Professional Documents

Culture Documents

Globe Rev. A SHT 2

Globe Rev. A SHT 2

Uploaded by

Agus SupriadiCopyright:

Available Formats

You might also like

- OB MBA Final Summer 22 OB MBA Final Summer 22: Test ContentDocument10 pagesOB MBA Final Summer 22 OB MBA Final Summer 22: Test ContentDUAA ALJEFFRINo ratings yet

- Flexible Hose DatasheetDocument7 pagesFlexible Hose DatasheetchintanNo ratings yet

- Toothbrush AssignmentDocument4 pagesToothbrush Assignmentgeorgil jeemonNo ratings yet

- Globe Rev. A SHT 1Document1 pageGlobe Rev. A SHT 1Agus SupriadiNo ratings yet

- Jis 10k Flanged End Cast Iron Gate Valve - 5inch To 6inchDocument4 pagesJis 10k Flanged End Cast Iron Gate Valve - 5inch To 6inchctrijayaperkasaNo ratings yet

- Tstb-Ifp-40-004-A4 - 0 Ifp For Globe Valve Rev. 0Document8 pagesTstb-Ifp-40-004-A4 - 0 Ifp For Globe Valve Rev. 0agus supriadiNo ratings yet

- 1664189682389-2ba010110 Cced25030Document1 page1664189682389-2ba010110 Cced25030ylc956867No ratings yet

- Material Receiving Inspection SENDING ULN3 TO LPGU3Document30 pagesMaterial Receiving Inspection SENDING ULN3 TO LPGU3ReduddboyNo ratings yet

- Section9 - Double Block and Bleed ValveDocument6 pagesSection9 - Double Block and Bleed ValveFarras Surya NugrahaNo ratings yet

- D 1 1Document956 pagesD 1 1karthi82887100% (1)

- Data Sheet For Absorber Reflux Drum (GTPT-V-250-003)Document4 pagesData Sheet For Absorber Reflux Drum (GTPT-V-250-003)Mohamed hamza souissiNo ratings yet

- Check Valve DescriptionDocument1 pageCheck Valve DescriptionmoodydoodyNo ratings yet

- Tstb-Ifp-40-003-A4_0 Ifp for Check Valve Rev. 0Document9 pagesTstb-Ifp-40-003-A4_0 Ifp for Check Valve Rev. 0agus supriadiNo ratings yet

- C2C-1254-NSD-612-R6 Manual Valve With Limit SwitchDocument13 pagesC2C-1254-NSD-612-R6 Manual Valve With Limit Switchpraveen kumar vengadasamyNo ratings yet

- Ball Valves Jis10k Flanged End 0Document5 pagesBall Valves Jis10k Flanged End 0Royal BoardNo ratings yet

- f13 Rfs Ansi150 Cast Steel Flange End Ball Valves IdDocument5 pagesf13 Rfs Ansi150 Cast Steel Flange End Ball Valves IdsimanjuntakagusboyNo ratings yet

- CORROSION COUPON AT AR 701 Project Description ADocument2 pagesCORROSION COUPON AT AR 701 Project Description AKian GancangNo ratings yet

- Ficha Tecnica Bomba OH2Document1 pageFicha Tecnica Bomba OH2VICTOR ALFONSO GARCIA LOPEZNo ratings yet

- 5 PDFDocument28 pages5 PDFJunaidNo ratings yet

- BK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentDocument67 pagesBK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentPanneer SelvamNo ratings yet

- Data Sheet: Document NoDocument3 pagesData Sheet: Document Nobagus handokoNo ratings yet

- 11d Pms Rev00a Ongc 27jul15Document3 pages11d Pms Rev00a Ongc 27jul15abhiNo ratings yet

- Ed0754a 50a10 Ab4dDocument3 pagesEd0754a 50a10 Ab4dRocco SozeNo ratings yet

- Level Gauge-Bicolor DrumDocument4 pagesLevel Gauge-Bicolor DrumJKKNo ratings yet

- HD 282 Butterfly Valves R02 17Document4 pagesHD 282 Butterfly Valves R02 17Satish IndiaNo ratings yet

- Datasheet For Ball ValveDocument1 pageDatasheet For Ball ValvevalveNo ratings yet

- Ca 3241Document1 pageCa 3241Tien LamNo ratings yet

- Especificacion B2AS1Document9 pagesEspecificacion B2AS1Jorge TagleNo ratings yet

- FU01-S01-02-005-01 Pipe Spec CS22Document8 pagesFU01-S01-02-005-01 Pipe Spec CS22Javed NasirNo ratings yet

- Elbow PDFDocument9 pagesElbow PDFPetropipe AcademyNo ratings yet

- Datasheet & Specification For Deluge ValveDocument2 pagesDatasheet & Specification For Deluge ValvechintanNo ratings yet

- WAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1Document5 pagesWAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1tope odumboniNo ratings yet

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- Anexo Fire PumpsDocument37 pagesAnexo Fire PumpsTommy salimNo ratings yet

- FU01-S01-02-003-01 Pipe Spec CS12Document8 pagesFU01-S01-02-003-01 Pipe Spec CS12Javed NasirNo ratings yet

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- DATA SHEET MTO # 1 (ITEM # 13) Data Sheet-8 Inch To 24 Inch Size-Reduced Port-Double Block Bleed-Gear OperatedDocument1 pageDATA SHEET MTO # 1 (ITEM # 13) Data Sheet-8 Inch To 24 Inch Size-Reduced Port-Double Block Bleed-Gear OperatedQualival EgyptNo ratings yet

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- Datasheet For Ball Valve123Document1 pageDatasheet For Ball Valve123valveNo ratings yet

- Pipe Material Specs (MCP)Document106 pagesPipe Material Specs (MCP)BoulHich BoulHich100% (1)

- Expansion Bellow SpecificationDocument1 pageExpansion Bellow SpecificationASHWINI BHOSALENo ratings yet

- 3-Way Ball Valve Reference List FormatDocument1 page3-Way Ball Valve Reference List FormatJaydeep PanchalNo ratings yet

- Liquip TrapDocument1 pageLiquip TrapKhánh TrầnNo ratings yet

- Flexible HoseDocument1 pageFlexible HoseKhánh TrầnNo ratings yet

- Specification Sheet: Customer Name PO Number Vendor Name Vendor Reference Document Title Revision NoDocument13 pagesSpecification Sheet: Customer Name PO Number Vendor Name Vendor Reference Document Title Revision NoAmit SurtiNo ratings yet

- Knoc026 G07 0002 CDocument3 pagesKnoc026 G07 0002 CHuyen Trang LeNo ratings yet

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

- 150 # ANSI Piping DataDocument21 pages150 # ANSI Piping DataMekar MeinaNo ratings yet

- Design Calculation-Spacer SpoolDocument8 pagesDesign Calculation-Spacer SpoolHasmukh Dave100% (1)

- 3.EBS1-EPFA76-EBPI-DSEQ-1001-D02 Datasheet For Piping ValvesDocument5 pages3.EBS1-EPFA76-EBPI-DSEQ-1001-D02 Datasheet For Piping ValvesRedhaa .kNo ratings yet

- Piping Materials Specification Class D15KdDocument3 pagesPiping Materials Specification Class D15KdQeyratNo ratings yet

- Butterfly Valve GRWDocument8 pagesButterfly Valve GRWilkinNo ratings yet

- Specification Cum General Arrangement Drawing Model No.: Srg-1 Reflex Level GaugeDocument1 pageSpecification Cum General Arrangement Drawing Model No.: Srg-1 Reflex Level GaugeHemant NimaseNo ratings yet

- Material - Specification Hyundai KC02Document3 pagesMaterial - Specification Hyundai KC02DilermandoNo ratings yet

- Data Sheet UbsvDocument6 pagesData Sheet UbsvMeet JaniNo ratings yet

- Ss Globe Valve 150# - 1Document1 pageSs Globe Valve 150# - 1Vijay GaikwadNo ratings yet

- Virgo ValvesDocument26 pagesVirgo ValvesslavaNo ratings yet

- EHK-IKPP-IS-DTS-005 Datasheet For Pressure Safety Valve Rev 2Document7 pagesEHK-IKPP-IS-DTS-005 Datasheet For Pressure Safety Valve Rev 2nathaNo ratings yet

- N2 - Rev ADocument13 pagesN2 - Rev AChirag ShahNo ratings yet

- NDT Request Form - 19Document3 pagesNDT Request Form - 19Firas AlbaweiNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Soil StiffnessDocument1 pageSoil StiffnessAgus SupriadiNo ratings yet

- SPECIFICATION FOR PIPING FABRICATION, WELDING, INSPECTION AND TESTING Rev. ADocument15 pagesSPECIFICATION FOR PIPING FABRICATION, WELDING, INSPECTION AND TESTING Rev. AAgus SupriadiNo ratings yet

- Globe Rev. A SHT 1Document1 pageGlobe Rev. A SHT 1Agus SupriadiNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. ADocument6 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. AAgus SupriadiNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. A CoverDocument5 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. A CoverAgus SupriadiNo ratings yet

- Specification For Piping Thermal InsulationDocument14 pagesSpecification For Piping Thermal InsulationAgus SupriadiNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. ADocument19 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. AAgus SupriadiNo ratings yet

- Specification For Piping MaterialDocument9 pagesSpecification For Piping MaterialAgus SupriadiNo ratings yet

- General Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Document20 pagesGeneral Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Agus SupriadiNo ratings yet

- 802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A of Civil Construction and Infrastructure Works, Stage 2Document11 pages802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A of Civil Construction and Infrastructure Works, Stage 2Agus SupriadiNo ratings yet

- 802-CBN-00-PR-CE-LIFTING PROCEDURE-049-B of Civil Construction and Infrastructure Works, Stage 2Document12 pages802-CBN-00-PR-CE-LIFTING PROCEDURE-049-B of Civil Construction and Infrastructure Works, Stage 2Agus SupriadiNo ratings yet

- Estimasi Harga Material Perpipaan Nike Project No Quantity Size (Inch)Document4 pagesEstimasi Harga Material Perpipaan Nike Project No Quantity Size (Inch)Agus SupriadiNo ratings yet

- UntitledDocument3 pagesUntitledAgus SupriadiNo ratings yet

- 6-HG-1000-G (Sheet 1 - 11)Document11 pages6-HG-1000-G (Sheet 1 - 11)Agus SupriadiNo ratings yet

- Attachment 1 Pipe Bend ModellingDocument1 pageAttachment 1 Pipe Bend ModellingAgus SupriadiNo ratings yet

- Exh B2Document163 pagesExh B2Agus SupriadiNo ratings yet

- ISO 9001 Auditing Practices Group Guidance On:: The Need For A 2 Stage Approach To AuditingDocument2 pagesISO 9001 Auditing Practices Group Guidance On:: The Need For A 2 Stage Approach To AuditingAgus SupriadiNo ratings yet

- Contractor'S Reply To Company'S Comments: (Ref. No.) SubjectDocument1 pageContractor'S Reply To Company'S Comments: (Ref. No.) SubjectAgus SupriadiNo ratings yet

- GRSM 00 Cons PL 015 Rev.2 Pipeline Tie in ProcedureDocument7 pagesGRSM 00 Cons PL 015 Rev.2 Pipeline Tie in ProcedureAgus SupriadiNo ratings yet

- Sarulla Geotermal Power ProjectDocument1 pageSarulla Geotermal Power ProjectAgus SupriadiNo ratings yet

- Branch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangDocument6 pagesBranch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangAgus SupriadiNo ratings yet

- Branch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangDocument6 pagesBranch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangAgus SupriadiNo ratings yet

- Load Hot TapDocument1 pageLoad Hot TapAgus SupriadiNo ratings yet

- Manual Blender 2.78 (1683 Páginas)Document2 pagesManual Blender 2.78 (1683 Páginas)Jose F CDNo ratings yet

- Frequency Response Analysis and Short-Circuit Impedance Measurement in Detection of Winding Deformation Within Power TransformersDocument8 pagesFrequency Response Analysis and Short-Circuit Impedance Measurement in Detection of Winding Deformation Within Power TransformersRoyer Guerra huamanNo ratings yet

- Full Download Auditing The Art and Science of Assurance Engagements Canadian 13th Edition Arens Solutions ManualDocument35 pagesFull Download Auditing The Art and Science of Assurance Engagements Canadian 13th Edition Arens Solutions Manualpickersgillvandapro100% (36)

- Tps 54312Document27 pagesTps 54312Dino NecciNo ratings yet

- API 614 Comments Mac-Su-3563-EDocument17 pagesAPI 614 Comments Mac-Su-3563-EJESUSNo ratings yet

- AirCheck Detail Report - PK8AP02Document100 pagesAirCheck Detail Report - PK8AP02Trion Ragil NugrohoNo ratings yet

- DatasheetsDocument2 pagesDatasheetsAndrewNo ratings yet

- Fortin Cali Suite v2.0.0Document19 pagesFortin Cali Suite v2.0.0Kresimir HruskovecNo ratings yet

- Furun Catalouge PDFDocument9 pagesFurun Catalouge PDFdeboline mitraNo ratings yet

- Final Date Sheet For Internal Class Test May 2023Document13 pagesFinal Date Sheet For Internal Class Test May 2023Manvi AroraNo ratings yet

- Sri Krishna Arts and Science Computer Technology: Course Coordinator Dr. V. S. Anita Sofia Prof. & HeadDocument78 pagesSri Krishna Arts and Science Computer Technology: Course Coordinator Dr. V. S. Anita Sofia Prof. & HeadAnita Sofia VNo ratings yet

- Faculty of Management and Tecnology Harishchandra Post Graduate CollegeDocument16 pagesFaculty of Management and Tecnology Harishchandra Post Graduate Collegeaniket chauhanNo ratings yet

- COA Chapter 4Document33 pagesCOA Chapter 4dagneNo ratings yet

- Datasheet4u (4) lf411Document4 pagesDatasheet4u (4) lf411JaviNo ratings yet

- Groupes - S5 Ling 2016 12 28Document47 pagesGroupes - S5 Ling 2016 12 28Kabe LabelloNo ratings yet

- PARTIIOUTPUTDEVICEDocument333 pagesPARTIIOUTPUTDEVICEFiras BEN HMIDANo ratings yet

- Undergraduate Students Adoption To App Based Stock Market InvestmentDocument18 pagesUndergraduate Students Adoption To App Based Stock Market InvestmentKunal MishraNo ratings yet

- EwrweDocument54 pagesEwrweyiuloi997023No ratings yet

- Bayesian Estimation Example Using Pymc: Scipy 2010 Lightning TalkDocument12 pagesBayesian Estimation Example Using Pymc: Scipy 2010 Lightning TalkArmandoNo ratings yet

- Philips Projection Catalogue 2021-22Document15 pagesPhilips Projection Catalogue 2021-22James StanleyNo ratings yet

- Ford Everest 2018 ZADocument9 pagesFord Everest 2018 ZAbsinghbeNo ratings yet

- Iwt PracticalDocument18 pagesIwt Practical[04] - Abrar ShahNo ratings yet

- ORGANIZATIONAL CULTURE Organizational Culture and Leadership, 3rd EditionDocument458 pagesORGANIZATIONAL CULTURE Organizational Culture and Leadership, 3rd Editionrisda islamiyah100% (1)

- Tutorial Manual 2021-22 - Sem-III - MOS - MITSOEDocument97 pagesTutorial Manual 2021-22 - Sem-III - MOS - MITSOEJeetender MishraNo ratings yet

- Revision DCP Class XIIDocument11 pagesRevision DCP Class XIIRudra Narayan MishraNo ratings yet

- Flow Control ValveDocument5 pagesFlow Control Valvezakaria100% (1)

- 41 Comp Lab LPoly J47Document23 pages41 Comp Lab LPoly J47Amel ElfirjaniNo ratings yet

- Introduction of InheritDocument2 pagesIntroduction of InheritNugroho BagusNo ratings yet

Globe Rev. A SHT 2

Globe Rev. A SHT 2

Uploaded by

Agus SupriadiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Globe Rev. A SHT 2

Globe Rev. A SHT 2

Uploaded by

Agus SupriadiCopyright:

Available Formats

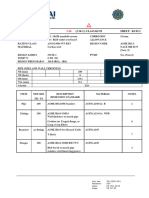

Client : Contractor :

DED EXPANSION NICKEL HEAP LEACH 5,000 T/Y

Doc. No

DATA SHEET FOR GLOBE VALVE Page Rev.

BMR-PIP-DTS-ST-0001

2 of 2 A

LINE CLASS 5K - 20K

1 Valve Type : GLOBE VALVE PARTS DESCRIPTION AND MATERIAL LIST :

2 JIS Class : 5K - 20K 1 Body : ASTM A216-WCB

3 Size Range : 2" - 24" 2 Bonnet : ASTM A216-WCB

4 Material : CARBON STEEL 3 Stem : A182 F6

5 Material Class/Line Class : LINE CLASS 5K - 20K 4 Disc : A216 WCB + 13% Cr

5 Seat : A105 + SteLlite

6 Bonnet Bolt : A193-B7

7 Bonnet Nut : A194-2H

VALVE DESIGN : 8 Handwheel : MANUFACTURER STANDARD

1 Design Code : JIS B2071 & B2081 9 Gland : A2176 40

2 Pressure-Temp. Rating : JIS B2071 & B2081 10 Gasket : SS304 + GRAPHITE

3 End Connection : RF x RF AS PER JIS B2002

4 Face to Face Dimension : JIS B2002

5 Body Configuration : BOLTED BONNET, OS&Y, RISING STEM

6 Disc Type : CONICAL PLUG

7 Bore Type : FULL

Valve Operation (Note 6)

8 : HANDWHEEL / GEAR OPERATION

9 Service : ACID, FIRE WATER, STEAM, GASES, OIL, WATER, SEA WATER

10 Fire Test : MANUFACTURER STANDARD

TECHNICAL DELIVERY REQUIREMENTS :

1 Inspection and Testing : JIS B2071 & B2081

2 Visual Inspection : JIS B2071 & B2081

3 Marking : RF x RF AS PER JIS B2002

4 Documentation : JIS B2002

: MILL CERTIFICATE

: CERTIFICATE OF COMPLIANCE

: PRESSURE TEST REPORT

5 Certification : BS EN 10204 3.1 / 3.2

6 Painting : REFER TO DOC. BMR-QAC-PRC-ST-0002

PAINTING PROCEDURE

NOTES :

1 ALL VALVES SHALL BE SUPPLIED IN ACCORDANCE WITH THE APPLICABLE ASME CODES & STANDARD STATED IN THIS DOCUMENT

2 IN ADDITION TO THE NAME PLATES, EACH VALVE SHALL BE SUPPLIED WITH 316SS VALVE TAG STAMP SECURELY FIXED TO THE VALVE WITH 316SS WIRE

3 TEST DURATION AND LEAKAGE RATES SHALL BE IN ACCORDANCE WITH JIS B2003

4 GASKET / PACKING SHALL BE SUITABLE FOR THE SERVICE AND DESIGN CONDITIONS AS STATED ABOVE

5 TAGGING VALVE NUMBER REFER TO P&ID

6 MANUAL HANDWHEEL USED FOR SIZE 2" - 6 " AND GEAR OPEARTION USED 8" ABOVE

7 IF THERE ARE DIFFERENCES IN MATERIAL SPECIFICATIONSOF PARTS, VENDORS MUST ENSURE THE QUALITY OF THE PARTS MUST BE EQUIVALENT OR ABOVE

8 SEE APPENDIX 1 FOR TOP COAT & APPENDIX 2 FOR PAINTING SYSTEM (RECOMEND USING SP2)

9 ALL OTHER ITEMS NOT MENTIONED IN THE MATERIAL LIST ABOVE, AS PER MANUFACTURING STANDARDS

You might also like

- OB MBA Final Summer 22 OB MBA Final Summer 22: Test ContentDocument10 pagesOB MBA Final Summer 22 OB MBA Final Summer 22: Test ContentDUAA ALJEFFRINo ratings yet

- Flexible Hose DatasheetDocument7 pagesFlexible Hose DatasheetchintanNo ratings yet

- Toothbrush AssignmentDocument4 pagesToothbrush Assignmentgeorgil jeemonNo ratings yet

- Globe Rev. A SHT 1Document1 pageGlobe Rev. A SHT 1Agus SupriadiNo ratings yet

- Jis 10k Flanged End Cast Iron Gate Valve - 5inch To 6inchDocument4 pagesJis 10k Flanged End Cast Iron Gate Valve - 5inch To 6inchctrijayaperkasaNo ratings yet

- Tstb-Ifp-40-004-A4 - 0 Ifp For Globe Valve Rev. 0Document8 pagesTstb-Ifp-40-004-A4 - 0 Ifp For Globe Valve Rev. 0agus supriadiNo ratings yet

- 1664189682389-2ba010110 Cced25030Document1 page1664189682389-2ba010110 Cced25030ylc956867No ratings yet

- Material Receiving Inspection SENDING ULN3 TO LPGU3Document30 pagesMaterial Receiving Inspection SENDING ULN3 TO LPGU3ReduddboyNo ratings yet

- Section9 - Double Block and Bleed ValveDocument6 pagesSection9 - Double Block and Bleed ValveFarras Surya NugrahaNo ratings yet

- D 1 1Document956 pagesD 1 1karthi82887100% (1)

- Data Sheet For Absorber Reflux Drum (GTPT-V-250-003)Document4 pagesData Sheet For Absorber Reflux Drum (GTPT-V-250-003)Mohamed hamza souissiNo ratings yet

- Check Valve DescriptionDocument1 pageCheck Valve DescriptionmoodydoodyNo ratings yet

- Tstb-Ifp-40-003-A4_0 Ifp for Check Valve Rev. 0Document9 pagesTstb-Ifp-40-003-A4_0 Ifp for Check Valve Rev. 0agus supriadiNo ratings yet

- C2C-1254-NSD-612-R6 Manual Valve With Limit SwitchDocument13 pagesC2C-1254-NSD-612-R6 Manual Valve With Limit Switchpraveen kumar vengadasamyNo ratings yet

- Ball Valves Jis10k Flanged End 0Document5 pagesBall Valves Jis10k Flanged End 0Royal BoardNo ratings yet

- f13 Rfs Ansi150 Cast Steel Flange End Ball Valves IdDocument5 pagesf13 Rfs Ansi150 Cast Steel Flange End Ball Valves IdsimanjuntakagusboyNo ratings yet

- CORROSION COUPON AT AR 701 Project Description ADocument2 pagesCORROSION COUPON AT AR 701 Project Description AKian GancangNo ratings yet

- Ficha Tecnica Bomba OH2Document1 pageFicha Tecnica Bomba OH2VICTOR ALFONSO GARCIA LOPEZNo ratings yet

- 5 PDFDocument28 pages5 PDFJunaidNo ratings yet

- BK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentDocument67 pagesBK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentPanneer SelvamNo ratings yet

- Data Sheet: Document NoDocument3 pagesData Sheet: Document Nobagus handokoNo ratings yet

- 11d Pms Rev00a Ongc 27jul15Document3 pages11d Pms Rev00a Ongc 27jul15abhiNo ratings yet

- Ed0754a 50a10 Ab4dDocument3 pagesEd0754a 50a10 Ab4dRocco SozeNo ratings yet

- Level Gauge-Bicolor DrumDocument4 pagesLevel Gauge-Bicolor DrumJKKNo ratings yet

- HD 282 Butterfly Valves R02 17Document4 pagesHD 282 Butterfly Valves R02 17Satish IndiaNo ratings yet

- Datasheet For Ball ValveDocument1 pageDatasheet For Ball ValvevalveNo ratings yet

- Ca 3241Document1 pageCa 3241Tien LamNo ratings yet

- Especificacion B2AS1Document9 pagesEspecificacion B2AS1Jorge TagleNo ratings yet

- FU01-S01-02-005-01 Pipe Spec CS22Document8 pagesFU01-S01-02-005-01 Pipe Spec CS22Javed NasirNo ratings yet

- Elbow PDFDocument9 pagesElbow PDFPetropipe AcademyNo ratings yet

- Datasheet & Specification For Deluge ValveDocument2 pagesDatasheet & Specification For Deluge ValvechintanNo ratings yet

- WAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1Document5 pagesWAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1tope odumboniNo ratings yet

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- Anexo Fire PumpsDocument37 pagesAnexo Fire PumpsTommy salimNo ratings yet

- FU01-S01-02-003-01 Pipe Spec CS12Document8 pagesFU01-S01-02-003-01 Pipe Spec CS12Javed NasirNo ratings yet

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- DATA SHEET MTO # 1 (ITEM # 13) Data Sheet-8 Inch To 24 Inch Size-Reduced Port-Double Block Bleed-Gear OperatedDocument1 pageDATA SHEET MTO # 1 (ITEM # 13) Data Sheet-8 Inch To 24 Inch Size-Reduced Port-Double Block Bleed-Gear OperatedQualival EgyptNo ratings yet

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- Datasheet For Ball Valve123Document1 pageDatasheet For Ball Valve123valveNo ratings yet

- Pipe Material Specs (MCP)Document106 pagesPipe Material Specs (MCP)BoulHich BoulHich100% (1)

- Expansion Bellow SpecificationDocument1 pageExpansion Bellow SpecificationASHWINI BHOSALENo ratings yet

- 3-Way Ball Valve Reference List FormatDocument1 page3-Way Ball Valve Reference List FormatJaydeep PanchalNo ratings yet

- Liquip TrapDocument1 pageLiquip TrapKhánh TrầnNo ratings yet

- Flexible HoseDocument1 pageFlexible HoseKhánh TrầnNo ratings yet

- Specification Sheet: Customer Name PO Number Vendor Name Vendor Reference Document Title Revision NoDocument13 pagesSpecification Sheet: Customer Name PO Number Vendor Name Vendor Reference Document Title Revision NoAmit SurtiNo ratings yet

- Knoc026 G07 0002 CDocument3 pagesKnoc026 G07 0002 CHuyen Trang LeNo ratings yet

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

- 150 # ANSI Piping DataDocument21 pages150 # ANSI Piping DataMekar MeinaNo ratings yet

- Design Calculation-Spacer SpoolDocument8 pagesDesign Calculation-Spacer SpoolHasmukh Dave100% (1)

- 3.EBS1-EPFA76-EBPI-DSEQ-1001-D02 Datasheet For Piping ValvesDocument5 pages3.EBS1-EPFA76-EBPI-DSEQ-1001-D02 Datasheet For Piping ValvesRedhaa .kNo ratings yet

- Piping Materials Specification Class D15KdDocument3 pagesPiping Materials Specification Class D15KdQeyratNo ratings yet

- Butterfly Valve GRWDocument8 pagesButterfly Valve GRWilkinNo ratings yet

- Specification Cum General Arrangement Drawing Model No.: Srg-1 Reflex Level GaugeDocument1 pageSpecification Cum General Arrangement Drawing Model No.: Srg-1 Reflex Level GaugeHemant NimaseNo ratings yet

- Material - Specification Hyundai KC02Document3 pagesMaterial - Specification Hyundai KC02DilermandoNo ratings yet

- Data Sheet UbsvDocument6 pagesData Sheet UbsvMeet JaniNo ratings yet

- Ss Globe Valve 150# - 1Document1 pageSs Globe Valve 150# - 1Vijay GaikwadNo ratings yet

- Virgo ValvesDocument26 pagesVirgo ValvesslavaNo ratings yet

- EHK-IKPP-IS-DTS-005 Datasheet For Pressure Safety Valve Rev 2Document7 pagesEHK-IKPP-IS-DTS-005 Datasheet For Pressure Safety Valve Rev 2nathaNo ratings yet

- N2 - Rev ADocument13 pagesN2 - Rev AChirag ShahNo ratings yet

- NDT Request Form - 19Document3 pagesNDT Request Form - 19Firas AlbaweiNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Soil StiffnessDocument1 pageSoil StiffnessAgus SupriadiNo ratings yet

- SPECIFICATION FOR PIPING FABRICATION, WELDING, INSPECTION AND TESTING Rev. ADocument15 pagesSPECIFICATION FOR PIPING FABRICATION, WELDING, INSPECTION AND TESTING Rev. AAgus SupriadiNo ratings yet

- Globe Rev. A SHT 1Document1 pageGlobe Rev. A SHT 1Agus SupriadiNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. ADocument6 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. AAgus SupriadiNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. A CoverDocument5 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. A CoverAgus SupriadiNo ratings yet

- Specification For Piping Thermal InsulationDocument14 pagesSpecification For Piping Thermal InsulationAgus SupriadiNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. ADocument19 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. AAgus SupriadiNo ratings yet

- Specification For Piping MaterialDocument9 pagesSpecification For Piping MaterialAgus SupriadiNo ratings yet

- General Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Document20 pagesGeneral Piping Design: Document No. Rev.: A BMR-PIP-DBS-ST-0001 Page 1 of 20Agus SupriadiNo ratings yet

- 802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A of Civil Construction and Infrastructure Works, Stage 2Document11 pages802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A of Civil Construction and Infrastructure Works, Stage 2Agus SupriadiNo ratings yet

- 802-CBN-00-PR-CE-LIFTING PROCEDURE-049-B of Civil Construction and Infrastructure Works, Stage 2Document12 pages802-CBN-00-PR-CE-LIFTING PROCEDURE-049-B of Civil Construction and Infrastructure Works, Stage 2Agus SupriadiNo ratings yet

- Estimasi Harga Material Perpipaan Nike Project No Quantity Size (Inch)Document4 pagesEstimasi Harga Material Perpipaan Nike Project No Quantity Size (Inch)Agus SupriadiNo ratings yet

- UntitledDocument3 pagesUntitledAgus SupriadiNo ratings yet

- 6-HG-1000-G (Sheet 1 - 11)Document11 pages6-HG-1000-G (Sheet 1 - 11)Agus SupriadiNo ratings yet

- Attachment 1 Pipe Bend ModellingDocument1 pageAttachment 1 Pipe Bend ModellingAgus SupriadiNo ratings yet

- Exh B2Document163 pagesExh B2Agus SupriadiNo ratings yet

- ISO 9001 Auditing Practices Group Guidance On:: The Need For A 2 Stage Approach To AuditingDocument2 pagesISO 9001 Auditing Practices Group Guidance On:: The Need For A 2 Stage Approach To AuditingAgus SupriadiNo ratings yet

- Contractor'S Reply To Company'S Comments: (Ref. No.) SubjectDocument1 pageContractor'S Reply To Company'S Comments: (Ref. No.) SubjectAgus SupriadiNo ratings yet

- GRSM 00 Cons PL 015 Rev.2 Pipeline Tie in ProcedureDocument7 pagesGRSM 00 Cons PL 015 Rev.2 Pipeline Tie in ProcedureAgus SupriadiNo ratings yet

- Sarulla Geotermal Power ProjectDocument1 pageSarulla Geotermal Power ProjectAgus SupriadiNo ratings yet

- Branch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangDocument6 pagesBranch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangAgus SupriadiNo ratings yet

- Branch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangDocument6 pagesBranch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangAgus SupriadiNo ratings yet

- Load Hot TapDocument1 pageLoad Hot TapAgus SupriadiNo ratings yet

- Manual Blender 2.78 (1683 Páginas)Document2 pagesManual Blender 2.78 (1683 Páginas)Jose F CDNo ratings yet

- Frequency Response Analysis and Short-Circuit Impedance Measurement in Detection of Winding Deformation Within Power TransformersDocument8 pagesFrequency Response Analysis and Short-Circuit Impedance Measurement in Detection of Winding Deformation Within Power TransformersRoyer Guerra huamanNo ratings yet

- Full Download Auditing The Art and Science of Assurance Engagements Canadian 13th Edition Arens Solutions ManualDocument35 pagesFull Download Auditing The Art and Science of Assurance Engagements Canadian 13th Edition Arens Solutions Manualpickersgillvandapro100% (36)

- Tps 54312Document27 pagesTps 54312Dino NecciNo ratings yet

- API 614 Comments Mac-Su-3563-EDocument17 pagesAPI 614 Comments Mac-Su-3563-EJESUSNo ratings yet

- AirCheck Detail Report - PK8AP02Document100 pagesAirCheck Detail Report - PK8AP02Trion Ragil NugrohoNo ratings yet

- DatasheetsDocument2 pagesDatasheetsAndrewNo ratings yet

- Fortin Cali Suite v2.0.0Document19 pagesFortin Cali Suite v2.0.0Kresimir HruskovecNo ratings yet

- Furun Catalouge PDFDocument9 pagesFurun Catalouge PDFdeboline mitraNo ratings yet

- Final Date Sheet For Internal Class Test May 2023Document13 pagesFinal Date Sheet For Internal Class Test May 2023Manvi AroraNo ratings yet

- Sri Krishna Arts and Science Computer Technology: Course Coordinator Dr. V. S. Anita Sofia Prof. & HeadDocument78 pagesSri Krishna Arts and Science Computer Technology: Course Coordinator Dr. V. S. Anita Sofia Prof. & HeadAnita Sofia VNo ratings yet

- Faculty of Management and Tecnology Harishchandra Post Graduate CollegeDocument16 pagesFaculty of Management and Tecnology Harishchandra Post Graduate Collegeaniket chauhanNo ratings yet

- COA Chapter 4Document33 pagesCOA Chapter 4dagneNo ratings yet

- Datasheet4u (4) lf411Document4 pagesDatasheet4u (4) lf411JaviNo ratings yet

- Groupes - S5 Ling 2016 12 28Document47 pagesGroupes - S5 Ling 2016 12 28Kabe LabelloNo ratings yet

- PARTIIOUTPUTDEVICEDocument333 pagesPARTIIOUTPUTDEVICEFiras BEN HMIDANo ratings yet

- Undergraduate Students Adoption To App Based Stock Market InvestmentDocument18 pagesUndergraduate Students Adoption To App Based Stock Market InvestmentKunal MishraNo ratings yet

- EwrweDocument54 pagesEwrweyiuloi997023No ratings yet

- Bayesian Estimation Example Using Pymc: Scipy 2010 Lightning TalkDocument12 pagesBayesian Estimation Example Using Pymc: Scipy 2010 Lightning TalkArmandoNo ratings yet

- Philips Projection Catalogue 2021-22Document15 pagesPhilips Projection Catalogue 2021-22James StanleyNo ratings yet

- Ford Everest 2018 ZADocument9 pagesFord Everest 2018 ZAbsinghbeNo ratings yet

- Iwt PracticalDocument18 pagesIwt Practical[04] - Abrar ShahNo ratings yet

- ORGANIZATIONAL CULTURE Organizational Culture and Leadership, 3rd EditionDocument458 pagesORGANIZATIONAL CULTURE Organizational Culture and Leadership, 3rd Editionrisda islamiyah100% (1)

- Tutorial Manual 2021-22 - Sem-III - MOS - MITSOEDocument97 pagesTutorial Manual 2021-22 - Sem-III - MOS - MITSOEJeetender MishraNo ratings yet

- Revision DCP Class XIIDocument11 pagesRevision DCP Class XIIRudra Narayan MishraNo ratings yet

- Flow Control ValveDocument5 pagesFlow Control Valvezakaria100% (1)

- 41 Comp Lab LPoly J47Document23 pages41 Comp Lab LPoly J47Amel ElfirjaniNo ratings yet

- Introduction of InheritDocument2 pagesIntroduction of InheritNugroho BagusNo ratings yet