Professional Documents

Culture Documents

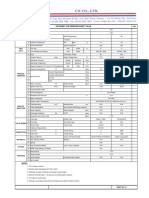

150FV002-IFT-Data Sheet

150FV002-IFT-Data Sheet

Uploaded by

gerardoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

150FV002-IFT-Data Sheet

150FV002-IFT-Data Sheet

Uploaded by

gerardoCopyright:

Available Formats

1 Tag No.

0150-FV -002 Project Name A3AG00

2 P&ID No. A3AG-0150-50PI-001 Plant Name CODELCO GABY

GENERAL

3 Service CAUDAL ACIDO SULFURICO TAMBOR ACIDIFICADO Area Name 0100

4 Location Field Unit Name 0150

5 Line No. 0150-SA-4"-S1-2247-N Construction Work Package K-104

6 Equipment No. Amb. Temp. Min. to Max. -6 to 30 ºC

7 Area Class. Unclassified Atm.Press. Sour Service 74,5 kPag

2/6/200781 Line Size In 4 in Schedule In

PIPE

9 Out 4 in Out

10 Pipe Material S.S. 316L Sch 40S Pipe Insulation

11 Units Min. Flow Norm. Flow Max. Flow Shut-Off

12 Flow Rate m³/h 0 15 29

13 Inlet Pressure kPa-g 558 539 514

14 Pressure Drop kPa 399 314 653 kPa

15 Operating Temperature ºC 10 15 30

16 Operating Density kg/m³ 1846 1840 1826

17 Operating S. G. 1.8478 1.8418 1.8278

18 Molecular Weight

19 Operating Viscosity cP 40 32 14.6

PROCESS

20 Specific Heat Ratio

21 Inlet Vapour Pressure Pa-a 0.013

22 Calculated CV

23 % Open % 0

24 Sound Press. Lvl Allow./Pred. dBA 85 / 85 / 85 /

25

26 pH / % Solids

27 Fluid Ácido Sulfúrico Concentrado 75 Manufacturer VTS

POSITIONER or I/P

28 Fluid Phase Liquid 76 Model No.

29 Design Press Design Temp kPa-g ºC 77 Type SMART

30 Critical Press Critical Temp kPa-g ºC 78 Tag No Digital Interface

31 % SuperHt. Compressibility 79 Signal: Inlet 4 to 20 mA+Hart

32 Body Type Globe 80 Outlet 4 to 20 mA+Hart

33 Size VTS 2 in 81 Sig Output Incr/Decr Increases

34 ANSI Class ANSI 150 82 Gauges Bypass Supply & Output

35 Max Pressure VTS 83 Advanced Diagnostics Hart

36 Max Temperature VTS 84 PID Controller Backup LAS

37 Body/Bonnet Material Alloy 20 85 Manufacturer

VALVE BODY

SWITCHES or XMTR

38 Liner Material ID 86 Model No.

39 End In RF FLG 87 Type

40 Connection Out RF FLG 88 Tags

41 Flg Face Finish ANSI B16.6-81 89 Quantity Power Supply

42 End Ext / Material 90 Rating (Amps/ Volts /Hertz)

43 Flow Direction Bonnet Type Forward Standard 91 Actuation Points Contacts

44 Lub & Iso Vlv Lube 92 Manufacturer VTS

TESTS AIR SET

45 Packing Material PTFE 93 Model No.

46 Packing Type V-Ring; Spring Type 94 Set Pressure VTS kPa-g

47 Bolting Material 316SS 95 Filter Gauge Yes

48 Type Standard 96 Press. Test Yes

49 Size Rated Travel VTS VTS 97 ANSI / FCI Leakage Class

50 Characteristic Equal % 98 Non Destructive Examination

51 Balanced / Unbalanced VTS 99 Manufacturer

VALVE TRIM

52 Rated CV VTS 100 Model No. / Rating

SOLENOID

53 FL XT VTS VTS 101 Type

54 Plug / Ball / Disk Material Alloy 20 102 Tag No.

55 Seat / Ring Material PTFE 103 Pneumatic Connection

56 Cage / Guide Material Alloy 20 104 Coil Rating / Power Supply

57 Stem / Shaft Material Alloy 20 105 Coil Housing

58 Leak Class ANSI/FCI IV 106 When De-Energ. Valve

59 107 Coil JB Elec Connection

60 Manufacturer VTS 108 Manufacturer VTS

PURCHASE

61 Model No. 109 Model No. VTS

62 Type Diaphragm 110 Req Order No. A3AG-0000-70RQ-918-71500

63 Size Eff Area VTS 111 P.O. No. Item No.

64 On / Off Modulating Modulating 112 Serial No.

TEMPLATE REV - 1.00 - 19-Jan-2004

65 Min Required Pressure VTS kPa-g 113 Electrical Approval Std

ACTUATOR

66 Max Allowable Pressure VTS kPa-g 114 Local Vendor Unit Price (US$)

67 Available Air Min 500 kPa-g 1.-VTS: Vendor to specify.

68 Supply Press Max 700 kPa-g 2.-Stainless Steel name tag shall be included.

NOTES

69 Bench Range to 3.-Painting for corrosive ambient.

70 Orientation Vert. Up 4.-Position transmitter included.

71 Handwheel Type Required 5.-Factory calibration sheet included.

72 Fail Valve Position Close

73 Mechanical Limit Stop

74 Air to Open / Close Open

INSTRUMENT DATA SHEET DATA SHEET DOC NO:

CONTROL VALVE

A3AG-0150-70HD-013

B 2/5/2007 Client approval MR SB CL

A 1/3/2007 Internal review MR SB CL SHEET: of REV:

REV DATE DESCRIPTION BY CHK APPR CLT CODE: 72 B

You might also like

- Bahria Building by LawsDocument48 pagesBahria Building by LawsAhsan Buriro56% (72)

- Air-To-Water Heat Pump: Shanghai Hezhong Carrier Air-Conditioning Equipment Co., LTDDocument7 pagesAir-To-Water Heat Pump: Shanghai Hezhong Carrier Air-Conditioning Equipment Co., LTDguy namNo ratings yet

- Choke Valve DatasheetDocument1 pageChoke Valve DatasheetMuhammad Rizqi SiregarNo ratings yet

- World Trade ParkDocument33 pagesWorld Trade ParkDevendra Sharma67% (3)

- 150HV051-IFT-Data SheetDocument1 page150HV051-IFT-Data SheetgerardoNo ratings yet

- 150FV054-IFT-Data SheetDocument1 page150FV054-IFT-Data SheetgerardoNo ratings yet

- 150FV104-IFT-Data SheetDocument1 page150FV104-IFT-Data SheetgerardoNo ratings yet

- 150HV003-IFT-Data SheetDocument1 page150HV003-IFT-Data SheetgerardoNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- A11627SE-08 - CVDS Rev B Technical Specification 840GDocument2 pagesA11627SE-08 - CVDS Rev B Technical Specification 840GMichael Adu-boahenNo ratings yet

- A11627SE-04 - CVDS Rev C Technical Specification 840GDocument2 pagesA11627SE-04 - CVDS Rev C Technical Specification 840GMichael Adu-boahenNo ratings yet

- NSDocument1 pageNSXemtintuc Xem TinNo ratings yet

- Data Sheet & Sizing SheetDocument3 pagesData Sheet & Sizing SheetazitaggNo ratings yet

- Datasheet For PSVDocument1 pageDatasheet For PSVlãng duNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- Control Valve Data Sheet: (Printed 2007-01-16 9:46 AM) K2 - 2006 (A1.3)Document2 pagesControl Valve Data Sheet: (Printed 2007-01-16 9:46 AM) K2 - 2006 (A1.3)Mateus EliasNo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- MQ13 02 DS 3510 Inhv142b - R0Document2 pagesMQ13 02 DS 3510 Inhv142b - R0JHONATAN RODRIGUEZ VENTONo ratings yet

- GBCPP PCV 2030Document1 pageGBCPP PCV 2030Firstyan Dhika AldaniNo ratings yet

- KSB MIL Controls Limited Valve Specification SheetDocument2 pagesKSB MIL Controls Limited Valve Specification SheetPablo TorresNo ratings yet

- Extracted Pages From 1.2 P2B-00-52-ABB-273-001 REV.1 INSTRUMENT DATA SHEET AMMONIADocument2 pagesExtracted Pages From 1.2 P2B-00-52-ABB-273-001 REV.1 INSTRUMENT DATA SHEET AMMONIALoolooNo ratings yet

- 077154C - 1813 PDS 1543 001 A Technip India LTD.: Client MRPL Location Mangalore, Karnata Unit New LPG AtuDocument1 page077154C - 1813 PDS 1543 001 A Technip India LTD.: Client MRPL Location Mangalore, Karnata Unit New LPG AtuChakravarthy BharathNo ratings yet

- Abb-02-Ics-Das-Enf-000-00001-00 Z-03Document2 pagesAbb-02-Ics-Das-Enf-000-00001-00 Z-03mvdeole7056No ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- MKI-DS-J-001-A4 - Rev A Data Sheet PCVDocument60 pagesMKI-DS-J-001-A4 - Rev A Data Sheet PCVFIRMANSYAHNo ratings yet

- Desuper-heater Specification Sheet فناورانDocument1 pageDesuper-heater Specification Sheet فناورانMAHDINo ratings yet

- Documents For Approval Rev-1 - ApprovedDocument42 pagesDocuments For Approval Rev-1 - ApprovedAbhijeet WayaseNo ratings yet

- Atlas Copco India LTD.: Gas Process ApplicationDocument4 pagesAtlas Copco India LTD.: Gas Process ApplicationAmit SurtiNo ratings yet

- PVVDocument10 pagesPVVJorge Arturo Rodríguez HerreraNo ratings yet

- PI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Document1 pagePI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Annie De WildeNo ratings yet

- 1-MVCP00116-885PSVr2 20210524100343 852 XDocument4 pages1-MVCP00116-885PSVr2 20210524100343 852 XŁukasz BolewskiNo ratings yet

- File 5Document1 pageFile 5VENKATACHALAM SUBBARAJNo ratings yet

- A307 Ius Uv DS 1201Document2 pagesA307 Ius Uv DS 1201smartravi222No ratings yet

- Datasheet For Restriction OrificeDocument1 pageDatasheet For Restriction OrificeRajesh Rajesh67% (3)

- Q1Co 3000 Q1Co 3620 3620-FIT - 286Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 286JHONATAN RODRIGUEZ VENTONo ratings yet

- En2458 75 Lit60001 - 09Document1 pageEn2458 75 Lit60001 - 09Dela AmandaNo ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (KG/H) (CP) (Psi (A) )Document5 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (KG/H) (CP) (Psi (A) )Elias EliasNo ratings yet

- Severn GloconDocument6 pagesSevern GloconAmit Surti0% (1)

- 1.2. Sample - Datasheet Antisurge ValveDocument1 page1.2. Sample - Datasheet Antisurge ValveMuhammad FauzanNo ratings yet

- Data Sheet - Rev 01Document158 pagesData Sheet - Rev 01Martin DanzeNo ratings yet

- Severn Glocon Lot2Document5 pagesSevern Glocon Lot2Amit SurtiNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 186Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 186JHONATAN RODRIGUEZ VENTONo ratings yet

- 07-PSV-07 Folha de Dados ValbracDocument1 page07-PSV-07 Folha de Dados ValbracRODRIGO CARDOSONo ratings yet

- Control Valve Data SheetDocument6 pagesControl Valve Data Sheetsiseset100% (1)

- Tag No FT-1033: SHEET: 27 OF 102Document1 pageTag No FT-1033: SHEET: 27 OF 102hendra hermawanNo ratings yet

- Instrument Data For Coriolis Flow TransmitterDocument2 pagesInstrument Data For Coriolis Flow Transmitterdilip matalNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- PCV Data Sheet PDFDocument5 pagesPCV Data Sheet PDFveenaNo ratings yet

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Document7 pagesData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaNo ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Document16 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Elias EliasNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- VRQ 4Document2 pagesVRQ 4Esteban ArguelloNo ratings yet

- Data Book MX200 v1 0 77Document1 pageData Book MX200 v1 0 77Rober Marcial Apaza CaunaNo ratings yet

- A307 Ius FV DS 1311Document2 pagesA307 Ius FV DS 1311Ravi KumarNo ratings yet

- VRQ 3Document2 pagesVRQ 3Esteban ArguelloNo ratings yet

- DASDocument39 pagesDASchakrapani vagish chandra pandeyNo ratings yet

- 141014.datasheet For PSV-1323Document2 pages141014.datasheet For PSV-1323ocanhthuNo ratings yet

- Planta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEDocument1 pagePlanta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEAnthony InostrozaNo ratings yet

- 150HV051-IFT-Data SheetDocument1 page150HV051-IFT-Data SheetgerardoNo ratings yet

- 150HV003-IFT-Data SheetDocument1 page150HV003-IFT-Data SheetgerardoNo ratings yet

- 150FV104-IFT-Data SheetDocument1 page150FV104-IFT-Data SheetgerardoNo ratings yet

- 150FV054-IFT-Data SheetDocument1 page150FV054-IFT-Data SheetgerardoNo ratings yet

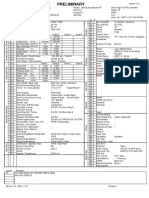

- အေဆာက္အဦးလုပ္ငန္း အေျခခံစံႏႈန္းမ်ားDocument313 pagesအေဆာက္အဦးလုပ္ငန္း အေျခခံစံႏႈန္းမ်ားKhaing SuNo ratings yet

- Nammaaaa 000031Document147 pagesNammaaaa 000031mohammad qaruishNo ratings yet

- Scissor Lift DocumentDocument14 pagesScissor Lift DocumentTamil SelvanNo ratings yet

- Room Air Conditioner: Service ManualDocument70 pagesRoom Air Conditioner: Service ManualHa Bao AnhNo ratings yet

- ISSA2013Ed CabinStores v100 Часть10Document2 pagesISSA2013Ed CabinStores v100 Часть10AlexanderNo ratings yet

- Katalog Griff 2021Document75 pagesKatalog Griff 2021Meita RatrianaNo ratings yet

- Viking Main Control ValveDocument3 pagesViking Main Control Valvearf laade100% (1)

- ead-120109-00-0107-NOSING JOINTS - ETAG 032-4 - UnlockedDocument80 pagesead-120109-00-0107-NOSING JOINTS - ETAG 032-4 - UnlockedMarko ZgbNo ratings yet

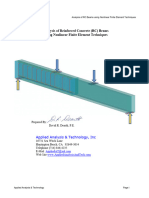

- Analysis Reinforced Concrete (RC) Beams Nonlinear - FEADocument27 pagesAnalysis Reinforced Concrete (RC) Beams Nonlinear - FEADavid R. DearthNo ratings yet

- T-Bar Product InformationDocument14 pagesT-Bar Product InformationEd2sverissimoNo ratings yet

- Armstrong - Vinyl Pattern TypesDocument24 pagesArmstrong - Vinyl Pattern TypesAndy NgNo ratings yet

- Pos 105 - 109Document1 pagePos 105 - 109ismet mehmetiNo ratings yet

- AlNi B2Document2 pagesAlNi B2Pei Yu ChenNo ratings yet

- GlasGrid BrochureDocument24 pagesGlasGrid BrochureUjjval SolankiNo ratings yet

- Asbestos Flyer PDFDocument4 pagesAsbestos Flyer PDFaung moe tunNo ratings yet

- 300 Lb. Companion Flange: Wetted Surfaces Contain No More Than .025% LeadDocument2 pages300 Lb. Companion Flange: Wetted Surfaces Contain No More Than .025% LeadSiddiqui Muhammad AshfaqueNo ratings yet

- Seajet 117 Multipurpose Epoxy PrimerDocument2 pagesSeajet 117 Multipurpose Epoxy PrimerAleš NovakNo ratings yet

- What Is Drag in PhysicsDocument7 pagesWhat Is Drag in PhysicssureshNo ratings yet

- Basic Thermodynamics Video To Text Lecture Notes 06 NptelDocument30 pagesBasic Thermodynamics Video To Text Lecture Notes 06 NptelKart01100% (2)

- Erection Progress Report For CDC Erection Progress Report For CDCDocument7 pagesErection Progress Report For CDC Erection Progress Report For CDCAbdulrahman AlkilaniNo ratings yet

- Checklist Fire PDFDocument1 pageChecklist Fire PDFMadan TiwariNo ratings yet

- BALANCES MONITORING T6 As of Jan 28 2020Document137 pagesBALANCES MONITORING T6 As of Jan 28 2020Harvey Ian Pagatpatan AquinoNo ratings yet

- Onshore Pipe Systems For Hydrocarbons Transportation: Company SpecificationDocument30 pagesOnshore Pipe Systems For Hydrocarbons Transportation: Company SpecificationamerNo ratings yet

- ArreortúaDocument2 pagesArreortúaChristopel William PaneNo ratings yet

- Journal of Cleaner ProductionDocument8 pagesJournal of Cleaner ProductionTeuku Budi AuliaNo ratings yet

- Astm 197 Anse B16.3Document3 pagesAstm 197 Anse B16.3Hernan VichNo ratings yet

- 1.introduction To Foundation Engineering and Shallow FoundationDocument45 pages1.introduction To Foundation Engineering and Shallow FoundationGladys Leonor100% (1)