Professional Documents

Culture Documents

Syllabus

Syllabus

Uploaded by

hamza balOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Syllabus

Syllabus

Uploaded by

hamza balCopyright:

Available Formats

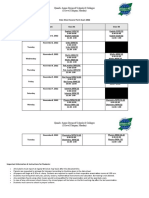

MAK-224E ENGINEERING MATERIALS

(CRN # 11277)

2022/2023 FALL Term

Week Date Day Period Room Text Reference HW Subject

1 20.09.2022 Tuesday 11:30 – 13:30 D351 Notes Failure of materials

2 27.09.2022 Tuesday 11:30 – 13:30 D351 Notes HW1 Tensile behavior of materials

3 04.10.2022 Tuesday 11:30 – 13:30 D351 Notes Non-destructive testing

4 11.10.2022 Tuesday 11:30 – 13:30 D351 Notes Fracture of materials

5 18.10.2022 Tuesday 11:30 – 13:30 D351 Notes Fatigue of materials

6 25.10.2022 Tuesday 11:30 – 13:30 D351 Notes Creep of materials

7 01.11.2022 Tuesday 11:30 – 13:30 D351 Notes Corrosion in materials

8 08.11.2022 Tuesday NO CLASS (Fall Break)

9 15.11.2022 Tuesday 11:30 – 13:30 D351 Notes Corrosion in materials

10 22.11.2022 Tuesday 11:30 – 13:30 D351 Notes Wear of materials

11 29.11.2022 Tuesday 11:30 – 13:30 D351 Notes HW2 Steels and coding, cast irons

12 06.12.2022 Tuesday 11:30 – 13:30 D351 Notes Nonferrous metals and alloys

13 13.12.2022 Tuesday 11:30 – 13:30 D351 Notes Ceramics

14 20.12.2022 Tuesday 11:30 – 13:30 D351 Notes Polymers

15 27.12.2022 Tuesday 11:30 – 13:30 D351 Notes Composites

Instructor: Prof. Dr. Levent Trabzon (Office: 232) Teaching Assistant: to be announced (TBA)

E-Mail: levent.trabzon@itu.edu.tr

Office Hours: TBA

MAK-224E ENGINEERING MATERIALS (CRN: 11277) – Fall 2022

Objectives of the course:

1. To give students the background required to pursue further studies in materials processing, design and related engineering fields.

2. To develop an understanding of the differences between engineering materials through the application of laboratory experiments to determine their physical and

mechanical behavior.

3. To introduce students the failure modes and the use of non-destructive testing techniques of engineering materials.

Outcomes or performance criteria of the course:

1. Demonstrate through laboratory work, knowledge of physical and mechanical properties of materials including heat treatment and non-destructive testing.

2. Recognize and state the Iron-Cementite phase diagram sufficiently to visualize it in discussions of heat treatment of steels and cast irons.

3. Recognize the use of TTT diagrams in heat treatment of steels.

4. Describe the iron and steel making practice in industry.

5. Be familiar with the designations of metals and alloys used in USA, Germany and Turkey.

6. To familiarize the students with the English terminology used in materials science technology.

7. Select a non-ferrous metal or alloy for a specific application.

8. Select a steel or cast iron for a specific application by recognizing the relations between chemical composition, structure and mechanical properties.

9. Describe structures of polymers and their effects upon mechanical properties and production methods.

10. Describe structures of ceramic materials and their effects upon mechanical properties and production methods.

11. List the ways in which composites are strengthened and describe their production methods.

12. Recognize the types of material failures, including fatigue, creep and inelastic deformation.

13. Understand the philosophy behind the non-destructive testing and become familiar with NDT techniques.

Prerequisite: MAK 213

Textbook: Donald R. ASKELAND, The Science and Engineering of Materials, 3rd ed., PWS Pub. Co, 1994.

Course Handout Materials

Other References: W.F. Smith, Principles of Materials Science and Engineering, 2nd, ed., McGraw Hill, New York, 1990.

J.F. Shackelford, Introduction to Materials Science for Engineers, 3rd ed., McMillan Pub. Co., 1992.

W.D. Callister, Materials Science and Engineering-An Introduction, John Wiley & Sons, 2000.

Grading System: Midterm Exam: 50 %

Final Exam: 50 %

Attendance: Regular and punctual class attendance is expected.

Requirements to take

the Final Exam: - A minimum attendance of 70% for lectures, AND

- A minimum score of 40/100 in the midterm exam.

MAK-224E ENGINEERING MATERIALS (CRN: 11277) – Fall 2022

You might also like

- Engineering Materials MAK - 224E: Prof. Dr. Ersan ÜstündağDocument35 pagesEngineering Materials MAK - 224E: Prof. Dr. Ersan ÜstündağMücahit YaylaNo ratings yet

- Exam Schedule 2022 ArrearDocument102 pagesExam Schedule 2022 ArrearGuru EnfielderNo ratings yet

- PETE 220 - Syllabus - 20221 v1Document4 pagesPETE 220 - Syllabus - 20221 v1Alpay AkpınarNo ratings yet

- Syllabus 2034Document2 pagesSyllabus 2034mazen_yasser4228No ratings yet

- S.E. 2019 Pattern Insem Exam Timetable For Oct - 2022 ExamDocument21 pagesS.E. 2019 Pattern Insem Exam Timetable For Oct - 2022 ExamDhavalNo ratings yet

- Branch: All Branches of B.TechDocument8 pagesBranch: All Branches of B.TechSonu BandhaniNo ratings yet

- Thermodynamices CH 2Document15 pagesThermodynamices CH 2Rebar QadrNo ratings yet

- EAS6242 Fall 2021 SyllabusDocument6 pagesEAS6242 Fall 2021 SyllabusTheBeardlessFaceNo ratings yet

- Institute of Engineering & Technology, LucknowDocument10 pagesInstitute of Engineering & Technology, LucknowDivyansh TripathiNo ratings yet

- Schedule of 4th & 6th Semester 19-20-BatchesDocument18 pagesSchedule of 4th & 6th Semester 19-20-BatchesAgha Shafi Jawaid KhanNo ratings yet

- BTech Civil TT2023 231110 115936Document2 pagesBTech Civil TT2023 231110 115936Lakshya wardhan singh ShekhawatNo ratings yet

- Common Prepare Cons. Matrls and ToolsDocument29 pagesCommon Prepare Cons. Matrls and ToolsMa Joan Aguilar RodriguezNo ratings yet

- Grade 12 - Second Trimester Mid-Term - Study MaterialDocument2 pagesGrade 12 - Second Trimester Mid-Term - Study MaterialHkOffishallNo ratings yet

- Bikaner Technical University, Bikaner Examination Schedule For B.Tech. Iisem (Back) Commencing From 11/10/2022 Academic Session 2021-22Document1 pageBikaner Technical University, Bikaner Examination Schedule For B.Tech. Iisem (Back) Commencing From 11/10/2022 Academic Session 2021-22Manish MahawarNo ratings yet

- Two Cycle Heat Treatment (Austempering + Tempering) of Low C Equivalent Ductile IronDocument58 pagesTwo Cycle Heat Treatment (Austempering + Tempering) of Low C Equivalent Ductile IronsaltbathNo ratings yet

- Cven9513 Advanced Foundation Engineering: School of Civil and Environmental EngineeringDocument6 pagesCven9513 Advanced Foundation Engineering: School of Civil and Environmental EngineeringNA PoNo ratings yet

- F.Y.B.Sc. REGULAR 2019 Credit-System SPL 11072022Document5 pagesF.Y.B.Sc. REGULAR 2019 Credit-System SPL 11072022RiteshNo ratings yet

- Date Sheet of DAE S2021Document63 pagesDate Sheet of DAE S2021captjackNo ratings yet

- Mca 2009 ND21Document2 pagesMca 2009 ND21BensonNo ratings yet

- T.E. 2019 Pattern Endsem Timetable Nov 22 - 113423Document22 pagesT.E. 2019 Pattern Endsem Timetable Nov 22 - 113423Jopi mofNo ratings yet

- Uttarakhand Board of Technical Education, Roorkee Semester /annual Examination-2022 (Summer) - New CourseDocument28 pagesUttarakhand Board of Technical Education, Roorkee Semester /annual Examination-2022 (Summer) - New CoursePiyush TomarNo ratings yet

- Time Table Oct-Nov 2022 (As Levels)Document2 pagesTime Table Oct-Nov 2022 (As Levels)Agus Ahmadi IrvanNo ratings yet

- Revision Plan O-III Feb To March.Document2 pagesRevision Plan O-III Feb To March.Ahsan RazaNo ratings yet

- Clpe-16 CT-2Document1 pageClpe-16 CT-2sachin mauryaNo ratings yet

- Time Table For Axum 2nd Sem 2021-22 - Year 5Document1 pageTime Table For Axum 2nd Sem 2021-22 - Year 5Aklilu NegaNo ratings yet

- Dec 2020 Jan 2021 Sem Viii r2012 CbsgsDocument6 pagesDec 2020 Jan 2021 Sem Viii r2012 Cbsgssagar borhadeNo ratings yet

- Nd21 PHD ExamDocument7 pagesNd21 PHD ExamThara NikashNo ratings yet

- ST DATESHEET FOR B. ARC (4th, 6th & 8th Semester) FEB 2022Document2 pagesST DATESHEET FOR B. ARC (4th, 6th & 8th Semester) FEB 2022pratyush saxenaNo ratings yet

- CT-III VIIsemDocument1 pageCT-III VIIsemMurugaanandam SNo ratings yet

- Single Aging Characteristics of Aluminum 6063 AlloyDocument12 pagesSingle Aging Characteristics of Aluminum 6063 Alloychenna kesavaNo ratings yet

- Scheme Summer 2021 (Old Course)Document31 pagesScheme Summer 2021 (Old Course)rahulchandrbhatt007No ratings yet

- Tanévi Időbeosztás - 2022 - 23 - M3 - ENDocument6 pagesTanévi Időbeosztás - 2022 - 23 - M3 - ENShalabh SharmaNo ratings yet

- S.E. - 2019 Pattern Timetable NOV DECDocument21 pagesS.E. - 2019 Pattern Timetable NOV DECpadwaldeepa9No ratings yet

- DEC-2022 1 Sem Regular Exam Time TableDocument2 pagesDEC-2022 1 Sem Regular Exam Time TableAsmatullah khanNo ratings yet

- Revision Plan Chemistry For Feb, March, 2022Document2 pagesRevision Plan Chemistry For Feb, March, 2022Ahsan RazaNo ratings yet

- H Seyin Thesis ReportDocument158 pagesH Seyin Thesis ReportJoanCastellóBelenguerNo ratings yet

- Uttarakhand Board of Technical Education, Roorkee Semester /annual Examination-2021-22 (Winter) - New CourseDocument10 pagesUttarakhand Board of Technical Education, Roorkee Semester /annual Examination-2021-22 (Winter) - New CourseShubham RawatNo ratings yet

- 939 DipTimeTable3Document100 pages939 DipTimeTable3Praba KaranNo ratings yet

- WWT552SEM Course Outline: Prepared By: Silivio Vueti (ALE, I/Arts)Document13 pagesWWT552SEM Course Outline: Prepared By: Silivio Vueti (ALE, I/Arts)SarahNo ratings yet

- 3st Lect ME 524.Document34 pages3st Lect ME 524.Ziad TarekNo ratings yet

- Project Report On Erosion Wear of MaterialsDocument44 pagesProject Report On Erosion Wear of MaterialsNABIL HUSSAINNo ratings yet

- UTB ProjectDocument8 pagesUTB ProjectNoor AssignmentsNo ratings yet

- Ecse 222 - Digital Logic: Electrical and Computer Engineering Mcgill UniversityDocument9 pagesEcse 222 - Digital Logic: Electrical and Computer Engineering Mcgill University15257-Mohammed AL NomanNo ratings yet

- ENGR0022 Syllabus Fall2013Document2 pagesENGR0022 Syllabus Fall2013BigMace23No ratings yet

- First Term Exam 2021 Date SheetDocument2 pagesFirst Term Exam 2021 Date SheeteankuetNo ratings yet

- 2nd Sem 2K21 Spring-2022 Materials & Construction IDocument4 pages2nd Sem 2K21 Spring-2022 Materials & Construction IHMS shahidNo ratings yet

- Re - Examinations Routine 2022Document1 pageRe - Examinations Routine 2022Prakriti DhakalNo ratings yet

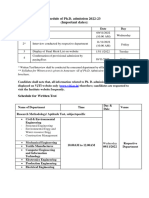

- Schedule of PH.D Admission 2022 23Document2 pagesSchedule of PH.D Admission 2022 23mahendrajadhav007mumbaiNo ratings yet

- Branch: All Branches BtechDocument1 pageBranch: All Branches BtechSonu BandhaniNo ratings yet

- Final F.Y. BSC Sem II Old Exam October - November 2023Document3 pagesFinal F.Y. BSC Sem II Old Exam October - November 2023bhaiyajain566No ratings yet

- EIT Midterm ExamDocument5 pagesEIT Midterm Examjehan sawaftaNo ratings yet

- Cven3303 Steel Structures: School of Civil and Environmental EngineeringDocument7 pagesCven3303 Steel Structures: School of Civil and Environmental Engineeringvixivi6780No ratings yet

- 6308662515a7470011c52feb - ## - Udaan 3.0 2023 - ScienceDocument2 pages6308662515a7470011c52feb - ## - Udaan 3.0 2023 - ScienceRajaNo ratings yet

- Time Table of S.Y.B.sc. Computer Science (2019) (Credit System)Document3 pagesTime Table of S.Y.B.sc. Computer Science (2019) (Credit System)mehvishtpatwegar3621No ratings yet

- Insaat Sinav Progr 2022 2023guz Ver2Document11 pagesInsaat Sinav Progr 2022 2023guz Ver2Erhee BoldNo ratings yet

- Computer Science & Engineering: Branch: All Branches of B.TechDocument9 pagesComputer Science & Engineering: Branch: All Branches of B.TechBella HadidNo ratings yet

- MSE 201 - Course Outline-Lecture Schedule-2019-2020Document1 pageMSE 201 - Course Outline-Lecture Schedule-2019-2020oyekanayotunde56No ratings yet

- Final Thesis IpsaDocument73 pagesFinal Thesis IpsaVasu RajaNo ratings yet

- 2023-11-13-CBCS-NEP-B. Tech Sem. III-IDocument2 pages2023-11-13-CBCS-NEP-B. Tech Sem. III-IAjit SinghNo ratings yet

- HW1 Fall 2022Document4 pagesHW1 Fall 2022hamza balNo ratings yet

- HW2 Fall 2022Document3 pagesHW2 Fall 2022hamza balNo ratings yet

- Ödev 1Document5 pagesÖdev 1hamza balNo ratings yet

- HW1 Airsoft Round AerodynamicsDocument3 pagesHW1 Airsoft Round Aerodynamicshamza balNo ratings yet

- What Are The Thermal, Electrical, and Physical Properties of The Panasonic HIPER V R-1755V MaterialDocument5 pagesWhat Are The Thermal, Electrical, and Physical Properties of The Panasonic HIPER V R-1755V MaterialjackNo ratings yet

- 22f-UC Runway Beam DesignDocument2 pages22f-UC Runway Beam DesignParthiban ArivazhaganNo ratings yet

- Full-Scale Experimental Study of An Embankment Reinforced by GeosyntheticsDocument8 pagesFull-Scale Experimental Study of An Embankment Reinforced by GeosyntheticsgadNo ratings yet

- Design in Timber To Ms 544 Part2: Week 5Document40 pagesDesign in Timber To Ms 544 Part2: Week 5Muhd FaridNo ratings yet

- Summary of Items Discussed in 2 - 2024 ADF On 3.5.2024Document10 pagesSummary of Items Discussed in 2 - 2024 ADF On 3.5.2024YUK LAM WONGNo ratings yet

- Bridge Deck FormworkDocument8 pagesBridge Deck Formworkedgarabraham100% (1)

- Lecture 2Document82 pagesLecture 2Zuhal ZaeemNo ratings yet

- LokfixDocument4 pagesLokfixANIL KUMARNo ratings yet

- Inventory of Tools & EquipmentDocument6 pagesInventory of Tools & EquipmentKevin MacaraegNo ratings yet

- Boliers and Pressure VesselsDocument33 pagesBoliers and Pressure VesselsMarcelo Chaves RestrepoNo ratings yet

- C CF 2020 PDFDocument212 pagesC CF 2020 PDFJobert RamirezNo ratings yet

- Quick Reference Guide: Section VIII, Division I - 2017 EditionDocument1 pageQuick Reference Guide: Section VIII, Division I - 2017 EditionVenicio AchermanNo ratings yet

- Reejoy S. Andrin, Ce Mr. Jessie Jay Ano-Os: A. General Notes Table of Lap Splices H. MasonryDocument1 pageReejoy S. Andrin, Ce Mr. Jessie Jay Ano-Os: A. General Notes Table of Lap Splices H. Masonryreejoy1994No ratings yet

- Equivalent GradesDocument37 pagesEquivalent GradesUmesh SakhareliyaNo ratings yet

- STM Ec2Document39 pagesSTM Ec2Vincenzo MondelliNo ratings yet

- C15100 Alloy - CuZr0,15Document17 pagesC15100 Alloy - CuZr0,15kristechnikNo ratings yet

- Rolta Piping GuideDocument224 pagesRolta Piping GuideSudhesh Rajamoorthy100% (4)

- As1288-2006 Australian Standards Glass in BuildingDocument8 pagesAs1288-2006 Australian Standards Glass in Buildingla_civilNo ratings yet

- Peikko Lifting Systems PDFDocument16 pagesPeikko Lifting Systems PDFErickzelaya2014No ratings yet

- Re-Engineering & Rla: Floating Storage TK - Kapuas-118Document81 pagesRe-Engineering & Rla: Floating Storage TK - Kapuas-118Handhang Maulana Aji AkbarNo ratings yet

- VK301Document4 pagesVK301jhoger2012No ratings yet

- PVC Conduit Pipe & Accessories - 1st May 2018Document1 pagePVC Conduit Pipe & Accessories - 1st May 2018Rajat ChandelNo ratings yet

- CHE 406, Spring 2020 (Lecture 5) Transport Phenomena (Chapter 2)Document26 pagesCHE 406, Spring 2020 (Lecture 5) Transport Phenomena (Chapter 2)Ahmad IjazNo ratings yet

- Ee502 25Document29 pagesEe502 25Gopi RamNo ratings yet

- Lecture 6 - Road FoundationDocument9 pagesLecture 6 - Road FoundationIsworoDwipayanaNo ratings yet

- Issues To Address... : Chapter 14/15-1Document11 pagesIssues To Address... : Chapter 14/15-1Alex Nico JhoentaxsNo ratings yet

- Laboratory Manual: Heat Transfer ME-316-EDocument27 pagesLaboratory Manual: Heat Transfer ME-316-EMark KNo ratings yet

- Sand CastingDocument46 pagesSand Castingjimmy mlelwaNo ratings yet

- Grounding PresentationDocument113 pagesGrounding PresentationPrashant ShahNo ratings yet

- Co/Tri-generation: FactsheetDocument3 pagesCo/Tri-generation: FactsheetAlexandre Cozzolino SermariniNo ratings yet