Professional Documents

Culture Documents

Springchecklist

Springchecklist

Uploaded by

mcjuddy0 ratings0% found this document useful (0 votes)

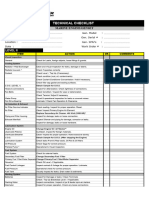

11 views1 pageThe document provides a comprehensive checklist for commissioning a C&C29 sailboat. It includes over 80 individual items to inspect across several categories including sails and rigging, safety gear, electrical systems, engines, plumbing, electronics, and various other vessel systems. The checklist ensures thorough examination of critical components like turnbuckles, cotter pins, running rigging, lifejackets, batteries, lights, bilge pumps, seacocks, bottom paint, and documentation before taking the boat out for the season.

Original Description:

Original Title

springchecklist

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a comprehensive checklist for commissioning a C&C29 sailboat. It includes over 80 individual items to inspect across several categories including sails and rigging, safety gear, electrical systems, engines, plumbing, electronics, and various other vessel systems. The checklist ensures thorough examination of critical components like turnbuckles, cotter pins, running rigging, lifejackets, batteries, lights, bilge pumps, seacocks, bottom paint, and documentation before taking the boat out for the season.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views1 pageSpringchecklist

Springchecklist

Uploaded by

mcjuddyThe document provides a comprehensive checklist for commissioning a C&C29 sailboat. It includes over 80 individual items to inspect across several categories including sails and rigging, safety gear, electrical systems, engines, plumbing, electronics, and various other vessel systems. The checklist ensures thorough examination of critical components like turnbuckles, cotter pins, running rigging, lifejackets, batteries, lights, bilge pumps, seacocks, bottom paint, and documentation before taking the boat out for the season.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 1

C&C29 Spring Commissioning Checklist

Sails and Rigging Engine At Rest

operate all sail furlers, inspect tuff-luff system check engine oil level

check integrity of mast boot check tranmission oil level

inspect turnbuckles and toggles for cracks and rust check & adjust belt tension

check all cotter pins and rings check safety wire on shaft setscrews

operate winches, grease as needed check & tighten hose clamps

check all running rigging for chafe inspect hoses for chaffing and bulging

check all lines for proper whipping snug up bolts on engine & accessories

inspect sail seams, corners, grommets, battens, etc exercise and open fuel tank petcocks

check all masthead hardware inspect engine exhaust anodes

inspect shaft anodes

Safety clean & lube articulating props

check onboard safety gear clean raw water strainer

check expiration dates on safety gear exercise, lube, & open inlet seacock

check expiration dates on fire extinguishers

check expiration dates on first aid kit components Engine Running

inspect seizing wires of anchor shackles monitor oil pressure

inspect lifelines for integrity exercise & lube throttle controls

pressure test propane appliances test transmission shifting

inspect cockpit drains for blockage look for oil leaks

look for raw water/coolant leaks

Electrical System look for leaks around hoses & filters

battery #1 voltage at 12.6VDC ensure exhaust water flows

battery #2 voltage at 12.6VDC verify engine temperature after 15 min. run

clean & tighten battery terminals check alternator output at 13.5VDC

operate circuit breakers/switches monitor tachometer for smooth engine ops

test lights & clean contacts or replace bulbs monitor packing gland drip rate 3 to 5 per min.

side bow/anchor cabin

stern steaming compass Systems

strobe spreader run heater or A/C; check for proper operation

run watermaker; replace filters?; leak check

Electronics run refrigerator; clean radiators; check ops

clean and lube electrical connector contacts

monitor VHF radio transmit power Various

clean and lube transducer O-rings lube and adjust steering

tighten all instrument connections clean and grease porthole gaskets

touch up paint on bare wood

Plumbing ensure docking lines and fenders are on board

test electric bilge pump list all onboard tools

clean bilge strainers as needed list all spare bulbs, fuses, hoses, clamps and tapes

test pump float switch with water in bilge ensure docs, registration and licenses are on board

empty bilge with manual bilge pump make sure nav aids and charts are on board

exercise and lube head pumps and y-valves bottom paint inspect and recoat if needed

run and test freshwater pumps cutless bearing inspect & replace if needed

exercise and lubricate all seacocks inspect stuffing box hoses & clamps

flush antifreeze from freshwater hoses and pumps clean, repair & wax gelcoat

remove & clean engine & head anti-siphon valves clean the stainless

leak check windows, ports, & hatches; caulk

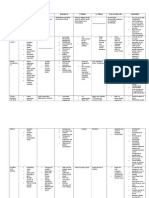

You might also like

- Technical Report Checklist - MARINE ENGINESDocument2 pagesTechnical Report Checklist - MARINE ENGINESsary qasimNo ratings yet

- VMC Preventive Master Check ListDocument33 pagesVMC Preventive Master Check Listmugunthaa6686% (14)

- Quarterly Extruder Performance Checklist: Control Panel Barrel HeatersDocument1 pageQuarterly Extruder Performance Checklist: Control Panel Barrel HeatersAntonius Prakosa100% (2)

- Centrifugal Chiller Maintenance ChecklistDocument1 pageCentrifugal Chiller Maintenance Checklistosama alabsiNo ratings yet

- Preventive Maintenance ChecklistDocument5 pagesPreventive Maintenance ChecklistshabkhaizNo ratings yet

- Testing & Commissioning of Chilled Water PumpsDocument3 pagesTesting & Commissioning of Chilled Water Pumpsamg00750% (4)

- Plunger Lift Preliminary ChecklistDocument1 pagePlunger Lift Preliminary ChecklistMuhammad ShahrukhNo ratings yet

- (Vjc-A320) Question PDFDocument74 pages(Vjc-A320) Question PDFmiew100% (6)

- A. For T-SectionsDocument17 pagesA. For T-SectionsJio SandagNo ratings yet

- PM Inspection SheetDocument4 pagesPM Inspection SheetYogeshNo ratings yet

- Impac Vehicle Maintenance Sheet - C, D, EDocument6 pagesImpac Vehicle Maintenance Sheet - C, D, EFranklyn MunroeNo ratings yet

- Check ListDocument36 pagesCheck ListChief Engineer TransOMNo ratings yet

- Передача вахтиDocument3 pagesПередача вахтиВалерий РыбалкаNo ratings yet

- Sample Preventative Maintenance Inspection Sheet: Fixed Route Vehicle InspectionDocument4 pagesSample Preventative Maintenance Inspection Sheet: Fixed Route Vehicle InspectionVin BdsNo ratings yet

- Boiler Chiller ChecklistDocument5 pagesBoiler Chiller ChecklistSyed Haider Abbas KazmiNo ratings yet

- Quality Check in G-9Document1 pageQuality Check in G-9mukeshhNo ratings yet

- Checklist PPM AircondDocument6 pagesChecklist PPM AircondsyahirahafiqahNo ratings yet

- Unloader Check ListDocument1 pageUnloader Check ListAnonymous ahdhFMaNo ratings yet

- Boatsmart Pre Season Maint ChecklistDocument1 pageBoatsmart Pre Season Maint ChecklistZdravko PodolskiNo ratings yet

- Annual Inspection Checklist PDF 2Document14 pagesAnnual Inspection Checklist PDF 2Tarek ElghazzalyNo ratings yet

- Pre Commissioning ChecksDocument25 pagesPre Commissioning Checkske72012No ratings yet

- PML 087a - PMS - EngineDocument70 pagesPML 087a - PMS - EngineFidriNo ratings yet

- Lesson Hydraulic Control Oil TroubleshootingDocument6 pagesLesson Hydraulic Control Oil Troubleshootingmister pogi100% (1)

- ChecklistDocument2 pagesChecklistdassayevNo ratings yet

- Watchkeeping and TroubleshootingDocument16 pagesWatchkeeping and TroubleshootingAditya Joglekar100% (1)

- MOH Generator TasklistDocument2 pagesMOH Generator TasklistSijo T JohnyNo ratings yet

- Pump Start Up ChecklistDocument1 pagePump Start Up ChecklistSharif Mohammad AdwanNo ratings yet

- Crane Check ListDocument2 pagesCrane Check ListJuned Hamid KhanNo ratings yet

- 7.2.5 CT'S, PT's & CVT'sDocument3 pages7.2.5 CT'S, PT's & CVT'sGAJANAN PNo ratings yet

- Vom - Iv-Sopm-Form-077 Engine Room Pre Arrival and Departure Checklist Rev 0Document1 pageVom - Iv-Sopm-Form-077 Engine Room Pre Arrival and Departure Checklist Rev 0AL HafidzkyNo ratings yet

- Metal Trim: Periodic Maintenance Overhauling of Machines & EquipmentsDocument3 pagesMetal Trim: Periodic Maintenance Overhauling of Machines & EquipmentsVirendra KumarNo ratings yet

- Preventive Maintenance ACDocument29 pagesPreventive Maintenance ACsabar nhfdiNo ratings yet

- SLPG Gtg-2yDocument5 pagesSLPG Gtg-2yAshraf MohammedNo ratings yet

- 2000H Service 16M GraderDocument3 pages2000H Service 16M GraderMohamedNo ratings yet

- MSES Inspection ChecklistDocument5 pagesMSES Inspection ChecklistJaymar Bobier DuculanNo ratings yet

- Equipment O&M ChecklistsDocument11 pagesEquipment O&M ChecklistsAsebaho BadrNo ratings yet

- ChecklistDocument3 pagesChecklistAndy Noven KrisdiantoNo ratings yet

- Pre-Mob Function Test Certificate W 590 COMP-034 FP-030Document15 pagesPre-Mob Function Test Certificate W 590 COMP-034 FP-030Mohamed ShafeeqNo ratings yet

- Why It Pays To Maintain Your BoilerDocument2 pagesWhy It Pays To Maintain Your BoilerOmar KhaledNo ratings yet

- 2000H Service Wheel Loader 993KDocument4 pages2000H Service Wheel Loader 993KmhmdtrainingNo ratings yet

- Transformer Daily Checklist Month:: Description of The Equipment Location CapacityDocument10 pagesTransformer Daily Checklist Month:: Description of The Equipment Location Capacityabdulkadir aliNo ratings yet

- Maintenance - Sub StationDocument13 pagesMaintenance - Sub StationsonukumarmarchadNo ratings yet

- Technical Health DCCMDocument25 pagesTechnical Health DCCMibsamengistu29No ratings yet

- Section 2.16 - Life Saving Appliances Maintenance. Maintenance Code N - 1 Month Components Working DescriptionDocument10 pagesSection 2.16 - Life Saving Appliances Maintenance. Maintenance Code N - 1 Month Components Working DescriptionRochmat AdityaNo ratings yet

- Iw Maintenance Schedule To 2000 HoursDocument6 pagesIw Maintenance Schedule To 2000 HoursJoss RamosNo ratings yet

- Weekly Maintenance Checklist TemplateDocument3 pagesWeekly Maintenance Checklist Templateayat hidayatNo ratings yet

- Equipme NT Daily/Weely Monthly Annually 5 Years 10 Years Non-Scheduled StandardDocument4 pagesEquipme NT Daily/Weely Monthly Annually 5 Years 10 Years Non-Scheduled StandardmuhammadfurQanmirzaNo ratings yet

- ServiceTATA Bus PM Check ListDocument7 pagesServiceTATA Bus PM Check Listalexberhane3No ratings yet

- PM Text As Per Bcel-002Document4 pagesPM Text As Per Bcel-002Jay Rameshbhai ParikhNo ratings yet

- Checklist - Pumps ReciprocatingDocument14 pagesChecklist - Pumps Reciprocatingh_patnaikNo ratings yet

- Несення Вахти в МКОDocument1 pageНесення Вахти в МКОВалерий РыбалкаNo ratings yet

- CL GL Hal Ni 205Document4 pagesCL GL Hal Ni 205LismiantoNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- Warman-Flow System Maintenance ChecklistDocument2 pagesWarman-Flow System Maintenance ChecklistWilliam EvansNo ratings yet

- Stručni Test Engleskog JezikaDocument3 pagesStručni Test Engleskog JezikadjukalNo ratings yet

- Check List For Ul Pumps Standard Set D+e+jn PDFDocument6 pagesCheck List For Ul Pumps Standard Set D+e+jn PDFdesign sseNo ratings yet

- F0556 Crane Weekly Check (Offshore)Document2 pagesF0556 Crane Weekly Check (Offshore)Vimal Singh0% (1)

- Meat and Poultry Roasting ChartsDocument2 pagesMeat and Poultry Roasting ChartsmcjuddyNo ratings yet

- SteeringchecklistDocument2 pagesSteeringchecklistmcjuddyNo ratings yet

- FallchecklistDocument3 pagesFallchecklistmcjuddyNo ratings yet

- Downloaded From Manuals Search EngineDocument118 pagesDownloaded From Manuals Search EnginemcjuddyNo ratings yet

- Com1367 NB EngDocument2 pagesCom1367 NB EngmcjuddyNo ratings yet

- Product Installation Manual: E N G I N E SDocument79 pagesProduct Installation Manual: E N G I N E SmarcusNo ratings yet

- P0016Document3 pagesP0016raul diazNo ratings yet

- Technological University (Thanlyin) : Department of Mechanical EngineeringDocument11 pagesTechnological University (Thanlyin) : Department of Mechanical EngineeringNyan GyishinNo ratings yet

- Thermal ScienceDocument1 pageThermal Scienceram dasNo ratings yet

- Modeling, Design and Control of A Ship Carried 3 DOF Stabilized PlatformDocument9 pagesModeling, Design and Control of A Ship Carried 3 DOF Stabilized PlatformAji Brahma NugrohoNo ratings yet

- Carburetor Fuel System: By: Abel AbebeDocument167 pagesCarburetor Fuel System: By: Abel AbebeMc AxNo ratings yet

- Sim SDL Bce314l Ulo 2Document27 pagesSim SDL Bce314l Ulo 2Paolo DiezNo ratings yet

- Linier Momentum and ImpulseDocument8 pagesLinier Momentum and ImpulseSharonNo ratings yet

- Design Calculations For No-Head, Low-Head Waterwheels... by RuDocument2 pagesDesign Calculations For No-Head, Low-Head Waterwheels... by RuSPYDERSKILL100% (1)

- Asme Section II A Sa-181 Sa-181mDocument4 pagesAsme Section II A Sa-181 Sa-181mAnonymous GhPzn1xNo ratings yet

- Design and Analysis of Pedal Box With Braking SystemDocument4 pagesDesign and Analysis of Pedal Box With Braking SystemEditor IJTSRDNo ratings yet

- 30gtn 1pd UpdateDocument100 pages30gtn 1pd UpdateSyed Ali KhanNo ratings yet

- Ducted Split System 53QDMT48-518A6 Heat Pump 380-415V / 3Ph / 50HzDocument3 pagesDucted Split System 53QDMT48-518A6 Heat Pump 380-415V / 3Ph / 50Hzm.effat3No ratings yet

- C-31-Rubber Lined Piping System PDFDocument6 pagesC-31-Rubber Lined Piping System PDFvedadonNo ratings yet

- Shimi Profile 09-08-2023Document59 pagesShimi Profile 09-08-2023Velur Ranganathan GanapathyNo ratings yet

- Lecture Notes On Engineering Thermodynamics (Me 204 Thermodynamics Ii)Document6 pagesLecture Notes On Engineering Thermodynamics (Me 204 Thermodynamics Ii)Ali ŞenerNo ratings yet

- Sebp4963 21 01 Allcd - 008Document735 pagesSebp4963 21 01 Allcd - 008juanNo ratings yet

- HG 2310 LCDDocument2 pagesHG 2310 LCDPetr PetrovNo ratings yet

- Seven States of MatterDocument4 pagesSeven States of Mattermsngr00No ratings yet

- RCD 4A Singly Reinforced Concrete Beam 1 PDFDocument4 pagesRCD 4A Singly Reinforced Concrete Beam 1 PDFLouella Jim AlquizarNo ratings yet

- Hydro-Test CalculationDocument5 pagesHydro-Test CalculationRitu Singh100% (1)

- RT-138 A1 PDFDocument5 pagesRT-138 A1 PDFRaul DiazNo ratings yet

- Shear-Strength DataDocument19 pagesShear-Strength Datacheveresan123No ratings yet

- Painting OilingDocument4 pagesPainting Oilingprsureshbabu7230No ratings yet

- Braking SystemDocument79 pagesBraking Systempavel35No ratings yet

- AP 1 CH 2 Notes - Annotated ADocument21 pagesAP 1 CH 2 Notes - Annotated AJayson Yalung06No ratings yet

- Technical Session Transmission Line - IIIDocument80 pagesTechnical Session Transmission Line - IIIKaushal Ghimire100% (2)

- Spirax Sarco Design of Fluid Systems 2Document66 pagesSpirax Sarco Design of Fluid Systems 2mahonde100% (2)