Professional Documents

Culture Documents

Datablad 2452916 Enda Epc9513 230 Pid Universalregulator B e J K L N R S T U pt100 NTC Relae 2 A SSR B X H 96 MM X 96 MM

Datablad 2452916 Enda Epc9513 230 Pid Universalregulator B e J K L N R S T U pt100 NTC Relae 2 A SSR B X H 96 MM X 96 MM

Uploaded by

BILAL FAROOQUICopyright:

Available Formats

You might also like

- C-6.2 HSTDocument38 pagesC-6.2 HSTBILAL FAROOQUI100% (1)

- User Manual: HGM6100U Series Automatic Control ControllersDocument39 pagesUser Manual: HGM6100U Series Automatic Control ControllersMohamed R KhamissNo ratings yet

- N2006 PidDocument8 pagesN2006 PidSarah KempNo ratings yet

- Electrical - BB International PDFDocument480 pagesElectrical - BB International PDFedelmolina100% (3)

- In Electrical Electronic MeasurementDocument29 pagesIn Electrical Electronic Measurementsiddhartha bharadwajNo ratings yet

- Honeywell Water Flow Switch 6000Document2 pagesHoneywell Water Flow Switch 6000parvez_ameenNo ratings yet

- 1st Semester Syllabus 2015 16Document54 pages1st Semester Syllabus 2015 16KrishnaMurthyTPNo ratings yet

- PD9001Document13 pagesPD9001Sher BahadarNo ratings yet

- DCL400Document2 pagesDCL400taleb 6269No ratings yet

- TC 513Document25 pagesTC 513MuthuRaj TcsNo ratings yet

- Smart TripDocument2 pagesSmart TripkaicyemNo ratings yet

- Farnell Temp ControllerDocument1 pageFarnell Temp ControllerKumarNo ratings yet

- PID+Fuzzy Temperature ControllerDocument23 pagesPID+Fuzzy Temperature ControllerWilly TurdoNo ratings yet

- PID500-T Instruction ManualDocument24 pagesPID500-T Instruction Manualraghunathreddy naniNo ratings yet

- Adr 130Document16 pagesAdr 130miri10861No ratings yet

- Mcih IndicatorDocument2 pagesMcih IndicatorAryan rajputNo ratings yet

- Oim Ai 7X82DDocument10 pagesOim Ai 7X82Ddeepesh1011No ratings yet

- Linear Servomotor General Instructions: Serial Converter Unit (Model: JZDP-¡00¡-¡¡¡-E)Document8 pagesLinear Servomotor General Instructions: Serial Converter Unit (Model: JZDP-¡00¡-¡¡¡-E)Edwin Aguila CerónNo ratings yet

- Wenling Yuhai Electromechanical 180sy-M35015 Sg-50a DatasheetDocument62 pagesWenling Yuhai Electromechanical 180sy-M35015 Sg-50a DatasheetJoimir PerezNo ratings yet

- Digital Process Indicator Selectron PIC152Document1 pageDigital Process Indicator Selectron PIC152industrialindiaNo ratings yet

- Low Power, 16-/24-Bit Sigma-Delta ADC For Bridge Sensors AD7796/AD7797Document24 pagesLow Power, 16-/24-Bit Sigma-Delta ADC For Bridge Sensors AD7796/AD7797vuongqnamNo ratings yet

- PT PID+Fuzzy Temperature Controller - B0Document17 pagesPT PID+Fuzzy Temperature Controller - B0Johnny Liu JohnnyNo ratings yet

- MR9270S V1.0Document43 pagesMR9270S V1.0AztvNo ratings yet

- Auto-Tune Pid Temperature & Timer General Specifications: N L1 L2 L3Document4 pagesAuto-Tune Pid Temperature & Timer General Specifications: N L1 L2 L3sharawany 20No ratings yet

- PID110 Temprature ControllersDocument2 pagesPID110 Temprature ControllersvishadkapadiaNo ratings yet

- N2006P PID Installation & WiringDocument8 pagesN2006P PID Installation & WiringFarlepNo ratings yet

- Masibus Digital Controller 5002uDocument20 pagesMasibus Digital Controller 5002uSOURISH100% (2)

- Instruction Manual Pmo 215x 415xDocument10 pagesInstruction Manual Pmo 215x 415xMARCOSNo ratings yet

- Digital Elcb Tester: 7 Functions 17 RangesDocument1 pageDigital Elcb Tester: 7 Functions 17 RangesArsh AlamNo ratings yet

- Adam-4022t Manual v2.2Document32 pagesAdam-4022t Manual v2.2Biplab DattaNo ratings yet

- TDAX023100Document3 pagesTDAX023100Abdul KurniadiNo ratings yet

- Specifications: - : User'S Operating Manual For Pid Digital Temperature ControllerDocument9 pagesSpecifications: - : User'S Operating Manual For Pid Digital Temperature ControllerAnjum ParkarNo ratings yet

- A6-SG 6 DIGITAL WEIGHING Controller: DescriptionDocument3 pagesA6-SG 6 DIGITAL WEIGHING Controller: DescriptionVu Minh CuongNo ratings yet

- 10.709 Gbps Laser Diode Driver Chipset: A To 1200 ADocument12 pages10.709 Gbps Laser Diode Driver Chipset: A To 1200 ABanyugeaNo ratings yet

- PID5030 M53om101 Issue14 Dt.23.10.13Document21 pagesPID5030 M53om101 Issue14 Dt.23.10.13Pandu BirumakovelaNo ratings yet

- LMC110 00 - en UsDocument3 pagesLMC110 00 - en UsSoumyabrata PradhanNo ratings yet

- Ai 5982 Digital Temperature ControllerDocument6 pagesAi 5982 Digital Temperature ControllerAlex RestrepoNo ratings yet

- Enda Ehtc7425A Humidity and Temperature Controller: Technical SpecificationsDocument8 pagesEnda Ehtc7425A Humidity and Temperature Controller: Technical SpecificationsNader MohammedNo ratings yet

- Digital Autozero & Span Option: Technical DataDocument2 pagesDigital Autozero & Span Option: Technical DataGopal HegdeNo ratings yet

- Components: Systems Injectors Electronic Control Module Sensors Elements MonitoringDocument37 pagesComponents: Systems Injectors Electronic Control Module Sensors Elements Monitoringjibv100% (1)

- CMT-007A - Digital CounterDocument4 pagesCMT-007A - Digital CounterSHARAB IMTIAZNo ratings yet

- Voltage Output Temperature Sensor With Signal Conditioning AD22100Document12 pagesVoltage Output Temperature Sensor With Signal Conditioning AD22100Дьяволенок никитоNo ratings yet

- Temp ControllersDocument14 pagesTemp ControllersramatajamaNo ratings yet

- Etr9040 ManualDocument24 pagesEtr9040 ManualLindo PatoNo ratings yet

- Manual Control CrisolDocument60 pagesManual Control CrisolBaruch Cervantes GonzalezNo ratings yet

- Programmable Thermocouple ConverterDocument5 pagesProgrammable Thermocouple ConvertercanopusinstrumentsNo ratings yet

- 10 - 61-611-EN-B-01 - 2011ABB PLC UnitDocument12 pages10 - 61-611-EN-B-01 - 2011ABB PLC UnitDawood KSNo ratings yet

- File 1729 BGDocument2 pagesFile 1729 BGmahmoudNo ratings yet

- Eliwell BrochuresDocument7 pagesEliwell Brochuresunder word under wordNo ratings yet

- PROCESS CALIBRATOR Atek 830Document5 pagesPROCESS CALIBRATOR Atek 830BenabidNo ratings yet

- ESM Xx20 Manual MultilenguajeDocument64 pagesESM Xx20 Manual MultilenguajeRonal IsnadoNo ratings yet

- Temperature Controller Catalog - EngDocument9 pagesTemperature Controller Catalog - EngJuan Gervacio OrtegaNo ratings yet

- TIM-94N / TIM-94N-B / TIM-94N-BN: DescriptionDocument5 pagesTIM-94N / TIM-94N-B / TIM-94N-BN: Descriptionluat1983No ratings yet

- Oriface and Jet Analysis TaturialDocument13 pagesOriface and Jet Analysis TaturialWegdan AldobaiNo ratings yet

- LMC400 00 - en UsDocument3 pagesLMC400 00 - en UsSoumyabrata PradhanNo ratings yet

- Products Catalogue 2010-11Document10 pagesProducts Catalogue 2010-11Gyanesh BhujadeNo ratings yet

- Compact General Purpose ControllersDocument12 pagesCompact General Purpose ControllersCarlos GusmaoNo ratings yet

- Pic152a ViDocument2 pagesPic152a Viiyappan5016100% (1)

- Controlador de Processos WEST P4170Document2 pagesControlador de Processos WEST P4170Alexandre Caique SampaioNo ratings yet

- Frenic Multi Quick Guide Lift en PDFDocument18 pagesFrenic Multi Quick Guide Lift en PDFLong NguyễnNo ratings yet

- Multispan TC-19Document4 pagesMultispan TC-19Karan SolankiNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- ATS NED Project-BilalDocument17 pagesATS NED Project-BilalBILAL FAROOQUINo ratings yet

- Building - Your - Own - PC - Complete - Manual - Sep - 2023 Ijaba - InfoDocument128 pagesBuilding - Your - Own - PC - Complete - Manual - Sep - 2023 Ijaba - InfoBILAL FAROOQUINo ratings yet

- Automotive Maintenance - PDF PDF BooksDocument100 pagesAutomotive Maintenance - PDF PDF BooksBILAL FAROOQUINo ratings yet

- Proposal FypDocument2 pagesProposal FypBILAL FAROOQUINo ratings yet

- 1204 Ses Shops Arc Form 1 RecordDocument1 page1204 Ses Shops Arc Form 1 RecordBILAL FAROOQUINo ratings yet

- Cga C-6.1 Last PageDocument1 pageCga C-6.1 Last PageBILAL FAROOQUINo ratings yet

- 1201-Ses-Shop Shop Production ReportDocument1 page1201-Ses-Shop Shop Production ReportBILAL FAROOQUINo ratings yet

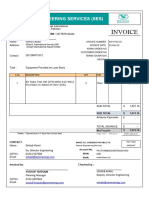

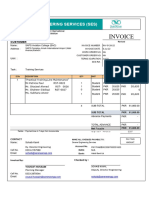

- INV 0132 22 (Gerry's Dnata)Document1 pageINV 0132 22 (Gerry's Dnata)BILAL FAROOQUINo ratings yet

- Cga C-8-2017 Last PageDocument2 pagesCga C-8-2017 Last PageBILAL FAROOQUINo ratings yet

- Inv 0145 22 (Assl)Document1 pageInv 0145 22 (Assl)BILAL FAROOQUINo ratings yet

- Cga C-6.1 First Page-2019Document2 pagesCga C-6.1 First Page-2019BILAL FAROOQUINo ratings yet

- Cga-6.3 - 2019 First PageDocument2 pagesCga-6.3 - 2019 First PageBILAL FAROOQUINo ratings yet

- INV 0144 22 (Jordan Aviaition)Document1 pageINV 0144 22 (Jordan Aviaition)BILAL FAROOQUINo ratings yet

- Inv 0148 22 (Fly Baghdad)Document1 pageInv 0148 22 (Fly Baghdad)BILAL FAROOQUINo ratings yet

- INV 0140 22 (Air Sial Limited)Document1 pageINV 0140 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

- Inv 0147 22 (Vision Air)Document1 pageInv 0147 22 (Vision Air)BILAL FAROOQUINo ratings yet

- Inv 0139 22 (Vision Air)Document1 pageInv 0139 22 (Vision Air)BILAL FAROOQUINo ratings yet

- Inv 0135 22 (Pia)Document1 pageInv 0135 22 (Pia)BILAL FAROOQUINo ratings yet

- Inv 0131 22Document1 pageInv 0131 22BILAL FAROOQUINo ratings yet

- C-8 HSTDocument10 pagesC-8 HSTBILAL FAROOQUINo ratings yet

- INV 0141 22 (Air Sial Limited)Document1 pageINV 0141 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

- Whole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022Document2 pagesWhole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022BILAL FAROOQUINo ratings yet

- C 6 HSTDocument30 pagesC 6 HSTBILAL FAROOQUINo ratings yet

- C-6.1 HSTDocument24 pagesC-6.1 HSTBILAL FAROOQUINo ratings yet

- Inv 0128 22Document1 pageInv 0128 22BILAL FAROOQUINo ratings yet

- 2.8 NDT Bsi ShopDocument5 pages2.8 NDT Bsi ShopBILAL FAROOQUINo ratings yet

- 2.7 Galley Equipment Shop (c06)Document5 pages2.7 Galley Equipment Shop (c06)BILAL FAROOQUINo ratings yet

- 2.3 ReservedDocument2 pages2.3 ReservedBILAL FAROOQUINo ratings yet

- 2.6 Battery Shop (c05)Document6 pages2.6 Battery Shop (c05)BILAL FAROOQUINo ratings yet

- Marine Electrical Power Analysis PDFDocument4 pagesMarine Electrical Power Analysis PDFinfraNo ratings yet

- Tesys T - LTMR100CFMDocument4 pagesTesys T - LTMR100CFMdul theoNo ratings yet

- MKT2015019674EN 7750 SR Portfolio R13 DataSheet PDFDocument5 pagesMKT2015019674EN 7750 SR Portfolio R13 DataSheet PDFquocan100% (1)

- Lab Sheet 2 PDFDocument13 pagesLab Sheet 2 PDFmalaNo ratings yet

- Control Cable TCP01 FOR CONTINUITYDocument23 pagesControl Cable TCP01 FOR CONTINUITYFendi ahmadNo ratings yet

- Experiment-2: Asymmetrical AC ControllerDocument17 pagesExperiment-2: Asymmetrical AC ControlleraashishNo ratings yet

- Electrical Safety in Low Voltage Distribution Systems Up To 1 000 V A.C. and 1 500 V D.C. Equipment For Testing, Measuring or Mo - Libgen - LiDocument22 pagesElectrical Safety in Low Voltage Distribution Systems Up To 1 000 V A.C. and 1 500 V D.C. Equipment For Testing, Measuring or Mo - Libgen - LiDavidAlbertoMedinaMedinaNo ratings yet

- IEC StandardsDocument22 pagesIEC StandardsBasim Al-AttarNo ratings yet

- ABB Basic Electricity CourseDocument12 pagesABB Basic Electricity CourseViduranga BandaraNo ratings yet

- Wasion Energy Smart Energy Brochure 2024Document21 pagesWasion Energy Smart Energy Brochure 2024Hassan AzmatNo ratings yet

- Super Efficient AC - DaikinDocument35 pagesSuper Efficient AC - DaikinSaravanan SengazhaniNo ratings yet

- Report - Inorbit Mall - Services - T.D - Week PDFDocument78 pagesReport - Inorbit Mall - Services - T.D - Week PDFBhavya MewadaNo ratings yet

- Solar Nylon Anti-Rodent & Anti-Termite CableDocument1 pageSolar Nylon Anti-Rodent & Anti-Termite CablePrateek GuptaNo ratings yet

- Role of HVDC in Future Power Systems: by Dr.V.Rajini Professor/EEE SSN College of EnggDocument87 pagesRole of HVDC in Future Power Systems: by Dr.V.Rajini Professor/EEE SSN College of EnggAnonymous hzXy93FAENo ratings yet

- Rme Trivia (Q&a)Document23 pagesRme Trivia (Q&a)Jeffrey PobleteNo ratings yet

- Dewalt d25481Document12 pagesDewalt d25481Vasilic NikolaNo ratings yet

- 10 SM 2017 Science Hindi PDFDocument215 pages10 SM 2017 Science Hindi PDFNAEEM MALIKNo ratings yet

- Surge Current Protection Using Super Conductors Report - NewDocument22 pagesSurge Current Protection Using Super Conductors Report - Newsourav83% (6)

- Anti-Static and Clean-Room Equipment: Static Eliminator General CatalogueDocument44 pagesAnti-Static and Clean-Room Equipment: Static Eliminator General Cataloguesangaji hogyNo ratings yet

- Klauke - Bi-Metal Lugs & ConnectorsDocument6 pagesKlauke - Bi-Metal Lugs & ConnectorsBiplab PaulNo ratings yet

- X Ray GeneratorDocument70 pagesX Ray Generatorub17075% (4)

- Aladin: Association of Light and Detector For Individual NoticeDocument1 pageAladin: Association of Light and Detector For Individual NoticeRicardo GutiérrezNo ratings yet

- Marine Electrical 101Document59 pagesMarine Electrical 101Muhammad Adam100% (1)

- NemoDocument35 pagesNemoJonathan HardyNo ratings yet

- 1SBC100214C0201 - Main Catalog 2019 PDFDocument912 pages1SBC100214C0201 - Main Catalog 2019 PDFDangQuangTrungNo ratings yet

Datablad 2452916 Enda Epc9513 230 Pid Universalregulator B e J K L N R S T U pt100 NTC Relae 2 A SSR B X H 96 MM X 96 MM

Datablad 2452916 Enda Epc9513 230 Pid Universalregulator B e J K L N R S T U pt100 NTC Relae 2 A SSR B X H 96 MM X 96 MM

Uploaded by

BILAL FAROOQUIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datablad 2452916 Enda Epc9513 230 Pid Universalregulator B e J K L N R S T U pt100 NTC Relae 2 A SSR B X H 96 MM X 96 MM

Datablad 2452916 Enda Epc9513 230 Pid Universalregulator B e J K L N R S T U pt100 NTC Relae 2 A SSR B X H 96 MM X 96 MM

Uploaded by

BILAL FAROOQUICopyright:

Available Formats

english

Read this document carefully before using this device. The guarantee will be expired by device damages if you don’t attend to the directions

in the user manual. Also we don't accept any compensations for personal injury, material damage or capital disadvantages.

ENDA EPC9513 Series Programmable Profile Controller

Thank you for choosing EPC9513 series programmable profile controller.

96x96mm sized.

3,5 inches TFT , graphic and 5 digit display.

1230.6

Selectable TC, RTD, NTC, R, mA, V or mV inputs.

Input offset feature. PV °C

PV-SV Program 1 is running

32 point linearization for analog inputs.

200

Selectable relay, SSR,motorized valve or analog outputs.

1200.0

175

Selectable , input proportional transmitter output(mA or V). SV °C 150

50ms sampling time. 125

100

PID control. A3

75

PID selftune. A1

Prog.No: 1 Seg.No: 1 50

A2

PID auto-tune. Prog.Remaining Time(min): 1:0 25

SSR

Selftune automatic PID calculation or

0%

0 min

PRESS SET TO START PROFILE CONTROLLER 2 4 6 8 10 12 14 16

manually enter PID parameters if known. ENDA EPC9513 ENDA EPC9513

Soft-Start feature.

24Vdc for sensor supply.

16 program and 8 step for profile control.

Selectable Single Setpoint Mode or Profile Control Mode.

Digital inputs for profile control.

In case of sensor failure manually , periodical or auto-periodical

control can be selected.

Security levels for menu and configuration pages.

RS485 ModBus protocol communication feature.(optional)

CE marked according to Europen Norms.

Please see EPC9513 Series Modbus Address Map and Connection

Order Code : EPC 9 5 1 3 Diagram Guide for Modbus feature.

Analog Inputs

Input Type Range Accuracy Input Resist. Cable Color Standart

B (Pt30Rh-Pt6Rh) 200,0 ... 1800,0°C 392,0 ... 3272,0°F % ±0.1 and ±2°C (3,6°F) + undefined - white

E (NiCr-Con) -100,0 ..... 900,0°C -148,0 ... 1652,0°F % ±0.1 and ±0,5°C (1°F) + purple - white

EN 60584

J (Fe-Con) -100,0 ..... 900,0°C -148,0 ... 1652,0°F % ±0.1 and ±0,5°C (1°F) + black - white

K (NiCr-Ni) -100,0 ... 1300,0°C -148,0 ... 2372,0°F % ±0.1 and ±0,5°C (1°F) + green - white

L (Fe-Con) -100,0 ..... 900,0°C -148,0 ... 1652,0°F % ±0.1 and ±1.5°C (2.7°F) + red - blue DIN43710

TC Ri > 100kΩ

N (NiCrSi-NiSi) -200,0 ... 1300,0°C -328,0 ... 2372,0°F % ±0.1 and ±0,5°C (1°F) + lilac - white

R (Pt13Rh-Pt) 0,0 ... 1700,0°C 32,0 ... 3092,0°F % ±0.1 and ±1°C (1.8°F) + orange - white

EN 60584

S (Pt10Rh-Pt) 0,0 ... 1700,0°C 32,0 ... 3092,0°F % ±0.1 and ±1°C (1.8°F) + orange - white

T (Cu-Con) -250,0 ..... 300,0°C -418,0 ..... 572,0°F % ±0.1 and ±0,5°C (1°F) + brown - white

U (Cu-Con) -200,0 ..... 400,0°C -328,0 ..... 752,0°F % ±0.1 and ±0,5°C (1°F) + red - brown DIN43710

RTD Pt100 -200,0 ..... 850,0°C -328,0 ... 1562,0°F % ±0.1 and ±0,5°C (1°F) Ri > 100kΩ Sensor current 250µA EN 60751

-100,00 ... 160,00°C -148,00 .. 320,00°F

NTC NTC -60,0 ..... 150,0°C -76,0 ..... 302,0°F % ±0.1 and ±0,5°C (1°F) Ri > 100kΩ

0 - 20mA

mA % ±0.1 and ±1 digit Ri = 50Ω

4 - 20mA

-32768 ... 32767

mV 0 - 150mV % ±0.1 and ±20µV Ri > 100kΩ

-3276,8 ... 3276,7

0 - 5V

-327,68 ... 327,67

V 1 - 5V % ±0.1 and ±1 digit Ri > 100kΩ

-32,768 ... 32,767

0 - 10V

0 - 550Ω % ±0.2 and ±0.1Ω

Ω Ri > 100kΩ Sensor current 250µA

0 - 10kΩ % ±0.5 and ±10Ω

DIGITAL INPUTS (In order to use for profile control process)

Start-Stop Input / Pause-Resume Input /

5V or 30V pulse , Ri=100kΩ

Previous Program Input / Next Program Input

OUTPUTS

Control/A.3/Valve On 250V AC, 2A . Selectable as NO+NC.10.000.000 switch without load and 200.000 switch under 250V AC 2A (resistive load)

Alarm 1 250V AC, 2A . Selectable as NO+NC.10.000.000 switch without load and 200.000 switch under 250V AC 2A (resistive load)

Alarm 2/Valve Off 250V AC, 2A . Selectable as NO.10.000.000 switch without load and 200.000 switch under 250V AC 2A (resistive load)

SSR Max. 40mA , 0 - 12Volt , short-circuit protection.

mA 0 - 20mA or 4 - 20mA DC, % ±0,5 (Max. load resistance is 750 O.)

V 0 - 10V DC, % ±0,5 Max. 30mA (short-circuit protection.)

ELECTRICAL CHARACTERISTICS

Supply 90-250V AC, 50/60Hz

Power consumption Max. 7VA

Wiring 2.5mm² screw-terminal

EMC EN 61326-1: 2013

Safety requirements EN 61010-1: 2010 (Pollution degree 2 , overvoltage category ||)

ENVIRONMENTAL CONDITIONS

Ambient/storage temp. 0 ... +50°C/-25 ... 70°C

Max. Relative humidity Relative humidity 80% for temperatures up to 31°C , decreasing linearly to 50% relative humidity at 40°C.

Rated pollution degree According to EN 60529 Front panel : IP65 , Rear panel : IP20

Height Max. 2000m

Do not use the device in locations subject to corrosive and flammable gases.

HOUSING

Housing type Suitable for flush-panel mounting.

Dimensions G96xY96xD81mm

Weight Approx. 400g.

Enclosure material Self extinguishing plastics.

While cleaning the device , solvents(thinner,gasoline,acid etc.) or corrosive materials must not be used.

SURAN Industrieelektronik Tel.: +49 (0)7451 / 625 617 E-mail : info@suran-elektronik.de 1. / 10

Dettinger Str. 9 / D-72160 Horb a.N Fax: +49 (0)7451 / 625 0650 Internet : www.suran-elektronik.de EPC9513-EN-12102021

DIMENSIONS

96mm

1

1230.6

1 16 29

PV °C 2

17 30

18 31

3 19 32

4 20 33

1200.0

21

SV °C 5 34

6 22

35

23

A3 7 24

36

25

A1

Prog.No: 1 Seg.No: 1 8

26 37

A2

Prog.Remaining Time(min): 1:0 9

SSR 27 38

0%

10 28

PRESS SET TO START PROFILE CONTROLLER 39

11 40

ENDA EPC9513

12 41

13 42

14 43

15

PANEL CUT-OUT

6mm 69mm 15mm

92mm

Flush mounting clamp

2 For removing the device from panel :

- While pressing both flush mounting clamps of the device

in direction 1 , pull it in direction 2.

Not :

1) Panel thickness should be maximum 7mm.

2) If there is no 60mm free space at the back

side of the device , it would be difficult to remove it from

panel.

CONNECTION DIAGRAM

ENDA EPC9513 is intended for installation in control panels. Make sure that the device is used only for intended purpose. The electrical connections

must carried out by a qualified staff and must be according to the relevant locally applicable regulations. During an installation , all of the cables that

are connected to the device must be free of electrical power. The device must be protected against inadmissible humidity , vibrations , severe soiling

and make sure that the operation temperature is not exceeded. The cables should not be close to the power cables or components.

16 29

-

16 29

1 90 - 250V AC SSR OUT 1

17 30 17 30

2 50/60Hz, MAX. 7VA 2 18 31

18 V OUT 31

- 3 19 32

3 +24V DC (max. 30mA) 19 - 32

mA OUT 4 20 33

4 GND1 20 33

5 21 34

21 34

5 +12V DC (max. 30mA) 6 22

Previous Program Input 22 23

35

35

6 Pause - Resume Input 23 Control 7 24

Start - Stop Input 24 Alarm 3 36 36

7 8 25

Next Program Input 25 Motorized 26 37

37 9

8 26 Valve On 27 38

38 28

9 27 GND 10 39

+12V 28 39 11 40

10

RTD Alarm 1 40 12 41

11

NTC TC mA/mV/V 41 42

- - 13

12 R

14 43

13 COM Alarm 2 42

{ 15

14 A ModBus Motorized 43

RS 485 Valve Off

15 B

Logic output of the instrument is not electrically insulated from the

SUPPLY VOLTAGE internal circuits. Therefore , when using grounding thermocouple , do

F 100 mA 250V AC not connect the logic output terminals to the ground.

Switch

90-250V AC 1 Line 90-230V AC

50/60Hz 50/60Hz

MAX. 7VA 2 Neutral MAX. 7VA Not : 1) Main supply cords shall meet the requirements of IEC 60227 or

Fuse should be IEC60245.

connected. Cable size: 1,5mm² 2)In accordance with safety regulations,the power supply switch shall

bring the identification of the relevant instrument and it should be easily

accessible by the operator.

Holding screw Equipment is protected throughout

0.4-0.5Nm by DOUBLE INSULATION.

SURAN Industrieelektronik Tel.: +49 (0)7451 / 625 617 E-mail : info@suran-elektronik.de 2. / 10

Dettinger Str. 9 / D-72160 Horb a.N Fax: +49 (0)7451 / 625 0650 Internet : www.suran-elektronik.de EPC9513-EN-12102021

HOME SCREEN

123.4

PV °C Unit

Process Value

200.0

SV °C

Set Value

A3

Program Number

Ouput/ Alarm Relay and SSR status.

A1

Prog.No: 1 Seg.No: 1 Segment Number

A2 Remaining time in min.

Prog.Remaining Time(min): 1:0

(If output is active,related led turns to green.) SSR

0% % Output ratio

PRESS SET TO START PROFILE CONTROLLER Message box

ENDA EPC9513

Back Key Increase Key

SET Key Decrease Key

Input Key

SET Key : Start/Stop profile controller in “Profile Controller Mode”, Select/Unselect parameter for increase/decrease parameter value in “Programming Mode”.

Change SV in “Single Setpoint Mode”.

Back Key : Return previous page in “Programming Mode”.

Enter Key : Enter main menu and open sub pages and transition between sub pages in “Programming Mode”.

Pause/Resume profile controller in “Profile Controller Mode”.

Increase Key : Transition between parameters (when parameter background is red)

and increase selected parameter value (when parameter background is green) in “Programming Mode”.

Decrease Key : Transition between parameters (when parameter background is red)

and decrease selected parameter value (when parameter background is green) in “Programming Mode”.

NOTE 1 : Device must be in “Profile Control Mode” in order to start/stop profile control by pressing Set Key.

NOTE 2 : When device in “Single Setpoint Mode”, Prog.No , Seg.No ve Prog.Remaning Time(min) informations are not shown on home screen.

NOTE 3 : If Increase Key is held down while the device is powered up , factory parameters will be restored.

NOTE 4 : “Single Setpoint Mode” can be selected under “Profile Controller Configuration Page” sub menu , device make a control related to SV ,

which can be adjusted on home screen in “Single Setpoint Mode”.

Adjusting Device Set Value in Single Setpoint Mode

123.4 123.4 123.4 123.4

PV °C PV °C PV °C PV °C

200.0 200.0 200.1 200.0

SV °C SV °C SV °C SV °C

A3 A3 A3 A3

A1 A1 A1 A1

A2 A2 A2 A2

SSR SSR SSR SSR

0% 0% 0% 0%

SINGLE SET POINT MODE IS RUNNING SINGLE SET POINT MODE IS RUNNING SINGLE SET POINT MODE IS RUNNING SINGLE SET POINT MODE IS RUNNING

If Set Key pressed once , SV’s color will be green. In this case SV is adjusted by pressing Increase/Decrease keys.

If Set Key pressed again or by waiting 3 seconds , SV’s color will be white on home screen.

Profile Control Mode

23.4 23.4

PV °C PV °C

PV-SV Program 1 is running

200

50.0 50.0

175

SV °C SV °C 150

125

Profile control 100

A3 A3

Profile control

is started by 75

program graph

A1

Prog.No: 0 Seg.No: 0 pressing A1

Prog.No: 1 Seg.No: 1 50

A2

Prog.Remaining Time(min): 0:0 A2

Prog.Remaining Time(min): 14:59 is shown

SSR

Set Key. SSR

25

0% 33% by pressing min

0

PRESS SET KEY TO START PROFILE CONTROL PROFILE CONTROL IS RUNNING Back Key. 2 4 6 8 10 12 14 16

Profile control is stopped by

Last saved program pressing Set Key and “PROFILE PV is sampled and saved

graph can be shown CONTROLLER IS STOPPED” once in every minute and

by pressing Back Key. message is given for 3 seconds shown on program graph.

and device is turned back to

home screen.

23.4

PV °C

PV-SV Profil control is finished. PV-SV Program 1 is running

200 200

50.0

175 175

150 SV °C 150

125 125

100 100

A3

75 75

50

A1

Prog.No: 1 Seg.No: 1 50

A2

25 Prog.Remaining Time(min): 14:59 25

SSR

min 33% min

0 0

2 4 6 8 10 12 14 16 PROFILE CONTROLLER IS STOPPED 2 4 6 8 10 12 14 16

SURAN Industrieelektronik Tel.: +49 (0)7451 / 625 617 E-mail : info@suran-elektronik.de 3. / 10

Dettinger Str. 9 / D-72160 Horb a.N Fax: +49 (0)7451 / 625 0650 Internet : www.suran-elektronik.de EPC9513-EN-12102021

Programming

Home Screen

123.4

PV °C

200.0

SV °C

Main menu is opened and “Programming Mode” is started by pressing Enter Key for 2 seconds.

A3

A1

Prog.No: 0 Seg.No: 0

A2

Prog.Remaining Time(min): 0:0

SSR

0%

PRESS SET TO START PROFILE CONTROLLER

EPC9513 PROFILE CONTROLLER

Desired sub menu is selected by pressing Increase/Decrease Keys.

Input Configuration Page

Output Configuration Page

Alarm Configuration Page Selected sub menu is opened by pressing Enter Key.

PID Control Configuration Page Selected sub menu can be opened if permission is given from “Security Configuration Page”.

Communication Configuration Page

Security Configuration Page If Back Key is pressed or by waiting 10 seconds , parameters will be saved and device turns back to home screen.

Calibration Page

Profile Controller Configuration Page

NOT 5 : If power failure is occurs while device is programming , parameters won’t be saved.

Programming Inputs (Input Configuration Page)

Desired parameter is selected by pressing Increase/Decrease Keys. Background of selected parameter turns red.

If SET Key is pressed , background of selected parameter turns to green and selected parameter can be adjusted to

Input Conf Digital Inputs Conf Linearization Table Conf desired value.

Input 1 Type J Type Thermocouple

If SET Key is pressed again , background of selected parameter turns to red and exits from parameter adjustment.

Scale Minimum -100.0

Scale Maxmimum 900.0

If Back Key pressed or by waiting 10 seconds , Input Configuration Page is closed and device turns back to main menu.

Unit °C

Input offset 0

Input Conf Digital Inputs Conf Linearization Table Conf Input Conf Digital Inputs Conf Linearization Table Conf

Coefficient of digital filter 4

Decimal Point XXX.X

Input 1 Type J Type Thermocouple Input 1 Type K Type Thermocouple

Minimum Set Value -100.0

Scale Minimum -100.0 Scale Minimum -100.0

Maximum Set Value 900.0

Scale Maxmimum 900.0 Scale Maxmimum 1300.0

Unit °C Unit °C

Input offset 0 Input offset 0

Coefficient of digital filter 4 Coefficient of digital filter 4

Decimal Point XXX.X Decimal Point XXX.X

Minimum Set Value -100.0 Minimum Set Value -100.0

Maximum Set Value 900.0 Maximum Set Value 1300.0

Input Conf Digital Inputs Conf Linearization Table Conf

Input 1 Type K Type Thermocouple

Scale Minimum -100.0

Scale Maxmimum 1300.0 Input 1 Type : Maximum Set Value : Input offset :

Unit °C B, E, J, K, L, N, R, S, T, U, Pt100, Adjustable between Adjustable between -99 ... 99.

Input offset 0 NTC, 0-20mA, 4-20mA, 0-5V, 1-5V, Scale Maximum and Coefficient of digital filter :

Coefficient of digital filter 4 0-10V, 0-150mV, 0-550Ω, 0-10kΩ Minimum Set Value. 1=200ms and it is device sampling time.

Decimal Point XXX.X

Minimum Set Value -100.0 Scale(Scale Min./Max.) : Unit : Adjustable between 1 ... 32.

Maximum Set Value 1300.0 Adjustable between °C, °F, bar, %RH, Hz, mA, A, Value of parameter should be increased in

-32768 ... 32767 mV, V, Ohm, kOhm, %, g, kg, interference.

(Just for mA, V, mV, k) cm, m, m/s, m/min, km/h,

Minimum Set Value : cm3/s, m3/h, l/s, l/min, l/h Decimal Point :

Adjustable between pH,EC According to range table ,

Scale Minimum and (Just for mA, V, mV, k) 1, 2 and 3 digit can be selected.

Maximum Set Value.

Input Conf Digital Inputs Conf Linearization Table Conf

Digital Inputs : Start/Stop , Pause/Resume , Next/Previous Program processes can be made by

digital inputs or device keypad.

If process will be performed only by Keypad ,“Keypad” must be selected.

Start - Stop Input: Keypad If process will be performed only by Digital Input ,“Digital Input” must be selected.

Pause - Resume Input: Digital Input If process will be performed both by Keypad and Digital Input ,“Keypad and Digital Input” must be selected.

Previous Program Input: Keypad - Digital Input

Next Program Input: Keypad

Start/Stop : Start-Stop Input and/or SET key.

Pause/Resume : Pause-Resume Input and/or Back key.

Previous program : Previous Program Input and/or Increase key.

Next program : Next Program Input and/or Decrease key.

Linearization Table Conf :

Input Conf Digital Inputs Conf Linearization Table Conf

Use Linearizasyon Table for 0-10 V

If input type is selected as mA, V, mV, or k, linearizaton can be done at 32 points.

0.00 0.00 2.58 0.00 5.16 0.00 7.74 0.00

0.32 0.00 2.90 0.00 5.48 0.00 8.06 0.00

Use Linearization Table for 0-10 V can be activated by pressing keys respectively.

0.65 0.00 3.23 0.00 5.81 0.00 8.39 0.00

0.97 0.00 3.55 0.00 6.13 0.00 8.71 0.00

Corresponding values of input signals must be entered to table in order to linearize at 32 points.

1.29 0.00 3.87 0.00 6.45 0.00 9.03 0.00

1.61 0.00 4.19 0.00 6.77 0.00 9.35 0.00

1.94 0.00 4.52 0.00 7.10 0.00 9.68 0.00

2.26 0.00 4.84 0.00 7.42 0.00 10.00 0.00

SURAN Industrieelektronik Tel.: +49 (0)7451 / 625 617 E-mail : info@suran-elektronik.de 4. / 10

Dettinger Str. 9 / D-72160 Horb a.N Fax: +49 (0)7451 / 625 0650 Internet : www.suran-elektronik.de EPC9513-EN-12102021

Programming

Programming Outputs(Output Configuration Page)

Control Conf Motorized Valve Conf

Output Conf

Output Type : Relay, SSR,Motorized Valve,0-20mA, 4-20mA or 0-10V. If relay is not selected for output type , relay

can be configured as Alarm3 or motorized valve.

Output Type Relay

Re-Transmission : If output type is selected as relay or SSR , re-transmission can be selected as a 0/4 -20mA or 0-10V.

Re-Transmission None

If output type is selected as a 0/4-20mA , re-transmission can be selected as a 0-10V.

Maxmimum Analog Output Value(%) 100 If output type is selected as 0-10V , re-transmission can be selected as a 0/4-20mA.

Minimum Analog Output Value(%) 0 Maximum Analog Output Value : % maximum analog output value.

Output Hysteresis 0 Minimum Analog Output Value : % minimum analog output value.

Output Power Offset Around Set Point(%) 0 Output Hysteresis : Adjustable between 0... 50. (If Proportional Band selected 0.0 , ON-OFF control and

output hysteresis will be active.)

Output Power Offset Around Set Point : Output power offset around SV according to error. In order to reach to SV fast.

TotalOuput(%) = system output(%)+ (100 / Proportional Band) *error *OutputPowerOffset/100.

Output Conf Control Conf Motorized Valve Conf Control Configuration : Selectable as Cool/Heat control. The cooling control is only ON-OFF control

(For Cooling control. Proportional Band must be 0.0).

COOL

Control Configuration

HEAT

Power Failure Behaviour : If power failure occurs when profile control is running and device is powered on after power failure:

Stop

- If Stop is selected , profile control stops and turns to initial state.

Power Failure Behaviour - If Resume is selected , profile control resumes from where it is stopped.

Resume

Output Power During Prob Failure(%) 0 Output Power During Prob Failure(%) : Adjustable between %0 ... %100. Output will continue in case of prob failure.

Soft Start Time(sec) 10 Soft Start Time(sec) : Adjustable between 0 ... 200 seconds.

OFF

Consistently Control If device is in profile control mode , programmed segments of profile control starts according to soft start time.

ON

If device is in “Single Setpoint Mode” , device starts to control according to soft start time after device is powered on.

SV Deviation 0 OFF

ON

Consistently Control : When profile control is finished ; If OFF is selected , profile control stops and turns to initial state.

If ON is selected , profile control continues to control at last set value.

SV Deviation : End of the every profile control step , If difference between process value and set value is bigger than

SV Deviation value ( SV - PV > SV Deviation ) then time countdown is paused and control remains at last set value until

difference between process value and set value is smaller than SV Deviation value ( SV - PV < SV Deviation ).

SV Deviation process can be enabled/disabled with ON/OFF option.

Output Conf Control Conf Motorized Valve Conf Motorized Valve Position When Power On: It provides to configuration of location of motorized valve when device

Close

power on.

Motorized Valve Position When Power On

Open Motorized Valve On/Off Time (sn): It can configuration between 2-300 seconds

Motorized Valve Control Period(%): Motorized valve configurations off time during on/off.This time gets by percent

Motorized Valve On/Off Time(sn) 10

on/off time of motorized valve. If this time is less than 2 seconds,time will be 2 seconds automatically.

Motorized Valve On Control Period(%) 20

Alarm Set Conf Alarm 1 Conf Alarm 2 Conf Alarm 3 Conf Programming Alarms(Alarm Configuration Page)

Alarm 1 Set Value : Adjustable between Alarm 1 Up Limit and Alarm 1 Low Limit.

Alarm 1 Set Value 150.0 Alarm 2 Set Value : Adjustable between Alarm 2 Up Limit and Alarm 2 Low Limit.

Alarm 2 Set Value 500.0 Alarm 3 Set Value : Adjustable between Alarm 3 Up Limit and Alarm 3 Low Limit.

(In order to use Alarm 3 , Output Type parameter must be different from Relay otherwise

Alarm 3 Set Value 850.0

Alarm 3 will be unavailable and Alarm 3 Conf page will be hidden.

Alarm 1 Hysteresis : Adjustable between 0 ... 50.

Alarm 1 Type : Independent alarm, Deviation alarm, Band alarm, Band Alarm with Inhibition or

Profil control alarm can be selected. (In order to select Profile control segment alarms , Alarm 1 segments

Alarm Set Conf Alarm 1 Conf Alarm 2 Conf Alarm 3 Conf

in Alarm Conf sub page of Profile Controller Configuration Page should be selected.

Alarm 1 Status : For the Independent alarm, Band alarm or Band Alarm with Inhibition to be active below the set value

Alarm 1 Hysteresis 0

LOW must be selected , to be active above the set value HIGH must be selected. If LOW is seleced for Band alarm ,

Alarm 1 Type Independent alarm will be activated in band. If HIGH is selected , alarm will be activated out of band.

Alarm 1 Status LOW

Alarm 1 Status During Probe Failure : For the alarm to be active in case of prob failure ON must be selected.

HIGH

Alarm 1 Status During Prob Failure OFF

For the alarm to be inactive in case of prob failure OFF must be selected.

ON

Alarm 1 Up Limit : Adjustable between Scale Maximum and Alarm 1 Low Limit.

Alarm 1 Up Limit 160.00

Alarm 1 Low Limit : Adjustable between Scale Minimum and Alarm 1 Up Limit.

Alarm 1 Low Limit -100.00

Alarm 2 “Alarm 2 Conf” and Alarm 3 “Alarm 3 Conf” are programmed in the same way.

SURAN Industrieelektronik Tel.: +49 (0)7451 / 625 617 E-mail : info@suran-elektronik.de 5. / 10

Dettinger Str. 9 / D-72160 Horb a.N Fax: +49 (0)7451 / 625 0650 Internet : www.suran-elektronik.de EPC9513-EN-12102021

Independent Alarm Deviation Alarm Band Alarm

Set Set Set

Value ON Value ON ON Value ON

Alarm Status Alarm Status Alarm Status

HIGH HIGH HIGH

OFF OFF OFF

ON ON ON

Alarm Status Alarm Status Alarm Status

LOW LOW LOW

OFF OFF OFF OFF

Alarm Alarm Alarm Alarm

Hysteresis Hysteresis Hysteresis Hysteresis

Alarm Set Set Alarm Set Set _ Alarm Set Set Alarm Set

+ Value Value +

Value Value Value Value Value

Band Alarm with Inhibition

Alarm Status : HIGH Alarm Status : LOW

Set Value+ Alarm Set Value Set Value+ Alarm Set Value

Set Value Set Value

Set Value- Alarm Set Value Set Value- Alarm Set Value

ON ON

OFF OFF

Beginning Band alarm is possible Beginning Band alarm is possible

of procedure of procedure

Programming

Programming PID Control (PID Control Configuration Page)

PID Control Conf

Proportional Band (%) : Adjustable between %0.0 ... %100.0.

If proportional band is selected 0.0 , ON-OFF control will be activated.

Proportional Band (%) 4.0

Integral Time (min) : Adjustable between 0.0 ... 100.0 minute.

Integral Time (min) 4.0

Derivate Time (min) : Adjustable between 0.0 ... 25.0 minute.

Derivative Time (min) 1.0 Control Period (sec) : Adjustable between 0 ... 250 second.

Control Period (sec) 4 Auto Tune : It allows to improve PID parameters after Self Tune. In normal operation, it provides the best control by automatically

Auto Tune OFF changing the PID parameters in case the measured value oscillates. If Auto Tune ON is selected, it is active and the display

ON shows AUTO TUNE RUNNING until Auto Tune is completed. Auto Tune OFF must be selected to stop the Auto Tune operation.

Start Selftune

PID Self Tune :

Self Tune is started by selecting Start Selftune with keys and pressing by key. SELF TUNE IS

STARTED and SELF TUNE IS RUNNING messages is shown respectively.

If key is pressed, SELF TUNE IS STOPPED message is shown and selftune is stopped and device turns back to

home screen.

When Self Tune process is successful:

- SELF TUNE IS FINISHED, PRESS BACK TO EXIT message is shown and waits for user intervention in profile control mode.

- SELF TUNE IS FINISHED, SINGLE SETPOINT IS RUNNING message is shown and continues to control.

In order to start Selftune process PV must be smaller than %60 of SV , otherwise SELF TUNE IS STARTED and

SELF TUNE IS STOPPED messages are shown respectively and home screen returned.

User must wait until PV drops under %60 of SV and start selftune again.

Modbus Conf Programming ModBus (Communication Configuration Page)

Modbus Communication

OFF

ON

Modbus Communication : If parameter is selected ON modbus will be active , otherwise will be inactive.

1

Device Address

Device Address : Adjustable between 1 ... 247

Baudrate 9600

Baudrate : 4800, 9600, 19200, 38400 or 57600.

Programming Keypad Security Level(Security Configuration Page)

Security Code 0 Security Code : In order to change security configuration , Security Code must be entered 123.

Input Configuration Page Visibility Yes Input Configuration Page Visibility : Yes, No or None.

Output Configuration Page Visibility Yes Output Configuration Page Visibility : Yes, No or None.

Alarm Configuration Page Visibility Yes

Alarm Configuration Page Visibility : Yes, No or None.

Yes

PID Control Configuration Page Visibility : Yes, No or None.

PID Control Configuration Page Visibility

Communication Configuration Page Visibility Yes

Communication Configuration Page Visibility : Yes, No or None.

Calibration Page Visibility Yes

Profile Controller Configuration Page Visibility Yes Calibration Page Visibility : Yes or None.

Enter security code in order to change page visibilities.

Profile Controller Configuration Page Visibility : Yes, No or None.

No : Page can be opened , parameters can not be changed.

Yes : Page can be opened , parameters can be changed. None : Page can not be opened.

SURAN Industrieelektronik Tel.: +49 (0)7451 / 625 617 E-mail : info@suran-elektronik.de 6. / 10

Dettinger Str. 9 / D-72160 Horb a.N Fax: +49 (0)7451 / 625 0650 Internet : www.suran-elektronik.de EPC9513-EN-12102021

Programming

Program Conf Alarms Conf Soft Start Conf Graph Page Programming Profile Controller (Profile Controller Configuration Page)

Program No: 1 Start Program: 1 Single Setpoint Program No : Adjustable between 1 ... 16.

Program Start Delay (min.): Time(min.) Temp. Start Program : Adjustable 1 ... 16.

0 Segment1: 0 0.0

Segment2: 0 0.0

Single Setpoint : If checkbox is selected , single set point will be activated.(In this case profile controller is inactive)

Max. Step Count :

8 Segment3 0 0.0 Program Start Delay(min.) : Adjustable between 0 ... 180.

Segment4 0 0.0

Program Repeat Count : Max. Step Count : Adjustable between 1 ... 8.

Segment5 0 0.0

1

Segment6 0 0.0 Program Repeat Count : Adjustable between 1 ... 8.

Next Program :

0

Segment7 0 0.0

Next Program : Adjustable between 0 ... 16. If 0 is selected , control will be stopped at end of the program.

Segment8 0 0.0

Segment1/Time(min.) : Adjustable between 0 ... 32000 min.

Segment1/Temp : Adjustable between Minimum Set Value and Maximum Set Value parameters.

2, 3 ... 8. Segments are programmed in the same way.

Program Conf Alarms Conf Soft Start Conf Graph Page

Alarm1 Alarm2

Segment1 Segment1/Alarm1 : If checkbox is selected , Alarm1 will be activated.

Segment2

Segment1/Alarm2 : If checkbox is selected , Alarm2 will be activated.

Segment3

Segment4 2, 3 ... 8. Segments are programmed in the same way.

Segment5

Segment6 If Alarm Type parameter is selected profile control alarm , Alarm1 and Alarm2 can be configured for the profile controller.

Segment7

Segment8

Program1 Segment Alarms

Program Conf Alarms Conf Soft Start Conf Graph Page Soft Start Conf :

Soft Start

Segment1 1. Segment Soft Start : If checkbox is selected , Soft Start will be activated.

Segment2 Value of Soft Start Time parameter will be used as a selected segment’s soft start time.

Segment3

Segment4

2, 3 ... 8. Segments are programmed in the same way.

Segment5

Segment6

Segment7

Segment8

Program1 Segment Soft Starts

Program Conf Alarms Conf Soft Start Conf Graph Page Graph Page :

SV Program 1 Graph

200 Configuration can be seen from Graph Page.

175 - Program number,

150 - Set values of segments

125

- Segment counts

100

- Segment lenght

75

50

25

0 min

2 4 6 8 10 12 14 16

MODBUS ERROR MESSAGES

Modbus protocol has two types error, communication error and operating error. Reason of the communication error is data corruption in transmission. Parity and CRC

control should be done to prevent communication error. Receiver side checks parity and CRC of the data. If they are wrong, the message will be ignored. If format of the

data is true but function doesn’t perform for any reason, operating error occurs. Slave realizes error and sends error message. Most significant bit of function is changed '1'

to indicate error in error message by slave. Error code is sent in data section. Master realizes error type via this message.

ModBus Error Codes

Error Code Name Meaning

The function code received in the query is not an allowable action for the slave. If a

Poll Program Complete command was issued, this code indicates that no program

01 ILLEGAL FUNCTION function preceded it.

ILLEGAL DATA ADDRESS The data address received in the query is not an allowable address for the slave.

02

03 ILLEGAL DATA VALUE A value contained in the query data field is not an allowable value for the slave.

Message example;

Structure of command message (Byte Format) Structure of response message (Byte Format)

Device Address (0A)h Device Address (0A)h

Function Code (01)h Function Code (81)h

Beginning address MSB (04)h

Error Code (02)h

of coils.

LSB (A1)h

LSB (B0)h

MSB (00)h CRC DATA

Number of coils (N)

MSB (53)h

LSB (01)h

LSB (AC)h

CRC DATA

MSB (63)h

SURAN Industrieelektronik Tel.: +49 (0)7451 / 625 617 E-mail : info@suran-elektronik.de 7. / 10

Dettinger Str. 9 / D-72160 Horb a.N Fax: +49 (0)7451 / 625 0650 Internet : www.suran-elektronik.de EPC9513-EN-12102021

You might also like

- C-6.2 HSTDocument38 pagesC-6.2 HSTBILAL FAROOQUI100% (1)

- User Manual: HGM6100U Series Automatic Control ControllersDocument39 pagesUser Manual: HGM6100U Series Automatic Control ControllersMohamed R KhamissNo ratings yet

- N2006 PidDocument8 pagesN2006 PidSarah KempNo ratings yet

- Electrical - BB International PDFDocument480 pagesElectrical - BB International PDFedelmolina100% (3)

- In Electrical Electronic MeasurementDocument29 pagesIn Electrical Electronic Measurementsiddhartha bharadwajNo ratings yet

- Honeywell Water Flow Switch 6000Document2 pagesHoneywell Water Flow Switch 6000parvez_ameenNo ratings yet

- 1st Semester Syllabus 2015 16Document54 pages1st Semester Syllabus 2015 16KrishnaMurthyTPNo ratings yet

- PD9001Document13 pagesPD9001Sher BahadarNo ratings yet

- DCL400Document2 pagesDCL400taleb 6269No ratings yet

- TC 513Document25 pagesTC 513MuthuRaj TcsNo ratings yet

- Smart TripDocument2 pagesSmart TripkaicyemNo ratings yet

- Farnell Temp ControllerDocument1 pageFarnell Temp ControllerKumarNo ratings yet

- PID+Fuzzy Temperature ControllerDocument23 pagesPID+Fuzzy Temperature ControllerWilly TurdoNo ratings yet

- PID500-T Instruction ManualDocument24 pagesPID500-T Instruction Manualraghunathreddy naniNo ratings yet

- Adr 130Document16 pagesAdr 130miri10861No ratings yet

- Mcih IndicatorDocument2 pagesMcih IndicatorAryan rajputNo ratings yet

- Oim Ai 7X82DDocument10 pagesOim Ai 7X82Ddeepesh1011No ratings yet

- Linear Servomotor General Instructions: Serial Converter Unit (Model: JZDP-¡00¡-¡¡¡-E)Document8 pagesLinear Servomotor General Instructions: Serial Converter Unit (Model: JZDP-¡00¡-¡¡¡-E)Edwin Aguila CerónNo ratings yet

- Wenling Yuhai Electromechanical 180sy-M35015 Sg-50a DatasheetDocument62 pagesWenling Yuhai Electromechanical 180sy-M35015 Sg-50a DatasheetJoimir PerezNo ratings yet

- Digital Process Indicator Selectron PIC152Document1 pageDigital Process Indicator Selectron PIC152industrialindiaNo ratings yet

- Low Power, 16-/24-Bit Sigma-Delta ADC For Bridge Sensors AD7796/AD7797Document24 pagesLow Power, 16-/24-Bit Sigma-Delta ADC For Bridge Sensors AD7796/AD7797vuongqnamNo ratings yet

- PT PID+Fuzzy Temperature Controller - B0Document17 pagesPT PID+Fuzzy Temperature Controller - B0Johnny Liu JohnnyNo ratings yet

- MR9270S V1.0Document43 pagesMR9270S V1.0AztvNo ratings yet

- Auto-Tune Pid Temperature & Timer General Specifications: N L1 L2 L3Document4 pagesAuto-Tune Pid Temperature & Timer General Specifications: N L1 L2 L3sharawany 20No ratings yet

- PID110 Temprature ControllersDocument2 pagesPID110 Temprature ControllersvishadkapadiaNo ratings yet

- N2006P PID Installation & WiringDocument8 pagesN2006P PID Installation & WiringFarlepNo ratings yet

- Masibus Digital Controller 5002uDocument20 pagesMasibus Digital Controller 5002uSOURISH100% (2)

- Instruction Manual Pmo 215x 415xDocument10 pagesInstruction Manual Pmo 215x 415xMARCOSNo ratings yet

- Digital Elcb Tester: 7 Functions 17 RangesDocument1 pageDigital Elcb Tester: 7 Functions 17 RangesArsh AlamNo ratings yet

- Adam-4022t Manual v2.2Document32 pagesAdam-4022t Manual v2.2Biplab DattaNo ratings yet

- TDAX023100Document3 pagesTDAX023100Abdul KurniadiNo ratings yet

- Specifications: - : User'S Operating Manual For Pid Digital Temperature ControllerDocument9 pagesSpecifications: - : User'S Operating Manual For Pid Digital Temperature ControllerAnjum ParkarNo ratings yet

- A6-SG 6 DIGITAL WEIGHING Controller: DescriptionDocument3 pagesA6-SG 6 DIGITAL WEIGHING Controller: DescriptionVu Minh CuongNo ratings yet

- 10.709 Gbps Laser Diode Driver Chipset: A To 1200 ADocument12 pages10.709 Gbps Laser Diode Driver Chipset: A To 1200 ABanyugeaNo ratings yet

- PID5030 M53om101 Issue14 Dt.23.10.13Document21 pagesPID5030 M53om101 Issue14 Dt.23.10.13Pandu BirumakovelaNo ratings yet

- LMC110 00 - en UsDocument3 pagesLMC110 00 - en UsSoumyabrata PradhanNo ratings yet

- Ai 5982 Digital Temperature ControllerDocument6 pagesAi 5982 Digital Temperature ControllerAlex RestrepoNo ratings yet

- Enda Ehtc7425A Humidity and Temperature Controller: Technical SpecificationsDocument8 pagesEnda Ehtc7425A Humidity and Temperature Controller: Technical SpecificationsNader MohammedNo ratings yet

- Digital Autozero & Span Option: Technical DataDocument2 pagesDigital Autozero & Span Option: Technical DataGopal HegdeNo ratings yet

- Components: Systems Injectors Electronic Control Module Sensors Elements MonitoringDocument37 pagesComponents: Systems Injectors Electronic Control Module Sensors Elements Monitoringjibv100% (1)

- CMT-007A - Digital CounterDocument4 pagesCMT-007A - Digital CounterSHARAB IMTIAZNo ratings yet

- Voltage Output Temperature Sensor With Signal Conditioning AD22100Document12 pagesVoltage Output Temperature Sensor With Signal Conditioning AD22100Дьяволенок никитоNo ratings yet

- Temp ControllersDocument14 pagesTemp ControllersramatajamaNo ratings yet

- Etr9040 ManualDocument24 pagesEtr9040 ManualLindo PatoNo ratings yet

- Manual Control CrisolDocument60 pagesManual Control CrisolBaruch Cervantes GonzalezNo ratings yet

- Programmable Thermocouple ConverterDocument5 pagesProgrammable Thermocouple ConvertercanopusinstrumentsNo ratings yet

- 10 - 61-611-EN-B-01 - 2011ABB PLC UnitDocument12 pages10 - 61-611-EN-B-01 - 2011ABB PLC UnitDawood KSNo ratings yet

- File 1729 BGDocument2 pagesFile 1729 BGmahmoudNo ratings yet

- Eliwell BrochuresDocument7 pagesEliwell Brochuresunder word under wordNo ratings yet

- PROCESS CALIBRATOR Atek 830Document5 pagesPROCESS CALIBRATOR Atek 830BenabidNo ratings yet

- ESM Xx20 Manual MultilenguajeDocument64 pagesESM Xx20 Manual MultilenguajeRonal IsnadoNo ratings yet

- Temperature Controller Catalog - EngDocument9 pagesTemperature Controller Catalog - EngJuan Gervacio OrtegaNo ratings yet

- TIM-94N / TIM-94N-B / TIM-94N-BN: DescriptionDocument5 pagesTIM-94N / TIM-94N-B / TIM-94N-BN: Descriptionluat1983No ratings yet

- Oriface and Jet Analysis TaturialDocument13 pagesOriface and Jet Analysis TaturialWegdan AldobaiNo ratings yet

- LMC400 00 - en UsDocument3 pagesLMC400 00 - en UsSoumyabrata PradhanNo ratings yet

- Products Catalogue 2010-11Document10 pagesProducts Catalogue 2010-11Gyanesh BhujadeNo ratings yet

- Compact General Purpose ControllersDocument12 pagesCompact General Purpose ControllersCarlos GusmaoNo ratings yet

- Pic152a ViDocument2 pagesPic152a Viiyappan5016100% (1)

- Controlador de Processos WEST P4170Document2 pagesControlador de Processos WEST P4170Alexandre Caique SampaioNo ratings yet

- Frenic Multi Quick Guide Lift en PDFDocument18 pagesFrenic Multi Quick Guide Lift en PDFLong NguyễnNo ratings yet

- Multispan TC-19Document4 pagesMultispan TC-19Karan SolankiNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- ATS NED Project-BilalDocument17 pagesATS NED Project-BilalBILAL FAROOQUINo ratings yet

- Building - Your - Own - PC - Complete - Manual - Sep - 2023 Ijaba - InfoDocument128 pagesBuilding - Your - Own - PC - Complete - Manual - Sep - 2023 Ijaba - InfoBILAL FAROOQUINo ratings yet

- Automotive Maintenance - PDF PDF BooksDocument100 pagesAutomotive Maintenance - PDF PDF BooksBILAL FAROOQUINo ratings yet

- Proposal FypDocument2 pagesProposal FypBILAL FAROOQUINo ratings yet

- 1204 Ses Shops Arc Form 1 RecordDocument1 page1204 Ses Shops Arc Form 1 RecordBILAL FAROOQUINo ratings yet

- Cga C-6.1 Last PageDocument1 pageCga C-6.1 Last PageBILAL FAROOQUINo ratings yet

- 1201-Ses-Shop Shop Production ReportDocument1 page1201-Ses-Shop Shop Production ReportBILAL FAROOQUINo ratings yet

- INV 0132 22 (Gerry's Dnata)Document1 pageINV 0132 22 (Gerry's Dnata)BILAL FAROOQUINo ratings yet

- Cga C-8-2017 Last PageDocument2 pagesCga C-8-2017 Last PageBILAL FAROOQUINo ratings yet

- Inv 0145 22 (Assl)Document1 pageInv 0145 22 (Assl)BILAL FAROOQUINo ratings yet

- Cga C-6.1 First Page-2019Document2 pagesCga C-6.1 First Page-2019BILAL FAROOQUINo ratings yet

- Cga-6.3 - 2019 First PageDocument2 pagesCga-6.3 - 2019 First PageBILAL FAROOQUINo ratings yet

- INV 0144 22 (Jordan Aviaition)Document1 pageINV 0144 22 (Jordan Aviaition)BILAL FAROOQUINo ratings yet

- Inv 0148 22 (Fly Baghdad)Document1 pageInv 0148 22 (Fly Baghdad)BILAL FAROOQUINo ratings yet

- INV 0140 22 (Air Sial Limited)Document1 pageINV 0140 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

- Inv 0147 22 (Vision Air)Document1 pageInv 0147 22 (Vision Air)BILAL FAROOQUINo ratings yet

- Inv 0139 22 (Vision Air)Document1 pageInv 0139 22 (Vision Air)BILAL FAROOQUINo ratings yet

- Inv 0135 22 (Pia)Document1 pageInv 0135 22 (Pia)BILAL FAROOQUINo ratings yet

- Inv 0131 22Document1 pageInv 0131 22BILAL FAROOQUINo ratings yet

- C-8 HSTDocument10 pagesC-8 HSTBILAL FAROOQUINo ratings yet

- INV 0141 22 (Air Sial Limited)Document1 pageINV 0141 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

- Whole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022Document2 pagesWhole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022BILAL FAROOQUINo ratings yet

- C 6 HSTDocument30 pagesC 6 HSTBILAL FAROOQUINo ratings yet

- C-6.1 HSTDocument24 pagesC-6.1 HSTBILAL FAROOQUINo ratings yet

- Inv 0128 22Document1 pageInv 0128 22BILAL FAROOQUINo ratings yet

- 2.8 NDT Bsi ShopDocument5 pages2.8 NDT Bsi ShopBILAL FAROOQUINo ratings yet

- 2.7 Galley Equipment Shop (c06)Document5 pages2.7 Galley Equipment Shop (c06)BILAL FAROOQUINo ratings yet

- 2.3 ReservedDocument2 pages2.3 ReservedBILAL FAROOQUINo ratings yet

- 2.6 Battery Shop (c05)Document6 pages2.6 Battery Shop (c05)BILAL FAROOQUINo ratings yet

- Marine Electrical Power Analysis PDFDocument4 pagesMarine Electrical Power Analysis PDFinfraNo ratings yet

- Tesys T - LTMR100CFMDocument4 pagesTesys T - LTMR100CFMdul theoNo ratings yet

- MKT2015019674EN 7750 SR Portfolio R13 DataSheet PDFDocument5 pagesMKT2015019674EN 7750 SR Portfolio R13 DataSheet PDFquocan100% (1)

- Lab Sheet 2 PDFDocument13 pagesLab Sheet 2 PDFmalaNo ratings yet

- Control Cable TCP01 FOR CONTINUITYDocument23 pagesControl Cable TCP01 FOR CONTINUITYFendi ahmadNo ratings yet

- Experiment-2: Asymmetrical AC ControllerDocument17 pagesExperiment-2: Asymmetrical AC ControlleraashishNo ratings yet

- Electrical Safety in Low Voltage Distribution Systems Up To 1 000 V A.C. and 1 500 V D.C. Equipment For Testing, Measuring or Mo - Libgen - LiDocument22 pagesElectrical Safety in Low Voltage Distribution Systems Up To 1 000 V A.C. and 1 500 V D.C. Equipment For Testing, Measuring or Mo - Libgen - LiDavidAlbertoMedinaMedinaNo ratings yet

- IEC StandardsDocument22 pagesIEC StandardsBasim Al-AttarNo ratings yet

- ABB Basic Electricity CourseDocument12 pagesABB Basic Electricity CourseViduranga BandaraNo ratings yet

- Wasion Energy Smart Energy Brochure 2024Document21 pagesWasion Energy Smart Energy Brochure 2024Hassan AzmatNo ratings yet

- Super Efficient AC - DaikinDocument35 pagesSuper Efficient AC - DaikinSaravanan SengazhaniNo ratings yet

- Report - Inorbit Mall - Services - T.D - Week PDFDocument78 pagesReport - Inorbit Mall - Services - T.D - Week PDFBhavya MewadaNo ratings yet

- Solar Nylon Anti-Rodent & Anti-Termite CableDocument1 pageSolar Nylon Anti-Rodent & Anti-Termite CablePrateek GuptaNo ratings yet

- Role of HVDC in Future Power Systems: by Dr.V.Rajini Professor/EEE SSN College of EnggDocument87 pagesRole of HVDC in Future Power Systems: by Dr.V.Rajini Professor/EEE SSN College of EnggAnonymous hzXy93FAENo ratings yet

- Rme Trivia (Q&a)Document23 pagesRme Trivia (Q&a)Jeffrey PobleteNo ratings yet

- Dewalt d25481Document12 pagesDewalt d25481Vasilic NikolaNo ratings yet

- 10 SM 2017 Science Hindi PDFDocument215 pages10 SM 2017 Science Hindi PDFNAEEM MALIKNo ratings yet

- Surge Current Protection Using Super Conductors Report - NewDocument22 pagesSurge Current Protection Using Super Conductors Report - Newsourav83% (6)

- Anti-Static and Clean-Room Equipment: Static Eliminator General CatalogueDocument44 pagesAnti-Static and Clean-Room Equipment: Static Eliminator General Cataloguesangaji hogyNo ratings yet

- Klauke - Bi-Metal Lugs & ConnectorsDocument6 pagesKlauke - Bi-Metal Lugs & ConnectorsBiplab PaulNo ratings yet

- X Ray GeneratorDocument70 pagesX Ray Generatorub17075% (4)

- Aladin: Association of Light and Detector For Individual NoticeDocument1 pageAladin: Association of Light and Detector For Individual NoticeRicardo GutiérrezNo ratings yet

- Marine Electrical 101Document59 pagesMarine Electrical 101Muhammad Adam100% (1)

- NemoDocument35 pagesNemoJonathan HardyNo ratings yet

- 1SBC100214C0201 - Main Catalog 2019 PDFDocument912 pages1SBC100214C0201 - Main Catalog 2019 PDFDangQuangTrungNo ratings yet