Professional Documents

Culture Documents

Laboratory Quality Manual: Haren Textiles Pvt. LTD

Laboratory Quality Manual: Haren Textiles Pvt. LTD

Uploaded by

Ajay KajaniyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laboratory Quality Manual: Haren Textiles Pvt. LTD

Laboratory Quality Manual: Haren Textiles Pvt. LTD

Uploaded by

Ajay KajaniyaCopyright:

Available Formats

HAREN TEXTILES PVT. LTD.

M-QA-01-00

PAGE : 1 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

LABORATORY

QUALITY

MANUAL

DEVELOPED IN ACCORDANCE-TO AND FOR-COMPLIANCE WITH ISO 17025:2005

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 2 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

THIS QUALITY MANUAL IS RELEASED UNDER THE AUTHORITY OF;

AHAMED MANSOOR, LAB MANAGER

AND IS THE PROPERTY OF;

HAREN TEXTILES PVT. LTD.

HEAD OFFICE;

HAREN TEXTILES PVT. LTD.

WESTERN EXPRESS HIGHWAY

BEFORE TOLL NAKA

DAHISAR (EAST)

MUMBAI - 400068

MAHARASHTRA - INDIA

HAREN TESTING LAB: - ;

HAREN TEXTILES PVT. LTD.

PLOT NO. J-194, MIDC INDUSTRIAL AREA

TARAPUR - BOISAR

TALUKA - PALGHAR | PIN CODE - 401506

MAHARASHTRA - INDIA

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 3 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

DISTRUBUTION LIST

The following are the authorised holders of the controlled copy of HAREN TEXTILES PVT. LTD. LABORATORY QUALITY MANUAL;

DISTRIBUTED COPY TAG NAME (DESIGNATION) OF HOLDER DEPARTMENT

ORIGINAL AHAMED MANSOOR (LAB MANAGER) HAREN TESTING LAB

CONTROLLED COPY(SOFT) AYAN PATEL (LAB SUPERVISOR) HAREN TESTING LAB

CONTROLLED COPY(SOFT) NISHANT MEHTA (DIRECTOR) HAREN MANAGEMENT

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 4 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

ABBREVIATIONS

SR. NO. ABBREVIATION EXPANSION

1 LQM Laboratory Quality Manual

2 LMS Laboratory Management System

3 SOP Standard Operating Procedure

4 LAB Haren Textiles Pvt. Ltd. Laboratory

5 WI Work Instruction

6 NC Non-conformity

7 L List

8 F Formats

9 R Reports

DETAILED ABBREVIATION OF QUALITY DOC NUMBERS (Example)

SINGLE TEXT F PREFIX OF THE DOCUMENT NAME

Department (Lab is defined and under quality management and

DOUBLE TEXT QA

DIRECTORies)

NUMBER 05 Numbering the varoius formats

NUMBER 03 Numbering the addition in same formats

F FORMAT FORMAT SECTION

QA QUALITY ASSURENCE COMMON TO ALL DOC

05 FORMAT NUMBER Authorisation certificate

certificate to diff people but format no is same. Only certificate no will be

03 ADDITION NUMBER

change

VERSION 1.0, 2.0 A version is an iteration, something that is different than before.

REVISION 1.0, 2.0 A Revision is to make a new, amended, improved, or up-to-date version.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 5 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

ISSUE AND CONTROL

This Haren Textiles Pvt. Ltd. Laboratory Quality Manual (LQM) forms part of the overall Laboratory Management System

(LMS) of Haren Textiles Pvt. Ltd. and is, issued by the LAB MANAGER and approved by the DIRECTOR.

Changes may only be approved by LAB MANAGER and DIRECTOR.

This is a Controlled Document subject to updating and hence should not be copied and only signed.

Approved copies are used as working documents.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 6 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

DOCUMENT REVISION RECORD / HISTORY OF MODIFICATION

To ensure that every copy of this Haren Textiles Pvt. Ltd. Laboratory Quality Manual has a complete record of

amendaments in the appendix no.2. The below is an example of format.

EXAMPLE:

SECTION / CLAUSE /

DATE OF REASON FOR AUTHORISED

SR. NO. PAGE NO. PARA WHERE REVISION MADE

REVISION REVISION SIGNATORY

REVISION DONE

To establish zero

Organisation Chart Ronak shah

1.6 influence of

1 12 12.04.2017 updated for better Quality

(Management Req.) production dept on

clarity on structure In-Charge

Lab operations

Added;

7.1.5 Test Officers

performing the test are

not disclosed about the

To ensure intergrity

Customer where the fabric Ronak shah

7.1.5 and impartial testing

2 19 12.04.2017 shall be going. Only Quality

(Management Req.) and confidentialty

relevant DS related info is In-Charge

of customers' results

provided to ensure correct

DS & its Version are

followed for testing. This is

to ensure integirty in

testing.

Added;

4.1.3 Whenever there is

To ensure LAB can

change in the Version of

keep itself capable to Ronak shah

4.1.3 the Test Method or when

3 28 12.04.2017 test using newer Quality

(Techincal Req.) applying for validation of

Versions and In-Charge

new Test, capability to

Standards

perform updated version

or test ar met as detailed

in P-QA-18-00

Updated relevant SOP /

Document numbers in the Updated reference and Ronak shah

4 - - 12.04.2017 Manual as the original avoid any reference to Quality

reference documents are Obselete documents In-Charge

updated

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 7 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

TABLE OF CONTENTS

SECTION 4 - MANAGEMENT REQUIREMENTS

SUB SECTION NO. CONTENTS ISO 17025 : 2005 CLAUSE NO. PAGE NO.

1.0 Organisation 4.1 10

2.0 Management System 4.2 13

3.0 Document Control 4.3 15

4.0 Review of Requests, Tenders & Contracts 4.4 16

5.0 Subcontracting of Tests 4.5 17

6.0 Purchasing, Services & Supplies 4.6 17

7.0 Service to Customer 4.7 18

8.0 Complaints 4.8 19

9.0 Control of NC Testing 4.9 19

10.0 Improvement 4.10 20

11.0 Corrective Action 4.11 21

12.0 Preventive Action 4.12 22

13.0 Records 4.13 22

14.0 Internal Audits 4.14 24

15.0 Management Reviews 4.15 25

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 8 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

TABLE OF CONTENTS

SECTION 5 - TECHNICAL REQUIREMENTS

SUB SECTION NO. CONTENTS ISO 17025 : 2005 CLAUSE NO. PAGE NO.

1.0 General 5.1 26

2.0 Personnel 5.2 26

3.0 Accommodation & Environmental Conditions 5.3 27

4.0 Test Methods & Method Validation 5.4 28

5.0 Equipment 5.5 29

6.0 Measurement Traceability 5.6 31

7.0 Sampling 5.7 32

8.0 Handling of Test Items 5.8 32

9.0 Assuring Quality of Test Results 5.9 33

10.0 Reporting the Results 5.10 34

APPENDIX 1 to Section 8.4 for the

8.4 5.8 37

SAMPLE PROCESS FLOW IN LABORATORY

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 9 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

HAREN TESTING LAB QUALITY POLICY

We, at HAREN TEXTILES PVT. LTD. LABORATORY are committed to ensure continual improvement in achieving cusomters'

total satisfaction by consistently pursuing the agreed Quality Plan based on established Quality Standard.

The above policy is achieved through effective implementation of the ISO 17025 : 2005 Quality Management System

standard requirements following below listed objectives;

=> establishing a good management system to comply with the requirements as specified in ISO 17025 : 2005 and

continually improving the effectiveness of the management system

=> adopting good laboratory practices and recognised test methods

=> employing qualified personnel, providing them continuous training in testing and documentation and ensuring that they

understand and implement the policies and procedures in their work.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 10 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

MANAGEMENT REQUIREMENTS

1.0 ORGANISATION ISO / IEC 17025 CLAUSE 4.1

1.1 Legal Identification

1.1.1 LAB is an integral part of Haren Textiles Pvt. Ltd., held legally responsible. A copy of the registration certificate is

available in company records.

1.2 Commitment to meet ISO 17025:2005

1.2.1 The Management and staff are committed to carry out all testing activities in such a way to meet the requirements of

ISO 17025:2005 and customers of Haren Textiles Pvt. Ltd.

1.3 LMS to cover testing operations in its permanent and mobile facilities

1.3.1 The laboratory has permanent infrastructural facilities to carry out the tests for which it is to be accredited and the

LMS covers all testing operations carried out in its permanent facility

1.3.2 The Organisation does not have any mobile laboratory

1.4 Parent Organisation

1.4.1 LAB is wholly owned and part of Haren Textiles Pvt. Ltd., the parent Organisation. It is engaged in manufacturing of the

synthetic fabrics, based in Mumbai, Maharashtra, INDIA (Factory @ Tarapur, Maharashtra, INDIA). The personnel involved

in testing activities within LAB are not involved in any other activities of parent organisation, Haren Textiles Pvt. Ltd.

1.5 Management and Technical Staff

1.5.1 The Management System encompasses technical operations and support service personnel who support laboratory

testing activities identified in the current scope of testing. The operation of lab organisation is headed by LAB MANAGER

who is responsible for lab overall policy decisions. LAB MANAGER has complete control over operational, infrastructural

facilities and personnel. LAB SUPERVISOR has the authority and responsibility to identify the resources needed for testing

activities. LAB MANAGER has the authority and responsibility to implement, maintain and improve the Management

System. The Organisation Chart provides the status of various personnel and their responsibilities. The Organisation Chart

is provided in Section 1.6 (page no. 12)

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 11 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

1.5.2 It is ensured that the Management and Staff are free from commercial and financial pressures and influences that may

adversely affect the quality of testing or its results during the time of employment. Yearly Budget well forecasted planned

and shared with managaments to plan accordingly. (B-QA-01-00)

1.5.3 Protecting customers' confidential information and propietory rights;

Policy - To protect customers' confidential info and propietory rights, all visitors, who are not employee of Haren Textiles

Pvt. Ltd., must sign a 'Visitor Confidentiality Form' before visiting lab. All the electronic data is securely stored which is

only accessible by Lab personnel.

1.5.4 Laboratory's competence, impartiality and integrity.

1.5.4.1 It is essential that the management and testing personnel are not involved in activities that would affect the

confidence, impartiality, judgement or operational integrity.

1.5.4.2 The personnel involved in testing / lab are not allowed to undertake any other work during their tenure, unless they

are officially transferred from one department to another, after which they would not be involved in the functioning of lab.

1.5.5 The Organisation Structure along with the relationships between quality management, technical operations and

support services is provided in the organisation chart. The Job Descriptions along with their responsibility, authority and

interrelationship of all staff personnel are available in their respective personal files in Human Resource Department.

Each lab staffs and individual and lab performance are monitoring by their activities and end results towards to KPI

individual KPI's are such as TAT, testing Errors, Marks, Kaizen, test Delays, 6S, Other operational parameters, etc...

Those individual indicators feed into centralized PMS sheets every month and will be review yearly quarter with OPEX Team

1.5.6 LAB SUPERVISOR is involved in supervising all testing activities carried out by lab staff, including trainees

1.5.7 LAB SUPERVISOR - LAB SUPERVISOR has the overall responsibility & authority over the technical operations &

provisionoperations of laboratory activities. The Senior Lab Technician can perform the role of LAB SUPERVISOR in his/her

absence.

1.5.8 LAB MANAGER - The LAB MANAGER has responsibility and authority of over all quality matters concerning the

implementation of the Quality & Technical Management System at all times. He/She is responsible for communicating the

objectives of organisation and ensures that the staff are aware of the relevance and importance of their activities in

contributing to theachievement of the overall objectives. He/She is also responsible to take care to close any

non-conformity and subsequent action plan. He/She has direct access to highest level of Management at which decisions

are made on laboratory policies.The Lab supervisor can perform the role of LAB MANAGER in his/her absence.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 12 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

1.6 Organisation Chart for Haren Textiles Pvt. Ltd. AND Haren Textiles Pvt. Ltd. Laboratory

HAREN TEXTILES PVT. LTD. ORGANISATION CHART

HAREN TEXTILES BOARD OF

DIRECTORS

DIRECTOR FINANCE AND HR DIRECTOR OPERATIONS DIRECTOR SALES

DIRECTOR QUALITY, DEVELOPMENTS AND INNOVATIONS

ADMIN HEAD OPERATIONAL HEAD SALES TEAM

LAB MANAGER 1. QUALITY DEPARTMENT

1. AHAMED MANSOOR 2. HRP & SAFETY DEPARTMENT

(Lab QUALITY & Lab TECHNICAL) 3. OPEX

HEAD FINANCE AND ACCOUNTS HEAD WARPING, WEAVING SALES SUPPORT TEAM

LAB SUPERVISOR

2. AYAN PATEL

HEAD HUMAN RESOURCES HEAD KNITTING

SENIOR TEST OFFICER (3+ year)

3. SALMAN

HEAD DYEING AND FINISHING 4. MINISH

5. HIMANSHU

JUNIOR TEST OFFICER (1-3 year)

HEAD QC AND DESPATCH 5. HIMANSHU

6. RUCHIT KINI

7. ISHA MORE

Trainees (0-1 year)

8. ALI ASGHAR

9. SANTHOSH AADE

10. SANKET KAMBLE

HAREN TEXTILES PVT. LTD. LABORATORY ORGANISATION CHART

SENIOR TEST

OFFICER

DIRECTOR

QUALITY, NEW LAB MANAGER

DEVELOPMENTS LAB SUPERVISOR JUNIOR TEST

AND (QA & TECH) OFFICER

COMPLIANCES

TRAINEES

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 13 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

2.0 MANAGEMENT SYSTEM ISO / IEC 17025 CLAUSE 4.2

2.1 Management System : General Descriptions

2.1.1 A Laboratory Management System (LMS) meeting the requirements of ISO 17025 : 2005 has been implemented. This has

been documented and includes policies, systems, procedures and instructions necessary to assure the quality of test

results. This system documentation is communicated, made available and ensured that it is understood and implemented

by the appropriate personnel.

2.1.2 The policies related to quality including Policy Statement of LAB are provided in the Haren Textiles Pvt. Ltd. Lab Quality

Manual (LQM). The overall objectives as documented in the manual are reviewed during Management Review Meeting.

2.2 Quality Policy

2.2.1 The policy of LAB is to 'ENSURE CONTINUAL IMPROVEMENT IN ACHIEVING CUSTOMTERS TOTAL SATISFACTION BY

CONSISTENTLY PURSUING THE AGREED QUALITY PLAN BASED ON ESTABLISHED QUALITY STANDARD'

2.3 Regulatory Requirements

2.3.1 LAB is committed to meet the various regulatory requirements as required by its customers along with ISO 17025:2005

2.3.2 Appropriate Plan is prepared and verified that all regulation are met in applicable areas.

2.4 Qulaity Manual

2.4.1 The objectives of the LQM are to;

=> Define and document policies and practices along with any references necessary to supporting procedures including

technical procedures and to provide an outline of the structure of the documentation used in the LMS

=> Enable policies, procedures and commitment to good laboratory practice and high quality of testing and communicating

the importance of meeting customers' requirements

=> Define the roles and responsibility of quality and technical management including their responsibility for ensuring

compliance to ISO 17025 : 2005

=> Enable all the laboratory staff to understand the Quality System and implement them while honoring their duties and

responsibilites.

=> Enable the Audit of actual working against the stated good laboratory practice as required under ISO 17025 : 2005

=> Ensure efficient Laboratory Management System (LMS)

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 14 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

2.4.2 The DIRECTOR and LAB MANAGER are committed to the development and implementation of the LMS and to

continually improve its effectiveness. This is evaluated at Management Review Meetings.

2.4.3 Haren Textiles Pvt. Ltd. Laboratory Quality Manual is prepared by LAB MANAGER and approved by the DIRECTOR of

Haren Textiles Pvt. Ltd. The LAB MANAGER is responsible for compliance to ISO 17025:2005 and implementation of LMS.

2.4.4 The LAB MANAGER ensures that the integrity of the Management System is maintained wherever changes to the

Management System are planned and implemented.

2.4.5 Each distributed copy of the Quality Manual is assigned a copy number which is displayed on the 1st page. The

LAB MANAGER retains the signed Original Copy.

2.4.6 Copy No. are assigned as below;

ORIGINAL ==> Original Copy retained by the LAB MANAGER

CONTROLLED COPY ==> Controlled Copy with Laboratory In-Charge in Lab (accisible to all LAB Staff)

CONTROLLED COPY ==> Controlled Copy with DIRECTOR

2.5 Documentation Structure

2.5.1 The Quality System Documents comprises of Haren Textiles Pvt. Ltd. Laboratory Quality Manual (LQM), Lists for all the

Documents managed / maintained, Standard Operating Procedures, Work Instructions, Formats for all recordings and

reporting. LQM is the principle document prescribing how Quality System functions towards achieving quality objectives.

Next is the List of all the documents, SOP's, formats and reports. SOP's have basic procedural details with people

responsible for each activity. The Work Instructions are detailed step by step guide for all the tests performed in the lab.

This is to ensure no deviation while testing. Formats are used to record and maintain all the data related to all the actitives

carried out in LAB. This data is recorded in accordance to ISO 17025 : 2005 requirements. Reporting is final stage where

all records are represented in the manner as desired and demanded by customers.

2.6 Roles and Responsibilities of Quality and Technical Management Staff / Personnel

The Roles and Responsibilities of various Technical and Quality Personnel are defined in Section 1.5.7 and 1.5.8

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 15 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

LEVEL 1 Documents - Laboratory Quality Manual

LEVEL 2 Documents - Lists

LEVEL 3 Documents - SOP's

LEVEL 4 Documents - Work Instructions

LEVEL 5 Documents - Formats

LEVEL 6 Documents - Reports

3.0 DOCUMENT CONTROL ISO / IEC 17025 CLAUSE 4.3

3.1 Policy

3.1.1 To ensure that appropriate documentation is generated internally such as LQM, SOP, WI, Formats, Reports, Software,

Documentation from external sources such as International Standards, client's specifications are implemented and

controlled as required to facilitate the proper functioning of all test activities.

3.2 Document Approval and Issue

3.2.1 Level 1 Document is issued to the concerned as part of LMS documentation, issued by the LAB MANAGER,

approved and re-approved wherever required prior to the issue by the DIRECTOR. Level 2 and Level 3 documents are

prepared and issued by LAB MANAGER. Level 4 pictorial documents are prepared and issued by, LAB MANAGER

Level 5 and Level 6 recording and reporting documents are made and issed by LAB MANAGER

(in case of any deviation, the details for person preparing, approving and issuing shall be mentioned / specified on

individual concerned document).

3.2.2 A Master List of controlled documents is maintained indicating the current revision / distribution status / reviewing /

approval authority for each level of documents is available with the Quality Department to prevent the use of invalid /

obselete documents.

3.2.3 The Procedure adopted is according to the Internal / External Document and Data Control Procedure and ensures that;

==> authorised editions / versions of the appropriate documents are available at the required locations.

==> Documents are periodically reviewed before Management Reviews and changes made, whatever necessary to ensure

continual suitability and compliance with applicable requirements. All documents are reviewed at least once in 2 years.

==> Invalid or Obselete documents are promptly marked as OBSELETE and not allowed to use and ensure unintended use.

LAB MANAGER maintains the details for all the updates / changes for a clear record of document use / revision history.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 16 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

preservation purposes so that there is access to pertinent background information.

3.2.4 All Management System documents generated are uniquely identifiable (for example - M-QA-01-00) and carry Version

details, Revision details, Effective Date & also Page No. along with total no. of pages.

3.3 Document Changes

3.3.1 Changes to documents are reviewed and approved by the same functionary that performed the original documents

earlier. The altered text, wherever possible is identified in the document revision record (amendament history)

3.3.2 Documents are reissued by updating the Version and Revision for the document. The details about Version & Revision

are explained in P-QA-02-00 (Internal / External Document and Data Control Procedure)

3.3.3 The laboratory’s document control system allows for the revision and re-issue of documents only by the Quality

In-Charge with the Version, Revision and Effective Date clearly marked, signed and dated.

3.3.4 The Documents, including those in the computer system are maintained according to P-QA-02-00 (Internal / External

Document and Data Control Procedure)

REFERENCE - P-QA-02-00 Internal / External Document and Data Control Procedure

4.0 REVIEW OF REQUESTS ISO / IEC 17025 CLAUSE 4.4

4.1 Policy

4.1.1 In case of development sample, the Log-In Register In-Charge (LAB SUPERVISOR and / or Lab Staff) ensures that format -

F-QA-03-00 (Laboratory Test Request Form with Results - TRF) and sample are reviewed according to P-QA-01-00 (Sample

Log-in Procedure) before accepting the order. For inwarded bulk samples, TRF is not required, only the samples are checked

for appropriateness.

4.1.2 The Test Request is reviewed by LAB SUPERVISOR or LAB TEST OFFICERS ensures that;

a. The scope of the work including the test methods to be used is adequately defined, documented and understood.

b. The Laboratory has the necessary physical infrastructure, information resources and trained staff to carry out the tests

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 17 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

and the test methods are suitable to meet the submitters’ requirements.

c. In the case of new testing requirement the LAB SUPERVISOR ensures the availability of instrument / reference material /

required chemicals.

4.2 Review Request Record

4.2.1 All the requests from submitters are reviewed in practical manner from delivery point of view.

4.3 Deviation

There is no deviation allowed in the procedure for testing (sampling, testing, test methods). Testing is done according to ISO

Standard or Customer Prescribed method / standard.

4.4 Amendament

4.4.1 For any amendment / change in the test request after the commencement of work, the Review of Request is done

once again as per the original procedure and the details of amendments is communicated to all affected parties.

5.0 SUBCONTRACTING OF TESTS ISO / IEC 17025 CLAUSE 4.5

Haren Textiles Pvt. Ltd. LAB subcontracts testing work due to non-availability of capability /expertise (or) unforeseen

circumstances. Customer / Submitter of sample is informed about subcontracting in mail. The subcontracting is done only

to Customer nominated Laboratory or NABL accredited laboratories. The information is reflected in the reports issued.

6.0 PURCHASING, SERVICES AND SUPPLIES ISO / IEC 17025 CLAUSE 4.6

6. 1 Policy

6.1.1 This policy defines the procedure for purchase goods, supplies or outside services according to P-QA-03-00;

Purchasing (Equipments and Consumables) and Servicing

6.1.2 Whenever the above items are procured for testing activities, it is ensured that all such items as well as services

are checked for adequate quality to sustain confidence in the testing activities before use.

6.1.3 Wherever possible goods, supplies and services are purchased from those suppliers from approved supplier list or

any new supplier with prior approval from LAB MANAGER.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 18 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

6.1.4 Where independent assurance of quality is not available, it is ensured by inspection and through checking of goods

that specifications defined in the purchase order are met before use.

6.1.5 It is ensured that the purchase document contains quality, quantity and suppliers name. All purchase documents are

reviewed for technical content by LAB SUPERVISOR (if required), except capital equipment and glassware

6.1.6 It is responsibility of Lab & LAB MANAGER to evaluate the organization for seeking support for outside calibration

and Maintenance services maintaining the traceability as required by the Management System and International Standards

6.2 Records

6.2.1 A record is maintained under the purchasing procedure as given in P-QA-03-00 of all the suppliers which are

identified vendors and all are evaluated for quality and other parameters as mentioned in P-QA-03-00

6.2.2 Records of checks on critical items (if any items are classified as critical), received & approved are also maintained.

6.3 Storage

The LAB SUPERVISOR is responsible for storage of the reagents & consumable materials in suitable environmental

conditions as explained in P-QA-03-00

REFERENCE - P-QA-03-00 Purchasing (Equipments and Consumables) and Servicing

7.0 SERVICE TO CUSTOMER ISO / IEC 17025 CLAUSE 4.7

7.1 Policy

7.1.1 In line with ISO 17025:2005 criteria, great importance is attached to customer satisfaction. In this, the LAB MANAGER

plays a crucial role in dealing directly with person submitting sample to ensure that they are completely

satisfied with the services.

7.1.2 With the objective of providing complete satisfaction, opportunities are provided to customers to enable them if they

wish to monitor the laboratory's performance in relation to their testing activity.

7.1.3 Good communication is maintained with customers, providing clarification / guidance wherever required.

Communication with the person who submitted the sample is ensured if there is any delay in testing their sample due to

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 19 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

unforeseen reasons.

7.1.4 Witnessing of tests is allowed without affecting the confidentiality of customer and / or specified testing method.

7.1.5 Test Officers performing the test are not disclosed about the Customer where the fabric shall be going. Only relevant

DS related info is provided to ensure correct DS & its Version are followed for testing. This is to ensure integirty in testing.

8.0 COMPLAINTS ISO / IEC 17025 CLAUSE 4.8

8.1 Policy

8.1.1 The Policy to deal with complaints from whatever source in a prompt and efficient manner in accordance to the

ISO 17025:2005, Clause 4.8 and P-QA-07-00.

8.2 Responsibility

On receipt of customer (submitter) complaint, forward to LAB for registering complaint and acknowledge the customer or

submitter about the complaint providing assurance to check and revert in accordance to P-QA-07-00. LAB MANAGER

investigates the problem involving the appropriate laboratory staff and takes necessary corrective actions. Complaints of

a technical nature or where there is an NC in testing, corrective action is suggested by the LAB SUPERVISOR along with the

concerned functional after investigation. LAB MANAGER ensures the implementation of the corrective action (long term

or short term) and subsequent preventive actions.

8.3 Records

8.3.1 All records pertaining to customer complaints, investigations undertaken, corrective action and closure details are

maintained and reviewed at the Management Review Meeting.

9.0 CONTROL OF NC TESTING ISO / IEC 17025 CLAUSE 4.9

9.1 Policy

To evaluate any non conformities in testing and take necessary corrective action to rectify the same for the complete

satisfaction of the customer.

9.2 Responsibility

LAB MANAGER

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 20 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

9.3 Setps Taken and Records

9.3.1 If non-conformity is found in testing, record in NC Log book (F-QA-04-00) in accordance with SOP for control of NC,

P-QA-11-00. The LAB MANAGER is assigned to deal with respective personnel for closure of nonconformity.

9.3.2 Comprehensive details of the investigation & any resultant corrective / preventive action required is recorded in the

In-house Nonconformity Log Book and the department HOD’s approval obtained when any report is revised.

Corrective actions are taken immediately along with the decision about the acceptability of the NC which includes halting

of further work and withholding of relevant test reports if necessary after evaluating the significance of the non conforming

work.

9.3.3 Records of relevant NC's is maintained in the LAB by LAB MANAGER & these are made available at Mgt Reviews.

REFERENCE - P-QA-07-00 and P-QA-11-00

10.0 IMPROVEMENTS ISO / IEC 17025 CLAUSE 4.10

10.1 Policy

10.1.1 Strive to continually improve the effectiveness of its LMS though the use of Quality Policy, Quality Objectives, Audit

Results, analysis of data, corrective and preventive action and Management Reviews.

10.2 Responsibility

10.2.1 LAB MANAGER

10.3 Steps taken to continually improve the effectiveness of the management system

10.3.1 Communication and interaction with staff at all times and at all levels by means of notice board displays & review

meetings.

10.3.2 Continuos and systematic training on LMS

10.3.3 Interaction with submitters, obtaining and reviewing feedback from them.

10.3.4 Allowing customers to witness tests being performed on their samples and getting their comments on performance.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 21 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

REFERENCE - Customer Feedback Form

11.0 CORRECTIVE ACTION ISO / IEC 17025 CLAUSE 4.11

11.1 Policy

11.1.1 To take immediate corrective action in accordance with ISO 17025:2005 wherever non conformity is encountered

either in testing or due to departures from stated policies and procedures.

11.2 Responsibility

11.2.1 LAB MANAGER / LAB SUPERVISOR

11.3 Identification of NC's

11.3.1 The NCs are usually identified through internal / external audits, procedural audits, Management Reviews, feedback

from customers and interaction with staff and so on.

11.4 Cause Analysis

11.4.1 The root cause of the problem is determined through a investigation. The root cause could include wrongly

stated customer requirements, sample type / specifications, test methods, staff skill, quality of consumables, use of wrong

consumable, capacity of instrument and calibration status.

11.5 Selection and implementation of Corrective Action

11.5.1 Once the cause is identified, potential corrective actions are planned and the one which is most likely to eliminate

the problem and prevent recurrence is selected for implementation. Corrective actions are always carried out in a degree

appropriate to the magnitude and risk of the problem.

11.5.2 The root cause as well as all potential corrective actions are recorded in the In-house Nonconformity Register Form

and maintained.

11.5.3 It is the ultimate responsibility of the LAB MANAGER to ensure that the corrective actions taken are implemented

properly and are effective.

11.5.4 AUDITS - Where a complaint / investigation or any other issue raises a doubt concerning compliance with stated

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 22 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

policies or procedures with the requirements of ISO 17025:2005 standard or otherwise concerning the quality testing

activities, the LAB MANAGER ensures that those areas of activity and responsibility involved are promptly audited in

accordance with Section 4.14 (Internal Audit) of ISO 17025:2005 Standard.

REFERENCE - P-QA-11-00

12.0 PREVENTIVE ACTION ISO / IEC 17025 CLAUSE 4.12

12.1 Policy

12.1.1 A proactive process of identifying improvement measures and potential non-conformances is followed both in the

Management System and Technical Procedures.

12.2 Responsibility

12.2.1 LAB MANAGER

12.3 The identification of preventive action could be based on the findings from;

==> Reviewing of Repeatability and correlation results(Same reports testing in other validated labs)

==> Review of standard operational procedures

==> Trend Analysis of Quality Control data(Blocking Rate, Limits)

==> Internal or external Audits

12.4 Once preventive actions are identified, action plans are developed, implemented and monitored so that occurrence of

non-conformances can be stopped and the quality of work can be improved.

12.5 Preventive action includes application of controls to study the effectiveness of the preventive action.

REFERENCE - P-QA-07-00

13.0 RECORDS ISO / IEC 17025 CLAUSE 4.13

13.1 Policy

13.1.1 To have a well-established system of documentation to ensure identification, collection, filing, storage, access and

retrieval, maintenance and disposal of records.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 23 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

13.1.2 All records are ensured to be legible and are placed in suitable environment & are maintained as hard/soft copies

(as applicable) to protect them from damage or loss. Retention times for records have been established.

13.1.3 All records are held secure and in confidence.

13.1.4 Procedure P-QA-12-00 describes how records stored electronically are protected & to prevent unauthorized access

or amendment to these records.

13.2 Quality Records

13.2.1 Records related to all testing activities are maintained so as to provide sufficient information to enable any source

of error to be identified and if necessary enable testing to be repeated under conditions close to the original.

13.2.2 The records include for each test performed, all information required to compile test reports as per ISO 17025:2005.

13.2.3 The record identification and numbering system follows a logical sequence and retained in specific areas in

accordance with P-QA-12-00

13.2.4 All original observations, calculations and notes are clearly, legibly and permanently recorded by the testing staff

at the time they are made. Entries in the Chain of Custody Form, Observation Records and Instrument Log Records, include

the name of persons carrying out the tests and the dates.

13.2.5 When mistakes occur in manual recording, any mistake will not be erased, made illegible or deleted, but crossed out

and correction entered alongside. All such corrections made to records are endorsed and dated by the person making the

original entry and apprroved by the LAB SUPERVISOR

13.3 Protection and Retention

13.3.1 The LAB SUPERVISOR is responsible for the maintenance of all technical records such as sampling data sheets, order

acknowledgement, analysis request and disposal records, test reports, environmental monitoring records, etc.

13.3.2 Records pertaining to LMS and quality like audit and Management Reviews, customer complaints, proficiency and

inter laboratory testing are maintained by the LAB MANAGER.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 24 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

13.3.3 P-QA-12-00 provides a complete list of quality records, person responsible for their maintenance, retention time &

location.

REFERENCE - P-QA-12-00

14.0 INTERNAL AUDITS ISO / IEC 17025 CLAUSE 4.14

14.1 Policy

14.1.1 Internal Audits of the Laboratory Management System are carried out in accordance with the requirements of

ISO 17025:2005 Clause 4.14 and P-QA-13-00 at regular defined intervals by trained qualified personnel to ensure that

policies and procedures as set out in this LQM are being adhered to.

14.2 Responsibility

14.2.1 An audit plan is prepared & administered by the LAB MANAGER ensuring that each area is audited at least once

every twelve months.

14.2.2 The LAB MANAGER is also responsible for the operation of all auditing activities and the verification of the

completion of any corrective action. The LAB MANAGER ensures that the DIRECTOR is immediately informed of failures

and delays in the implementation of corrective action.

14.2.3 The LAB MANAGER ensures that the staff is not allowed to audit their own activities. Auditor should be

independent of area of activity being audited.

14.2.4 The LAB MANAGER may also draw upon an external body or individual to carry out internal audits to meet the

requirements of the Laboratory

14.2.5 The LAB MANAGER is responsible for follow-up of audit activities to verify and record the implementation and

effectiveness of corrective actions taken to present in management review.

14.3 Documentation

14.3.1 The audit documentation used, e.g. audit schedule reports, summaries, checklists are all maintained by the Quality

In-Charge and are placed at the Management Review.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 25 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

15.0 MANAGEMENT REVIEW ISO / IEC 17025 CLAUSE 4.15

15.1 Policy

15.1.1 Management Review is carried out in at-least once in a year. If need or urgency we can arrange and it should be

record in MRM file. (Refer to 15.2.2 for areas to be covered).

15.1.2 Management Reviews are planned meetings chaired by the DIRECTOR, LAB MANAGER and LAB SUPERVISOR to ensure

the continuing effectiveness of the LMS.

15.2 Responsibility

15.2.1 The LAB MANAGER is responsible for ensuring that relevant Management Review topics including ISO 17025:2005

standard requirement are included in the Management Review agenda and that the reviews are scheduled to cover all these

topics at-least once in a year and that complete records of the reviews are maintained.

15.2.2 The topics to be considered during the review includes suitability of the Quality Policy and procedures, reports from

supervisory and managerial staff, the outcome of external assessments and internal quality audits, corrective & preventive

actions, complaints/feedback from customers, changes in volume and type of work, personnel requirement, training, scope

for improvement, review, approval and re-approval of all documents and other relevant issues.

During MRM, shall discuss about Previous year and current year Lab Budgets, Departmental KPI's and Individual KPI's such

as their Individual TAT, NC, Performances and structural changes.

15.2.3 The LAB MANAGER also has the overall responsibility to ensure that Management Reviews are conducted in

accordance with the requirements and actions that arise from them are carried out within an appropriate and agreed time

frame.

15.3 Documentation

15.3.1 Documentation concerning Management Reviews is generated, maintained and retained by the LAB MANAGER.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 26 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

TECHNICAL REQUIREMENTS

1.0 GENERAL ISO / IEC 17025 CLAUSE 5.1

1.1 The following factors contribute to the correctness and reliability of test results and are dealt with in Section 5 of

ISO 17025:2005 - Personnel, Accommodation and Environmental Conditions, Test Methods and Equipment, Measurement

Traceability, Sampling and the Handling of items.

1.2 As the extent to which the above factors contribute to total uncertainty of measurement varies depending on the type

of tests carried out, these factors are taken into account in selection of equipment and training the personnel.

2.0 PERSONNEL ISO / IEC 17025 CLAUSE 5.2

2.1 Policy

2.1.1 The Laboratory Management is committed to ensure the availability of sufficient qualified and trained personnel to

operate specific instruments, perform tests, evaluate results sign test under appropriate supervision.

2.1.2 Responsibilities are assigned based on technical qualification, training, experience and or demonstrable skills.

2.1.3 Wherever it is mandatory that personnel performing specific tests hold personal certification it is ensured that such

requirements are fulfilled.

2.1.4 The policy is to draw up systematic plans for upgrading technical skills and providing training in required areas.

Training is provided based on procedure P-QA-14-00 – Procedure for Identifying Training Needs, Providing Training and

Evaluation. The training program is drawn based on the position of personnel appointed. The effectiveness of the training

programme is systematically evaluated.

2.2 Work

2.2.1 Personnel are employed full time for carrying out testing and administrative work.

2.2.2 Job descriptions for all managerial, technical and support personnel including their responsibilities with respect to

performing specific tests, issuing test reports and operating specific instruments are provided in their individual files with

LAB MANAGER

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 27 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

3.0 ACCOMMODATION AND ENVIRONMENTAL CONDITIONS ISO / IEC 17025 CLAUSE 5.3

3.1 Policy

3.1.1 The Laboratory environment is maintained such that the quality of tests being carried out is not jeopardized. Special

attention is paid to environmental requirements of relevant standards / specifications and adequate lighting facilities to

ensure correct performace of test.

3.1.2 It is ensured that environmental conditions do not invalidate results or adversely affect the required quality of any

measurement

3.2 Responsibilty

3.2.1 LAB SUPERVISOR

3.3 Accommodation and Environmental Conditions

3.3.1 Effective monitoring, control and recording of environmental conditions as appropriate to the testing activities is

being carried out with particular attention being paid to humidity, electrical supply, temperature etc.

3.3.2 Where environmental conditions drift out of specification, all testing activities are suspended until the environment

has returned to specification. Where activities have been suspended the causes are investigated and the details recorded

including any corrective and preventive action.

3.3.3 Adequate space to carry out various activities related to the scope of work & the areas with incompatible activities

are well separated to prevent cross contamination. Laboratory sections are provided with sufficient lighting & ventilation.

3.4 Access

3.4.1 Access to the testing sections and equipment are restricted to authorized personnel designated by the LAB SUPERVISOR.

3.5 Safety

3.5.1 Safety equipment like fire extinguishers, gloves, first aid kits are available in the testing areas and in appropriate

places. Training is given on first aid for some of the staff.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 28 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

3.6 House Keeping

3.6.1 Nomination of any competent staff for monitoring the good housekeeping arrangements in line with P-QA-16-00.

4.0 TEST METHODS AND METHOD VALIDATION ISO / IEC 17025 CLAUSE 5.4

4.1 Policy

4.1.1 To use only appropriate test methods to meet customer’s requirements for all tests included in its scope of activities.

The procedures of standards used are only International Standard Procedures and validated test methods.

4.1.2 Testing procedures, methods and specification are updated systematically and are made readily available to the

personnel as defined in P-QA-02-00. It is the responsibility of the LAB MANAGER to ensure that only current standards

and specifications are used. In case a necessity is felt, the deviation is validated as described in P-QA-17-00

4.1.3 Whenever there is change in the Version of the Test Method or when applying for validation of new Test, capability to

perform updated version or test ar met as detailed in P-QA-18-00

4.2 Responsibility

4.2.1 LAB MANAGER / LAB SUPERVISOR

4.3 Laboratory Developed Methods

4.3.1 The Laboratory may develop In House methods based on capability & the same will be implemented after validation.

4.4 Non-Standard Methods

4.4.1 The laboratory may use their own internal methods based on the validation.

4.5 Validation of Methods

4.5.1 In-house developed / conceptualised Methods shall be used after validation from the concerned customer(s). In

case customer has not specified any International Standard or their own standards, LAB has the right to use in-house

standard by comparing the results with Internation Standard.

4.6 Measurement Uncertainty

4.6.1 Measurement Uncertainty is a parameter associated with analysis along with value, which gives confidence on the

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 29 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

acceptance of results.

4.6.2 Measurement Uncertainty is calculated taking into account all the parameters that contribute to the measurement

of analysis.

4.6.3 Evaluation of the uncertainty of measurement verified in-house using P-QA-06-00

REFERENCE - P-QA-06-00 Measurement Traceability

4.7 Control of Data

4.7.1 The integrity of test data is ensured at all times with associated documents and records being retained & maintained

in accordance with P-QA-02-00.

4.7.2 All calculations and data transfers are subject to appropriate checks.

REFERENCE - P-QA-02-00 - Internal / External Document and Data Control Procedure

5.0 EQUIPMENT ISO / IEC 17025 CLAUSE 5.5

5.1 All instruments / equipment required for the correct performance of all tests provided under the scope of activities is

available, calibrated wherever required and maintained properly.

5.2 It is ensured that all instruments and its software used for testing and sampling are capable of achieving the accuracy

required and comply with specification relevant to the tests. Calibrations programs are established for key equipment

which affect the test result and all instruments where required are calibrated before being placed in service.

5.3 All equipment including software received into the Laboratory for use in test activities are subject to appropriate

receiving, checking, testing and calibration procedures prior to use.

5.4 Equipment is operated only by authorized personnel.

5.5 Each equipment is uniquely identified and identification is displayed.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 30 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

5.6 A comprehensive list of all testing instruments and equipment available is maintained by the LAB SUPERVISOR.

5.7 A history card is maintained for each instrument & includes the following as required by ISO 17025:2005 Clause 5.5;

a. Name of the Equipment

b. Name of manufacturer and model or type identification

c. Any Serial Number allocated by the manufacturer or internally assgined by LAB

d. Details of any checks made for compliance with relevant standards

e. Date when equipment was placed in service

f. Copy of Manufacturers Instruction Manual where available

g. Details of maintenance schedule and its implementation.

h. History of Repair

5.8 Laboratory purchases only new equipment, or well conditioned equipments.

5.9 Maintenance department ensures that all testing equipment is serviced and maintained on a regular basis as

appropriate. It is also ensured that all such instruments are protected from misuse.

5.10 Any equipment that has suffered damage during use is identified as such, segregated and subject to review, repair,

test & recalibration as appropriate before further use. It is the responsibility of all technicians to ensure that any damage

to an instrument is reported immediately to concerned Technician through LAB SUPERVISOR as applicable.

5.11 Where the equipment requires calibration, the record also includes calibration status, calibration reports with

adjustment, acceptance criteria and due date for next calibration and other relevant calibration documents.

5.12 Calibrated equipment wherever practical is labeled or marked in associated List, to indicate the status of Calibration

and the date when recalibration is due.

5.13 Based on the actual use of all related equipment, intermediate checks are required on some instruments. The check

points and its frequency are determined based on its use. The procedure P-QA-15-00 is followed for the same.

5.14 Safe handling, transport and storage of instruments are ensured by Maintenance department.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 31 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

5.15 Correction factors due to calibration are updated in the system where applicable.

5.16 Care is taken to ensure that equipments and its software are safeguarded from adjustments that would invalidate

results by having only authorised personnel to operate.

5.17 Any item or equipment that suffers damage, overloading or mishandling or that gives suspect results or that is shown

by calibration or otherwise to be unfit for use is immediately withdrawn from use. These items are clearly labelled as

"UNDER MAINTENANCE" and are returned to service only after they are repaired and / or recalibrated as appropriate.

REFERENCE - P-QA-15-00, F-QA-26-00

6.0 MEASUREMENT TRACEABILITY ISO / IEC 17025 CLAUSE 5.6

6.1 Policy

6.1.1 It is the responsibility of the Maintenance department and LAB MANAGER to ensure that all testing equipment

which are having significant effect on the test result are calibrated before being put into service by external accredited

Calibation Laboratory in accordance with the requirements of ISO 17025:2005

6.1.2 To ensure timely calibration of inspection, measuring and test equipment so as to ensure the accuracy and validity

of test result to the specified requirement.

6.2 Calibration of Measuring Instruments and Reference Standards

6.2.1 Calibration of Measuring instruments is carried out externally. Only calibration laboratories accredited by NABL is

used. For Calibration Procedure P-QA-10-00 is followed.

6.3 Testing

6.3.1 Identification of test samples, test reports, measuring and test equipment are implemented & maintained to avoid

the mixing and to ensure that they are traceable back when needed. To ensure proper identification & traceability of test

samples, reports and equipment P-QA-04-00 is followed.

6.4 Reference Material

6.4.1 It is the responsibility of the LAB SUPERVISOR to ensure that the laboratory holds sufficient Standard Reference

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 32 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

Materials from authorised sources to cover the range of tests performed.

6.4.2 Storage

Reference Standards are stored separately, wherever needed transported safely & in appropriate environmental conditions

to prevent contamination or deterioration.

REFERENCE - P-QA-06-00

P-QA-10-00

P-QA-04-00

7.0 SAMPLING ISO / IEC 17025 CLAUSE 5.7

7.1 Policy

7.1.1 Haren Textiles Pvt Ltd lab is not doing this procedure. All Testing samples are submitting from Finishing departments

or by other departments and we are considering them as customers. We are not drawn any samples from bulks randomly

8.0 HANDLING OF TEST ITEMS ISO / IEC 17025 CLAUSE 5.8

8.1 Policy

8.1.1 Samples received from submitters are handled in accordance with the requirements of P-QA-05-00. The procedure

includes details for time of receipt, handling, protection, storage, retention, disposal, of the test items including all steps

necessary to protect the integrity of the test sample.

8.2 Sample Identification

8.2.1 An accountability system is established comprising traceability & control of samples as they are processed through

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 33 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

the laboratory. All samples received are allocated and identified by an unique code number. All laboratory work records,

intermediate sample containers, data sheets and reports of analysis originating from the Laboratory testing sections are

identified by this unique code no. This is also to ensure that samples do not get lost or mixed up within or between jobs.

8.3 Condition on Receipt

8.3.1 The very first step in the accountability process is checking for technical parameters and all relevant information.

Before any testing work is taken up, the compatibility of the work requested with the physical condition of the samples

including abnormalities and insufficiencies & the capabilities are verified. The same will be checked by Log-In personnel.

8.3.2 If they are uncertain as to whether a sample can be accepted for a test or not and requires technical assistance, they

check with the concerned team before accepting the sample.

8.4 Sample Handling, Storage and Disposal

8.4.1 There are procedures and facilities for safe handling, storage and sample preparation during testing. Samples are

kept in safe custody, before, during and after analysis, and also during the stipulated storage period.

8.4.2 Samples after analysis are retained and disposed off after a stipulated period of time.

REFERENCE - APPENDIX 1 for the SAMPLE PROCESS FLOW IN LABORATORY (Pg. 37 in Quality Manual) and P-QA-05-00

9.0 ASSURING THE QUALITY OF TEST RESULTS ISO / IEC 17025 CLAUSE 5.9

9.1 Quality Control (QC) Practices

9.1.1 The QC programme comprises;

* Use of Standard Reference Material (SRM). Tests are systematically carried out with a SRM.

* Dynamical Frequency Control Testing (DFC) & Inter Laboratory Comparisons (Every 1/16th reports) : A DFC and inter

laboratory testing plan /is prepared the samples analyzed by the LAB SUPERVISOR & SENIOR TEST OFFICER and

samples sent out as per schedule and results documented.

* Perform the repeatability / re-test on the retained sample, retained at stores, by pulling randomly to maintain the

confidence in testing

9.2 Besides the above, other QC measures like correlation of results for different characteristics of an item where possible

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 34 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

are also carried out and data recorded. LAB MANAGER initiates corrective action wherever required.

9.3 Review of quality control data is regularly carried out and it is ensured that corrective actions are taken immediately

whenever NC's occur and to prevent incorrect test results being reported.

9.4 Responsibility

9.4.1 LAB MANAGER

REFERENCE - P-QA-09-00

10.0 REPORTING THE RESULTS ISO / IEC 17025 CLAUSE 5.10

10.1 Policy

10.1.1 It is the responsibility of the LAB SUPERVISOR/SENIOR TEST OFFICER to ensure that the results of tests are reported

accurately, clearly, unambiguously & objectively to the submitter using an authorised Test Report. For all reports, relevant

information listed in ISO 17025:2005 Clause 5.10.2 to 5.10.10 are available.

10.1.2 LAB SUPERVISOR puts the initials at designated place & Mailing the report to concerned functional heads after

approved by Lab Manager. Send the approved report to the concerned department who has submitted the sample for testing.

For external customers, Mail the report to Customers as per BSR file which provided by Folding dept along with Marketing /

PPC team who are in communication with the customer.

10.1.3 The requirements of ISO 17025:2005 apply to all forms of presentation of test results. The report includes all info

that is relevant to the validity and application of the test and information on the test method used.

10.2 This information is provided such that it is easy to understand. It is ensured that information provided in the test

report reduces the possibility of misuse or misunderstanding.

10.3 The pages of the Test Report are so numbered & the end of report indicated as to minimize the possibility of addition

or removal of pages or tampering with information presented. The Test Report clearly states that the results are only for the

item tested. No partial report is allowed to release.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 35 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

10.4 Authorisation

10.4.1 Only authorized signatories recognized are allowed to sign Test Reports. A list of authorized signatories is available

in L-QA-11-00

10.4.2 It is ensured that all test reports issued are factually correct and checked and endorsed by an authorized person

before issue

10.4.3 Each test report issued provides at least the following information;

==> A title "LAB TEST REPORT NO."

==> The name, Haren Textiles Pvt. Ltd. and address

==> Internal lot no, sort no & Shade

10.5 Identification of the Test Procedure

a. An unambiguous identification of sample tested and condition and description where relevant.

b. Date of receipt of test item and dates of performance of testing. Reference to sampling procedure where relevant.

c. Date of issue of Test Report

d. The test results with unit of measurement

e. Signature, Name and Designation of the person authorizing Test Report

10.6 Additional Information

10.6.1 Additions to and information on specific test conditions such as environmental conditions are available in the

relevant documents and can be provided if the customer so requires.

10.7 Amedaments to Test Report

10.7.1 If any request is received from any concerned department to change/modify the report, review the request and its

feasibility to implement the same. Modify the report with new data (technical or informational) with change in the report

number by adding Clause "REV 1". If further revision is required the modify the clause to “REV 2”, “REV 3”…

10.8 Transmission of Results

10.8.1 When the results of tests are dispatched to submitter, care is taken to ensure the protection of proprietary rights and

confidential information and the requirements of ISO 17025:2005 Clause 5.4.7 and 5.10.7 are met.

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 36 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

10.8.2 Send the approved report to the concern department who has submitted the sample for testing. Store the tested

specimen along with raw data sheets in defined storage area for specified time period.

REFERENCE - P-QA-08-00

- THE END -

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 37 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.2022

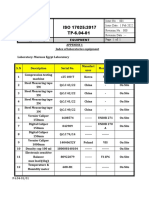

APPENDIX 1 to Section 8.4 - SAMPLE PROCESS FLOW IN LABPRATORY

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 38 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.22

DOCUMENT REVISION RECORD / HISTORY OF MODIFICATION

APPENDIX no 2 to page no 6 - document revision record - history of modification

DATE OF

SECTION / CLAUSE /

REVISION/ REASON FOR AUTHORISED

SR. NO. PAGE NO. PARA WHERE REVISION MADE

REVISION REVISION SIGNATORY

REVISION DONE

NO.

Organisation Chart To establish zero Ronak shah

1.6 12.04.2017

1 12 updated for better influence of production Quality

(Management Req.) Rev: 1

clarity on structure dept on Lab operations In-Charge

Added;

7.1.5 Test Officers

performing the test are not

disclosed about the

To ensure intergrity

Customer where the fabric Ronak shah

7.1.5 12.04.2017 and impartial testing

2 19 shall be going. Only Quality

(Management Req.) Rev: 1 and confidentialty

relevant DS related info is In-Charge

of customers' results

provided to ensure correct

DS & its Version are

followed for testing. This is

to ensure integirty in

testing.

Added;

4.1.3 Whenever there is

change in the Version of To ensure LAB can

12.04.2017 Ronak shah

4.1.3 the Test Method or when keep itself capable to

3 28 Rev: 1 Quality

(Techincal Req.) applying for validation of test using newer

In-Charge

new Test, capability to Versions and Standards

perform updated version

or test ar met as detailed

in P-QA-18-00

Updated relevant SOP /

Document numbers in the Updated reference and Ronak shah

12.04.2017

4 - - Manual as the original avoid any reference to Quality

Rev: 1

reference documents are Obselete documents In-Charge

updated

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 39 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.22

DOCUMENT REVISION RECORD / HISTORY OF MODIFICATION

APPENDIX no 2 to page no 6 - document revision record - history of modification

DATE OF

SECTION / CLAUSE /

REVISION/ REASON FOR AUTHORISED

SR. NO. PAGE NO. PARA WHERE REVISION MADE

REVISION REVISION SIGNATORY

REVISION DONE

NO.

Appointed the LAB

LAB MANAGER is replaced MANAGER who has the

27-09-2020 NISHANT MEHTA

5 All - the designation of Quality ability to be

Rev: 2 (DIRECTOR)

incharge responsible of Quality

and Technical

AHAMED MANSOOR is AHAMED MANSOOR is

27-09-2020 NISHANT MEHTA

6 All - replaced the name of appointed as LAB

Rev: 2 (DIRECTOR)

Ronak Shah MANAGER

Sanket Bari (Lab

Supervisor) is replaced AYAN PATEL is AHAMED

27-09-2020 Arun kahar(Lab incharge)

7 All - promoted as lab MANSOOR

Rev: 2 supervisor=incharge is supervisor (LAB MANAGER)

suggested by management

LQM has a complete

AHAMED

27-09-2020 record of amendaments in To get maintain the

8 6 - MANSOOR

Rev: 2 the end of the QM. Modification of record

(LAB MANAGER)

(Current Sheet)

LAB MANAGER Appointed to maintain

AHAMED

27-09-2020 resposibility concerns the lab quality &

9 11 1.5.8 MANSOOR

Rev: 2 Quality & also Technical technical management

(LAB MANAGER)

management system. system

ACTION PREPARED AND ISSUED BY; CHECKED AND AGREED UPON BY; APPROVED BY;

NAME AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

SIGNATURE AHAMED MANSOOR AYAN PATEL NISHANT MEHTA

DESIGNATION LAB MANAGER LAB SUPERVISOR DIRECTOR

HAREN TEXTILES PVT. LTD. M-QA-01-00

PAGE : 40 OF 43

HAREN TEXTILES LAB

VERSION : 1.0

REVISION : 6.0

QUALITY MANUAL

EFF. DATE : 16.11.22

DOCUMENT REVISION RECORD / HISTORY OF MODIFICATION

APPENDIX no 2 to page no 6 - document revision record - history of modification

DATE OF

SECTION / CLAUSE /

REVISION/ REASON FOR AUTHORISED

SR. NO. PAGE NO. PARA WHERE REVISION MADE

REVISION REVISION SIGNATORY

REVISION DONE

NO.

Organisation Chart

updated with LAB

Organisation Chart AHAMED

27-09-2020 MANAGER

10 12 - updated for better MANSOOR

Rev: 2 (Quality&Technical), Lab

clarity on structure (LAB MANAGER)

supervisor replacing Lab

Incharge

Corrected the reference Avoiding to lead AHAMED

wherever 27-09-2020

11 - document numbers in confusion while MANSOOR

required Rev: 2

quality manual referring (LAB MANAGER)

15.1.1 Management it is fulfilled the

Review is carried out in at- requirement even we

AHAMED

27-09-2020 least once in a year. If conduct as one time in

12 25 15.1.1 MANSOOR

Rev: 2 need or urgency we can year and can reduce

(LAB MANAGER)

arrange and it should be the time management

record in MRM files. too

Detailed abbreviation of