26Document12 pages1E4 Rev 26Oscar RaudaNo ratings yet

- F.a.a.-P.m.a. Model 1u128a and 1u128bDocument5 pagesF.a.a.-P.m.a. Model 1u128a and 1u128b19600702No ratings yet

- Sin TreuilDocument30 pagesSin TreuilCédric BoblinNo ratings yet

- Safety Information Notice: Subject: General Flight Safety of Helicopters - Issue of EHEST LeafletDocument21 pagesSafety Information Notice: Subject: General Flight Safety of Helicopters - Issue of EHEST LeafletFidel ArellanoNo ratings yet

- 320 Plate FailureDocument4 pages320 Plate Failuregulam husseinNo ratings yet

- Training Manual Da40 (Engine) - CompleteDocument348 pagesTraining Manual Da40 (Engine) - CompleteConsistencyNo ratings yet

- O-320-B & D Parts Catalog PC-203-9Document85 pagesO-320-B & D Parts Catalog PC-203-9Nathaniel LuraNo ratings yet

- CN 2015-19-07Document6 pagesCN 2015-19-07secretariatNo ratings yet

- 3731 I 25 Rev 0 ENDocument1 page3731 I 25 Rev 0 ENEder Jael Edwin CaNo ratings yet

- Continental Engine TBO Extensions SIL98-9BDocument4 pagesContinental Engine TBO Extensions SIL98-9BOscar RaudaNo ratings yet

- ASBAS350630038ENR0Document14 pagesASBAS350630038ENR0Rodrigo Salgado100% (1)

- Manual de Componente Frenos Lj-25Document156 pagesManual de Componente Frenos Lj-25Oficina TecnicaNo ratings yet

- EASBAS355620036ENR2Document14 pagesEASBAS355620036ENR2Raymond ZamoraNo ratings yet

- 3353 I 53 Rev 0 ENDocument2 pages3353 I 53 Rev 0 ENRaymond ZamoraNo ratings yet

- SL 50Document5 pagesSL 50catseekit 캣시킷No ratings yet

- Service Bulletin: Piper Considers Compliance MandatoryDocument10 pagesService Bulletin: Piper Considers Compliance MandatoryJean AbrialNo ratings yet

- List of Part-66 TYpe Ratings Iaw EDD 2015-020-RDocument519 pagesList of Part-66 TYpe Ratings Iaw EDD 2015-020-RSahan DharmasiriNo ratings yet

- Cat Upgrade Kit: Installation ManualDocument12 pagesCat Upgrade Kit: Installation ManualGilberNo ratings yet

- Type Certificate Data Sheet No. 1E4Document12 pagesType Certificate Data Sheet No. 1E4flyingemuNo ratings yet

- EASA TCDS E.005 (IM) Teledyne Continental IO 360 Series Engines 01 31032004Document24 pagesEASA TCDS E.005 (IM) Teledyne Continental IO 360 Series Engines 01 31032004Ken VanNo ratings yet

- SIL98-9E: Service Information LetterDocument4 pagesSIL98-9E: Service Information LetterOmri AmayaNo ratings yet

- 2011-26-04 Lycoming Engines (Formerly Textron Lycoming Division, AVCO Corporation)Document4 pages2011-26-04 Lycoming Engines (Formerly Textron Lycoming Division, AVCO Corporation)sandyNo ratings yet

- Piper - 1379 BulletinDocument5 pagesPiper - 1379 BulletinFRRNo ratings yet

- 3065 I 28 Rev 0 - EN PDFDocument2 pages3065 I 28 Rev 0 - EN PDFBartholemeu Jay SimpsonNo ratings yet

- Service Newsletter: Technical SupportDocument2 pagesService Newsletter: Technical Supportdsgarcia26No ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Reducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemFrom EverandReducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNo ratings yet

- Easa Ad 2017-0165 1Document3 pagesEasa Ad 2017-0165 1Raymond ZamoraNo ratings yet

- ASB - BK117C2 24 010 Rev2 ENDocument9 pagesASB - BK117C2 24 010 Rev2 ENRaymond ZamoraNo ratings yet

- EASBAS355620036ENR2Document14 pagesEASBAS355620036ENR2Raymond ZamoraNo ratings yet

- ASBAS365250167ENR0Document13 pagesASBAS365250167ENR0Raymond ZamoraNo ratings yet

- SB - BK117C2 85 052 Rev0 ENDocument16 pagesSB - BK117C2 85 052 Rev0 ENRaymond ZamoraNo ratings yet

- Safran EHM - 2523-Document Upload-7261-1!10!20201129 - Engine Health Management in Safran Aircraft EnginesDocument8 pagesSafran EHM - 2523-Document Upload-7261-1!10!20201129 - Engine Health Management in Safran Aircraft EnginesRaymond ZamoraNo ratings yet

- 3372 S 52 Rev 0 ENDocument10 pages3372 S 52 Rev 0 ENRaymond ZamoraNo ratings yet

- Alert Service Bulletin: No. AS365-53.00.62Document21 pagesAlert Service Bulletin: No. AS365-53.00.62Raymond ZamoraNo ratings yet

- Alert: Service BulletinDocument28 pagesAlert: Service BulletinRaymond ZamoraNo ratings yet

- 3353 I 53 Rev 0 ENDocument2 pages3353 I 53 Rev 0 ENRaymond ZamoraNo ratings yet

- 3297 S 00 Rev 0 ENDocument5 pages3297 S 00 Rev 0 ENRaymond ZamoraNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document6 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Raymond ZamoraNo ratings yet

- Service Bulletin: SB MBB-BK117 C-2-67-019Document12 pagesService Bulletin: SB MBB-BK117 C-2-67-019Raymond ZamoraNo ratings yet

- Alert Service Bulletin: ASB MBB-BK117 C-2-65A-007Document6 pagesAlert Service Bulletin: ASB MBB-BK117 C-2-65A-007Raymond ZamoraNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document4 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Raymond ZamoraNo ratings yet

- IN 3323 63 Rev0 ENDocument1 pageIN 3323 63 Rev0 ENRaymond ZamoraNo ratings yet

- Alert Service Bulletin: EmergencyDocument13 pagesAlert Service Bulletin: EmergencyRaymond ZamoraNo ratings yet

- ASBAS365630018ENR1ERRDocument31 pagesASBAS365630018ENR1ERRRaymond ZamoraNo ratings yet

- Service Bulletin: SubjectDocument18 pagesService Bulletin: SubjectRaymond ZamoraNo ratings yet

- Transmittal: ASB 92-29-007A Revision A - July 11, 2013Document15 pagesTransmittal: ASB 92-29-007A Revision A - July 11, 2013Raymond ZamoraNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Raymond ZamoraNo ratings yet

- Easa Airworthiness Directive: AD No.: 2015-0044Document3 pagesEasa Airworthiness Directive: AD No.: 2015-0044Raymond ZamoraNo ratings yet

- Alert Service Bulletin: ASB MBB-BK117 C-2-67A-015Document6 pagesAlert Service Bulletin: ASB MBB-BK117 C-2-67A-015Raymond ZamoraNo ratings yet

- Safety Information Bulletin: AirworthinessDocument2 pagesSafety Information Bulletin: AirworthinessRaymond ZamoraNo ratings yet

- Airworthiness Directive: Released by Direction Generale de L'Aviation CivileDocument2 pagesAirworthiness Directive: Released by Direction Generale de L'Aviation CivileRaymond ZamoraNo ratings yet

- Service Bulletin: MBB-BK117 C-2Document14 pagesService Bulletin: MBB-BK117 C-2Raymond ZamoraNo ratings yet

- Alert Service Bulletin: ASB MBB BK117 C 2 29A 003Document14 pagesAlert Service Bulletin: ASB MBB BK117 C 2 29A 003Raymond ZamoraNo ratings yet

- Alert Service Bulletin As365Document8 pagesAlert Service Bulletin As365Raymond ZamoraNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document5 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Raymond ZamoraNo ratings yet

- Superseded: Airworthiness Directive No F-2005-033 ADocument2 pagesSuperseded: Airworthiness Directive No F-2005-033 ARaymond ZamoraNo ratings yet

- Exposure: The PhotoreactionDocument16 pagesExposure: The PhotoreactionGeetha ThiruvengadamNo ratings yet

- Ultimate Goals of LifeDocument11 pagesUltimate Goals of LifeDaniel C. DequiñaNo ratings yet

- Ketu in Jaimini-4Document8 pagesKetu in Jaimini-4Ramesh DoddaNo ratings yet

- A Level Biology Statistics Summary Test Formula Use Degrees of Freedom Accept/reject Null Hypothesis Extra InformationDocument12 pagesA Level Biology Statistics Summary Test Formula Use Degrees of Freedom Accept/reject Null Hypothesis Extra InformationmohammedNo ratings yet

- Nisarg CSCDocument34 pagesNisarg CSCNarendra MehtaNo ratings yet

- Pre-Excavation ChecklistDocument2 pagesPre-Excavation ChecklistminimeezyNo ratings yet

- Chapter 3 - Pneumatic ActuatorsDocument10 pagesChapter 3 - Pneumatic ActuatorserickaNo ratings yet

- Poultry Anatomy and PhysiologyDocument40 pagesPoultry Anatomy and PhysiologyMamtaNo ratings yet

- LogDocument123 pagesLogMalik nabeelNo ratings yet

- Airbus FBW Flight Control Laws: Abbreviated SummaryDocument5 pagesAirbus FBW Flight Control Laws: Abbreviated SummaryPiyushNo ratings yet

- Princess Negonna and Prince NeosomDocument194 pagesPrincess Negonna and Prince Neosomniksaniksa780No ratings yet

- LECTURE 1. PUMPS and FANS.Document21 pagesLECTURE 1. PUMPS and FANS.RocsNo ratings yet

- Qualitative Analysis For Active Sulfur Species in Fuels and Solvents (Doctor Test)Document2 pagesQualitative Analysis For Active Sulfur Species in Fuels and Solvents (Doctor Test)Mikael Salamanca100% (1)

- Nirman VriddhiDocument24 pagesNirman VriddhiNarmad RavalNo ratings yet

- 4.1 Foundation SettlementDocument49 pages4.1 Foundation SettlementRadifan HalifNo ratings yet

- Borrowing Costs PDFDocument9 pagesBorrowing Costs PDFanjcabsNo ratings yet

- Little Baguio Building Rules and Regulations DraftDocument7 pagesLittle Baguio Building Rules and Regulations DraftJun Dela CruzNo ratings yet

- Manual Haier HYC-390 enDocument24 pagesManual Haier HYC-390 enDaniel BuitragoNo ratings yet

- SLG Chem2 LG 4.9 BuffersDocument6 pagesSLG Chem2 LG 4.9 BuffersIman SontousidadNo ratings yet

- Mvc2 ManualDocument49 pagesMvc2 ManualMICHELLE ALEXANDRA SOTOMAYOR MONTECINOSNo ratings yet

- Coastkeeper Alliance LawsuitDocument24 pagesCoastkeeper Alliance LawsuitKTXL DigitalNo ratings yet

- Chang Chemistry - Assessment Chapter 7Document10 pagesChang Chemistry - Assessment Chapter 7haha_le12No ratings yet

- Physics Investigatory ProjectDocument23 pagesPhysics Investigatory ProjectManikandan s100% (1)

- Principles and Interpretation of CardiotocographyDocument9 pagesPrinciples and Interpretation of CardiotocographyCKNo ratings yet

- AS3696747610644481465148739173 Content 11Document15 pagesAS3696747610644481465148739173 Content 11Shivraj ChouguleNo ratings yet

- Offshore Wind FarmDocument32 pagesOffshore Wind FarmKonstantinos Papadopoulos100% (1)

- China in 50 DishesDocument112 pagesChina in 50 Dishesdikstraa100% (1)