Professional Documents

Culture Documents

Hangsterfers S 388

Hangsterfers S 388

Uploaded by

游宜盛Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hangsterfers S 388

Hangsterfers S 388

Uploaded by

游宜盛Copyright:

Available Formats

S-388 Coolant Concentrate: Water Soluble Oil, Chlorine-free, Dye-free, Perfume-free

GENERAL DESCRIPTION

Chlorine-Free, Non-Toxic, Non-Irritating and Especially for the machining of disk drive

Non-Corrosive. components.

Dye-free, Perfume-free, Amine-free, Phosphate- Easily cleaned in either aqueous or solvent-

free and Nitrite-free. based cleaning systems.

Bio-stable formulation for extended life and Outstanding performance on aluminum

minimized waste. machining, including small drills and small taps.

Ideal for continuous use recycling systems and Compatible with all common machine tool

central systems. components, including paint and seals.

Reduce inventories; multi-purpose formulation Excellent rejection of foreign contamination,

eliminates need for multiple coolants. including tramp oils.

Advanced Synthetic Extreme Pressure Additives.

APPLICATIONS

Primary Secondary

CNC Turning CNC Milling and Drilling Broaching, Shaping & Slotting Gear Cutting & Finishing

Tapping & Threading Reaming & Boring Drawing Forming

Sawing & Cut-off Light Stamping Heavy Stamping Fine Blanking

High Speed Machining High Pressure Machining Grinding, including:

Conventional Contract Shop Applications Centerless, Creepfeed, Surface, ID/OD and Rotary.

MATERIALS

Primary Secondary

Aluminum Alloys Titaniums Brass, Bronze & Copper Alloys Precious Metals

High Temperature Alloys Powdered Metals Ductile Iron & Cast Iron Ceramics & Glass

Nickel Alloys Composites & Plastics Tungston Refractory Metals

Stainless Steels: Bhn 250-350 Steels-Bhn250-350

Stainless Steels: Bhn 350-450 Steels- Bhn 350-450

INSTRUCTIONS

Pre-mixing Procedures: Recommended Concentrations:

Always premix coolant before adding to the machine Application Ratio

Concentrate: Water

% Refractometer

sump. General Cutting 1:20 - 1:10 5% - 10% 5 - 10

Never add straight water or straight concentrate directly Severe Cutting 1:10 - 1:5 10% - 20% 10 - 20

to the machine's sump.

For best results a Hangsterfer’s recommended General Grinding 1:40 - 1:20 2.5% - 5% 2.5 - 5

proportioning device should be used. General Deformation 1:40 - 1:10 2.5% - 10% 2.5 - 10

If mixing by hand, always add concentrate to water, and Severe Deformation 1:10 - 1:5 10% - 20% 10 - 20

then agitate.

Make-up Procedures: Recommended Maintenance Equipment:

It is important to remember that as water evaporates Hangsterfer's Accumix 14100 is a premium piston-style

from the coolant, the concentration will increase. proportioning device that insures proper proportioning and

To maintain the recommended concentration in the mixing of the water and concentrate. A tight, stable

machine, make-up coolant should be pre-mixed at half emulsion is the result.

the % concentration as the initial fill. Hangsterfer's Basic Refractometer measures

To maintain 6% in the machine, first charge the machine concentrations from 0% to 18% and is one of the most

at 6%, then add make-up at 3% to keep the machine full. important tools a shop can have in regards to coolant

This will keep the machine at 6%. maintenance.

Never add just straight water to reduce the concentration, Hangsterfer's Basic Belt Skimmer removes tramp oil from

always add a light pre-mixed coolant the machine sump as it accumulates. Take advantage of

the tramp oil rejecting properties of the coolant and

maximize sump life.

Hangsterfer’s Laboratories, Inc. www.hangsterfers.com

175 Ogden Road tel: +1-856-468-0216

Mantua, New Jersey 08051 fax: +1-856-468-0200

United States of America toll free North America: +1-800-433-LUBE

MAINTENANCE

S-388 is a biostable coolant, designed to control the growth of bacteria. Regular maintenance is required for

maximum performance. Concentration should be monitored regularly with a calibrated refractometer. S-388

gives a direct read on the refractometer (e.g. 5=5%). Tramp oils should be removed from the coolant surface

regularly to prevent unwanted bacterial growth. Keep the coolant system free of cleaners, solvents and other

contaminants.

PRODUCT CHARACTERISTICS

Product S-388

Form Liquid Concentration Dilution Table

Color Amber

Odor Mild % Ratio Refractometer

Specific Gravity 0.97 20% 1:5 20

Viscosity: SUS @ 100oF 220 15% 1:7 15

cSt @ 40oC 48 10% 1:10 10

Flash Point, COC, oF/oC 323 / 162 7.5% 1:13 7.5

Fire Point, COC, oF/oC 343 / 173 5% 1:20 5

Pour Point, oF/oC <0 / -18 4% 1:25 4

Solubility in Water 100% 3% 1:33 3

Boiling Point, oF/oC 289 / 143 2.5% 1:40 2.5

Vapor Pressure, mm Hg @ 25º <0.01 2% 1:50 2

pH @ 10% 9.0 1% 1:100 1

SHIPPING UNITS

S-388 is available in 5 gallon, 55 gallon and Intermediate Bulk Containers (275 or 330 gallons). All products are

distributed worldwide.

Revised: November 5, 2008

All reasonable care has been taken to ensure that the information contained in this publication is true and accurate. No warranty is expressed or implied regarding the accuracy of the data.

Also, seller is not liable for any loss, damage or liability resulting from the use of the product in the buyer’s manufacturing processes or in combination with other substances. MSDS’s are

available for all Hangsterfer’s products and should be consulted as needed.

You might also like

- Question 1 - Expository EssayDocument3 pagesQuestion 1 - Expository EssayMahinNo ratings yet

- Water-Soluble Metalworking Fluids - General Information BookletDocument13 pagesWater-Soluble Metalworking Fluids - General Information Bookletsurajit7guptaNo ratings yet

- Crystal Cut 322 BACDocument2 pagesCrystal Cut 322 BACMiguel Lobos CofreNo ratings yet

- Coolant Eontrim c270 Eon @209ldrumDocument4 pagesCoolant Eontrim c270 Eon @209ldrumfdssdfdsfNo ratings yet

- Product Information Flyer: Cimstar® 40LfDocument2 pagesProduct Information Flyer: Cimstar® 40LfsobheysaidNo ratings yet

- Techno Flow: Progressive Cavity PumpsDocument4 pagesTechno Flow: Progressive Cavity PumpsYogesh SharmaNo ratings yet

- Met-Kleen 155: Innovative Cleaning TechnologyDocument1 pageMet-Kleen 155: Innovative Cleaning TechnologyMiguel BorbaNo ratings yet

- Coolsurf RCO 70 TDS 1Document2 pagesCoolsurf RCO 70 TDS 1Dinesh babuNo ratings yet

- Aquamet 700 HP ECODocument3 pagesAquamet 700 HP ECOranjanguptNo ratings yet

- Met-Kleen 140 (7.8.13)Document1 pageMet-Kleen 140 (7.8.13)tribolasNo ratings yet

- Solder Recommendations: VishayDocument1 pageSolder Recommendations: Vishaymarcelinoandika132No ratings yet

- Tectyl Cool 260 PDS ENDocument1 pageTectyl Cool 260 PDS ENQuy NguyenNo ratings yet

- TDS (Specialties) SolcutDocument1 pageTDS (Specialties) SolcutD Wahyu BawonoNo ratings yet

- Lactuca 3000 Metal Working Fluid Cutting OilDocument2 pagesLactuca 3000 Metal Working Fluid Cutting OilAbhimanyaNo ratings yet

- L2141DFVCVDocument2 pagesL2141DFVCVManuel Alejandro Arguelles AcevedoNo ratings yet

- Product Information Flyer: CIMTECH® 420Document2 pagesProduct Information Flyer: CIMTECH® 420sobheysaidNo ratings yet

- Product Information Flyer: Cimtech® 410CDocument2 pagesProduct Information Flyer: Cimtech® 410CsobheysaidNo ratings yet

- Cimstar Qualstar LFZDocument2 pagesCimstar Qualstar LFZsobheysaidNo ratings yet

- Product Information Flyer: CIMSTAR® 10-570-HFP With FACT™Document2 pagesProduct Information Flyer: CIMSTAR® 10-570-HFP With FACT™sobheysaidNo ratings yet

- Product Information Flyer: Cimstar® 40Document2 pagesProduct Information Flyer: Cimstar® 40sobheysaidNo ratings yet

- Thinner Msds PDFDocument2 pagesThinner Msds PDFEka KusyantoNo ratings yet

- Pack RYTDocument41 pagesPack RYTGonzalo Alonso QuintanaNo ratings yet

- Product Information Flyer: CIMSTAR® 3890Document2 pagesProduct Information Flyer: CIMSTAR® 3890sobheysaidNo ratings yet

- Z&s PADocument8 pagesZ&s PAguven44No ratings yet

- MobilCut Series PdsDocument4 pagesMobilCut Series PdsNoche de EstrellasNo ratings yet

- Petronas Pressol: Premium Grade Air Compressor OilsDocument1 pagePetronas Pressol: Premium Grade Air Compressor OilsMujeeb SiddiqueNo ratings yet

- I I Formularies Hard Surface Cleaning Industrial Metal Cleaners 110-12-009 USDocument8 pagesI I Formularies Hard Surface Cleaning Industrial Metal Cleaners 110-12-009 USbexigaobrother100% (5)

- Tds Sitala Ce3402Document2 pagesTds Sitala Ce3402alexNo ratings yet

- Training For Tensioning Hydraulic System MPS MillsDocument69 pagesTraining For Tensioning Hydraulic System MPS MillsImam SampoernoNo ratings yet

- Acidizing PresentationDocument55 pagesAcidizing PresentationAbhishek Tripathi100% (4)

- Product Information Flyer: Cimstar® Qual StarDocument2 pagesProduct Information Flyer: Cimstar® Qual StarsobheysaidNo ratings yet

- Artclean CWDocument1 pageArtclean CWVishwanath ShettyNo ratings yet

- Piston Fluid - tcm742-1607660 - tcm836-1777166 PDFDocument2 pagesPiston Fluid - tcm742-1607660 - tcm836-1777166 PDFJan HendriksNo ratings yet

- Bpxe Acf2urDocument2 pagesBpxe Acf2urmilo ,miloNo ratings yet

- Product Information Flyer: CIMTECH® 495-OIDocument2 pagesProduct Information Flyer: CIMTECH® 495-OIsobheysaidNo ratings yet

- EHYDF2 Hydraulic Filtration CAT2300-13 OP3Document12 pagesEHYDF2 Hydraulic Filtration CAT2300-13 OP3hariana100% (1)

- Tekna Heavy Oil Technology For Offshore Applications: Chemistry and Physics of Heavy Oil and Other DispersionsDocument31 pagesTekna Heavy Oil Technology For Offshore Applications: Chemistry and Physics of Heavy Oil and Other DispersionsPrince OmaNo ratings yet

- Renoclean Bio Rig WashDocument2 pagesRenoclean Bio Rig WashdnoaisapsNo ratings yet

- Hydraulic Vane Pumps Subplate and Flange Mounted: RA 10 336/12.04 Replaces: 07.03 1/12Document12 pagesHydraulic Vane Pumps Subplate and Flange Mounted: RA 10 336/12.04 Replaces: 07.03 1/12Bryan Edu Curay ZavalaNo ratings yet

- Hidraulik EPDocument1 pageHidraulik EPpssuriNo ratings yet

- 21 - Resins For Road Marking PaintsDocument4 pages21 - Resins For Road Marking Paintsraj jangid100% (1)

- 0760 B1 - FRL Beware BulletinDocument6 pages0760 B1 - FRL Beware Bulletinooo246oooNo ratings yet

- Eneos 10W40 SM PDSDocument2 pagesEneos 10W40 SM PDSCoc ZaaNo ratings yet

- Maintenance FOWADocument44 pagesMaintenance FOWANartoNo ratings yet

- Taro 30 DP PDFDocument3 pagesTaro 30 DP PDFHassan KhalifeNo ratings yet

- Bpxe AbpcktDocument2 pagesBpxe Abpcktmilo ,miloNo ratings yet

- Vorta Cutfine EcoxxDocument1 pageVorta Cutfine EcoxxferdiNo ratings yet

- Product Information Flyer: CIMTECH® 285Document2 pagesProduct Information Flyer: CIMTECH® 285sobheysaidNo ratings yet

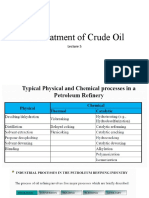

- Pre-Treatment of Crude OilDocument25 pagesPre-Treatment of Crude OilAbhisek AgarwalNo ratings yet

- Eraspray ES81A HBDocument5 pagesEraspray ES81A HBdody andiNo ratings yet

- Soluble Oakflo 800Document2 pagesSoluble Oakflo 800slpampcpoNo ratings yet

- Optimization of Operating Parameters of Oil Desalting in Southern Treatment Unit Hmdalgeria 2157 7463 1000271Document6 pagesOptimization of Operating Parameters of Oil Desalting in Southern Treatment Unit Hmdalgeria 2157 7463 1000271engr.shahid041No ratings yet

- Bechem CoolantsDocument1 pageBechem CoolantsChung LeNo ratings yet

- Oil STATION EQUIPMENT Design 2024Document48 pagesOil STATION EQUIPMENT Design 2024JohnsonNo ratings yet

- Sinopec EP Golden GreaseDocument2 pagesSinopec EP Golden GreaseYoong TanNo ratings yet

- TDS Sinopec HP-R Grease enDocument2 pagesTDS Sinopec HP-R Grease ennghiaNo ratings yet

- Mi Deq & Retap PollutionDocument29 pagesMi Deq & Retap PollutionAmrik SinghNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- The Nail technician’s Career Guide - The blueprint to a successful nail salon businessFrom EverandThe Nail technician’s Career Guide - The blueprint to a successful nail salon businessNo ratings yet

- Advent 7109 User ManualDocument73 pagesAdvent 7109 User ManualDaveW1958No ratings yet

- Tendernotice 1Document46 pagesTendernotice 1IMT HANDWARANo ratings yet

- Asus ROG Zephyrus S GX531: 1.what Are The Main Characteristics?Document3 pagesAsus ROG Zephyrus S GX531: 1.what Are The Main Characteristics?mihaelahristeaNo ratings yet

- MatrixDocument105 pagesMatrixAsafAhmad100% (1)

- Chiller Unit CostDocument3 pagesChiller Unit CostKullamas UdoNo ratings yet

- Basic Service Purchase Order Process - DIEN MaterialDocument6 pagesBasic Service Purchase Order Process - DIEN MaterialDanielleNo ratings yet

- GenII Main Rotor Sikorsky S76 Pushrod 1.00Document23 pagesGenII Main Rotor Sikorsky S76 Pushrod 1.00agripinaluzmilaaNo ratings yet

- Receptionists Competency Standard Booklet Printed PDFDocument19 pagesReceptionists Competency Standard Booklet Printed PDFMicula OanaNo ratings yet

- CertificateDocument5 pagesCertificateRavi JoshiNo ratings yet

- Addressing Sexual Harassment at Workplace - Without Author's NameDocument15 pagesAddressing Sexual Harassment at Workplace - Without Author's Namemehjabin ferdous moneesaNo ratings yet

- How To Make Bregedel TempeDocument2 pagesHow To Make Bregedel Tempetriana puji50% (2)

- Solution Manager 7Document24 pagesSolution Manager 7Md Abdullah Al MamunNo ratings yet

- 33KV, 1250a, 26.3ka (3 Sec) Pix-36 Cico Panel SWBD#20211101 - 100747# - 102943Document49 pages33KV, 1250a, 26.3ka (3 Sec) Pix-36 Cico Panel SWBD#20211101 - 100747# - 102943Ashok Patel100% (1)

- Dual Tone Multi Frequency SignalingDocument4 pagesDual Tone Multi Frequency Signalingmrana_56No ratings yet

- Passive Suppression of Nonlinear Panel Flutter Using Piezoelectric Materials With Resonant CircuitDocument12 pagesPassive Suppression of Nonlinear Panel Flutter Using Piezoelectric Materials With Resonant CircuitYonghui XUNo ratings yet

- Komal Kamble - ResumeDocument2 pagesKomal Kamble - ResumeSumit GoleNo ratings yet

- Effects of Parental Warmth and Academic Pressure On Anxiety and Depression Symptoms in Chinese AdolescentsDocument11 pagesEffects of Parental Warmth and Academic Pressure On Anxiety and Depression Symptoms in Chinese AdolescentsJr SparkNo ratings yet

- Essay Service UkDocument7 pagesEssay Service Ukb6zm3pxh100% (2)

- E25bmhs 2007Document63 pagesE25bmhs 2007Luis GallardoNo ratings yet

- MScFE 620 DTSP - Compiled - Notes - M1 PDFDocument25 pagesMScFE 620 DTSP - Compiled - Notes - M1 PDFRocApplyNo ratings yet

- SBR in Plant TechnologyDocument27 pagesSBR in Plant TechnologydesNo ratings yet

- 5 AxisDocument37 pages5 Axispradeep_02100% (1)

- Unit OneDocument9 pagesUnit OneMb BlackNo ratings yet

- Ken Weaver Mechanical Engineer ResumeDocument2 pagesKen Weaver Mechanical Engineer Resumeapi-308328805No ratings yet

- Humphree Course StabilisingDocument8 pagesHumphree Course StabilisingMatNo ratings yet

- Dissertation Tolga UhlmannDocument8 pagesDissertation Tolga UhlmannBestPaperWritingServiceClarksville100% (1)

- Conformity Compliance and ObedienceDocument14 pagesConformity Compliance and ObedienceUjjwalBansalNo ratings yet

- UAS General English-2-2021Document12 pagesUAS General English-2-2021Putri Pradnya DewantiNo ratings yet

- Stable ResonatorDocument4 pagesStable ResonatorIjaz TalibNo ratings yet