Professional Documents

Culture Documents

Test C

Test C

Uploaded by

Sidney Daros JuniorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test C

Test C

Uploaded by

Sidney Daros JuniorCopyright:

Available Formats

January 19, 1999

VK-500 Tests and Adjustment

Procedures

1 VK-500 Rev. C and Later Initial Channel Test

Initial Conditions:

Channel connected to the power transformer.

The power is OFF.

The fuses F1 and F2 are removed from holders.

Output of the channel is shorted with wire jumper.

TEST:

1. Connect the DC voltmeter between the 110V rail (bottom end of resistor R33)

and GND (right end of resistor R21).

2. Turn the power ON and monitor the voltage on 110V supply. It should ramp

up gradually.

3. After about 10 seconds the relay should click.

4. Measure voltage between top end of resistor R33 and GND. Using R9

trimpot adjust this voltage to 60V.

5. Turn the power OFF.

6. Short the external power supply leads and set its current limit to 200mA.

7. Remove the U5 from its socket.

8. Connect the external variable DC power supply to the left group of

MOSFET’s. Connect the NEGATIVE lead to the test pin located near the relay

K1 and under the WHT label. Connect the POSITIVE lead to the top end of R58.

9. Make sure the supply is OFF and its voltage control is at minimum.

10. Turn the power to the board ON.

11. Turn the external DC supply ON.

12. While monitoring the current on external DC supply, slowly raise its voltage.

If current increases to over .2A and current limit LED on power supply comes

ON, turn the trimpot R56 counterclockwise to reduce the current to under .1A.

13. At maximum voltage of 70V on external supply adjust the current to .2A.

14. Turn everything OFF.

15. Connect the external supply to the right group of MOSFET’s: NEG. to the

test point to the right of the K1 relay, POS. to top of R67.

16. Repeat steps 7 through 11 using R70 for adjustment.

17. Disconnect the external DC supply.

18. Install 10A Fast fuses in F1 and F2 position.

19. Connect two DC voltmeters across the resistors R14 and R16.

20. Turn the power ON.

21. Wait for the relay to click and monitor the voltages across the R14 and R16.

22. Using R56 and R70, set these voltages to .075V. Turn the trimpots very

slowly, allow the currents to stabilize for 20 to 30 seconds, then adjust again in

small increments.

23. Turn the board OFF.

2. VK-500 Module Test and Adjustment

1. Position the assembled module vertically on a bench and connect to the

power transformer.

2. Connect a 10 Ohm 10W power resistor to the module’s output.

3. Make sure that U5 is removed from its socket.

4. Connect two DC voltmeters to the resistors R14 and R16.

5. Connect a DC voltmeter to the external 10 Ohm resistor.

6. Turn the power ON and monitor the voltages on voltmeters.

7. Allow the module to stabilize while periodically (every 10 minutes or so)

adjusting the voltages across R14 and R16 to .07V. This adjustment may take

about 2 hours or longer.

8. Use R70 to adjust the voltage across the 10 Ohm resistor to be 0+/- 200mV.

Do not touch the R56 during this time. Repeat adjustments several times.

9. Turn the power OFF.

10. Install the U5 dual optocoupler.

11. Turn the power ON.

12. Monitor the voltages. The voltage across the 10 Ohm resistor should settle

after about two to three minutes to a value within +/- 100mV.

13. Use R75 to adjust this value as close to zero as possible.

14. Turn the power OFF and disconnect the module.

3 VK-500 Final Test Adjustments

I Bias Adjustment

1. Remove the U5 from its socket.

2. Connect two DC voltmeters set to 2V scale across the R14 and R16 resistors

on left channel (polarity is unimportant).

3. Put a 10 Ohm 10W power resistor across the left channel output terminals.

4. Turn the left channel of VK-500 ON.

5. After the relay clicks, check the voltages across R14 and R16 - they should

be under .150V. Allow unit to stabilize for at least two hour.

6. Adjust the voltage across R14 to .070V using R56 trimpot.

7. Adjust the voltage across R16 to .070V using R70 trimpot.

8. Allow the unit to run for about 30 minutes.

9. Adjust the currents again.

10. Move one DC voltmeter from R16 to the output (across the 10 Ohm

resistor).

11. Allow the unit to run for several hours while adjusting the voltages.

12. Adjust the voltage across R14 to .070V using R56.

13. Using R70 trimpot adjust the output voltage to 0 +/- 10mV. Move slowly and

allow unit to stabilize between steps.

14. Connect a DC voltmeter between the NEG output terminal and the top end

of R80 (it is located about 1/2” to the left of the R70 trimpot).

15. Using R70, adjust this voltage to be between 18V and 20V.

16. Repeat these steps as nesessary.

17. Turn the unit OFF and install the U5.

Do the same steps on the right channel. It can be done in parallel.

II Gain Adjustment

1. Turn R52’s on both channels fully counterclockwise.

2. Measure output voltages on both channels.

3. On a channel with LOWER output voltage, adjust the R52 so the output

voltage is the same as on the other channel.

III Frequency Response and Distortion Tests

Perform the Frequency Response and Distortion vs. Output Power tests.

IV Distortion Test and Adjustment

On the units with higher than normal distortion do the following:

1. Turn the unit OFF.

2. Measure the resistance across the resistors R34 and R40. They should be

around 300+/- 5 Ohm and very close to each other. If one side reads close

to 327 Ohm, or higher, that means there is at least one defective 3.6k 2W

resistor on that side. In that case add one (or more if required) 3.6k 2W

resistor in parallel with the R34 or R40.

3. Turn the unit ON and let it stabilize.

4. Apply input signal of 1V 1kHz.

5. Adjust the R37 trimpot for lowest output distortion.

6. Measure the AC voltages across the resistors R60 and R61. They should be

within 1% from each other.

7. If they are different, then connect an external capacitance substitution box to

the side with lower reading (the bottom ends of the R60 and R64 pair, or the

R61 and R63 pair). Record which side it is (left or right)

8. Adjust the capacitance box for the lowest output distortion.

9. Trim the R37 again.

10. Adjust the capacitance again. Record the capacitance value.

11. Turn the unit OFF, remove the channel from the chassis and lift the main PC

board.

12. Install a capacitor with the standard value closest to the recorder one on the

side with the lower AC reading. Use the following locations to install the new

part:

Left side: Across the C24

Right side Across the C23

13. Reassemble the unit and repeat the test.

You might also like

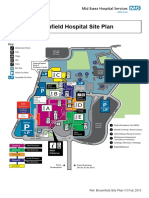

- Broomfield Hospital Site Plan: Café Shops Lifts Information PointsDocument1 pageBroomfield Hospital Site Plan: Café Shops Lifts Information Pointsady trader0% (2)

- LEM Active P SeriesDocument8 pagesLEM Active P Seriesjuan manuel sierra solisNo ratings yet

- Specifications of Avr - SMR (Mosfet)Document4 pagesSpecifications of Avr - SMR (Mosfet)Александр ЩеблыкинNo ratings yet

- Manual Chasis 25B800-7562Document16 pagesManual Chasis 25B800-7562Bren RgzNo ratings yet

- Research Methods For Architecture Ebook - Lucas, Ray - Kindle Store PDFDocument1 pageResearch Methods For Architecture Ebook - Lucas, Ray - Kindle Store PDFMohammed ShriamNo ratings yet

- Manual of Aircraft Accident and Incident Investigation: Doc 9756 AN/965Document40 pagesManual of Aircraft Accident and Incident Investigation: Doc 9756 AN/965james_bembrick100% (1)

- TESTDocument5 pagesTESTSidney Daros JuniorNo ratings yet

- Servicing The KL400Document20 pagesServicing The KL400Pisu Miau Pisu MiauNo ratings yet

- Rca ctc179cm Chassis (ET)Document32 pagesRca ctc179cm Chassis (ET)titoritomex100% (1)

- 4570 NDocument12 pages4570 NDaniboy1994No ratings yet

- Zero Crossing Detector and Window DetectorDocument7 pagesZero Crossing Detector and Window DetectorTimoth Dev50% (2)

- MANSON Power Supply - SPS9400 - ServiceManualDocument18 pagesMANSON Power Supply - SPS9400 - ServiceManualrangerfordNo ratings yet

- Winco 60711-018 Rotating Field Ts GuideDocument4 pagesWinco 60711-018 Rotating Field Ts GuideZeck100% (1)

- Experiment EG220Document30 pagesExperiment EG220Ishaku Balami67% (6)

- Test Procedure and Settings of RCCDocument5 pagesTest Procedure and Settings of RCCkundan kunalNo ratings yet

- Variable Power Supply Using Fixed Voltage Regulator IcDocument2 pagesVariable Power Supply Using Fixed Voltage Regulator IcBuzurjmeherNo ratings yet

- Calibracion BOVIE ELECTROSUGICALDocument1 pageCalibracion BOVIE ELECTROSUGICALCarlos AndresNo ratings yet

- 0-50V 3A Variable Power SupplyDocument17 pages0-50V 3A Variable Power SupplyferdinandNo ratings yet

- AV1000 + Assembly + ManualDocument22 pagesAV1000 + Assembly + ManualAnonymous V1NW1Cm3w4100% (3)

- AVR EA 16-Manual-EnDocument6 pagesAVR EA 16-Manual-EnSyed Mohammad NaveedNo ratings yet

- Advr 16 Manual enDocument6 pagesAdvr 16 Manual enabuzer1981No ratings yet

- Ic Applications Lab NewDocument12 pagesIc Applications Lab NewSandy RonaldoNo ratings yet

- E1585-English User ManualDocument6 pagesE1585-English User ManualedsonNo ratings yet

- ADVR-12: Hybrid Universal Analog Digital Voltage Regulator Operation ManualDocument10 pagesADVR-12: Hybrid Universal Analog Digital Voltage Regulator Operation ManualcarmeniyoNo ratings yet

- 2 Guide SSHV2Document3 pages2 Guide SSHV2Calsonic CMGNo ratings yet

- Instruction Manual FOR Voltage Regulator Model: AVC63-4: Confidential InformationDocument3 pagesInstruction Manual FOR Voltage Regulator Model: AVC63-4: Confidential InformationgovindarulNo ratings yet

- Variable Power Supply UsingDocument3 pagesVariable Power Supply UsingKushagra Trivedi0% (1)

- 0-30V Stabilized Variable Power Supply With Current ControlDocument3 pages0-30V Stabilized Variable Power Supply With Current ControlWaskita IITNo ratings yet

- 50a Service Manual PDFDocument15 pages50a Service Manual PDFalan scapeNo ratings yet

- Lucas Generator and Control Box Tests 1963Document28 pagesLucas Generator and Control Box Tests 19632humbersNo ratings yet

- Generator Automatic Voltage Regulator Operation ManualDocument6 pagesGenerator Automatic Voltage Regulator Operation ManualVijays HiremathNo ratings yet

- AD30TC Testissue9-2Document4 pagesAD30TC Testissue9-2Bruno EstevesNo ratings yet

- Troubleshooting and Service Information For Voltmaster GeneratorsDocument15 pagesTroubleshooting and Service Information For Voltmaster GeneratorsMd Rodi Bidin100% (1)

- Generator Automatic Voltage Regulator Operation Ea465 Generator Automatic VoltageDocument6 pagesGenerator Automatic Voltage Regulator Operation Ea465 Generator Automatic Voltagefahad pirzadaNo ratings yet

- Specifications of Avr - Uvr7Document4 pagesSpecifications of Avr - Uvr7Александр ЩеблыкинNo ratings yet

- Ea16 Manual enDocument6 pagesEa16 Manual enabuzer1981No ratings yet

- Voltage StabilizerDocument6 pagesVoltage StabilizerShaikh Hassan Atik100% (1)

- Lab 1 Power SupplyDocument7 pagesLab 1 Power SupplyKatherine YenNo ratings yet

- P E Lab FinalDocument63 pagesP E Lab FinalARVIND100% (1)

- Schmitt Inverter Waveform GeneratorDocument40 pagesSchmitt Inverter Waveform GeneratorsaravananNo ratings yet

- SS15A3P ManualDocument6 pagesSS15A3P ManualBurce MherjheNo ratings yet

- Lab Power Supply 0-20V and 0.002-4A: InstructablesDocument9 pagesLab Power Supply 0-20V and 0.002-4A: InstructablesOliveira OliveiraNo ratings yet

- Instruction Manual FOR Voltage Regulator Model: VR63-4C/UL: Interconnection DiagramsDocument3 pagesInstruction Manual FOR Voltage Regulator Model: VR63-4C/UL: Interconnection DiagramsgovindarulNo ratings yet

- SGDO-FSU Troubleshooting ProcedureDocument2 pagesSGDO-FSU Troubleshooting ProcedurePeter SnellNo ratings yet

- IZH JUPITER Charging System BPV 14-10Document5 pagesIZH JUPITER Charging System BPV 14-10Rosca DragosNo ratings yet

- Boletin QSC rmx2450Document2 pagesBoletin QSC rmx2450Joseph Manny Spanish100% (1)

- ReporteDocument3 pagesReporteMisael KantunNo ratings yet

- 50W DIY Hi-Fi Audio AmplifierDocument7 pages50W DIY Hi-Fi Audio AmplifierGoran ŠtetinNo ratings yet

- QSC RMX Calibracion de BIASDocument3 pagesQSC RMX Calibracion de BIASElimene BlancaNo ratings yet

- V4H Rev2 SetupDocument5 pagesV4H Rev2 SetupbobannesicNo ratings yet

- V000000 HAB HIG 00 RT A deDocument5 pagesV000000 HAB HIG 00 RT A denew20 new20No ratings yet

- Rotek: Sx460 Avr, ReplacementDocument5 pagesRotek: Sx460 Avr, Replacementمحمد فضل الدلندوكNo ratings yet

- RLC Series Circuit 07-07-11 PDFDocument10 pagesRLC Series Circuit 07-07-11 PDFMuhammed HuzaifaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Easy(er) Electrical Principles for General Class Ham License (2015-2019)From EverandEasy(er) Electrical Principles for General Class Ham License (2015-2019)Rating: 5 out of 5 stars5/5 (1)

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- TESTDocument5 pagesTESTSidney Daros JuniorNo ratings yet

- UntitledDocument1 pageUntitledSidney Daros JuniorNo ratings yet

- Polyvox PR2200Document1 pagePolyvox PR2200Sidney Daros JuniorNo ratings yet

- Telefunken Dominante Ed SchematicDocument3 pagesTelefunken Dominante Ed SchematicSidney Daros Junior100% (1)

- Paaragraphs: Annual Home Brew NightDocument12 pagesPaaragraphs: Annual Home Brew NightSidney Daros JuniorNo ratings yet

- Pasolink NEO Version Up Procedure - Ver3.1.7 - by PNMXJDocument15 pagesPasolink NEO Version Up Procedure - Ver3.1.7 - by PNMXJdlgt63No ratings yet

- Lacerte Jennifer ResumeDocument1 pageLacerte Jennifer Resumejennifer_lacerteNo ratings yet

- Financial StatementDocument17 pagesFinancial StatementNaveen AggarwalNo ratings yet

- WP1088 - DCMA 14 Point PDFDocument7 pagesWP1088 - DCMA 14 Point PDFpaspargiliusNo ratings yet

- BSBCMM511 Simulation PackDocument4 pagesBSBCMM511 Simulation PackmiraNo ratings yet

- A Master Forms Residential IndexDocument70 pagesA Master Forms Residential IndexAlberta Real EstateNo ratings yet

- Apron An Apron Is A Garment That Is Worn Over Other Clothing and Covers Mainly The Front of The BodyDocument3 pagesApron An Apron Is A Garment That Is Worn Over Other Clothing and Covers Mainly The Front of The BodyMicahDelaCruzCuatronaNo ratings yet

- 2012 GR 7 Maths PDFDocument8 pages2012 GR 7 Maths PDFmarshy bindaNo ratings yet

- Tristanmarzeski Com ResumeDocument1 pageTristanmarzeski Com Resumeapi-235468779No ratings yet

- Historical Background of LubricantsDocument21 pagesHistorical Background of LubricantsDinesh babuNo ratings yet

- DS - Unit 3 - NotesDocument13 pagesDS - Unit 3 - NotesManikyarajuNo ratings yet

- Dressmaking 10 - 1st PT - TOS - Key To Correction 2Document8 pagesDressmaking 10 - 1st PT - TOS - Key To Correction 2Sonia CanaNo ratings yet

- Debug Tacacs CiscoDocument5 pagesDebug Tacacs CiscodeztrocxeNo ratings yet

- ION-Evolution - ERA PANOS-RSDocument29 pagesION-Evolution - ERA PANOS-RSSokratesNo ratings yet

- Lab 10 - Proximity Sensors and Switches: FormatDocument5 pagesLab 10 - Proximity Sensors and Switches: FormatHasrat Ahmad AbdullahNo ratings yet

- Tel. ++39 011 9648211 - Fax ++39 011 9648222 E-Mail: Irem@irem - It - WWW - Irem.itDocument8 pagesTel. ++39 011 9648211 - Fax ++39 011 9648222 E-Mail: Irem@irem - It - WWW - Irem.itkenneth molina100% (1)

- PragmaticsDocument10 pagesPragmaticsDisya RusmadinantiNo ratings yet

- Instructional Methods For Teaching Social Studies: A Survey of What Middle School Students Like and Dislike About Social Studies InstructionDocument4 pagesInstructional Methods For Teaching Social Studies: A Survey of What Middle School Students Like and Dislike About Social Studies InstructionShally GuptaNo ratings yet

- Present Etac Dep Psis PDFDocument96 pagesPresent Etac Dep Psis PDFRobiahZakariaNo ratings yet

- Strategic Management in SamsungDocument41 pagesStrategic Management in Samsungkrupamayekar100% (2)

- Arm RollDocument2 pagesArm Rollahmad elnggarNo ratings yet

- Essay EnvironmentDocument4 pagesEssay Environmenttuevptvhd100% (2)

- What Would Humans Do in A World of super-AI TEchnologyDocument9 pagesWhat Would Humans Do in A World of super-AI TEchnologyRahmati RahmatullahNo ratings yet

- Jadual BerkalaDocument2 pagesJadual BerkalaRohani Yusof75% (4)

- Clause Based ChecklistDocument9 pagesClause Based ChecklistLim Kim YookNo ratings yet

- Associated Labor Union v. BorromeoDocument2 pagesAssociated Labor Union v. BorromeoJaneen ZamudioNo ratings yet

- Cisco GGSNDocument386 pagesCisco GGSNtrunto0% (1)