Professional Documents

Culture Documents

Sample

Sample

Uploaded by

Zia KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sample

Sample

Uploaded by

Zia KhanCopyright:

Available Formats

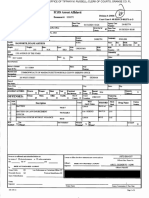

11/10/2019 Print Permit - VCRN-ARC-2019-07067

Hamad International Airport

LOA Permit To Work s.kooliyat@rlrjv.com

No

38216

No

PPTW

No

No

NoNo

NoNo

Norma

Normal Works

VCRN-ARC-2019-07067

PIC Name: Shihas Kooliyat Chalil Start: 02-Nov-2019 06:00 AM

Contact: 33085164 Finish: 30-Nov-2019 06:00 PM

Company: RLR JV Contract Package: RTC-153-2015

Section: Architectural

Attachments

Application No Name Upload Date File Size Uploaded By Document Type Created TypeDOC

VCRN-ARC-2019-0706 LocationMap (10-24-2019_8-45-50_A 10/24/2019 8:45 107 KB Shihas Kooliyat Chalil Location Map 10/24/2019 8:45 WD

7 M)

Approval Details

Group Comments Approved Date Phone Number

PM Henry Ntale (Not Required) 10/28/2019 12:06 - 11/4/2019 10:08

Tej Bahadur Ale (Approve) On 10/28/2019 12:06 - 11/4/2019 10:08

(Tej Bahadur Ale) Approved

PTW Team PTW Committee (Approve) On 11/4/2019 10:08 - 11/5/2019 13:14 11/5/2019 13:14

(Girish Alukkal Gopinathan)

Asset Owners Team Car Parking and Landside (Approve) On 11/5/2019 13:14 - 11/7/2019 7:47 11/7/2019 7:47 Retails :;

(Aidan Gerrard Dawson) Please follow HIA safety guidelines.

Food & Beverages :;

QDF :;

IT :;

BHS :;

Security :;

Lounges :;

Airfield Safety :;

QR :;

QAS :;

Ops Safety and FCC

:;

Terminal Soft Services :;

Terminal Operation Team Terminal Ops Approvers group (Approve) On 11/7/2019 7:47 - 11/10/2019 9:12 11/10/2019 9:13

(Omar Abdulla A M Al Ansari - 74308) approved

https://epermits.hamadairport.com.qa/Lists/Print Permit/DispForm.aspx?ID=38167&PermiitemID=8612&Statuscheck=PPTW 1/4

11/10/2019 Print Permit - VCRN-ARC-2019-07067

Work Details

Work Title: Repair and Re-polishing of Terrazzo Flooring, Cleaning and maintence of ceiling tile, glazing and cladding work.

Description:

*Plastic Barricade will use for the working area.

*Re-polish the area until the transition of divider strips to maintain the equality of the floor finish.

*While polishing the terrazzo floor, the water from the machine should be vacuumed immediately to avoid any damage/leaks to other trades.

*Allow 15 to 20 minutes of time at the end of the day for housekeeping and removing the waste to designate a waste area and also to check the m

achine plug if properly removed from the outlet or immediately removed if not in use.

*Ambient temperature of the installation area for process shall not exceed 60̊ F or 32.2̊C. Ensure the “wild-air” air- conditioning is in good working c

ondition. The maximum relative humidity should not exceed 60%.

* Application of silicone sealant for glazing and cladding works.

*Floor area must be clean with a water buffer machine.

*Apply the first coat with short nap roller or lamb’s wool applicator, squeegee or sprayer / equivalent to the whole area that has been polished.

*Let dry the penetration sealer dry for 60 to 120 minutes before the final sealer application.

*Apply the first coat which is the final sealer with 3M 55433 easy shine applicator kit or equivalent to the whole area that has been polished.

*Let dry for 30 minutes before the second coat.

*After dry, apply the second coat of the final sealer to the whole area that has been polished.

*Let dry for 30 to 60 minutes.

*Area must be closed. NO TRAFFIC allowed while the final coat is not totally dry.

*Re-installation of ceiling tiles.

*Aluminum scaffolding will use for Re-installation of ceiling tiles.

*Correct the alignment of ceiling tiles.

*Application of white silicon for sealant.

*Reinstallation of hand-rail glasses.

*Glass suckers will be used for lifting and shifting handrail glass.

*Application of black silicon for VCN outer glass.

*General cleaning for the floor, stairs, ceiling tiles, glazing (internal and external), handrails, access way, automatic sliding door and removal of stai

n marks.

Building: A1180-Vertical Circular Node (VCN) Floor: GF 1F 2F

Work Category: Maintenance

Area of Work (Room no. or Room name or Room purpose):

All three levels of VCN west car park level-1

What system or equipment is being worked on:

Buffing machine, terrazo grinding machine, vaccum cleaner and aluminium scaffold platform.

Hazards involved:

Work on or near live electrical conductors Work on Site Roads Is Lock Out/Tag Out (LOTO) required? No

Work on Dangerous Machinery Hot Works

Work in confined spaces Work on Fire Protection System

HP systems(Gas,air,liquid,etc) Hazardous substances

Ground Work / Excavations Radiation

Work at Height Mechanical Isolation

IT Change Control Board approval required: No

Location Approvers Required: Yes

If Location Approver Required, select the Retail Lounges QR

location (asset owner):

Food & Beverages MOI Fire Life Safety

true

QDF Airfield safety Terminal Soft Services (TSS)

Security BHS Car Parking and Landside

IT QAS

If workers’ tools are carried airside, the Applicant is responsible to provide and implement all the measures to be applied to ensure that the mentioned tools

shall not be left unattended, shall be accounted for and secured after the work is terminated. Failure to provide the before mentioned measures may result

in an immediate suspension of the work permit.

Job Safety Analysis

Edit Job Step No Job Step Associated Hazard Associated Risk RR Rating Controls in Place CR Rating

https://epermits.hamadairport.com.qa/Lists/Print Permit/DispForm.aspx?ID=38167&PermiitemID=8612&Statuscheck=PPTW 2/4

11/10/2019 Print Permit - VCRN-ARC-2019-07067

Edit Job Step No Job Step Associated Hazard Associated Risk RR Rating Controls in Place CR Rating

001 Site Preparation Slip and Fall Injury

2C I: Plastic jersey Barrication

2D

P: Anti Slip safety Shoes

D: Display of HIA Emergency contact numbersAlw

ays work on levelled surface. All workers shall be

provided with tool box talks prior to works

002 Terrazzo Re-poli Slip, trip and Fall. Injury

shing works on f

3C P: Anti Slip Safety Shoes, Safety Harness

2D

loor D: All workers shall be provided tool box talks pri

or to work. Proper house keeping must maintain

till completion of the work and floor must kept dr

ied.

002 Terrazzo Re-poli Noise Accute hearing heal

shing works on f th issues.

2C RorS: Replace with less noisy equipment.

2D

loor P: Appropriate ear protection must be used as pe

r manufaturers recomentation.

D: Operator must be trained and competant to d

o the job and operator must be briefed about the

the associated hazard involved. Proper maintena

nce of floor grinding machince must be carried o

ut prior to work.

002 Terrazzo Re-poli Electricity Electrocution

shing works on f

4B C: Power codes must be inspected by competatnt

2C

loor person prior to use.

P: Appropriate PPE must always be worn

D: STARRT briefing must be conducted prior com

mencing the work. . All tools/equipment must be

operated by authorized & competent personal o

nly.

003 Erection of Alum Slip, Trips & Fall Injury

inium Mobile Sc

3C I: Barrication

2D

affolding P: Anti Slip Safety Shoes, Safety Harness

D: Always wear Safety Harness and Safety Harnes

s must always be hooked. All workers shall be pro

vided tool box talks prior to work.

003 Erection of Alum Manual Handling Body pain, hand inj

inium mobile sc ury

3C RorS: Do not carry heavy loads

2D

affolding P: Hard hat, Safety Shoes, Hand Gloves and Safet

y Glass

D: Manual Handling Training. Loads to be shared

equally. Arrange work flows. Maintain good postu

re during work, Scaffolder must be competent.

003 Erection of Alum work at height Serious injuries

inium Mobile Sc

4B P: Safety Harness, Hard hat, Safety Shoes, Hand G

2D

affolding loves and Safety Glass

D: Ensure proper access and walkways in working

areas. Edge protections shall be provided when w

orkers are executing their task. Work at Height Tr

aining to be provided

003 Erection of Alum Drop of Materials and Head Injury, Body I

inium mobile sc Tools njury

3C P: Hard hat, Safety Shoes, Hand Gloves and Safet

2D

affolding y Glass

D: Always install toe board on work platforms. Ma

ke personnel aware of the hazard with training.

004 Re-installation o work at height Serious injuries

f Ceiling Tile

4B I: Barricade the work area

2D

C: Scaffold must be erected and tagged by comp

etent person.

P: Hard hat, Safety Shoes, Hand Gloves and Safet

y Glass

D: Ensure proper access and walkways in working

areas. Edge protections shall be provided when w

orkers are executing their task. Work at Height Tr

aining to be provided

004 Application of w Contact and inhalation Skin and eye irritati

hite silicon for s of chemicals. on

3C C: All appropraite precausions must be followed a

2D

ealant s per the MSDS.

P: Wear protective gloves/ eye protection/ face pr

otection. Use personal protective equipment as s

pecfied in the SDS

D: Applicators involved must be breifed about th

e task and associated hazard. SDS must be availa

ble in the work location all the time.

https://epermits.hamadairport.com.qa/Lists/Print Permit/DispForm.aspx?ID=38167&PermiitemID=8612&Statuscheck=PPTW 3/4

11/10/2019 Print Permit - VCRN-ARC-2019-07067

Edit Job Step No Job Step Associated Hazard Associated Risk RR Rating Controls in Place CR Rating

005 Re-Installation o Manual handling twist injury and bod

f handrail glasse y pain, Crush and c

3C RorS: Do not carry heavy loads,

2D

s ut injury. C: Use mechanical Aids instead of manual handlin

g, where ever possible

P: Hard hat, Safety Shoes, Hand Gloves and Safet

y Glass

D: Manual Handling Training. Loads to be shared

equally. Arrange work flows. Maintain good postu

re during work. Work must be done under contin

uos monitoring. Store glass in the temporary stor

age area with appropriate barricade and signage

s.

005 Re-Installation o Slip, Trips & Fall Inury

f handrail glasse

3C P: Anti Slip Safety Shoes, Safety Harness

2D

s D: All workers shall be provided tool box talks pri

or to work. Store glass in the temporary storage a

rea with appropriate barricade and signages. Wor

k area must be kept clear for any obstruction.

006 Application of bl Contact and inhalation Skin and eye irritati

ack silicon for se of chemicals. on

3C C: All appropraite precausions must be followed a

2D

alant at VCN out s per the MSDS.

er glasses. P: Wear protective gloves/ eye protection/ face pr

otection. Use personal protective equipment as s

pecfied in the SDS

D: Applicators involved must be breifed about th

e task and associated hazard. SDS must be availa

ble in the work location all the time.

007 Housekeeping Sharp Object from was Hand Injury

te materials during Cle

3D P: Full coverall, hard hat, Safety Shoes, Hand Glov

2D

aning es and Safety Glass

D: Safety monitoring during the work. Provide loc

al welfare facilities for the duration of the work.

Mechanical means will be used instead of manua

l.

https://epermits.hamadairport.com.qa/Lists/Print Permit/DispForm.aspx?ID=38167&PermiitemID=8612&Statuscheck=PPTW 4/4

You might also like

- Cracked Addons2.2Document84 pagesCracked Addons2.2Erik Andreoni0% (1)

- Marshalling KioskDocument4 pagesMarshalling KioskThant Zin100% (1)

- Oerlikon Compact PowerDocument79 pagesOerlikon Compact Powerincim100% (2)

- 5745 004 Pve P 155 01Document51 pages5745 004 Pve P 155 01Gaurav KumarNo ratings yet

- Ram KrishanDocument2 pagesRam KrishanDaksh MishraNo ratings yet

- HVAC CDocs PDFDocument9 pagesHVAC CDocs PDFAiron Jay MangabatNo ratings yet

- Bike InsuranceDocument6 pagesBike InsuranceVeerareddy KNo ratings yet

- LT Bill 57000406406 201907Document2 pagesLT Bill 57000406406 201907Faku RikiNo ratings yet

- D081206987 15695121842765333 SchedulescDocument2 pagesD081206987 15695121842765333 SchedulescsnzrealtorsNo ratings yet

- Reliance General Insurance Company Limited: Reliance Two Wheeler Package Policy - ScheduleDocument6 pagesReliance General Insurance Company Limited: Reliance Two Wheeler Package Policy - ScheduleAashish aryaNo ratings yet

- Policy D083915524Document2 pagesPolicy D083915524ZishanNo ratings yet

- REHANA BEGUM AP21CJ5205 HERO MOTOCORP PLEASURE 2022-10-15 2023-10-14 Digit Two-Wheeler Liabilty Only PolicyDocument2 pagesREHANA BEGUM AP21CJ5205 HERO MOTOCORP PLEASURE 2022-10-15 2023-10-14 Digit Two-Wheeler Liabilty Only PolicyZakir SzaNo ratings yet

- Gasbill 9565210000 202110 20211110165635Document1 pageGasbill 9565210000 202110 20211110165635Broken HeartNo ratings yet

- File CoverDocument1 pageFile CoverAE MeenkaraNo ratings yet

- Design Memorandum - 9962-001-IS-155-PVM-Z-005-03Document63 pagesDesign Memorandum - 9962-001-IS-155-PVM-Z-005-03anishgirmeNo ratings yet

- Carl Stahl TAS00003YT-Revision2Document1 pageCarl Stahl TAS00003YT-Revision2Sinoj AntonyNo ratings yet

- Pan CardDocument2 pagesPan CardbrijmohanchimNo ratings yet

- SBTE Kerala - APRIL 2022 REV2015: State Board of Technical Education Kerala Provisional Admission Ticket - April 2022Document2 pagesSBTE Kerala - APRIL 2022 REV2015: State Board of Technical Education Kerala Provisional Admission Ticket - April 2022Harsha patelNo ratings yet

- DIGIT TW TP MGRAW680LNT 1662093081449Document2 pagesDIGIT TW TP MGRAW680LNT 1662093081449bishnuPrasadPatiNo ratings yet

- Reliance General Insurance Company Limited: AKEPN2524LDocument6 pagesReliance General Insurance Company Limited: AKEPN2524LvidyahemNo ratings yet

- Invoice 2420780Document1 pageInvoice 2420780tonyNo ratings yet

- CreateDS PDF PDFDocument2 pagesCreateDS PDF PDFsubir kumar AdhikaryNo ratings yet

- ChimneyDocument1 pageChimneyNur SugiartoNo ratings yet

- 2079 80 18 enDocument1 page2079 80 18 enDeepak SinghNo ratings yet

- Gms Saidabad Monthly Return ProformaDocument4 pagesGms Saidabad Monthly Return ProformaBrekhna JanNo ratings yet

- TrainingDocument2 pagesTrainingBalaji PadalaNo ratings yet

- Epariksha Id: 16El2892/Jun/6384: Grade As Stated in RecordDocument3 pagesEpariksha Id: 16El2892/Jun/6384: Grade As Stated in Recordabhinay singhNo ratings yet

- Contoh InvoiceDocument1 pageContoh InvoiceRoket MarketNo ratings yet

- Reliance General Insurance Company Limited: "A" Policy For Act Liability Insurance (Private Car) - Policy ScheduleDocument6 pagesReliance General Insurance Company Limited: "A" Policy For Act Liability Insurance (Private Car) - Policy Schedulekaran katariaNo ratings yet

- NarasimhaDocument1 pageNarasimhaVenkatesh ReddyNo ratings yet

- D078791485 7923167745248018 TpschedulescDocument2 pagesD078791485 7923167745248018 TpschedulescItz AbieNo ratings yet

- Gasbill 8411590000 201904 20190527151608Document1 pageGasbill 8411590000 201904 20190527151608Naveed Aslam KhanNo ratings yet

- Invoice 179778Document1 pageInvoice 179778Trading premiumNo ratings yet

- Gasbill Nov 2018Document1 pageGasbill Nov 2018ramzan rajwaniNo ratings yet

- Fu LL de CK FH N A MA G01: UnregisteredDocument2 pagesFu LL de CK FH N A MA G01: UnregisteredSyed AmeenNo ratings yet

- Reliance General Insurance Company LimitedDocument8 pagesReliance General Insurance Company Limitedaamir khanNo ratings yet

- DIGIT TW TP MGRGP2HIA5F 1662537477355Document2 pagesDIGIT TW TP MGRGP2HIA5F 1662537477355er.malikahemadNo ratings yet

- Reliance General Insurance Company LimitedDocument8 pagesReliance General Insurance Company Limitedshashi123hierarchyNo ratings yet

- PayslipDocument1 pagePayslipwisdomsikarNo ratings yet

- PayslipDocument1 pagePayslipwisdomsikarNo ratings yet

- MH19Document2 pagesMH19danish090717No ratings yet

- LT BILL 28006041007 Jul23Document2 pagesLT BILL 28006041007 Jul23Kalyan GaineNo ratings yet

- Kiran 3rd YearDocument2 pagesKiran 3rd YearBalaji PadalaNo ratings yet

- Visual Welding Join 575,576Document6 pagesVisual Welding Join 575,576haris pratamaNo ratings yet

- FCI Jan-2024 BillDocument1 pageFCI Jan-2024 BillJunaid SiddiquiNo ratings yet

- BillDocument1 pageBillAamir KhowajaNo ratings yet

- Reliance General Insurance Company Limited: Reliance Private Car Package Policy-ScheduleDocument9 pagesReliance General Insurance Company Limited: Reliance Private Car Package Policy-Schedulehgfh hgfNo ratings yet

- Power Supplies PDFDocument292 pagesPower Supplies PDFAsad100% (1)

- Amp - Dpmo - Penugasan - SCREEN WASH PAITONDocument1 pageAmp - Dpmo - Penugasan - SCREEN WASH PAITONAbdan SyakuroNo ratings yet

- Exam Pass CardDocument1 pageExam Pass Cardochiengtonny549No ratings yet

- 077154C-000-NM-6300-001 - E NDT RequirementDocument8 pages077154C-000-NM-6300-001 - E NDT RequirementAnbu AlagupandianNo ratings yet

- Chennai RR Medicos PVT LTD Invoice Copy Dose Meds Technologies Private LimitedDocument1 pageChennai RR Medicos PVT LTD Invoice Copy Dose Meds Technologies Private LimitedSKILLER GaneshNo ratings yet

- Invoice 3500441Document1 pageInvoice 3500441zoom.lldikti15No ratings yet

- Invoice 3575087Document1 pageInvoice 3575087Mohammad amir udinNo ratings yet

- Getaran Lengan DrillDocument2 pagesGetaran Lengan DrillRandy AdisyahNo ratings yet

- Drawing5 Layout1bDocument1 pageDrawing5 Layout1bStephen HartNo ratings yet

- Perspective Site Develepment Plan: 12A07 ExistingDocument1 pagePerspective Site Develepment Plan: 12A07 ExistingSancho AcbangNo ratings yet

- D046877524 2778799158605940 SchedulescDocument3 pagesD046877524 2778799158605940 SchedulescPooja NigamNo ratings yet

- UpdatedDocument2 pagesUpdatedRitesh YadavNo ratings yet

- Epcot Incident ReportDocument4 pagesEpcot Incident ReportBoston 25 DeskNo ratings yet

- Invoice 3105427Document1 pageInvoice 3105427Hary AntoNo ratings yet

- Mental HealthDocument24 pagesMental Healthnitin pareekNo ratings yet

- Macys Resume-2-2Document2 pagesMacys Resume-2-2api-269130288No ratings yet

- Quickstart Guide: EnglishDocument10 pagesQuickstart Guide: EnglishAnnekiNo ratings yet

- E-Proceedings - ICCRET-2023Document30 pagesE-Proceedings - ICCRET-2023RAGHIB R SHARIFNo ratings yet

- Problem Book in RelativityDocument25 pagesProblem Book in Relativitylinamohdzhor481520% (5)

- Lady Macbeth - Infirm of PurposeDocument7 pagesLady Macbeth - Infirm of PurposeBen TaylorNo ratings yet

- 2012 KCSE Physics Paper 3Document5 pages2012 KCSE Physics Paper 3lixus mwangiNo ratings yet

- Yea Kaeps800000042k SGDV Ac APDocument24 pagesYea Kaeps800000042k SGDV Ac APthanh_cdt01No ratings yet

- BHIR121 102 Bussiness Comm Assignment 1Document7 pagesBHIR121 102 Bussiness Comm Assignment 1nncptp7nsbNo ratings yet

- Chapter 7Document6 pagesChapter 7Glace AbellanaNo ratings yet

- Ls Fitting SlidesDocument33 pagesLs Fitting Slidesjaneth44No ratings yet

- Tomb Raider Underworld (Europe) (PC) (En, FR, De, Es, It) (v1.1) - Crystal Dynamics - Free Download, Borrow, ADocument1 pageTomb Raider Underworld (Europe) (PC) (En, FR, De, Es, It) (v1.1) - Crystal Dynamics - Free Download, Borrow, Afrancisco perezNo ratings yet

- Exp 6Document12 pagesExp 6Mehul VermaNo ratings yet

- Comparison of The Main Ethanol Dehydration TechnolDocument7 pagesComparison of The Main Ethanol Dehydration TechnolLuiz Rodrigo AssisNo ratings yet

- Safe Work in Confined Spaces: Confined Spaces Regulations 1997 Approved Code of Practice, Regulations and GuidanceDocument44 pagesSafe Work in Confined Spaces: Confined Spaces Regulations 1997 Approved Code of Practice, Regulations and GuidanceantonpeleleNo ratings yet

- 4.25 BLISC Syllabus For CBGSDocument21 pages4.25 BLISC Syllabus For CBGSsubhash.bansode1790No ratings yet

- The Ecology of DragonsDocument2 pagesThe Ecology of DragonsMarti LelisNo ratings yet

- BSAD 120A Syllabus Spring 2022 - TaggedDocument9 pagesBSAD 120A Syllabus Spring 2022 - Taggedgia chaseNo ratings yet

- DanielsDocument5 pagesDanielstv_whiteboyNo ratings yet

- Introduction To Tech Communication & Project Management: Arthur C.M. Chen 617 253-7312, RM 38-460 Acmchen@alum - Mit.eduDocument21 pagesIntroduction To Tech Communication & Project Management: Arthur C.M. Chen 617 253-7312, RM 38-460 Acmchen@alum - Mit.eduTejal1212No ratings yet

- Technical and Operating Documentation: Smoke and Heat Exhaust Control Unit MCR 9705Document24 pagesTechnical and Operating Documentation: Smoke and Heat Exhaust Control Unit MCR 9705Constantin GubavuNo ratings yet

- 13.4 Electrical Diagram: 9 - 9461 02 E Service Manual Screw Compressor SK Sigma Control 2Document17 pages13.4 Electrical Diagram: 9 - 9461 02 E Service Manual Screw Compressor SK Sigma Control 2Mehedi HasanNo ratings yet

- Construct A Context Data-Flow Diagram, Illustrating The Customer Tracking System's ScopeDocument7 pagesConstruct A Context Data-Flow Diagram, Illustrating The Customer Tracking System's ScopeChristine Corpuz GuzmanNo ratings yet

- 06impersonal Passive - AnswersDocument9 pages06impersonal Passive - AnswersJayavelu Damu0% (1)

- What I Kno1Document3 pagesWhat I Kno1Wrensly CalimlimNo ratings yet

- Use Case ModelingDocument10 pagesUse Case ModelingrealsutanNo ratings yet

- Creating Barcodes in OfficeDocument24 pagesCreating Barcodes in OfficeMaxi Rambi RuntuweneNo ratings yet