Professional Documents

Culture Documents

PIPA Effect of Chlorine On Polyolefins

PIPA Effect of Chlorine On Polyolefins

Uploaded by

anwer_quadriCopyright:

Available Formats

You might also like

- Handbook of PVC Pipe Design and Construction: (First Industrial Press Edition)From EverandHandbook of PVC Pipe Design and Construction: (First Industrial Press Edition)No ratings yet

- BOQ of Factory Building - Civil, CostingDocument16 pagesBOQ of Factory Building - Civil, CostingMaciek Majewski100% (1)

- List of Steel Mills in BangladeshDocument2 pagesList of Steel Mills in BangladeshImran hosen67% (3)

- Full Paper - Watertight Drainage SystemDocument7 pagesFull Paper - Watertight Drainage SystemHenry TuraldeNo ratings yet

- Failure PVC PipeDocument31 pagesFailure PVC PipeHAJEYYNo ratings yet

- VEGA - Indonesia PresentationDocument62 pagesVEGA - Indonesia PresentationSteve WanNo ratings yet

- Plastic Pipe FactsDocument10 pagesPlastic Pipe FactsYanAdhiPraNo ratings yet

- Effects of Chlorinated Water On Polymeric Water Distribution SystemsDocument4 pagesEffects of Chlorinated Water On Polymeric Water Distribution SystemsJohn BundangNo ratings yet

- Chlorinated Polyvinyl ChlorideDocument5 pagesChlorinated Polyvinyl ChloridehimanshuahirNo ratings yet

- Effects of Chlorinated Water On Plastic Based Water Delivery System by SolveyDocument3 pagesEffects of Chlorinated Water On Plastic Based Water Delivery System by Solveyeitan-daliaNo ratings yet

- Tests On A Polyvinyl Chloride Pipe From An ExistinDocument13 pagesTests On A Polyvinyl Chloride Pipe From An Existinfarkad rawiNo ratings yet

- Characteristics of Drinking Water Polyethylene Pipes Tested With The Purpose of Quality CertificationDocument53 pagesCharacteristics of Drinking Water Polyethylene Pipes Tested With The Purpose of Quality CertificationOmar HusseinNo ratings yet

- Effects of Disinfection On Newly Constructed Polyethylene Water Mains TR-34 / 2001 BDocument14 pagesEffects of Disinfection On Newly Constructed Polyethylene Water Mains TR-34 / 2001 BToBert100% (1)

- Pu LiningDocument4 pagesPu LiningAnonymous gPoQKbdEKNo ratings yet

- Effects of CL Water On PE PipesDocument12 pagesEffects of CL Water On PE Pipessoylent2No ratings yet

- Influence of Residual Chlorine and Pressure On Degradation of Polybutylene PipeDocument9 pagesInfluence of Residual Chlorine and Pressure On Degradation of Polybutylene Pipehy LiuNo ratings yet

- Critical Consideration For Accelerated Aging of HDPEDocument14 pagesCritical Consideration For Accelerated Aging of HDPEsandrine guerinNo ratings yet

- Marvellous Osemenahon - 23PCA02585 - Arc817-1Document8 pagesMarvellous Osemenahon - 23PCA02585 - Arc817-1marvellous oseNo ratings yet

- The Health Safety and Environmental Performance of PVC PipeDocument8 pagesThe Health Safety and Environmental Performance of PVC PipeUnibellNo ratings yet

- Arc 817 MarvelDocument7 pagesArc 817 Marvelmarvellous oseNo ratings yet

- Health Safety and Environmental Performance of PVC PipeDocument8 pagesHealth Safety and Environmental Performance of PVC PipeUnibellNo ratings yet

- What Beyond Plastics Gets Wrong About PVC Pipes - 11Document13 pagesWhat Beyond Plastics Gets Wrong About PVC Pipes - 11SREENATH SREEDHARANNo ratings yet

- 0608 Tech 1aguapotableDocument4 pages0608 Tech 1aguapotableMiguel ValdovinosNo ratings yet

- Art10 PDFDocument11 pagesArt10 PDFDuong DoanNo ratings yet

- Journal AWWA - 2016 - Connell - PEX and PP Water Pipes Assimilable Carbon Chemicals and Odors PDFDocument13 pagesJournal AWWA - 2016 - Connell - PEX and PP Water Pipes Assimilable Carbon Chemicals and Odors PDFNermeen ElmelegaeNo ratings yet

- Use of Preservation Chemicals Following Hydrostatic Testing of PipelinesDocument3 pagesUse of Preservation Chemicals Following Hydrostatic Testing of PipelinesAmirah AqilahNo ratings yet

- PVC G11Document3 pagesPVC G11Arvie MontesorNo ratings yet

- Corrosion Protection Evaluation of Some Organic Coatings Incorrosion Protection EvaluationDocument61 pagesCorrosion Protection Evaluation of Some Organic Coatings Incorrosion Protection EvaluationUsama Awad100% (1)

- Sustainable Reverse Osmosis Application On Municipal WastewaterDocument13 pagesSustainable Reverse Osmosis Application On Municipal WastewaterRicleto EspinosaNo ratings yet

- Study Takes Comprehensive Look at PVC Life Cycle Assessment Sustainability 1Document3 pagesStudy Takes Comprehensive Look at PVC Life Cycle Assessment Sustainability 1UnibellNo ratings yet

- Life Cycle Assessment of PVC Water and Sewer Pipe and Comparative Sustainability Analysis of Pipe Materials PDFDocument108 pagesLife Cycle Assessment of PVC Water and Sewer Pipe and Comparative Sustainability Analysis of Pipe Materials PDFraghuwanshi12No ratings yet

- Fox Et Al 2014Document11 pagesFox Et Al 2014Mosameem ARNo ratings yet

- A Review On The Durability of PVC Sewer PipesDocument19 pagesA Review On The Durability of PVC Sewer PipesPaula T. LimaNo ratings yet

- 1 s2.0 S0043135422014257 MainDocument9 pages1 s2.0 S0043135422014257 MainSURAJ KUMARNo ratings yet

- Plastic Pipework: Solid Wall PipeDocument4 pagesPlastic Pipework: Solid Wall PipesiswoutNo ratings yet

- Al-Jasser, A.O. 2007 - Chlorine Decay in Drinking-Water Transmission and Distribution Systems Pipe Service Age EffectDocument10 pagesAl-Jasser, A.O. 2007 - Chlorine Decay in Drinking-Water Transmission and Distribution Systems Pipe Service Age EffectRebeca RochaNo ratings yet

- Stainless Steels and Drinking Water Around The WorldDocument12 pagesStainless Steels and Drinking Water Around The WorldVizit31No ratings yet

- Echnical Eport: L T P P P M P W ADocument12 pagesEchnical Eport: L T P P P M P W AJabnon NonjabNo ratings yet

- Sanders PosterDocument0 pagesSanders Posterjepro91No ratings yet

- Pipe Association: Issue BriefDocument1 pagePipe Association: Issue BriefmrkhaireeNo ratings yet

- Rozelle 1987Document7 pagesRozelle 1987Nermeen ElmelegaeNo ratings yet

- PVC Pipe Longevity ReportDocument24 pagesPVC Pipe Longevity ReportUnibellNo ratings yet

- The Fatigue Performance of Electrofusion Tapping Tees Subject To Contamination - Final VersionDocument25 pagesThe Fatigue Performance of Electrofusion Tapping Tees Subject To Contamination - Final VersionrsahaNo ratings yet

- PoseidonDocument9 pagesPoseidonarissacuyosNo ratings yet

- Survey of Green Building Water Systems RevealsDocument10 pagesSurvey of Green Building Water Systems RevealsGary Kiel Palacios EspinozaNo ratings yet

- NSS (2011) SHTM 04-01 Part F Chloramination of Water Supplies - Part2Document8 pagesNSS (2011) SHTM 04-01 Part F Chloramination of Water Supplies - Part2alang_businessNo ratings yet

- Polymers 14 00133 v3Document16 pagesPolymers 14 00133 v3Faiz IbrahimNo ratings yet

- MEE2Document24 pagesMEE2johnmarie DyMyNo ratings yet

- Water Filtration: Nonwoven Fabric FiltersDocument15 pagesWater Filtration: Nonwoven Fabric FiltersMark Roger Huberit IINo ratings yet

- Dudu 2019 IOP Conf. Ser. Mater. Sci. Eng. 514 012008Document10 pagesDudu 2019 IOP Conf. Ser. Mater. Sci. Eng. 514 012008Hhhh GehrhhNo ratings yet

- Mechanical Properties Molecular Structures HDPE Polymers Accepted-ManuscriptDocument29 pagesMechanical Properties Molecular Structures HDPE Polymers Accepted-Manuscriptsiddiqui4303379No ratings yet

- ENE-101 Lec 4 IncompDocument34 pagesENE-101 Lec 4 IncompMaheen HayatNo ratings yet

- Chloride Diffusivity in Red Mud-Ordinary Portland Cement Concrete Determined by Migration TestsDocument9 pagesChloride Diffusivity in Red Mud-Ordinary Portland Cement Concrete Determined by Migration TestsShweta MahajanNo ratings yet

- Impact of Potable Water Disinfectants On Pe PipeDocument35 pagesImpact of Potable Water Disinfectants On Pe PipeSaif AhmedNo ratings yet

- Components of Plumbing and Sanitation: Mr. Shashikant Gopal Kamble, Prof. M. B. Kumthekar, Mr. Deepak H. KoliDocument9 pagesComponents of Plumbing and Sanitation: Mr. Shashikant Gopal Kamble, Prof. M. B. Kumthekar, Mr. Deepak H. KolierpublicationNo ratings yet

- 1 s2.0 S0011916411009155 MainDocument7 pages1 s2.0 S0011916411009155 MaintfemilianNo ratings yet

- Driscopipe 3408 SpecsDocument12 pagesDriscopipe 3408 SpecsBasil OguakaNo ratings yet

- ANN Model To Predict The Influence of Chemical and Biologic 2014 Procedia enDocument10 pagesANN Model To Predict The Influence of Chemical and Biologic 2014 Procedia enMohamed FirthousNo ratings yet

- Biofilter in Water and Wastewater TreatmentDocument13 pagesBiofilter in Water and Wastewater TreatmentDinda ArdiasariNo ratings yet

- Special Water Wastewater EckertDocument7 pagesSpecial Water Wastewater EckertMilan JoksimovicNo ratings yet

- Finolex PVC Products Cata Cum Tecnical DetailsDocument40 pagesFinolex PVC Products Cata Cum Tecnical DetailsVedachalam Mani100% (1)

- Corrosion and Odor Management in Sewer Systems (09-05-18)Document6 pagesCorrosion and Odor Management in Sewer Systems (09-05-18)Marcos Damião Resende LeiteNo ratings yet

- Plumbing Design and EstimateDocument3 pagesPlumbing Design and EstimateMaribel B GarciaNo ratings yet

- 03-Production Planning, Control and Maintenance-1Document51 pages03-Production Planning, Control and Maintenance-1anwer_quadriNo ratings yet

- EBook-Marketing MGTDocument200 pagesEBook-Marketing MGTanwer_quadriNo ratings yet

- 02 Entrepreneurship 1Document66 pages02 Entrepreneurship 1anwer_quadriNo ratings yet

- 04 FG ME Home Owner Sell SheetDocument2 pages04 FG ME Home Owner Sell Sheetanwer_quadriNo ratings yet

- UntitledDocument127 pagesUntitledanwer_quadriNo ratings yet

- FlowGuard CPVC Vs PEXDocument2 pagesFlowGuard CPVC Vs PEXanwer_quadriNo ratings yet

- FlowGuard CPVC Vs Other CPVCDocument2 pagesFlowGuard CPVC Vs Other CPVCanwer_quadriNo ratings yet

- FlowGuard CPVC ME General PresentationDocument75 pagesFlowGuard CPVC ME General Presentationanwer_quadriNo ratings yet

- M SD 230 (B)Document2 pagesM SD 230 (B)anwer_quadriNo ratings yet

- Air Filter Test ServicesDocument9 pagesAir Filter Test Servicesanwer_quadriNo ratings yet

- Table Process MappingDocument1 pageTable Process Mappinganwer_quadriNo ratings yet

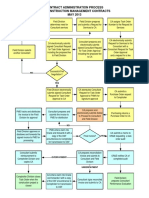

- Construction Project Flow Chart TemplateDocument1 pageConstruction Project Flow Chart Templateanwer_quadriNo ratings yet

- Nozzle Pump Selection - UpdatedDocument5 pagesNozzle Pump Selection - Updatedanwer_quadriNo ratings yet

- Chilled Water Pipe SizingDocument13 pagesChilled Water Pipe Sizinganwer_quadri100% (1)

- Ashrae Duct DesignDocument66 pagesAshrae Duct Designanwer_quadriNo ratings yet

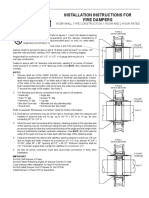

- FD Installation StandardsDocument4 pagesFD Installation Standardsanwer_quadriNo ratings yet

- The Managers Guide For WeldingDocument124 pagesThe Managers Guide For Weldinganwer_quadriNo ratings yet

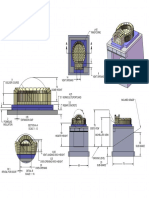

- FD & DFD 150X Models: Installation, Operation and Maintenance InstructionsDocument7 pagesFD & DFD 150X Models: Installation, Operation and Maintenance Instructionsanwer_quadriNo ratings yet

- Fire Damper Installation InstructionsDocument4 pagesFire Damper Installation Instructionsanwer_quadri100% (1)

- Leather Plague Doctor MaskDocument10 pagesLeather Plague Doctor MaskMarlon Escariote100% (1)

- Bill of QuantitiesDocument2 pagesBill of QuantitiesBeryl ValenzuelaNo ratings yet

- Chelating Therapy: Azeem ImamDocument14 pagesChelating Therapy: Azeem Imamazeem imamNo ratings yet

- Thallium SuperconductorDocument2 pagesThallium SuperconductorRishikeshav RaviNo ratings yet

- 1 Underbody Coating: 1.1 Modern Automotive Coating ProcessesDocument2 pages1 Underbody Coating: 1.1 Modern Automotive Coating ProcessesHari Tej100% (1)

- Bescom - Part-IV - 11 KV LabourDocument14 pagesBescom - Part-IV - 11 KV LabourAbdul QayumNo ratings yet

- The Encyclopedia of Explosives and Related Items PATR 2700 VOLUME 5Document785 pagesThe Encyclopedia of Explosives and Related Items PATR 2700 VOLUME 5Bloc22100% (1)

- Forging: Workshop Practice ME-105Document21 pagesForging: Workshop Practice ME-105Mazahir habibNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- 348 Tender Safety Items PDFDocument52 pages348 Tender Safety Items PDFsolid_impactNo ratings yet

- 14c-Handout Calculations Supporting Construction FramesDocument22 pages14c-Handout Calculations Supporting Construction FramesMohamed AdelNo ratings yet

- METSO DOA Dimesion ReportDocument8 pagesMETSO DOA Dimesion ReportNaresh KumarNo ratings yet

- Steel Forgings, Austenitic, For Pressure and High Temperature PartsDocument7 pagesSteel Forgings, Austenitic, For Pressure and High Temperature PartssarangNo ratings yet

- Pizza Oven SchematicDocument1 pagePizza Oven Schematicsir.roy.keaneNo ratings yet

- S.No - Experiment Observation InferenceDocument7 pagesS.No - Experiment Observation InferenceArchana ArchuNo ratings yet

- 70 A2019 NEC P06 SD SRStatements XDocument71 pages70 A2019 NEC P06 SD SRStatements XJasm MutingNo ratings yet

- DPP - Mole Concept - 2Document1 pageDPP - Mole Concept - 2Haresh Tripathy 2No ratings yet

- Modern Cable Hat in Paintbox Yarns Downloadable PDF 2Document4 pagesModern Cable Hat in Paintbox Yarns Downloadable PDF 2Viktor del campoNo ratings yet

- m4 U10Document15 pagesm4 U10Lasandu WanniarachchiNo ratings yet

- 4.6 Pile Details and Retaining Wall Details (Ajay Kushwaha)Document1 page4.6 Pile Details and Retaining Wall Details (Ajay Kushwaha)AJAY KUSHWAHA PILLAI HOC COANo ratings yet

- TLE 6 Lesson No.1 PowerpointDocument18 pagesTLE 6 Lesson No.1 PowerpointDexee Giel CanoyNo ratings yet

- BERNSTEIN Standard-EnclosuresDocument60 pagesBERNSTEIN Standard-EnclosuresDacar ValladaresNo ratings yet

- M3382 Spec (Fusible Link)Document4 pagesM3382 Spec (Fusible Link)DamonNo ratings yet

- Ingevity Capa CoatingsDocument4 pagesIngevity Capa CoatingsKanagarajan VijayakumarNo ratings yet

- British Columbia Mining, Advanced Projects and ExplorationDocument44 pagesBritish Columbia Mining, Advanced Projects and ExplorationaynalemNo ratings yet

- Evian Bottle Water Quality Report 2020Document11 pagesEvian Bottle Water Quality Report 2020Lokanathan ArriaNo ratings yet

- History of TextilesDocument44 pagesHistory of TextilesBright Mariya100% (1)

PIPA Effect of Chlorine On Polyolefins

PIPA Effect of Chlorine On Polyolefins

Uploaded by

anwer_quadriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PIPA Effect of Chlorine On Polyolefins

PIPA Effect of Chlorine On Polyolefins

Uploaded by

anwer_quadriCopyright:

Available Formats

PVC and Polyolefins Technical Information TN008 Rev 1

Chlorine Dioxide Disinfectant for Drinking Water –

Effect on pipe and seal materials

A variety of methods are used to disinfect drinking water in Australia. The major water agencies primarily

use either chloramines or chlorine. However, some operators of smaller, remote water treatment plants

may have chosen to use chlorine dioxide.

Chlorine dioxide has been shown to function differently from the other commonly used disinfectants in

that it oxygenates rather than chlorinatesi.

Chlorine dioxide has been shown to be more aggressive towards polyolefins such as polyethylene than

the other water treatment chemicals1, ii, iii, iv. Especially at service temperatures above 20°C, chlorine

dioxide will shorten the service life of polyethylene pipes. For this reason chlorine dioxide water

disinfection should not be used with polyethylene, polypropylene or polybutylene (i.e.

polyolefin) pipes. This applies to distribution, reticulation and plumbing applications.

Moreover, the aggressiveness of chlorine dioxide with polyethylene creates a complex situation such

that the usual Arrhenius relationship (rate process model) is not appropriatev. Predicting long-term

performance of PE in the presence of chlorine dioxide is therefore more complicated.

Whilst it has been shown that PVC is not attacked by chlorine dioxide at normal concentrationsvi,

consideration must be given to its effect on other parts of the system.

Chlorine dioxide is suspected of having an adverse effect on a number of elastomers commonly used

in seals in water applications, for example pipe seals, O-rings and gaskets. These elastomers can be

found throughout a water pipe network - distribution, reticulation and plumbing applications all use

elastomeric materials and it is recommended a comprehensive analysis be undertaken to assess the

impact of chlorine dioxide disinfection on the total system.

For more information on the performance of polyethylene in piping systems utilising chlorine or

chloramine disinfectants reference may be made to POP018 Polyethylene Drinking Water Pipes in

Contact with Chlorine and Chloramine Disinfectants.vii

For Further information please contact :

Plastics Industry Pipe Association of Australia Ltd

Suite 246, 813 Pacific Hwy, Chatswood NSW 2067 or email plasticspipe@pipa.com.au

i

S. Chung, K. Oliphant, P. Vibien, J Zhang, An examination of the relative impact of common potable water

disinfectants (chlorine, chloramines and chlorine dioxide) on plastic piping system components, ANTEC 2007,

p2940.

ii

Evaluating the compatibility of chemical disinfectants with plastic pipe materials use for potable water

distribution, Technical Memorandum, Carolla, Austin, Texas, August 2008.

iii

M. Rozenthal, The life cycle of polyethylene, ASTEE Conference, Nice 2009.

iv

X. Colin, L. Audouin, J. Verdu, M. Rozental-Evesque, F. Martin and F. Bourgine, Kinetic modelling of the

aging of polyethylene pipes for the transport of water containing disinfectants. Plastics Pipes XIII, Washington,

2006.

v

S. Chung, T. Li, K. Oliphant, P. Vibien, The mechanisms of chlorine dioxide oxidation of plastic piping

systems, Plastics Pipes XIV Conference, Budapest, 2008.

vi

J. Fumire, Resistance of PVC pipes against disinfectants, Plastics Pipes XIV Conference, Budapest, 2008.

vii

Plastics Industry Pipe Association of Australia, “Polyethylene Drinking Water Pipes in Contact with Chlorine

and Chloramine Disinfectants”, Industry Guideline POP018, PIPA, Chatswood, 2018.

You might also like

- Handbook of PVC Pipe Design and Construction: (First Industrial Press Edition)From EverandHandbook of PVC Pipe Design and Construction: (First Industrial Press Edition)No ratings yet

- BOQ of Factory Building - Civil, CostingDocument16 pagesBOQ of Factory Building - Civil, CostingMaciek Majewski100% (1)

- List of Steel Mills in BangladeshDocument2 pagesList of Steel Mills in BangladeshImran hosen67% (3)

- Full Paper - Watertight Drainage SystemDocument7 pagesFull Paper - Watertight Drainage SystemHenry TuraldeNo ratings yet

- Failure PVC PipeDocument31 pagesFailure PVC PipeHAJEYYNo ratings yet

- VEGA - Indonesia PresentationDocument62 pagesVEGA - Indonesia PresentationSteve WanNo ratings yet

- Plastic Pipe FactsDocument10 pagesPlastic Pipe FactsYanAdhiPraNo ratings yet

- Effects of Chlorinated Water On Polymeric Water Distribution SystemsDocument4 pagesEffects of Chlorinated Water On Polymeric Water Distribution SystemsJohn BundangNo ratings yet

- Chlorinated Polyvinyl ChlorideDocument5 pagesChlorinated Polyvinyl ChloridehimanshuahirNo ratings yet

- Effects of Chlorinated Water On Plastic Based Water Delivery System by SolveyDocument3 pagesEffects of Chlorinated Water On Plastic Based Water Delivery System by Solveyeitan-daliaNo ratings yet

- Tests On A Polyvinyl Chloride Pipe From An ExistinDocument13 pagesTests On A Polyvinyl Chloride Pipe From An Existinfarkad rawiNo ratings yet

- Characteristics of Drinking Water Polyethylene Pipes Tested With The Purpose of Quality CertificationDocument53 pagesCharacteristics of Drinking Water Polyethylene Pipes Tested With The Purpose of Quality CertificationOmar HusseinNo ratings yet

- Effects of Disinfection On Newly Constructed Polyethylene Water Mains TR-34 / 2001 BDocument14 pagesEffects of Disinfection On Newly Constructed Polyethylene Water Mains TR-34 / 2001 BToBert100% (1)

- Pu LiningDocument4 pagesPu LiningAnonymous gPoQKbdEKNo ratings yet

- Effects of CL Water On PE PipesDocument12 pagesEffects of CL Water On PE Pipessoylent2No ratings yet

- Influence of Residual Chlorine and Pressure On Degradation of Polybutylene PipeDocument9 pagesInfluence of Residual Chlorine and Pressure On Degradation of Polybutylene Pipehy LiuNo ratings yet

- Critical Consideration For Accelerated Aging of HDPEDocument14 pagesCritical Consideration For Accelerated Aging of HDPEsandrine guerinNo ratings yet

- Marvellous Osemenahon - 23PCA02585 - Arc817-1Document8 pagesMarvellous Osemenahon - 23PCA02585 - Arc817-1marvellous oseNo ratings yet

- The Health Safety and Environmental Performance of PVC PipeDocument8 pagesThe Health Safety and Environmental Performance of PVC PipeUnibellNo ratings yet

- Arc 817 MarvelDocument7 pagesArc 817 Marvelmarvellous oseNo ratings yet

- Health Safety and Environmental Performance of PVC PipeDocument8 pagesHealth Safety and Environmental Performance of PVC PipeUnibellNo ratings yet

- What Beyond Plastics Gets Wrong About PVC Pipes - 11Document13 pagesWhat Beyond Plastics Gets Wrong About PVC Pipes - 11SREENATH SREEDHARANNo ratings yet

- 0608 Tech 1aguapotableDocument4 pages0608 Tech 1aguapotableMiguel ValdovinosNo ratings yet

- Art10 PDFDocument11 pagesArt10 PDFDuong DoanNo ratings yet

- Journal AWWA - 2016 - Connell - PEX and PP Water Pipes Assimilable Carbon Chemicals and Odors PDFDocument13 pagesJournal AWWA - 2016 - Connell - PEX and PP Water Pipes Assimilable Carbon Chemicals and Odors PDFNermeen ElmelegaeNo ratings yet

- Use of Preservation Chemicals Following Hydrostatic Testing of PipelinesDocument3 pagesUse of Preservation Chemicals Following Hydrostatic Testing of PipelinesAmirah AqilahNo ratings yet

- PVC G11Document3 pagesPVC G11Arvie MontesorNo ratings yet

- Corrosion Protection Evaluation of Some Organic Coatings Incorrosion Protection EvaluationDocument61 pagesCorrosion Protection Evaluation of Some Organic Coatings Incorrosion Protection EvaluationUsama Awad100% (1)

- Sustainable Reverse Osmosis Application On Municipal WastewaterDocument13 pagesSustainable Reverse Osmosis Application On Municipal WastewaterRicleto EspinosaNo ratings yet

- Study Takes Comprehensive Look at PVC Life Cycle Assessment Sustainability 1Document3 pagesStudy Takes Comprehensive Look at PVC Life Cycle Assessment Sustainability 1UnibellNo ratings yet

- Life Cycle Assessment of PVC Water and Sewer Pipe and Comparative Sustainability Analysis of Pipe Materials PDFDocument108 pagesLife Cycle Assessment of PVC Water and Sewer Pipe and Comparative Sustainability Analysis of Pipe Materials PDFraghuwanshi12No ratings yet

- Fox Et Al 2014Document11 pagesFox Et Al 2014Mosameem ARNo ratings yet

- A Review On The Durability of PVC Sewer PipesDocument19 pagesA Review On The Durability of PVC Sewer PipesPaula T. LimaNo ratings yet

- 1 s2.0 S0043135422014257 MainDocument9 pages1 s2.0 S0043135422014257 MainSURAJ KUMARNo ratings yet

- Plastic Pipework: Solid Wall PipeDocument4 pagesPlastic Pipework: Solid Wall PipesiswoutNo ratings yet

- Al-Jasser, A.O. 2007 - Chlorine Decay in Drinking-Water Transmission and Distribution Systems Pipe Service Age EffectDocument10 pagesAl-Jasser, A.O. 2007 - Chlorine Decay in Drinking-Water Transmission and Distribution Systems Pipe Service Age EffectRebeca RochaNo ratings yet

- Stainless Steels and Drinking Water Around The WorldDocument12 pagesStainless Steels and Drinking Water Around The WorldVizit31No ratings yet

- Echnical Eport: L T P P P M P W ADocument12 pagesEchnical Eport: L T P P P M P W AJabnon NonjabNo ratings yet

- Sanders PosterDocument0 pagesSanders Posterjepro91No ratings yet

- Pipe Association: Issue BriefDocument1 pagePipe Association: Issue BriefmrkhaireeNo ratings yet

- Rozelle 1987Document7 pagesRozelle 1987Nermeen ElmelegaeNo ratings yet

- PVC Pipe Longevity ReportDocument24 pagesPVC Pipe Longevity ReportUnibellNo ratings yet

- The Fatigue Performance of Electrofusion Tapping Tees Subject To Contamination - Final VersionDocument25 pagesThe Fatigue Performance of Electrofusion Tapping Tees Subject To Contamination - Final VersionrsahaNo ratings yet

- PoseidonDocument9 pagesPoseidonarissacuyosNo ratings yet

- Survey of Green Building Water Systems RevealsDocument10 pagesSurvey of Green Building Water Systems RevealsGary Kiel Palacios EspinozaNo ratings yet

- NSS (2011) SHTM 04-01 Part F Chloramination of Water Supplies - Part2Document8 pagesNSS (2011) SHTM 04-01 Part F Chloramination of Water Supplies - Part2alang_businessNo ratings yet

- Polymers 14 00133 v3Document16 pagesPolymers 14 00133 v3Faiz IbrahimNo ratings yet

- MEE2Document24 pagesMEE2johnmarie DyMyNo ratings yet

- Water Filtration: Nonwoven Fabric FiltersDocument15 pagesWater Filtration: Nonwoven Fabric FiltersMark Roger Huberit IINo ratings yet

- Dudu 2019 IOP Conf. Ser. Mater. Sci. Eng. 514 012008Document10 pagesDudu 2019 IOP Conf. Ser. Mater. Sci. Eng. 514 012008Hhhh GehrhhNo ratings yet

- Mechanical Properties Molecular Structures HDPE Polymers Accepted-ManuscriptDocument29 pagesMechanical Properties Molecular Structures HDPE Polymers Accepted-Manuscriptsiddiqui4303379No ratings yet

- ENE-101 Lec 4 IncompDocument34 pagesENE-101 Lec 4 IncompMaheen HayatNo ratings yet

- Chloride Diffusivity in Red Mud-Ordinary Portland Cement Concrete Determined by Migration TestsDocument9 pagesChloride Diffusivity in Red Mud-Ordinary Portland Cement Concrete Determined by Migration TestsShweta MahajanNo ratings yet

- Impact of Potable Water Disinfectants On Pe PipeDocument35 pagesImpact of Potable Water Disinfectants On Pe PipeSaif AhmedNo ratings yet

- Components of Plumbing and Sanitation: Mr. Shashikant Gopal Kamble, Prof. M. B. Kumthekar, Mr. Deepak H. KoliDocument9 pagesComponents of Plumbing and Sanitation: Mr. Shashikant Gopal Kamble, Prof. M. B. Kumthekar, Mr. Deepak H. KolierpublicationNo ratings yet

- 1 s2.0 S0011916411009155 MainDocument7 pages1 s2.0 S0011916411009155 MaintfemilianNo ratings yet

- Driscopipe 3408 SpecsDocument12 pagesDriscopipe 3408 SpecsBasil OguakaNo ratings yet

- ANN Model To Predict The Influence of Chemical and Biologic 2014 Procedia enDocument10 pagesANN Model To Predict The Influence of Chemical and Biologic 2014 Procedia enMohamed FirthousNo ratings yet

- Biofilter in Water and Wastewater TreatmentDocument13 pagesBiofilter in Water and Wastewater TreatmentDinda ArdiasariNo ratings yet

- Special Water Wastewater EckertDocument7 pagesSpecial Water Wastewater EckertMilan JoksimovicNo ratings yet

- Finolex PVC Products Cata Cum Tecnical DetailsDocument40 pagesFinolex PVC Products Cata Cum Tecnical DetailsVedachalam Mani100% (1)

- Corrosion and Odor Management in Sewer Systems (09-05-18)Document6 pagesCorrosion and Odor Management in Sewer Systems (09-05-18)Marcos Damião Resende LeiteNo ratings yet

- Plumbing Design and EstimateDocument3 pagesPlumbing Design and EstimateMaribel B GarciaNo ratings yet

- 03-Production Planning, Control and Maintenance-1Document51 pages03-Production Planning, Control and Maintenance-1anwer_quadriNo ratings yet

- EBook-Marketing MGTDocument200 pagesEBook-Marketing MGTanwer_quadriNo ratings yet

- 02 Entrepreneurship 1Document66 pages02 Entrepreneurship 1anwer_quadriNo ratings yet

- 04 FG ME Home Owner Sell SheetDocument2 pages04 FG ME Home Owner Sell Sheetanwer_quadriNo ratings yet

- UntitledDocument127 pagesUntitledanwer_quadriNo ratings yet

- FlowGuard CPVC Vs PEXDocument2 pagesFlowGuard CPVC Vs PEXanwer_quadriNo ratings yet

- FlowGuard CPVC Vs Other CPVCDocument2 pagesFlowGuard CPVC Vs Other CPVCanwer_quadriNo ratings yet

- FlowGuard CPVC ME General PresentationDocument75 pagesFlowGuard CPVC ME General Presentationanwer_quadriNo ratings yet

- M SD 230 (B)Document2 pagesM SD 230 (B)anwer_quadriNo ratings yet

- Air Filter Test ServicesDocument9 pagesAir Filter Test Servicesanwer_quadriNo ratings yet

- Table Process MappingDocument1 pageTable Process Mappinganwer_quadriNo ratings yet

- Construction Project Flow Chart TemplateDocument1 pageConstruction Project Flow Chart Templateanwer_quadriNo ratings yet

- Nozzle Pump Selection - UpdatedDocument5 pagesNozzle Pump Selection - Updatedanwer_quadriNo ratings yet

- Chilled Water Pipe SizingDocument13 pagesChilled Water Pipe Sizinganwer_quadri100% (1)

- Ashrae Duct DesignDocument66 pagesAshrae Duct Designanwer_quadriNo ratings yet

- FD Installation StandardsDocument4 pagesFD Installation Standardsanwer_quadriNo ratings yet

- The Managers Guide For WeldingDocument124 pagesThe Managers Guide For Weldinganwer_quadriNo ratings yet

- FD & DFD 150X Models: Installation, Operation and Maintenance InstructionsDocument7 pagesFD & DFD 150X Models: Installation, Operation and Maintenance Instructionsanwer_quadriNo ratings yet

- Fire Damper Installation InstructionsDocument4 pagesFire Damper Installation Instructionsanwer_quadri100% (1)

- Leather Plague Doctor MaskDocument10 pagesLeather Plague Doctor MaskMarlon Escariote100% (1)

- Bill of QuantitiesDocument2 pagesBill of QuantitiesBeryl ValenzuelaNo ratings yet

- Chelating Therapy: Azeem ImamDocument14 pagesChelating Therapy: Azeem Imamazeem imamNo ratings yet

- Thallium SuperconductorDocument2 pagesThallium SuperconductorRishikeshav RaviNo ratings yet

- 1 Underbody Coating: 1.1 Modern Automotive Coating ProcessesDocument2 pages1 Underbody Coating: 1.1 Modern Automotive Coating ProcessesHari Tej100% (1)

- Bescom - Part-IV - 11 KV LabourDocument14 pagesBescom - Part-IV - 11 KV LabourAbdul QayumNo ratings yet

- The Encyclopedia of Explosives and Related Items PATR 2700 VOLUME 5Document785 pagesThe Encyclopedia of Explosives and Related Items PATR 2700 VOLUME 5Bloc22100% (1)

- Forging: Workshop Practice ME-105Document21 pagesForging: Workshop Practice ME-105Mazahir habibNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- 348 Tender Safety Items PDFDocument52 pages348 Tender Safety Items PDFsolid_impactNo ratings yet

- 14c-Handout Calculations Supporting Construction FramesDocument22 pages14c-Handout Calculations Supporting Construction FramesMohamed AdelNo ratings yet

- METSO DOA Dimesion ReportDocument8 pagesMETSO DOA Dimesion ReportNaresh KumarNo ratings yet

- Steel Forgings, Austenitic, For Pressure and High Temperature PartsDocument7 pagesSteel Forgings, Austenitic, For Pressure and High Temperature PartssarangNo ratings yet

- Pizza Oven SchematicDocument1 pagePizza Oven Schematicsir.roy.keaneNo ratings yet

- S.No - Experiment Observation InferenceDocument7 pagesS.No - Experiment Observation InferenceArchana ArchuNo ratings yet

- 70 A2019 NEC P06 SD SRStatements XDocument71 pages70 A2019 NEC P06 SD SRStatements XJasm MutingNo ratings yet

- DPP - Mole Concept - 2Document1 pageDPP - Mole Concept - 2Haresh Tripathy 2No ratings yet

- Modern Cable Hat in Paintbox Yarns Downloadable PDF 2Document4 pagesModern Cable Hat in Paintbox Yarns Downloadable PDF 2Viktor del campoNo ratings yet

- m4 U10Document15 pagesm4 U10Lasandu WanniarachchiNo ratings yet

- 4.6 Pile Details and Retaining Wall Details (Ajay Kushwaha)Document1 page4.6 Pile Details and Retaining Wall Details (Ajay Kushwaha)AJAY KUSHWAHA PILLAI HOC COANo ratings yet

- TLE 6 Lesson No.1 PowerpointDocument18 pagesTLE 6 Lesson No.1 PowerpointDexee Giel CanoyNo ratings yet

- BERNSTEIN Standard-EnclosuresDocument60 pagesBERNSTEIN Standard-EnclosuresDacar ValladaresNo ratings yet

- M3382 Spec (Fusible Link)Document4 pagesM3382 Spec (Fusible Link)DamonNo ratings yet

- Ingevity Capa CoatingsDocument4 pagesIngevity Capa CoatingsKanagarajan VijayakumarNo ratings yet

- British Columbia Mining, Advanced Projects and ExplorationDocument44 pagesBritish Columbia Mining, Advanced Projects and ExplorationaynalemNo ratings yet

- Evian Bottle Water Quality Report 2020Document11 pagesEvian Bottle Water Quality Report 2020Lokanathan ArriaNo ratings yet

- History of TextilesDocument44 pagesHistory of TextilesBright Mariya100% (1)