Professional Documents

Culture Documents

Timber Rules

Timber Rules

Uploaded by

John HansCopyright:

Available Formats

You might also like

- HDB Renovation QuotationDocument4 pagesHDB Renovation Quotation陈红玉100% (1)

- Appendix 1 Equipment Cost Estimates (Garrett)Document28 pagesAppendix 1 Equipment Cost Estimates (Garrett)Adhit Mart DithaNo ratings yet

- Contractor Progress Payment Free Excel TemplateDocument16 pagesContractor Progress Payment Free Excel TemplateSajathNo ratings yet

- Sample BOQDocument4 pagesSample BOQapi-3769014No ratings yet

- Boq of G-2 BuildingDocument26 pagesBoq of G-2 Buildingmalik mac80% (5)

- Tools Needed: Diy Patio Cooler Ice Chest PlansDocument15 pagesTools Needed: Diy Patio Cooler Ice Chest PlansBruno BenitezNo ratings yet

- Ultratorch UT 100SI Parts BreakdownDocument2 pagesUltratorch UT 100SI Parts Breakdownhuizar82No ratings yet

- 1X12X5.5 Vup PDFDocument55 pages1X12X5.5 Vup PDFShivam SharmaNo ratings yet

- A 641 - A 641M - 98 - Qty0ms9bnjqxts1sruqDocument6 pagesA 641 - A 641M - 98 - Qty0ms9bnjqxts1sruqHans AbantoNo ratings yet

- PILE Cap ULS NDocument4 pagesPILE Cap ULS NKhirai HelpNo ratings yet

- EN 14015 2004 Tanks - OldDocument34 pagesEN 14015 2004 Tanks - OldkitofanecoNo ratings yet

- Description Value (KN/M)Document7 pagesDescription Value (KN/M)BASHU DEV TIMALSINANo ratings yet

- Extension of Stainless Steel Refining Complex by Twin Tank VOD UnitDocument6 pagesExtension of Stainless Steel Refining Complex by Twin Tank VOD UnitJJNo ratings yet

- Tolerancije Za Limove - EN 10131 - RGBDocument6 pagesTolerancije Za Limove - EN 10131 - RGBujkicaNo ratings yet

- Seepage of WeirDocument41 pagesSeepage of WeiralfurqaanNo ratings yet

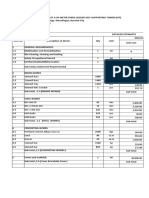

- Project Cost Estimate (All Included)Document5 pagesProject Cost Estimate (All Included)JMike P. FernandezNo ratings yet

- PROJECT: Package-4: Spur To Barwasini By-Pass (From UER II-PKG 1 (KM 7+750) To Barwasini By-Pass (NH 352-A) ) (KM 0+000 To KM 29+600)Document11 pagesPROJECT: Package-4: Spur To Barwasini By-Pass (From UER II-PKG 1 (KM 7+750) To Barwasini By-Pass (NH 352-A) ) (KM 0+000 To KM 29+600)Manupriya KapleshNo ratings yet

- Sample - Catamaran Trim & Stability BookletDocument37 pagesSample - Catamaran Trim & Stability BookletNiranjan Kumar Injeti100% (1)

- محاضرة تكاليف - 2Document6 pagesمحاضرة تكاليف - 2Sohila TorkyNo ratings yet

- 1 4571 PDFDocument7 pages1 4571 PDFSiis IngenieriaNo ratings yet

- Tata Steel - Hybox S700MHDocument2 pagesTata Steel - Hybox S700MHGabriel CamargoNo ratings yet

- Hydraulic Calculation of Pipelines ReportDocument91 pagesHydraulic Calculation of Pipelines Reportkanokwan jaruek100% (1)

- Quotation ForDocument4 pagesQuotation ForAnsaf AskyNo ratings yet

- Mohs' Scale of HardnessDocument9 pagesMohs' Scale of HardnessgldiasNo ratings yet

- Thesis EstimatesDocument14 pagesThesis EstimatesReinrose Sophia LimaNo ratings yet

- Mat 07000-07149 200411Document5 pagesMat 07000-07149 200411Ronaldo Bandeira RodriguesNo ratings yet

- Automotive CableDocument10 pagesAutomotive CableEquipmentDesignNo ratings yet

- Estimate List 1Document7 pagesEstimate List 1parecproNo ratings yet

- Element 73 - 211-RCDDocument28 pagesElement 73 - 211-RCDAsiimwe KasirikaNo ratings yet

- Aluminum Electrolytic Capacitors Radial Lead Type ADocument12 pagesAluminum Electrolytic Capacitors Radial Lead Type AYaraNo ratings yet

- Water TankDocument89 pagesWater TankDenishmakvanaNo ratings yet

- Acetona 8Document1 pageAcetona 8Abigail Salinas Del RioNo ratings yet

- 1.3.3.A ThermodynamicsDocument9 pages1.3.3.A ThermodynamicsSALTY RAMENNo ratings yet

- Bill of Materials: Material DescriptionDocument6 pagesBill of Materials: Material DescriptionRen GonzagaNo ratings yet

- Sewer Boq Muirigo Centre RoadDocument1 pageSewer Boq Muirigo Centre Roadclique cyberNo ratings yet

- Ak. Structural Design CalculationsDocument103 pagesAk. Structural Design CalculationsPEng. Tech. Alvince Korero100% (1)

- Tyvek SubtexDocument3 pagesTyvek SubtexSalman ShaikhNo ratings yet

- Building DesignDocument8 pagesBuilding Designshreejay maneNo ratings yet

- IUPT17012 - KH RESIDENCE 2B+G+5+ROOF RESIDENTIAL BUILDING at DIP-Dubai, PLOT NO. 5981336 - TO SummaryDocument6 pagesIUPT17012 - KH RESIDENCE 2B+G+5+ROOF RESIDENTIAL BUILDING at DIP-Dubai, PLOT NO. 5981336 - TO SummaryTinh T. LeNo ratings yet

- Bandera SkyCiv Report2Document6 pagesBandera SkyCiv Report2Julio Cesar Giraldo GonzalezNo ratings yet

- DIN 11850-1985-OtklDocument7 pagesDIN 11850-1985-OtklVasko MandilNo ratings yet

- Concrete Calculation For T4 and T6Document2 pagesConcrete Calculation For T4 and T6Goku SaitoNo ratings yet

- Proposed Residential Unit-Materials & Labor EstimatesDocument23 pagesProposed Residential Unit-Materials & Labor EstimatesVictor OuruNo ratings yet

- F 3 - 02 - Rjmtukve PDFDocument4 pagesF 3 - 02 - Rjmtukve PDFAnilNo ratings yet

- Building Estimation Excel Sheet 1Document20 pagesBuilding Estimation Excel Sheet 1Tanmay ManoharNo ratings yet

- Metalled Gravelled Transportation Rates TRUCK Asy Load: PORTER Asy LoadDocument22 pagesMetalled Gravelled Transportation Rates TRUCK Asy Load: PORTER Asy LoadLaxu KhanalNo ratings yet

- Product Datasheet: 6.3 MM (.250) UP-TP TerminalsDocument2 pagesProduct Datasheet: 6.3 MM (.250) UP-TP TerminalsAmine MaaouiNo ratings yet

- DH BadenDocument1 pageDH Badenjohn junior ubillus delgadoNo ratings yet

- Estimate Pakka FloorDocument9 pagesEstimate Pakka FloorhasiljiNo ratings yet

- 02-Ducting SmacnaDocument4 pages02-Ducting SmacnaSonghengNo ratings yet

- Core 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Document8 pagesCore 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Nguyen03No ratings yet

- Bid Form Sariaya Multi-Unit House - JJM, Sr. Commercial BidDocument23 pagesBid Form Sariaya Multi-Unit House - JJM, Sr. Commercial BidChristian Joy de GuzmanNo ratings yet

- 1.4401 EnglDocument4 pages1.4401 EnglpdmsNo ratings yet

- Electrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetDocument4 pagesElectrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetEvka AkováNo ratings yet

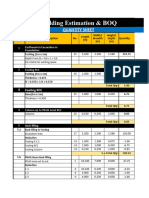

- Building Estimation: Quantity SheetDocument20 pagesBuilding Estimation: Quantity SheetAjay katkarNo ratings yet

- Building Estimation Excel Sheet 1Document20 pagesBuilding Estimation Excel Sheet 1Kushal ManeNo ratings yet

- Cost Benefits of Xypex Admix and Zeomighty and GraphsDocument2 pagesCost Benefits of Xypex Admix and Zeomighty and Graphssattar12345No ratings yet

- Soft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdDocument10 pagesSoft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdMohammadehsan SalarpourNo ratings yet

- For Gate EstimateDocument6 pagesFor Gate EstimateMarkko Buaya TalonNo ratings yet

- PSC Box Girder Bridge With Abutment & Pier Design in BSDocument446 pagesPSC Box Girder Bridge With Abutment & Pier Design in BSSANDIP100% (1)

- Developments in Structural Design Standards With Bamboo-Trujillo, DavidDocument8 pagesDevelopments in Structural Design Standards With Bamboo-Trujillo, DavidJohn HansNo ratings yet

- Bamboo To The Rescue in Costa Rica - Swenarski, LisaDocument4 pagesBamboo To The Rescue in Costa Rica - Swenarski, LisaJohn HansNo ratings yet

- Rules of Thumb Structural DesignDocument25 pagesRules of Thumb Structural DesignJohn HansNo ratings yet

- Coefficient TablesDocument3 pagesCoefficient TablesJohn HansNo ratings yet

- INDUSTRIAL ARTS - LESSON 1 Importance and Methods of Enhancing - Decorating Bamboo, Wood and Metal ProductsDocument18 pagesINDUSTRIAL ARTS - LESSON 1 Importance and Methods of Enhancing - Decorating Bamboo, Wood and Metal ProductsEthelinda GambolNo ratings yet

- Mapping of Significant Tangible Movable Heritage: Category: Works of Industrial/Commercial ArtsDocument6 pagesMapping of Significant Tangible Movable Heritage: Category: Works of Industrial/Commercial ArtsAmabelle Grace JostolNo ratings yet

- Camella Homes ReferenceDocument22 pagesCamella Homes ReferenceMarchus BasamotNo ratings yet

- The Grove Construction Guidelines V1.8Document33 pagesThe Grove Construction Guidelines V1.8Michael VisayaNo ratings yet

- BWP Gurjan Plywood HighlineDocument28 pagesBWP Gurjan Plywood Highlinekkinfra005No ratings yet

- QSI - Architectural Cabinets - 400Document114 pagesQSI - Architectural Cabinets - 400manuella258No ratings yet

- American Girl Dollhouse - Fits 18 Dolls Ana WhiteDocument1 pageAmerican Girl Dollhouse - Fits 18 Dolls Ana WhiteSchindler JoanieNo ratings yet

- Estimate FormatDocument4 pagesEstimate Format28Aakash MawadeNo ratings yet

- Poarr C20Document18 pagesPoarr C20slohariNo ratings yet

- Indian Standard: Specifjcation FOR Wooden Flush Door Shutters (Solid Core Type)Document14 pagesIndian Standard: Specifjcation FOR Wooden Flush Door Shutters (Solid Core Type)bharathchalamaniNo ratings yet

- BQ Revit LatestDocument2 pagesBQ Revit LatestSiti HajarNo ratings yet

- Workshop Practice Series 02 Vertical Milling in The Home WorkshopDocument49 pagesWorkshop Practice Series 02 Vertical Milling in The Home WorkshopParaschiv DariusNo ratings yet

- PT - Multi Hidrachrome Balikpapan: Daftar Mesin Peralatan No. Machine Name Brand Serial NO/Description Qty Year of PurchaseDocument2 pagesPT - Multi Hidrachrome Balikpapan: Daftar Mesin Peralatan No. Machine Name Brand Serial NO/Description Qty Year of PurchasejimivritNo ratings yet

- House Construction StepsDocument7 pagesHouse Construction StepsMarketing Essem18No ratings yet

- Cristobal, Rowela - Research Work #1Document8 pagesCristobal, Rowela - Research Work #1rowela cristobalNo ratings yet

- Rough Cut - Woodworking With Tommy Mac - 13 All-New Projects From Season 2Document178 pagesRough Cut - Woodworking With Tommy Mac - 13 All-New Projects From Season 2Edwin ThieroffNo ratings yet

- FH02DJA BuiltInBookcaseDocument12 pagesFH02DJA BuiltInBookcaseLoay Safieddine100% (1)

- Medium Balsa Stick: R7 Aluminium Tube SparDocument1 pageMedium Balsa Stick: R7 Aluminium Tube Sparairsoft doençaNo ratings yet

- Sioux 7192 PDFDocument22 pagesSioux 7192 PDFJeff LetcherNo ratings yet

- Rocking Airplane Kids ToyDocument34 pagesRocking Airplane Kids ToySergei100% (1)

- Sam MalofDocument5 pagesSam MalofMarcos SalazarNo ratings yet

- Iranian Petroleum Standards: (At Bathrooms & Kitchen)Document1 pageIranian Petroleum Standards: (At Bathrooms & Kitchen)babakfun2000No ratings yet

- Mustang Lumber Inc. vs. Court of AppealsDocument2 pagesMustang Lumber Inc. vs. Court of AppealsMrln VloriaNo ratings yet

- Critical Reviw Norman Fishers House - Tushar SharmapptxDocument55 pagesCritical Reviw Norman Fishers House - Tushar SharmapptxTushar SharmaNo ratings yet

- Formica Pocket Directory 2015 enDocument160 pagesFormica Pocket Directory 2015 enAnonymous JyjVdROGNo ratings yet

Timber Rules

Timber Rules

Uploaded by

John HansOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Timber Rules

Timber Rules

Uploaded by

John HansCopyright:

Available Formats

EXAM APPENDIX - TABLES

7PPX0 Dimensioning of structures - Timber

Table 2.1. Material factors γ m .

material Material factor γ m

sawn timber 1.30

glued laminated timber 1.25

LVL, plywood, OSB 1.20

connections 1.30

metal plate connectors 1.25

Table 2.2. Height factors k h and length actor k l .

Material tension parallel to the grain direction and bending

0.2

150

1.0 ≤ kh = ≤ 1.3

Sawn timber with ρ k ≤ 700 kg/m3 h

0.1

600

Glued laminated timber 1.0 ≤ kh = ≤ 1.1

h

LVL (laminated veneer lumber) Depending on variations to be determined according to EN 14374

Wood-based panels 1.0

Note: the reference length for the length factor k l is L = 3000 mm (element length).

Table 2.3. Climate classes.

Climate class ωaverage Description

[%]

1 12 Standard indoor conditions

2 20 Outdoor, covered structures

3 >20 - poorly ventilated spaces (indoor)

- fully exposed to outdoor conditions (not covered)

- structures in and underneath water

Table 2.4. Load duration classes.

Load duration class Cumulative duration of the Examples

characteristic load

Permanent Longer than 10 years Dead load

Long 6 months - 10 years Storage

Medium-Long 1 week - 6 months Life loads on floors

Short Less than 1 week Snow, wind (The Netherlands)

Instantaneous Accidental load, wind (Belgium)

7PPX0 Introduction to Timber Structures 1

Table 2.5. Values of k mod .

Material Standard Climate- Load duration class

class permanent long medium- short very short

(table 5.2) long

Sawn timber EN 14081-1 1 0.60 0.70 0.80 0.90 1.10

2 0.60 0.70 0.80 0.90 1.10

3 0.50 0.55 0.65 0.70 0.90

Glued EN 14080 1 0.60 0.70 0.80 0.90 1.10

laminated 2 0.60 0.70 0.80 0.90 1.10

wood 3 0.50 0.55 0.65 0.70 0.90

LVL EN 14374 , 1 0.60 0.70 0.80 0.90 1.10

EN 14279 2 0.60 0.70 0.80 0.90 1.10

3 0.60 0.55 0.65 0.70 0.90

Plywood EN 636

Parts 1, 2 and 3 1 0.60 0.70 0.80 0.90 1.10

Parts 2 and 3 2 0.60 0.70 0.80 0.90 1.10

Part 3 3 0.50 0.55 0.65 0.70 0.90

OSB EN 300

OSB/2 1 0.30 0.45 0.65 0.85 1.10

OSB/3, OSB/4 1 0.40 0.50 0.70 0.90 1.10

OSB/3, OSB/4 2 0.30 0.40 0.55 0.70 0.90

Table 2.6. ψ -factors for variable loads.

Load type Description ψ0 ψ1 ψ2

Category A dwellings 0.4 0.5 0.3

Category B offices 0.5 0.5 0.3

Category C congresses, meeting places, theatres, conferences 0.6 / 0.4a 0.7 0.6

Category D shopping 0.4 0.7 0.6

Category E storage 1.0 0.9 0.8

Category H roofs 0.0 0.0 0.0

snow 0.0 0.2 0.0

wind 0.0 0.2 0.0

a for escape routes like stairs: 0.6, other situations: 0.4

Note: the factor ψ 1 is used to determine the so-called frequent value of the variable loads in case

of fire design calculations. The factor ψ 1 is also used to determine the immediate deformations

due to the frequent value of the variable loads. These deformations are with the load combination

according to formula (6.15 b) in EN 1990 [11]. Traditionally there are no requirements for these

deformations in the Netherlands.

7PPX0 Introduction to Timber Structures 2

Table 2.7. k def factors for wood and wood-based materials.

Climate class

1 2 3

Sawn timber EN 14081-1 0.6 0.8 2.0

Glued laminated timber EN 14080 0.6 0.8 2.0

LVL EN 14374, EN 14279 0.6 0.8 2.0

Plywood EN 636

Part 1 0.8 - -

Part 2 0.8 1.0 -

Part 3 0.8 1.0 2.5

OSB EN

OSB/2 2.25 - -

OSB/3, OSB/4 1.50 2.25 -

Note: if it is to be expected, that the wood dries under permanent loading after erection, k def shall

be increased with 1,0.

7PPX0 Introduction to Timber Structures 3

Table 2.8. Strength classes for wood.

Strength class C18 C24 D30 D40 D50 D70 GL24h

Ultimate f m, k N/mm2 18 24 30 40 50 70 24

Limit

States ft ,0, k N/mm2 10 14.5 18 24 30 42 19.2

(ULS)

ft ,90, k N/mm2 0.4 0.4 0.6 0.6 0.6 0.6 0.5

fc,0,k N/mm2 18 21 24 27 30 36 24

fc,90,k N/mm2 2.2 2.5 5.3 5.5 6.2 12.0 2.5

fv,k N/mm2 3.4 4.0 3.9 4.2 4.5 5.0 3.5

ρk kg/m3 320 350 530 550 620 800 385

Em,0,k N/mm2 6,000 7,400 9,200 10,900 11,800 16,800 9,600

Seviceability Em,0, mean N/mm2 9,000 11,000 11,000 13,000 14,000 20,000 11,500

Limit

Em,90,mean N/mm2 300 370 730 870 930 1,330 300

States

(SLS) Gmean N/mm2 560 690 690 810 880 1,250 650

• A distinction is made between C-classes ("softwood") and D-classes ("hardwood").

• Any constructive element must be classified in class a strength (no batch approval allowed

based on the approval of random pieces).

• Wood for structural applications can mechanically or visually be graded. If the wood is

visually graded, in the Netherlands this has, for “softwoods” to be carried out according to

NEN 5499 [13]. The class T1 defined in NEN 5499 equals class C defined in the

“KVH”. The class T2 defined in NEN 5499 equals class B defined in the “KVH”.

• Visually graded Pine, spruce, larch, Douglas (European) and classified in class T1

according to NEN 5499 [13] meets the requirements for strength class C18.

• Visually graded Pine, spruce, larch, Douglas (European) and classified in class T2

according to NEN 5499 meets the requirements for strength class C24.

• Visually graded Douglas (European) and classified in classes T2 according to NEN 5499:

C22

• Oak (Central European), classified in class B accordance to “KVH”: C20

• Meranti (red): strength class D24

• Oak (Polish): D18 / D24 / D30

• Iroko: D24 (unsorted)

• Vitex, Robinia, Sucupira vermelho: D30

• Bilinga: D24 / D50

• Merbau: D30 / D50

• Teak, Iroko (sorted) Sucupira, Itauba, amarelo, Piquia: D40

• Bangkirai, Sapucaia, Angelim vermelho, Denya: D50

• Masseranduba, Cumaru: D60

• Azobé: D70

Note: the strength classes for the different wood species are based on "Wood hand Strength data

[12], a publication of “Centrum Hout” in Almere, the Netherlands.

7PPX0 Introduction to Timber Structures 4

EXAM APPENDIX - FORMULAS

7PPX0 Dimensioning of structures - Timber

Mechanics

q⋅L

V=

2

q ⋅ L2

M=

8

5 q ⋅ L4

w= ⋅

384 EI

F

V=

2

F ⋅L

M=

4

F ⋅ L3

w=

48 ⋅ EI

Safety factors

Consequence Class CC1 γ G = 1.08 γ Q = 1.35

Consequence Class CC2 γ G = 1.20 γ Q = 1.50

Design load Moment of resistance

qd = γ g ⋅ Gk + γ q ⋅ Qk 1

W = ⋅ b ⋅ h2

6

Final deflection

Moment of inertia

w fin = wG ⋅ (1 + kdef ) + wQ ⋅ (1 + ψ 2 ⋅ kdef ) 1

I= ⋅ b ⋅ h3

12

Load including creep

qcreep = Gk ⋅ (1 + kdef ) + Qk ⋅ (1 + ψ 2 ⋅ kdef ) Design value / characteristic value

f m,k f v,k

f m,d = ⋅ kmod fv ,d = ⋅ kmod

Unity Check stresses γM γM

σ m, d σ v,d

UC = UC =

f m, d fv,d Bending stress Shear stress

Md 3 Vd

σ m, d = σ v,d = ⋅

Unity Check deflection W 2 b⋅h

wfin

UC = wmax = 0.004 ⋅ L

wmax

7PPX0 Introduction to Timber Structures 5

You might also like

- HDB Renovation QuotationDocument4 pagesHDB Renovation Quotation陈红玉100% (1)

- Appendix 1 Equipment Cost Estimates (Garrett)Document28 pagesAppendix 1 Equipment Cost Estimates (Garrett)Adhit Mart DithaNo ratings yet

- Contractor Progress Payment Free Excel TemplateDocument16 pagesContractor Progress Payment Free Excel TemplateSajathNo ratings yet

- Sample BOQDocument4 pagesSample BOQapi-3769014No ratings yet

- Boq of G-2 BuildingDocument26 pagesBoq of G-2 Buildingmalik mac80% (5)

- Tools Needed: Diy Patio Cooler Ice Chest PlansDocument15 pagesTools Needed: Diy Patio Cooler Ice Chest PlansBruno BenitezNo ratings yet

- Ultratorch UT 100SI Parts BreakdownDocument2 pagesUltratorch UT 100SI Parts Breakdownhuizar82No ratings yet

- 1X12X5.5 Vup PDFDocument55 pages1X12X5.5 Vup PDFShivam SharmaNo ratings yet

- A 641 - A 641M - 98 - Qty0ms9bnjqxts1sruqDocument6 pagesA 641 - A 641M - 98 - Qty0ms9bnjqxts1sruqHans AbantoNo ratings yet

- PILE Cap ULS NDocument4 pagesPILE Cap ULS NKhirai HelpNo ratings yet

- EN 14015 2004 Tanks - OldDocument34 pagesEN 14015 2004 Tanks - OldkitofanecoNo ratings yet

- Description Value (KN/M)Document7 pagesDescription Value (KN/M)BASHU DEV TIMALSINANo ratings yet

- Extension of Stainless Steel Refining Complex by Twin Tank VOD UnitDocument6 pagesExtension of Stainless Steel Refining Complex by Twin Tank VOD UnitJJNo ratings yet

- Tolerancije Za Limove - EN 10131 - RGBDocument6 pagesTolerancije Za Limove - EN 10131 - RGBujkicaNo ratings yet

- Seepage of WeirDocument41 pagesSeepage of WeiralfurqaanNo ratings yet

- Project Cost Estimate (All Included)Document5 pagesProject Cost Estimate (All Included)JMike P. FernandezNo ratings yet

- PROJECT: Package-4: Spur To Barwasini By-Pass (From UER II-PKG 1 (KM 7+750) To Barwasini By-Pass (NH 352-A) ) (KM 0+000 To KM 29+600)Document11 pagesPROJECT: Package-4: Spur To Barwasini By-Pass (From UER II-PKG 1 (KM 7+750) To Barwasini By-Pass (NH 352-A) ) (KM 0+000 To KM 29+600)Manupriya KapleshNo ratings yet

- Sample - Catamaran Trim & Stability BookletDocument37 pagesSample - Catamaran Trim & Stability BookletNiranjan Kumar Injeti100% (1)

- محاضرة تكاليف - 2Document6 pagesمحاضرة تكاليف - 2Sohila TorkyNo ratings yet

- 1 4571 PDFDocument7 pages1 4571 PDFSiis IngenieriaNo ratings yet

- Tata Steel - Hybox S700MHDocument2 pagesTata Steel - Hybox S700MHGabriel CamargoNo ratings yet

- Hydraulic Calculation of Pipelines ReportDocument91 pagesHydraulic Calculation of Pipelines Reportkanokwan jaruek100% (1)

- Quotation ForDocument4 pagesQuotation ForAnsaf AskyNo ratings yet

- Mohs' Scale of HardnessDocument9 pagesMohs' Scale of HardnessgldiasNo ratings yet

- Thesis EstimatesDocument14 pagesThesis EstimatesReinrose Sophia LimaNo ratings yet

- Mat 07000-07149 200411Document5 pagesMat 07000-07149 200411Ronaldo Bandeira RodriguesNo ratings yet

- Automotive CableDocument10 pagesAutomotive CableEquipmentDesignNo ratings yet

- Estimate List 1Document7 pagesEstimate List 1parecproNo ratings yet

- Element 73 - 211-RCDDocument28 pagesElement 73 - 211-RCDAsiimwe KasirikaNo ratings yet

- Aluminum Electrolytic Capacitors Radial Lead Type ADocument12 pagesAluminum Electrolytic Capacitors Radial Lead Type AYaraNo ratings yet

- Water TankDocument89 pagesWater TankDenishmakvanaNo ratings yet

- Acetona 8Document1 pageAcetona 8Abigail Salinas Del RioNo ratings yet

- 1.3.3.A ThermodynamicsDocument9 pages1.3.3.A ThermodynamicsSALTY RAMENNo ratings yet

- Bill of Materials: Material DescriptionDocument6 pagesBill of Materials: Material DescriptionRen GonzagaNo ratings yet

- Sewer Boq Muirigo Centre RoadDocument1 pageSewer Boq Muirigo Centre Roadclique cyberNo ratings yet

- Ak. Structural Design CalculationsDocument103 pagesAk. Structural Design CalculationsPEng. Tech. Alvince Korero100% (1)

- Tyvek SubtexDocument3 pagesTyvek SubtexSalman ShaikhNo ratings yet

- Building DesignDocument8 pagesBuilding Designshreejay maneNo ratings yet

- IUPT17012 - KH RESIDENCE 2B+G+5+ROOF RESIDENTIAL BUILDING at DIP-Dubai, PLOT NO. 5981336 - TO SummaryDocument6 pagesIUPT17012 - KH RESIDENCE 2B+G+5+ROOF RESIDENTIAL BUILDING at DIP-Dubai, PLOT NO. 5981336 - TO SummaryTinh T. LeNo ratings yet

- Bandera SkyCiv Report2Document6 pagesBandera SkyCiv Report2Julio Cesar Giraldo GonzalezNo ratings yet

- DIN 11850-1985-OtklDocument7 pagesDIN 11850-1985-OtklVasko MandilNo ratings yet

- Concrete Calculation For T4 and T6Document2 pagesConcrete Calculation For T4 and T6Goku SaitoNo ratings yet

- Proposed Residential Unit-Materials & Labor EstimatesDocument23 pagesProposed Residential Unit-Materials & Labor EstimatesVictor OuruNo ratings yet

- F 3 - 02 - Rjmtukve PDFDocument4 pagesF 3 - 02 - Rjmtukve PDFAnilNo ratings yet

- Building Estimation Excel Sheet 1Document20 pagesBuilding Estimation Excel Sheet 1Tanmay ManoharNo ratings yet

- Metalled Gravelled Transportation Rates TRUCK Asy Load: PORTER Asy LoadDocument22 pagesMetalled Gravelled Transportation Rates TRUCK Asy Load: PORTER Asy LoadLaxu KhanalNo ratings yet

- Product Datasheet: 6.3 MM (.250) UP-TP TerminalsDocument2 pagesProduct Datasheet: 6.3 MM (.250) UP-TP TerminalsAmine MaaouiNo ratings yet

- DH BadenDocument1 pageDH Badenjohn junior ubillus delgadoNo ratings yet

- Estimate Pakka FloorDocument9 pagesEstimate Pakka FloorhasiljiNo ratings yet

- 02-Ducting SmacnaDocument4 pages02-Ducting SmacnaSonghengNo ratings yet

- Core 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Document8 pagesCore 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Nguyen03No ratings yet

- Bid Form Sariaya Multi-Unit House - JJM, Sr. Commercial BidDocument23 pagesBid Form Sariaya Multi-Unit House - JJM, Sr. Commercial BidChristian Joy de GuzmanNo ratings yet

- 1.4401 EnglDocument4 pages1.4401 EnglpdmsNo ratings yet

- Electrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetDocument4 pagesElectrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetEvka AkováNo ratings yet

- Building Estimation: Quantity SheetDocument20 pagesBuilding Estimation: Quantity SheetAjay katkarNo ratings yet

- Building Estimation Excel Sheet 1Document20 pagesBuilding Estimation Excel Sheet 1Kushal ManeNo ratings yet

- Cost Benefits of Xypex Admix and Zeomighty and GraphsDocument2 pagesCost Benefits of Xypex Admix and Zeomighty and Graphssattar12345No ratings yet

- Soft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdDocument10 pagesSoft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdMohammadehsan SalarpourNo ratings yet

- For Gate EstimateDocument6 pagesFor Gate EstimateMarkko Buaya TalonNo ratings yet

- PSC Box Girder Bridge With Abutment & Pier Design in BSDocument446 pagesPSC Box Girder Bridge With Abutment & Pier Design in BSSANDIP100% (1)

- Developments in Structural Design Standards With Bamboo-Trujillo, DavidDocument8 pagesDevelopments in Structural Design Standards With Bamboo-Trujillo, DavidJohn HansNo ratings yet

- Bamboo To The Rescue in Costa Rica - Swenarski, LisaDocument4 pagesBamboo To The Rescue in Costa Rica - Swenarski, LisaJohn HansNo ratings yet

- Rules of Thumb Structural DesignDocument25 pagesRules of Thumb Structural DesignJohn HansNo ratings yet

- Coefficient TablesDocument3 pagesCoefficient TablesJohn HansNo ratings yet

- INDUSTRIAL ARTS - LESSON 1 Importance and Methods of Enhancing - Decorating Bamboo, Wood and Metal ProductsDocument18 pagesINDUSTRIAL ARTS - LESSON 1 Importance and Methods of Enhancing - Decorating Bamboo, Wood and Metal ProductsEthelinda GambolNo ratings yet

- Mapping of Significant Tangible Movable Heritage: Category: Works of Industrial/Commercial ArtsDocument6 pagesMapping of Significant Tangible Movable Heritage: Category: Works of Industrial/Commercial ArtsAmabelle Grace JostolNo ratings yet

- Camella Homes ReferenceDocument22 pagesCamella Homes ReferenceMarchus BasamotNo ratings yet

- The Grove Construction Guidelines V1.8Document33 pagesThe Grove Construction Guidelines V1.8Michael VisayaNo ratings yet

- BWP Gurjan Plywood HighlineDocument28 pagesBWP Gurjan Plywood Highlinekkinfra005No ratings yet

- QSI - Architectural Cabinets - 400Document114 pagesQSI - Architectural Cabinets - 400manuella258No ratings yet

- American Girl Dollhouse - Fits 18 Dolls Ana WhiteDocument1 pageAmerican Girl Dollhouse - Fits 18 Dolls Ana WhiteSchindler JoanieNo ratings yet

- Estimate FormatDocument4 pagesEstimate Format28Aakash MawadeNo ratings yet

- Poarr C20Document18 pagesPoarr C20slohariNo ratings yet

- Indian Standard: Specifjcation FOR Wooden Flush Door Shutters (Solid Core Type)Document14 pagesIndian Standard: Specifjcation FOR Wooden Flush Door Shutters (Solid Core Type)bharathchalamaniNo ratings yet

- BQ Revit LatestDocument2 pagesBQ Revit LatestSiti HajarNo ratings yet

- Workshop Practice Series 02 Vertical Milling in The Home WorkshopDocument49 pagesWorkshop Practice Series 02 Vertical Milling in The Home WorkshopParaschiv DariusNo ratings yet

- PT - Multi Hidrachrome Balikpapan: Daftar Mesin Peralatan No. Machine Name Brand Serial NO/Description Qty Year of PurchaseDocument2 pagesPT - Multi Hidrachrome Balikpapan: Daftar Mesin Peralatan No. Machine Name Brand Serial NO/Description Qty Year of PurchasejimivritNo ratings yet

- House Construction StepsDocument7 pagesHouse Construction StepsMarketing Essem18No ratings yet

- Cristobal, Rowela - Research Work #1Document8 pagesCristobal, Rowela - Research Work #1rowela cristobalNo ratings yet

- Rough Cut - Woodworking With Tommy Mac - 13 All-New Projects From Season 2Document178 pagesRough Cut - Woodworking With Tommy Mac - 13 All-New Projects From Season 2Edwin ThieroffNo ratings yet

- FH02DJA BuiltInBookcaseDocument12 pagesFH02DJA BuiltInBookcaseLoay Safieddine100% (1)

- Medium Balsa Stick: R7 Aluminium Tube SparDocument1 pageMedium Balsa Stick: R7 Aluminium Tube Sparairsoft doençaNo ratings yet

- Sioux 7192 PDFDocument22 pagesSioux 7192 PDFJeff LetcherNo ratings yet

- Rocking Airplane Kids ToyDocument34 pagesRocking Airplane Kids ToySergei100% (1)

- Sam MalofDocument5 pagesSam MalofMarcos SalazarNo ratings yet

- Iranian Petroleum Standards: (At Bathrooms & Kitchen)Document1 pageIranian Petroleum Standards: (At Bathrooms & Kitchen)babakfun2000No ratings yet

- Mustang Lumber Inc. vs. Court of AppealsDocument2 pagesMustang Lumber Inc. vs. Court of AppealsMrln VloriaNo ratings yet

- Critical Reviw Norman Fishers House - Tushar SharmapptxDocument55 pagesCritical Reviw Norman Fishers House - Tushar SharmapptxTushar SharmaNo ratings yet

- Formica Pocket Directory 2015 enDocument160 pagesFormica Pocket Directory 2015 enAnonymous JyjVdROGNo ratings yet