Professional Documents

Culture Documents

JSA-pumping Lines Rig Up.

JSA-pumping Lines Rig Up.

Uploaded by

Aniekan AkpaidiokOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA-pumping Lines Rig Up.

JSA-pumping Lines Rig Up.

Uploaded by

Aniekan AkpaidiokCopyright:

Available Formats

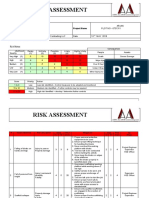

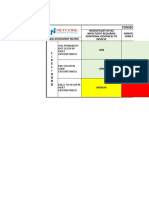

JOB SAFETY ANALYSIS

Job Title/Task: QMS Document No: REV: 00 Date: Page:

Rig up pump lines NISNL/OPS/RA/02 23/03/2019 1 of 3

Department: Location: Analysed By: Reviewed By: Approved By: RPC: (Risk Priority Code):

Operations Port Harcourt Temitope Adewumi Dumbari Nwikwor Austin Edema 3

REVIEW (completed offshore – use Review of JSA’s Work Method)

Reviewed By: Supervisor: Date: Location:

Sequence of Hazard Hazard Effect HSC RPC Risk Reduction Measures HSC RPC

Basic Job

Steps

Hold Toolbox Bad 1.1 Incorrect 2 3 1.1.1 Identify the nearest telephone / radio with immediate access. 2 3

safety meeting instructions. emergency 1.1.2 Identify / post local emergency telephone number at a

with all reporting strategic location.

associated 1.1.3 Reinforce the information required by the emergency occurs.

personnel on 1.1.4 Identify escape route to muster point.

platform / rig.

Bad 1.2 Check well status 1 2 1.2.1 Wear the appropriate PPE for H2S, check valves status. 1 3

instructions. H2S / valves. 1.3.1 Highlight the location of the first aid kit, stretcher.

1.3 Confusion during 1.3.2 Specify emergency assembly point staff.

an emergency. 1.3.3 Assign specific duties based upon experience.

1.4 Incorrect / no PPE 1.4.1 Inspect each personnel’s PPE.

being used. 1.5.1 Attach caution tape around hazardous areas as a first line

1.5 Unwanted warning.

interference/ excess

manpower on site.

NISNL/OPS/RA/02 Once printed this document becomes uncontrolled Page 1 of 3

1.5.2 Install warning no entry signs at location, entrance printed in

both local language and English.

1.5.3 Only authorised persons allowed in the vicinity of the rig up.

1.6 Back injuries. 1.6.2 Obtain assistance when handling/ lifting heavy hoses

connection.

1.7 Confusion during 1.7.1 Adopt the correct posture when lifting heavy weights.

operation. Advise that all slippery surfaces be cleaned up immediately.

2. Remove iron Wrong handling 2.1 Smashed fingers 3 3 2.1.1 Grab iron in a safe area away from pinch points. 3 3

from rack or of equipment or toes.

container. 2.1.2 Establish good communication with helper.

2.2 Strained muscles.

2.1.3 Use gloves.

2.3 Back injuries.

2.2.1 Use proper lifting techniques.

3. Setting up Broken strands 3.1 Personnel injury. 2 2 3.1.1 Use proper PPE. 2 3

equipment. in wire or rope 3.1.2 Observe line.

on cat line or 3.1.3 Grasp hook not cable.

winch line. 3.1.4 Tie iron securely to rig.

3.1.5 Stand clear when lifting to floor.

Falling iron. 3.1.6 Look up, stay alert

3.1.7 Secure discharge lines using stains or chains.

Whipping iron.

Wrong position. 3.2 Back strain. 2 3 3.3.1 Use proper lifting techniques. 2 3

3.3.2 Use body system to lift iron.

Load too heavy. 3.3 Slippery 3.3.1 Check surface and exercise caution.

surface. 3.4.1 Secure to prevent contact with cable.

Bad whether

conditions 3.4 Damaged electric

cables.

3 3 1 3

NISNL/OPS/RA/02 Once printed this document becomes uncontrolled Page 2 of 3

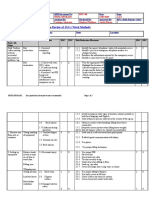

4. Connect 4.1 Personal injury. 3 3 4.1.1 Use proper PPE. 3 3

iron and hoses. 4.1.2 Use proper lifting technique.

4.2 Possible spills. 4.1.3 Use certified iron and hoses.

4.1.4 Clean and lubricate threads.

4.3 Dropping iron. 4.1.5 Check union gasket and big inch seals.

4.1.6 Ensure unions are tight.

4.1.7 Keep all personnel clear of Iron while lifting with hoist.

4.1.8 Secure iron to deck and well head.

5. Make up Wrong handling 5.1 Hand caught 3 3 5.1.1 Handle iron in a safe area away from pinch points.

wellhead of equipment. between 5.1.2 Use proper lifting techniques.

connections. connections. 2 3 5.1.3 Safety belt and line to be used at all times when working at

Unions and 5.2 Fall from height above six feet.

clamps not wellhead. 5.1.4 Use a brass hammer when close to the well head.

tightened.

Wrong handling

and lifting

technique.

Incorrect

handling.

NISNL/OPS/RA/02 Once printed this document becomes uncontrolled Page 3 of 3

You might also like

- Manual of Permitted Operations (MOPO)Document7 pagesManual of Permitted Operations (MOPO)Aniekan Akpaidiok100% (2)

- JSA Working at HeightDocument2 pagesJSA Working at HeightFadzira Syahira Fadzaleh100% (8)

- Mowing: Job Safety Analysis Mowing Operation Mowing With A Zero Turn or Riding LawnmowerDocument2 pagesMowing: Job Safety Analysis Mowing Operation Mowing With A Zero Turn or Riding LawnmowerRetselisitsoe100% (1)

- JSA For CT OperationsDocument39 pagesJSA For CT OperationsAniekan Akpaidiok0% (1)

- Barangay Poblacion I-ADocument24 pagesBarangay Poblacion I-AFreeNo ratings yet

- JSA 06 - Towing-Rig MoveDocument6 pagesJSA 06 - Towing-Rig MoveHaldar Bishwajit100% (2)

- WORK at HEIGHT Job Hazard AnalysisDocument3 pagesWORK at HEIGHT Job Hazard Analysistosin babayomi0% (1)

- JSA. Confined Space EntryDocument3 pagesJSA. Confined Space EntrySwaroop Cherry67% (3)

- JHA Scaffolding ErectionDocument12 pagesJHA Scaffolding ErectionChayank TiwariNo ratings yet

- Sealcoating /crack Repair Parking Lots: Job Safety AnalysisDocument3 pagesSealcoating /crack Repair Parking Lots: Job Safety AnalysisRetselisitsoe0% (1)

- JSA Scafffolding Erection Dismantling ModificationDocument14 pagesJSA Scafffolding Erection Dismantling ModificationSheri DiĺlNo ratings yet

- The Complete Guide To: First Aid at WorkDocument9 pagesThe Complete Guide To: First Aid at WorkmuneerpmhNo ratings yet

- Jsa For Receiving and Loading of Aggregates Onto Material BargeDocument2 pagesJsa For Receiving and Loading of Aggregates Onto Material BargeOgunwa EmmanuelNo ratings yet

- Lizof Jsa For ExcavationDocument2 pagesLizof Jsa For ExcavationOgunwa EmmanuelNo ratings yet

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- Jsa For Installation of Cyclone Rev 4Document10 pagesJsa For Installation of Cyclone Rev 4WilsonNo ratings yet

- Kta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Document3 pagesKta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Tuaman Engineering Limited: Job Safety Analysis (Jsa)Document6 pagesTuaman Engineering Limited: Job Safety Analysis (Jsa)abhijit janaNo ratings yet

- Risk Assessment - Method of Statement Hydraulic Cylinder Bearing Replacement-Tian Kun HaoDocument3 pagesRisk Assessment - Method of Statement Hydraulic Cylinder Bearing Replacement-Tian Kun HaoFebilaNo ratings yet

- 12 Scaffolding WorkDocument5 pages12 Scaffolding WorkKoneti JanardhanaraoNo ratings yet

- JSA Demolition Wall B#3Document2 pagesJSA Demolition Wall B#3tit somm100% (3)

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (4)

- 013A322B7E00019F - 2 - Rescue - Revised 10-05-12Document2 pages013A322B7E00019F - 2 - Rescue - Revised 10-05-12Nikhil Dangariya Regal Petro Trading FZENo ratings yet

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocument2 pagesJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiNo ratings yet

- Jsa For Cutting, Grinding and Welding For GulfconDocument3 pagesJsa For Cutting, Grinding and Welding For GulfconOgunwa Emmanuel100% (1)

- Construction Work JsaDocument21 pagesConstruction Work Jsaitsumar632No ratings yet

- Jsa For Sand Filling of SwampDocument5 pagesJsa For Sand Filling of SwampOgunwa Emmanuel50% (2)

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- JSAS For Pumping Main Treatment.Document2 pagesJSAS For Pumping Main Treatment.Aniekan AkpaidiokNo ratings yet

- Pipe Spool Replacement by Mobile CraneDocument8 pagesPipe Spool Replacement by Mobile CraneManikandanNo ratings yet

- 21.removal and Refixing of 02SDV3301C.Document3 pages21.removal and Refixing of 02SDV3301C.Mohammad Fazal KhanNo ratings yet

- 18.hot Tapping Preparation & Work.Document11 pages18.hot Tapping Preparation & Work.Zubair Ahmed KhaskheliNo ratings yet

- E 503 JsaDocument3 pagesE 503 Jsarizal azizanNo ratings yet

- Job Hazard AnalysisDocument2 pagesJob Hazard AnalysisMark DizonNo ratings yet

- M/S Kalachand Construction Job Hazard Analysis: JHA No.Document4 pagesM/S Kalachand Construction Job Hazard Analysis: JHA No.Dwitikrushna RoutNo ratings yet

- Job Safety Analysis: Lower The Equipments in The SiteDocument1 pageJob Safety Analysis: Lower The Equipments in The SiteHatem HusseinNo ratings yet

- Trial Run of Motor and Panels - 26.04.2019 - FinalDocument7 pagesTrial Run of Motor and Panels - 26.04.2019 - FinalChiranjit BhattacharjeeNo ratings yet

- Job Safety Analysis and Risk AssessmentDocument1 pageJob Safety Analysis and Risk Assessmentghada gattouchNo ratings yet

- HIRA of Batching Plant Erection.Document3 pagesHIRA of Batching Plant Erection.Gyanendra SrivastavaNo ratings yet

- Shuttering WorksDocument3 pagesShuttering WorksAbdul GhaffarNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument3 pagesR.K Construction: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Jha For SMP 2Document7 pagesJha For SMP 2Rohit TharseNo ratings yet

- JSA Confined Space To Carryout Manual Cleaning, Inspection, Grit Blasting and Painting Rev-00Document42 pagesJSA Confined Space To Carryout Manual Cleaning, Inspection, Grit Blasting and Painting Rev-00Syed Ahmed manzoor100% (1)

- Block WorkDocument4 pagesBlock WorkAbdul GhaffarNo ratings yet

- UntitledDocument5 pagesUntitledPranayNo ratings yet

- Ready Reckoner For Safety Precaution During Loading, Unloading & Transport of Mat PDFDocument1 pageReady Reckoner For Safety Precaution During Loading, Unloading & Transport of Mat PDFArvind MeenaNo ratings yet

- HIRA - Night Work Hazard ControlDocument3 pagesHIRA - Night Work Hazard ControlHiralal Pattanayak100% (2)

- MAB For JHADocument8 pagesMAB For JHARohit TharseNo ratings yet

- Installation of Vaporizers JSADocument6 pagesInstallation of Vaporizers JSAZubair Ahmed KhaskheliNo ratings yet

- Jsa Pulsation Dampener Maintenance and N2 Fill UpDocument2 pagesJsa Pulsation Dampener Maintenance and N2 Fill UpAdel AlKhedawyNo ratings yet

- Jsa No: 00 - Piling WorksDocument4 pagesJsa No: 00 - Piling WorksUMUTNo ratings yet

- Bar Fixing WorkDocument3 pagesBar Fixing WorkKoneti JanardhanaraoNo ratings yet

- HIRA of FTC Erection.Document3 pagesHIRA of FTC Erection.Gyanendra SrivastavaNo ratings yet

- JSA For Cleaning and Hydro Test of Test SeparatorDocument7 pagesJSA For Cleaning and Hydro Test of Test SeparatorNishantMittal100% (2)

- Jsa-013 Well DevelopmentDocument2 pagesJsa-013 Well DevelopmentRehman Muzaffar100% (2)

- RA - Maceio Terminal (MOORING AT OPEN TERMINAL)Document7 pagesRA - Maceio Terminal (MOORING AT OPEN TERMINAL)latish salianNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisDeshbandhu Aman PandeyNo ratings yet

- Safety Forum June 2020Document7 pagesSafety Forum June 2020AmirulAkmalNo ratings yet

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- Jsa-Spot Equipment On Boat or Barge.Document1 pageJsa-Spot Equipment On Boat or Barge.Aniekan AkpaidiokNo ratings yet

- Job Safety Analysis - Doc With Penumatic TestingDocument5 pagesJob Safety Analysis - Doc With Penumatic TestingDeshbandhu Aman Pandey100% (1)

- JSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Document7 pagesJSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Sebin VargheseNo ratings yet

- Applying Balance Skeletal TractionDocument3 pagesApplying Balance Skeletal Tractionpatrickulet01No ratings yet

- Jsa-Spot Equipment On Boat or Barge.Document1 pageJsa-Spot Equipment On Boat or Barge.Aniekan AkpaidiokNo ratings yet

- Jsa-Function Test Equipment.Document1 pageJsa-Function Test Equipment.Aniekan AkpaidiokNo ratings yet

- JSAS For Pumping Main Treatment.Document2 pagesJSAS For Pumping Main Treatment.Aniekan AkpaidiokNo ratings yet

- Module 100 - Introduction To QHSES ManagementDocument89 pagesModule 100 - Introduction To QHSES ManagementAniekan AkpaidiokNo ratings yet

- Scope of QMS - Netcore - 2021Document4 pagesScope of QMS - Netcore - 2021Aniekan AkpaidiokNo ratings yet

- Module 101-AssignmentDocument2 pagesModule 101-AssignmentAniekan AkpaidiokNo ratings yet

- Consequence: CODE: RPR.06.1 Revision Date: 22/01/2021Document12 pagesConsequence: CODE: RPR.06.1 Revision Date: 22/01/2021Aniekan AkpaidiokNo ratings yet

- Assignment TemplateDocument2 pagesAssignment TemplateAniekan AkpaidiokNo ratings yet

- Assignment Template (1) - Module 104Document1 pageAssignment Template (1) - Module 104Aniekan AkpaidiokNo ratings yet

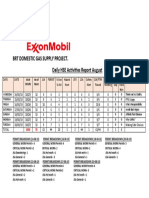

- Daily HSE Activities Report Aug-Wk9 (7th To 13th-19)Document1 pageDaily HSE Activities Report Aug-Wk9 (7th To 13th-19)Aniekan AkpaidiokNo ratings yet

- Working at Height PolicyDocument7 pagesWorking at Height PolicyAniekan AkpaidiokNo ratings yet

- Security Policy Statement-Rev01Document1 pageSecurity Policy Statement-Rev01Aniekan AkpaidiokNo ratings yet

- Daily HSE Activities Report AugSept-Wk12 (28th To 3rd-19)Document1 pageDaily HSE Activities Report AugSept-Wk12 (28th To 3rd-19)Aniekan AkpaidiokNo ratings yet

- Working at Height ProcedureDocument11 pagesWorking at Height ProcedureAniekan AkpaidiokNo ratings yet

- Daily HSE Activities Report Aug-Wk10 (14th To 20th-19)Document1 pageDaily HSE Activities Report Aug-Wk10 (14th To 20th-19)Aniekan AkpaidiokNo ratings yet

- Drop Object Prevention Policy and Procedure: NISNL-QHSE-DROPS-0421Document10 pagesDrop Object Prevention Policy and Procedure: NISNL-QHSE-DROPS-0421Aniekan AkpaidiokNo ratings yet

- MANAGEMENT OF CHANGE PROCEDURE NetcoreDocument12 pagesMANAGEMENT OF CHANGE PROCEDURE NetcoreAniekan AkpaidiokNo ratings yet

- NSTP-Sample Project ProposalDocument8 pagesNSTP-Sample Project ProposalMarey-vic RemoNo ratings yet

- First Aid KitDocument1 pageFirst Aid Kitapi-454487991No ratings yet

- DalupiriDocument2 pagesDalupiriInfirmaryNo ratings yet

- Lifing Plan (Building)Document15 pagesLifing Plan (Building)Utang “Teulunas” TeaNo ratings yet

- 2 DRRM H Matrices v5 2023Document35 pages2 DRRM H Matrices v5 2023Allan TampusNo ratings yet

- JSA-pumping Lines Rig Up.Document3 pagesJSA-pumping Lines Rig Up.Aniekan AkpaidiokNo ratings yet

- Wah Rescue PlanDocument2 pagesWah Rescue PlanJESUS BASILIO ANTONIONo ratings yet

- 5.6a First Aid Box Treatment - Inspection RegisterDocument1 page5.6a First Aid Box Treatment - Inspection RegisterSn Ahsan100% (1)

- DEL - 054 JSA For RadiographyDocument5 pagesDEL - 054 JSA For RadiographyViron BaxhiaNo ratings yet

- Setia Precast SDN BHD: Emergency Response and Preparedness PlanDocument20 pagesSetia Precast SDN BHD: Emergency Response and Preparedness PlanAisamuddin Rohaizai100% (1)

- St. John Ambulance Newsletter 2015Document2 pagesSt. John Ambulance Newsletter 2015Vanessa HaackNo ratings yet

- New Preparedness SurveyDocument13 pagesNew Preparedness SurveyGTCDRRMO Gen Trias CityNo ratings yet

- First Aid Checklist: # of Workers On Site General Contractor Responsibilities First Aid Kit Requirements orDocument1 pageFirst Aid Checklist: # of Workers On Site General Contractor Responsibilities First Aid Kit Requirements or4j1d4j4ngNo ratings yet

- ObjectivesDocument6 pagesObjectivesShaima SomraniNo ratings yet

- COO Craig Widener Retiring DSHR News: Happy Holidays. We Are Grateful For All You Do!Document7 pagesCOO Craig Widener Retiring DSHR News: Happy Holidays. We Are Grateful For All You Do!ARC of Greater IndianapolisNo ratings yet

- O o o O: II. Explain How The Unsafe Activities Identified in The Illustration Should Be Altered To Make Them SafeDocument2 pagesO o o O: II. Explain How The Unsafe Activities Identified in The Illustration Should Be Altered To Make Them Safewillzen CorpuzNo ratings yet

- Public First Aid Training Calendar 2023 - 2Document1 pagePublic First Aid Training Calendar 2023 - 2desa LicinNo ratings yet

- Online Survey On Early Preparedness Action For MayorsDocument8 pagesOnline Survey On Early Preparedness Action For MayorsJeffrey LoraNo ratings yet

- Work Immersion Portfolio 2024 2Document9 pagesWork Immersion Portfolio 2024 2Patricia SarahNo ratings yet

- English Formative 4 Exercises - Grade 4 - Sem 1Document6 pagesEnglish Formative 4 Exercises - Grade 4 - Sem 1Ronny LiemNo ratings yet

- Slasher v2Document8 pagesSlasher v2Karlos Córdova MéndezNo ratings yet

- First Aid Kit Cheat Sheet: by ViaDocument1 pageFirst Aid Kit Cheat Sheet: by ViaKathlene YuNo ratings yet

- ZLNG - ACTION ITEM LIST - CCCC KOM 20230718 - CCCC Reply - Att-4Document9 pagesZLNG - ACTION ITEM LIST - CCCC KOM 20230718 - CCCC Reply - Att-4saffririzal4237No ratings yet

- Fall Arrest Rescue PlanDocument1 pageFall Arrest Rescue PlanvictorNo ratings yet

- SOP For Tree Cutting at HPCL UNNAODocument3 pagesSOP For Tree Cutting at HPCL UNNAOamankumar100% (1)

- First Aid Box ContentsDocument2 pagesFirst Aid Box ContentssheedaabbasNo ratings yet

- USAR Category 2 - Field Operations GuideDocument71 pagesUSAR Category 2 - Field Operations GuideSérgio RibeiroNo ratings yet