Professional Documents

Culture Documents

Bricklaying

Bricklaying

Uploaded by

Dewi SartikaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bricklaying

Bricklaying

Uploaded by

Dewi SartikaCopyright:

Available Formats

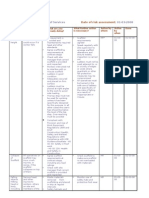

Hazard identification tool - Bricklaying

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

General planning Inadequate Task specific • Insufficient skills

training, injuries due to (competency) to complete the

consultation, inexperience, required task.

planning and inadequate • Inadequate consultation with

improvisation. consultation or relevant employees.

failure to provide • Inadequate competent

appropriate supervision.

equipment. • Planning for required

equipment not carried out.

• Improvisation using

inappropriate equipment.

Planning by Poor access to Slips, trips and • Access to work area cluttered

principal work areas. falls; abrasions, - poor housekeeping.

contractor or strains and • Area around work area

subcontractor sprains; manual cluttered with stored

handling injuries. materials and/or rubbish.

• Inadequate access for

bricklayers and their

equipment.

Depending on Insufficient Slips, trips and • Poor lighting provided to the

contract lighting. falls; walking into work face, especially in

conditions objects or basement and other enclosed

projections. areas.

• Access ways not suitably

defined or lighted.

Hazard Profile: Identification Tool for Bricklaying Page 1

Hazard identification tool - Bricklaying

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Lack of adequate Illness; breathing • Fuelled equipment operating

ventilation. difficulties – in confined areas such as

overcome by basements or below ground

fumes. car parks.

• Concrete pump or other

fuelled equipment running

continuously in the immediate

vicinity of the work area.

• No exhaust stack, scrubber

or catalytic converter fitted to

equipment.

• Constant wind blowing fumes

towards work area.

Working at height Fall from the • Inadequate strength in

near edge. edge. perimeter handrail or midrail

and fenderboard missing.

• Gaps in perimeter protection,

e.g. between screen or edge

scaffold.

• No catch scaffold provided.

Penetrations. Fall through • Penetration/s not meshed

penetration. covered, secured and

marked.

Planning by Exposure to ultra Skin cancer; • Personal protective clothing –

Bricklaying violet light, glare. sunburn, eye sunscreen 15-30+, long

Subcontractor damage. sleeved shirt, flap on hard hat

not worn.

• AS rated sunglasses not

worn.

Erecting working Manual handling. Sprains, strains • Lifting frames, planks and

platforms and fractures. other scaffolding materials.

• Passing up or receiving

scaffolding materials at

height.

• Carrying scaffolding material

up stairs.

Hazard Profile: Identification Tool for Bricklaying Page 2

Hazard identification tool - Bricklaying

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Moving bricks Manual handling. Sprains, strains • Incorrect type of trolley to lift

and blocks to and fractures. bricks packs.

work face • Poor terrain – does not suit

trolley

• Mechanical delivery on to first

floor slabs not used.

• Lifting too many bricks at one

time.

• Repetitive lifting of bricks.

• Increased weight of new

modular bricks and blocks.

• Pushing/pulling loaded brick

trolleys onto or off hoist

platform.

• Limited job rotation

opportunities.

Passing or Brick falls onto • Poor co-ordination when

throwing up tools person below. passing/throwing bricks up

and materials. onto scaffold.

• No safety helmet.

• Brick guards not in place on

scaffold.

Unstable ground Fall from scaffold • Ground not properly prepared

or incorrectly or with collapse. resulting in unsteady

constructed or Collapse of part of structure.

overloaded scaffold and • Scaffold incorrectly

scaffold. materials onto constructed, including planks

person below. too long creating unsupported

ends (trap).

• Inadequate edge protection

to working platform.

• Inadequate access onto

working platform.

• Scaffold overloaded with

bricks or loaded between

‘standard’ supports.

Hazard Profile: Identification Tool for Bricklaying Page 3

Hazard identification tool - Bricklaying

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Penetrations in Fall through • Penetration/s not meshed

slab. penetration. and covered or cover not

secured forming a ‘trap’.

Mixing mortar Cement added to Mortar splashes in • No water to work area to

and providing to mortar. eye/s. flush mortar from eye/s.

the work face • No PPE or incorrect PPE for

the required task.

Contact with Short or long term • Risk assessment not

substance health affect, e.g. undertaken.

classified as overcome by • Alternate (safer) substance

hazardous. vapours, rash, not considered.

allergy, disease. • No MSDS provided.

• No PPE or incorrect PPE for

the required task.

• Safety instructions ignored

and/or training in safe use of

the substance not provided.

• Barrier cream, or similar, not

available or not worn.

Electric mixer Electric shock, • Equipment faulty or

motor and leads. burns or damaged.

electrocution. • Extensive water use around

electrical equipment.

• Earth Leakage Switch not

installed on mains supply or

portable generator.

• Extension lead faulty.

• Extension lead not secured

above work area - lying in

water.

Moving parts of Finger/s or hand • Guard for mixer drive gear

machinery. caught in mixer missing or damaged.

drive gear. • Placing shovel into rotating

Shovel flung out of mixer drum - flung out striking

the drum. employee.

• Loose clothing caught by

moving parts of machinery.

Hazard Profile: Identification Tool for Bricklaying Page 4

Hazard identification tool - Bricklaying

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Manual Handling. Sprains, strains • Shoveling raw materials into

and fractures. mixer.

• Pushing barrow filled with

mortar.

• Use of inappropriate barrows

that cannot handle the load.

• Relocating mixer.

• Repetitious passing or

shovelling mortar up onto

scaffold.

• Limited job rotation

opportunities.

Standing on Fall from unstable • Standing on stack of bricks or

unstable stacks of stacks of bricks. blocks to pass up material.

bricks. • Brick stack collapses or

becomes unstable.

Cutting Electric cutting Electric shock, • Equipment faulty or

equipment (brick burns or damaged.

saw). electrocution. • Water saw sitting in water -

not on a wooden pallet, or

similar.

• Earth Leakage Switch not

installed on mains supply or

portable generator.

• Extension lead faulty or

damaged.

• Extension lead not secured

above work area - lying in

water.

Hazard Profile: Identification Tool for Bricklaying Page 5

Hazard identification tool - Bricklaying

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

High speed Struck by brick • Saw operator not

rotating saw piece flung out experienced.

blade. from the saw. • Saw blade damaged or

inappropriate size or type.

• Saw not adequately guarded.

• No PPE or incorrect PPE for

the required task.

• Other persons in the area not

protected from flying cut-offs.

Cutting bricks with Serious cut or • Equipment not adequately

water saw, angle other to person guarded.

grinder or trowel. cutting brick. • Angle grinder not fitted with

‘Dead Mans’switch.

• Angle grinder placed on

ground before the blade

stops turning.

• Incorrect blade/disk type, size

or fitting.

• Angle grinder blade overly

worn – disintegrates.

• Incorrect grip on brick (thumb

in the way) when whacking

with trowel.

Dust, grit or brick Grit or brick • No PPE or incorrect PPE for

splinters flung out splinter in eye/s. the required task.

by saw.

Noise. Hearing damage. • No engineering solution for

high noise level, e.g. quieter

tool.

• No temporary sound

absorption screen or barrier

to protect other persons in

the area, e.g. ply or

polystyrene.

• No PPE or incorrect PPE for

the required task.

Hazard Profile: Identification Tool for Bricklaying Page 6

Hazard identification tool - Bricklaying

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Laying Manual Handling. Sprains, strains • Repetitious stooping, twisting

and fractures. and lifting.

• Increased weight of modular

bricks, especially when lifting

them above shoulder height.

Correct working platforms to

minimise work above

shoulder height and below

knee height not used.

• Limited job rotation

opportunities.

Overhand Fall, or lean, • Loss of balance – fall against

brickwork to against wall, freshly mortared (green) wall.

external face. which gives way. • No scaffold.

• No means of preventing fall

from height.

Scaffold Partial or • Labourer inexperienced in

overloaded. complete collapse constructing working

causing a fall onto platforms.

the slab. • Planks not lapped correctly or

too long creating unsupported

ends (trap).

• Faulty plank gives way when

loaded

Overhead Hit head, face or • Services/obstructions on slab

obstructions. eye on soffit at a level where head

obstruction. contact may occur.

• No PPE or incorrect PPE for

the required task.

• Working platform too high.

Hazard Profile: Identification Tool for Bricklaying Page 7

Hazard identification tool - Bricklaying

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Fixing ties Use of explosive Concrete blows • EPT operator not

power tools (EPT). out or nail appropriately trained.

rebounds hitting • Wrong charge used in EPT

operator or causing concrete around

persons in vicinity. fixing to explode.

• EPT used on inappropriate

material – e.g. sandstone.

• Nail driven by EPT strikes

reinforcement or aggregate

and rebounds.

• Fixing too close to the edge

of a concrete column causing

side to explode outward.

• No PPE or incorrect PPE for

the required task.

• No eye or hearing protection

for operator or workers

affected nearby.

• Tool faulty.

• Tool not maintained.

• No warning signs.

Noise generated Hearing damage • No engineering solution for

by EPT. to operator or high noise level, e.g. quieter

surrounding tool.

person/s. • No temporary sound

absorption screen or barrier

to protect other persons in

the area, e.g. ply or other

suitable material.

• No PPE or incorrect PPE for

the required task.

W:\POLICYS\WPARTY\CISAC\Hazard Profiles\WordWAedits\HazProfBricklayingWA.doc

Hazard Profile: Identification Tool for Bricklaying Page 8

You might also like

- Risk Assessment For Installation of Cooling TowersDocument9 pagesRisk Assessment For Installation of Cooling TowersGirithar M Sundaram100% (2)

- C&C-EHS-F-002 HIRARC Eraction and Use of Scaffolding PDFDocument4 pagesC&C-EHS-F-002 HIRARC Eraction and Use of Scaffolding PDFNajman Hamdi100% (3)

- People Vs LopezDocument5 pagesPeople Vs LopezJosh Cabrera33% (3)

- Mobile - Scaffolds JSADocument10 pagesMobile - Scaffolds JSABojie Abogadie100% (2)

- JSA-RMC Pump ConcreteingDocument6 pagesJSA-RMC Pump ConcreteingRakeshkasarla100% (2)

- Accident Reporting ProcedureDocument2 pagesAccident Reporting ProcedurebmkallarackalNo ratings yet

- Kinesiology of Back and SpineDocument8 pagesKinesiology of Back and SpineVanessa Yvonne GurtizaNo ratings yet

- Risk Assessment Tipu-PremierDocument6 pagesRisk Assessment Tipu-PremierFahad HayatNo ratings yet

- Hazard Identification PlanDocument9 pagesHazard Identification PlanLijo JohnNo ratings yet

- FSR Poster WORKING AT HEIGHTS-1Document1 pageFSR Poster WORKING AT HEIGHTS-1sw2h2vgqzcNo ratings yet

- Hazard Analysis LulDocument21 pagesHazard Analysis LulKarl Ethan MontefalcoNo ratings yet

- Safe Work Method StatementDocument5 pagesSafe Work Method StatementShujaRehmanNo ratings yet

- Job Hazard AnalysisDocument5 pagesJob Hazard AnalysisShamel Jen FacundoNo ratings yet

- Toolbox Talk - Slips Trips & Falls - ENDocument1 pageToolbox Talk - Slips Trips & Falls - ENJomy JohnyNo ratings yet

- Working at Height Risk Assessment Mar 21Document2 pagesWorking at Height Risk Assessment Mar 21tariq1987No ratings yet

- Use of Hand ToolsDocument1 pageUse of Hand Toolsj8164322No ratings yet

- Solutions For Tree Care HazardsDocument2 pagesSolutions For Tree Care HazardsTerex14253No ratings yet

- Risk Assessment Hanging DoorsDocument11 pagesRisk Assessment Hanging DoorsMitchRappNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document2 pagesJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Night Work Risk Assessment1Document1 pageNight Work Risk Assessment1Muhammad ShafiqNo ratings yet

- C&C-EHS-F-002 HIRARC Working at Height (Tower and Monopole)Document5 pagesC&C-EHS-F-002 HIRARC Working at Height (Tower and Monopole)Najman HamdiNo ratings yet

- Lifting Operation Rev2Document29 pagesLifting Operation Rev2Chong Yun QingNo ratings yet

- Jsa For Lifting (Crane) : Sify Infinit Spaces Limited SiruseriDocument6 pagesJsa For Lifting (Crane) : Sify Infinit Spaces Limited SiruseriJISHNU EHSNo ratings yet

- Chapter 5Document49 pagesChapter 5JRyan Babiera NangkilNo ratings yet

- DOCS AND FILES-19128068-v1-DIT Min Const Safety Expectations Second Edition Aug 2022Document1 pageDOCS AND FILES-19128068-v1-DIT Min Const Safety Expectations Second Edition Aug 2022Nuragus HariyadiNo ratings yet

- Formwork Stripping FormsDocument1 pageFormwork Stripping FormspotNo ratings yet

- Job Safety Analysis FABCONDocument8 pagesJob Safety Analysis FABCONGladyNo ratings yet

- Attachemnt RA Work at HeightDocument4 pagesAttachemnt RA Work at Heightathul subashNo ratings yet

- Tata Power Central Odisha Distribution Limited Doc NoDocument7 pagesTata Power Central Odisha Distribution Limited Doc No9853318441No ratings yet

- Works On Asbestos RoofsDocument2 pagesWorks On Asbestos RoofscardyNo ratings yet

- Job Hazard Analysis: Basic Job Sequence Potential Hazards Control MeasuresDocument10 pagesJob Hazard Analysis: Basic Job Sequence Potential Hazards Control MeasuresM M PRADHANNo ratings yet

- Risk AssessmentDocument20 pagesRisk AssessmentAbuAbdullaMohsenNo ratings yet

- RISSK ASSESSMENT - Tapping and Connection of LPG Vapor LineDocument4 pagesRISSK ASSESSMENT - Tapping and Connection of LPG Vapor LineBrown's P LikoNo ratings yet

- Demolition 2016 VersionDocument3 pagesDemolition 2016 VersionArun Koshy AlexanderNo ratings yet

- Use of Mobile Towers 05Document1 pageUse of Mobile Towers 05cardyNo ratings yet

- Job Hazard Analysis DemolishDocument4 pagesJob Hazard Analysis Demolishyajid bustomiNo ratings yet

- Bonfire RADocument8 pagesBonfire RARichard PooleNo ratings yet

- Visitor Safety BrochureDocument2 pagesVisitor Safety BrochureseongqiNo ratings yet

- JHA Concrete Demolition HammerDocument2 pagesJHA Concrete Demolition HammerManoj TiwariNo ratings yet

- Scaffolding Erection &dismanlting JSADocument7 pagesScaffolding Erection &dismanlting JSAShahid Bhatti100% (1)

- Excavations JSA Final 2015Document5 pagesExcavations JSA Final 2015jithin shankarNo ratings yet

- Jsa For ScaffoldingDocument4 pagesJsa For ScaffoldingSampath Kumar KandasamyNo ratings yet

- Confined Space G3Document6 pagesConfined Space G3Vench Benedict LeañoNo ratings yet

- What Can Harm Jha FormworksDocument16 pagesWhat Can Harm Jha Formworksroland magoNo ratings yet

- Job Safety Analysis (Jsa)Document2 pagesJob Safety Analysis (Jsa)Ben Hammadi RymNo ratings yet

- JSA For Preparation of Roads and Asphalt WorkDocument6 pagesJSA For Preparation of Roads and Asphalt Workbaseet gazaliNo ratings yet

- Housekeeping: Control Measures/SafeguardsDocument2 pagesHousekeeping: Control Measures/SafeguardsShamel Jen FacundoNo ratings yet

- Working Heights Fall Arrest Systems PDFDocument4 pagesWorking Heights Fall Arrest Systems PDFPraful E. PawarNo ratings yet

- Assessment For CCTV System Testing & CommissioningDocument5 pagesAssessment For CCTV System Testing & CommissioningAnonymousNo ratings yet

- 9 - Risk Assessment - PaintingDocument8 pages9 - Risk Assessment - Paintingmahmoud nadaNo ratings yet

- Working at HeightDocument3 pagesWorking at HeightLawrenceNo ratings yet

- Toolbox Manual Material HandlingDocument2 pagesToolbox Manual Material Handlingkaderbouira0No ratings yet

- C&C-EHS-F-002 HIRARC Working at Height (Roof Top)Document4 pagesC&C-EHS-F-002 HIRARC Working at Height (Roof Top)Najman HamdiNo ratings yet

- Job Description: Area Owner: JSA Control Number: Prepared By: Department/Location: Reviewed By: Date/Time: Approved By: Supervised byDocument1 pageJob Description: Area Owner: JSA Control Number: Prepared By: Department/Location: Reviewed By: Date/Time: Approved By: Supervised bybadrul hisyamNo ratings yet

- General Guidance in Inclement Wether Conditions-EngDocument12 pagesGeneral Guidance in Inclement Wether Conditions-EngkarvizNo ratings yet

- Risk Assessment For Hand RenderingDocument5 pagesRisk Assessment For Hand RenderingSyed AmjadNo ratings yet

- Risk AssesmentDocument3 pagesRisk Assesmentmrogers72100% (4)

- JSA For Formwork (Shuttering)Document1 pageJSA For Formwork (Shuttering)HSE fahadNo ratings yet

- JSA For ExcavationsDocument3 pagesJSA For ExcavationsHSE fahadNo ratings yet

- Use of 110v Tools B 05Document1 pageUse of 110v Tools B 05cardyNo ratings yet

- JSA For Concrete PouringDocument1 pageJSA For Concrete PouringHSE fahadNo ratings yet

- Pelvic Trauma Final 210409Document8 pagesPelvic Trauma Final 210409Dwi ApriliziaNo ratings yet

- Artigo - JoelhoDocument4 pagesArtigo - JoelhoizabellegoesNo ratings yet

- PDF Anatomy of The Voice An Illustrated Guide For Singers Vocal Coaches and Speech Therapists Theodore Dimon Ebook Full ChapterDocument63 pagesPDF Anatomy of The Voice An Illustrated Guide For Singers Vocal Coaches and Speech Therapists Theodore Dimon Ebook Full Chapterkaren.johnson335100% (4)

- Camargo 2019Document9 pagesCamargo 2019Jefferson James Dos SantosNo ratings yet

- Job Hazard Analysis: Basic Job Sequence Potential Hazards Control MeasuresDocument10 pagesJob Hazard Analysis: Basic Job Sequence Potential Hazards Control MeasuresM M PRADHANNo ratings yet

- Psoas StretchesDocument9 pagesPsoas Stretcheswalterego58No ratings yet

- Simplifying Anatomy Printable Worksheet PDFDocument21 pagesSimplifying Anatomy Printable Worksheet PDFAarushi NairNo ratings yet

- Nervous System Head InjuryDocument11 pagesNervous System Head InjurydimlyNo ratings yet

- ProctopexyDocument6 pagesProctopexydrnareshkumar3281No ratings yet

- 165 Assignment 2Document3 pages165 Assignment 2anon-796869No ratings yet

- Flexibility ReflectionDocument1 pageFlexibility Reflectionapi-299321554100% (1)

- Research Journal of Pharmaceutical, Biological and Chemical SciencesDocument8 pagesResearch Journal of Pharmaceutical, Biological and Chemical SciencesSepti TjandraNo ratings yet

- Inion Freedom Brochure v2 12-2014Document11 pagesInion Freedom Brochure v2 12-2014Ivo van de KampNo ratings yet

- Journal of Biomechanics: Brooke A. Slavens, Neha Bhagchandani, Mei Wang, Peter A. Smith, Gerald F. HarrisDocument6 pagesJournal of Biomechanics: Brooke A. Slavens, Neha Bhagchandani, Mei Wang, Peter A. Smith, Gerald F. HarriscahyoNo ratings yet

- Approaches To Therapeutic Exercise and Activity For NeurologicalDocument69 pagesApproaches To Therapeutic Exercise and Activity For NeurologicalPedro M. BorgesNo ratings yet

- Cut Tex PRODocument3 pagesCut Tex PROLaurentius OktavianusNo ratings yet

- Lama v. BorrasDocument2 pagesLama v. BorrasMadison MonzonNo ratings yet

- $101 Million Award For Child With MMR Vaccine InjuryDocument1 page$101 Million Award For Child With MMR Vaccine InjuryFrank ReitemeyerNo ratings yet

- Label The Brain Anatomy DiagramDocument2 pagesLabel The Brain Anatomy DiagramEmMa DHieyahNo ratings yet

- English Test - Focus On Language: ORD OrmationDocument5 pagesEnglish Test - Focus On Language: ORD OrmationblueperlaNo ratings yet

- LectureDocument26 pagesLectureAyesha HashmatNo ratings yet

- Stairville Outdoor Stage PAR 12 × 3W TriDocument48 pagesStairville Outdoor Stage PAR 12 × 3W TrigaliNo ratings yet

- Original PDF Esska Instructional Course Lecture Book Glasgow 2018 PDFDocument41 pagesOriginal PDF Esska Instructional Course Lecture Book Glasgow 2018 PDFpatricia.morrison594100% (39)

- Radiographic Positioning and Special Procedure1Document38 pagesRadiographic Positioning and Special Procedure1renred1225No ratings yet

- Prolonged Labour: Hassan, MDDocument17 pagesProlonged Labour: Hassan, MDJessa BorreNo ratings yet

- The Vasper Report by Erica McLainDocument3 pagesThe Vasper Report by Erica McLainJacob PlummerNo ratings yet

- Selected Instructional Course LecturesDocument27 pagesSelected Instructional Course LecturesAhmad ShakirNo ratings yet