Professional Documents

Culture Documents

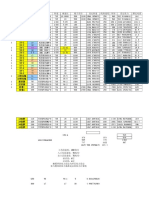

601ad1e4b932b908dfc38a2e - Zephyr Capacity Chart

601ad1e4b932b908dfc38a2e - Zephyr Capacity Chart

Uploaded by

shriram todkarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

601ad1e4b932b908dfc38a2e - Zephyr Capacity Chart

601ad1e4b932b908dfc38a2e - Zephyr Capacity Chart

Uploaded by

shriram todkarCopyright:

Available Formats

Blower Capacity Chart

Maximum Static

½ hp ¾ hp 1 hp 1½ hp 2 hp 3 hp 5 hp 7½ hp 10 hp

Pressure

Regular Fans 6” 7¼” 7½” 8½” 9” 9½” 11” 15” 19”

Hi-Static

7½” 8½” N/A N/A 11” 11” 13” 16” N/A

Large Fans

Wind Pressure Maximum Number of Stops

(At Chest) & C.F.M.

14 20 25 33 40 55 90 124 162

3” 630 900 1125 1485 1800 2475 4050 5559 1290

11 15 20 26 33 46 73 102 131

3½” 547 764 987 1307 1653 2276 3638 5100 6548

9 12 16 21 28 40 60 86 108

4” 475 649 864 1154 1510 2089 3272 4674 5890

7 10 13 18 24 33 52 75 93

4½” 413 534 755 1026 1371 1911 2945 4279 5301

6 8 11 15 20 29 44 65 79

5” 360 480 660 921 1235 1744 2655 3911 4779

- 6 - 12 15 22 33 60 59

6” 390 780 975 1441 2170 3250 3906

- - - - 11 17 26 39 47

7” 779 1176 1800 2680 3240

- - - - 8 13 21 30 38

8” 584 949 1533 2190 2759

- - - - - - 16 22 29

10” 1280 1799 2304

- - - - - - - 18 23

12” 1530 1974

- - - - - - - 15 19

14” 1350 1755

16” - - - - - - - - 15

1560

P.O. Box 156 Orrville, OH 44667 • 1.800.416.7426 • Zephyrblower.com • kate@zephyrblower.com

How to Calculate Blower Capacity

How to calculate number of stops and pressure:

Step 1: Calculate the number of stops on each pressure.

Great 7 stops x 3.25” pressure = 22.75” pressure units

Great 1 stop x 5” pressure = 5” pressure units

Swell 7 stops x 4” pressure = 28” pressure units

Choir 7 stops x 3.5” pressure = 24.5” pressure units

Choir 1 stop x 8” pressure = 8” pressure units

Pedal 2 stops x 5” pressure = 10” pressure units

Pedal 3 stops x 4” pressure = 12” pressure units

Step 2: Add the total stops listed. Add the total pressure units.

28 stops 110.25” pressure units

Step 3: Divide the total pressure units calculated above by the total stops listed.

110.25” pressure units/28 total stops = 3.9375” average pressure

(round up = 4”)

Step 4: Use the Zephyr Capacity Chart to find the recommended blower size.

At 4” of pressure, a 2 hp Zephyr Blower will accommodate a 28 stop

organ.

Helpful Tips:

• When counting stops, Manual 16’ stops with more than 61 pipes and unit action

should be counted as two stops.

• The maximum required pressure may increase the required blower size. A Blowers

static pressure should be two to three inches higher than the maximum required

pressure at the windchest.

• For Blowers in locations with higher elevation, discount the capacity by 4% for each

1,000 feet above sea-level (assuming zero-feet elevation).

• Use of Hi-Static Fans increases C.F.M. by 10-20% depending on horsepower.

P.O. Box 156 Orrville, OH 44667 • 1.800.416.7426 • Zephyrblower.com • kate@zephyrblower.com

You might also like

- Fluid Mechanics and Hydraulics 4th EditionDocument285 pagesFluid Mechanics and Hydraulics 4th Editionangela90% (10)

- Convective Heat and Mass Transfer 4th EdDocument347 pagesConvective Heat and Mass Transfer 4th Edsalih yigitNo ratings yet

- POE EOC Review KeyDocument9 pagesPOE EOC Review KeyRyan CedergrenNo ratings yet

- Field Duct Sizing ChartDocument1 pageField Duct Sizing ChartmemorydearNo ratings yet

- Large Scale Microbial Production of Advanced BiofuelsDocument9 pagesLarge Scale Microbial Production of Advanced BiofuelsGregoryBenzNo ratings yet

- Airstroke AirmountDocument112 pagesAirstroke Airmountvinay8464No ratings yet

- Kinematic Exam Problem by SAM-HW-1Document1 pageKinematic Exam Problem by SAM-HW-1sahel100% (1)

- TANQUES1Document20 pagesTANQUES1Roger David Melendez GuevaraNo ratings yet

- NT-133 Engl (sp1435)Document6 pagesNT-133 Engl (sp1435)AlanNo ratings yet

- Steel Weight Calculation CatalaugeDocument35 pagesSteel Weight Calculation CatalaugeShivprasad PatilNo ratings yet

- Wake Velocity Measurement For Flow Over A Circular Cylinder: Aim of The ExperimentDocument6 pagesWake Velocity Measurement For Flow Over A Circular Cylinder: Aim of The ExperimentPurvang ParmarNo ratings yet

- Natural Gas Filtration & Separation: To Separate Solid & Liquid Impurities From Natural GasDocument5 pagesNatural Gas Filtration & Separation: To Separate Solid & Liquid Impurities From Natural GasMehdi Hajd KacemNo ratings yet

- Gráfi Ca - Tabla 2Document3 pagesGráfi Ca - Tabla 2Anshelo Geiner Davila RamosNo ratings yet

- Calidad Grafica de Control 1Document23 pagesCalidad Grafica de Control 1Angie MacazanaNo ratings yet

- Volume CalculationDocument4 pagesVolume CalculationroyalnitinNo ratings yet

- Soal Bab 8.1 8.2 8.8Document6 pagesSoal Bab 8.1 8.2 8.8Tommy Indra KNo ratings yet

- Ram Spec s-28f9845Document2 pagesRam Spec s-28f9845Justine Kei Lim-OrtegaNo ratings yet

- Gas Pipeline Blocked Outlet and Pressure Surge CalculationDocument12 pagesGas Pipeline Blocked Outlet and Pressure Surge CalculationHarish KumarNo ratings yet

- 1com BN 1Document2 pages1com BN 1Carlos Daniel Condori RamosNo ratings yet

- FREEPHONE: 0800 117882 FREEFAX: 0800 575092: Guide To Lead Flashing Roll Weights To BS EN 12588Document1 pageFREEPHONE: 0800 117882 FREEFAX: 0800 575092: Guide To Lead Flashing Roll Weights To BS EN 12588Adie MorganNo ratings yet

- Calculo IIDocument24 pagesCalculo IIjose suniNo ratings yet

- Flange Weights by Pressure Class and SizeDocument1 pageFlange Weights by Pressure Class and SizeSirajia TradingNo ratings yet

- Tension Force Calculation Sheet For Steel Bolts PDFDocument1 pageTension Force Calculation Sheet For Steel Bolts PDFVỸ TRẦNNo ratings yet

- Keppel Piping Hand BookDocument21 pagesKeppel Piping Hand BooktinzarmoeNo ratings yet

- ASTM Bolt Torque ChartDocument8 pagesASTM Bolt Torque Chartmiguel angel bohorquez fajardoNo ratings yet

- Chapter 8Document30 pagesChapter 8Tess CoaryNo ratings yet

- Weights Mokveld Axial On-Off Valve-6-1Document2 pagesWeights Mokveld Axial On-Off Valve-6-1elperrote3No ratings yet

- XCMG 75 Tons Truck Crane QY75KDocument4 pagesXCMG 75 Tons Truck Crane QY75KZul FachmiNo ratings yet

- DENAIR Oil-Free Air CompressorDocument8 pagesDENAIR Oil-Free Air CompressorAlyasajaya EnergiNo ratings yet

- Storm 8 - 11Document2 pagesStorm 8 - 11A01 GALAXYNo ratings yet

- Calender NewDocument20 pagesCalender NewRAGHU MALLEGOWDANo ratings yet

- Model: SZ185: Technical DataDocument6 pagesModel: SZ185: Technical DataAli AlchmreNo ratings yet

- BUU BBA 1 Accounting-2014Document3 pagesBUU BBA 1 Accounting-2014lion kingNo ratings yet

- Tablas R C L Correas V GatesDocument44 pagesTablas R C L Correas V GatesTomásNo ratings yet

- Cat LocationDocument193 pagesCat LocationAbhimanyu ArjunNo ratings yet

- Field Duct Sizing Chart: Round Duct Size EstimateDocument1 pageField Duct Sizing Chart: Round Duct Size EstimateKhadija MirajNo ratings yet

- Roofrain Drain CalculationDocument2 pagesRoofrain Drain CalculationNghiaNo ratings yet

- 33 PTA Dimensions: Dimensions (Inches), Weight (LBS.)Document1 page33 PTA Dimensions: Dimensions (Inches), Weight (LBS.)Sandy ZhangNo ratings yet

- 越南2#HB线电机数据合算Document6 pages越南2#HB线电机数据合算Vũ HiệuNo ratings yet

- Result Ai TS 4XII 1Document2 pagesResult Ai TS 4XII 1Shree VishnuNo ratings yet

- Data - Q1 (Version 1)Document15 pagesData - Q1 (Version 1)baselzayied23No ratings yet

- Torque Tools Technical Information PDF710202195644Document6 pagesTorque Tools Technical Information PDF710202195644indra.entahlahNo ratings yet

- Installation and Operating Manual For Dab 4" Submersible Pumps S4A - S4B - S4C - S4D - S4E - S4FDocument14 pagesInstallation and Operating Manual For Dab 4" Submersible Pumps S4A - S4B - S4C - S4D - S4E - S4Fbagus saputraNo ratings yet

- PreparationDocument28 pagesPreparationAitbenahmed HibaNo ratings yet

- Date Sno BP - Cus.Name BP - Code Qty Product Name Del - Tot BP - Cu S.Cod E Del - Pric EDocument76 pagesDate Sno BP - Cus.Name BP - Code Qty Product Name Del - Tot BP - Cu S.Cod E Del - Pric EMechanical Robot Designers V CreationsNo ratings yet

- Pressure Conversion Wet Well Intake Pipe Sizing: 173.4 Amps 1.24x1.25x65a + 65A + 7.6ADocument2 pagesPressure Conversion Wet Well Intake Pipe Sizing: 173.4 Amps 1.24x1.25x65a + 65A + 7.6AMark Joey David100% (1)

- Area de PinturaDocument25 pagesArea de PinturaAlexandre FreitasNo ratings yet

- Regression StatisticsDocument9 pagesRegression Statisticskaran tripathiNo ratings yet

- Service Manual: Triplex Slush PumpsDocument26 pagesService Manual: Triplex Slush PumpsActivos FijosNo ratings yet

- Panneaux ThyboronDocument2 pagesPanneaux ThyboroninveststationNo ratings yet

- Pump Output1Document2 pagesPump Output1mohamed salemNo ratings yet

- FT in FT In: Minus Minus Minus Minus Minus MinusDocument9 pagesFT in FT In: Minus Minus Minus Minus Minus Minus2Suraj2No ratings yet

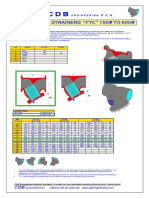

- Strainers FycDocument1 pageStrainers FycrodolfostiNo ratings yet

- CV-J.M: Flow Calculations and CV ValuesDocument1 pageCV-J.M: Flow Calculations and CV ValuessterlingNo ratings yet

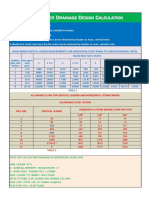

- Rain Water Drainage Design Calculation SheetDocument2 pagesRain Water Drainage Design Calculation SheetMohamed SewelamNo ratings yet

- M Ce CalculationsDocument4 pagesM Ce Calculationshengki wibowoNo ratings yet

- Exhaust Gas Brochure - Issue K PDFDocument12 pagesExhaust Gas Brochure - Issue K PDFFrancisco Mosquera LopezNo ratings yet

- Latihan Tes Olah TCM - ITCMDocument7 pagesLatihan Tes Olah TCM - ITCMRahmad Auliya Tri PutraNo ratings yet

- FormulasDocument5 pagesFormulasAndree AriasNo ratings yet

- N 7139 Technical DetailsDocument1 pageN 7139 Technical DetailsKengg dglNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- SEBD001407Document668 pagesSEBD001407Biswajit DasNo ratings yet

- Taper Lock Hubs and AdaptorsDocument4 pagesTaper Lock Hubs and AdaptorsPTE TOPPERNo ratings yet

- STULZ - Catalogo 2010Document32 pagesSTULZ - Catalogo 2010Franklin FernandezNo ratings yet

- Part 2 Cha-4Document25 pagesPart 2 Cha-4Yosafe MekonnenNo ratings yet

- (1.2c) Auxiliary Mechanism-Weft Fork (Side)Document10 pages(1.2c) Auxiliary Mechanism-Weft Fork (Side)sukanya prasadNo ratings yet

- VIKINGDocument12 pagesVIKINGeng.ahrteknikNo ratings yet

- 12-Mounting, Starting Up and Operating InstructionDocument19 pages12-Mounting, Starting Up and Operating InstructionGrisha Mari KosoyanNo ratings yet

- Tutorial 11 Geogrid Embankment (No Slip)Document14 pagesTutorial 11 Geogrid Embankment (No Slip)Juan Pablo Sanchez Melgarejo100% (1)

- Scope of Work Report MechanicalDocument4 pagesScope of Work Report MechanicalAbduljalil AlabidiNo ratings yet

- Dry Coolers Condensers PDFDocument36 pagesDry Coolers Condensers PDFChethan GowdaNo ratings yet

- VW Eos Front Brake CaliperDocument16 pagesVW Eos Front Brake CaliperNick PNo ratings yet

- JJMIE 41 09 Modified SOIDocument8 pagesJJMIE 41 09 Modified SOIED LiNo ratings yet

- Effect of Welding and Weld Repair On Crack Propagation BehaviorDocument8 pagesEffect of Welding and Weld Repair On Crack Propagation BehaviorMohamed AbdelAzizNo ratings yet

- Impact Vibration Control Using Semi-Active DamperDocument25 pagesImpact Vibration Control Using Semi-Active DamperVineesh KpNo ratings yet

- Correlation of Yield Strength and Tensile Strength With Hardness For Steels - SpringerDocument7 pagesCorrelation of Yield Strength and Tensile Strength With Hardness For Steels - SpringerJigar M. UpadhyayNo ratings yet

- JIS B2311 Steel Butt Welding Pipe Fittings For Ordinary UseDocument24 pagesJIS B2311 Steel Butt Welding Pipe Fittings For Ordinary Usense mcxNo ratings yet

- Vorticity PDFDocument4 pagesVorticity PDFirvhenNo ratings yet

- Physics ProjectDocument24 pagesPhysics ProjectAnarita TirkeyNo ratings yet

- TR50 Parts BookDocument276 pagesTR50 Parts BookRizal Assegaf100% (3)

- TM 5-3810-300-24&P3Document736 pagesTM 5-3810-300-24&P3svaasandNo ratings yet

- Electrical Plan ComputationDocument1 pageElectrical Plan ComputationMarc Adrienne MarquezNo ratings yet

- Excav. JCB - 330-370-Lc-Nlc-En (d52)Document32 pagesExcav. JCB - 330-370-Lc-Nlc-En (d52)Raul Apaza LujanNo ratings yet

- FM Safety Relief Valve Folder Vsr1n2colour Nov05Document4 pagesFM Safety Relief Valve Folder Vsr1n2colour Nov05jabalpuramit100% (1)

- Corolla Altis Minor ChangeDocument156 pagesCorolla Altis Minor Changedavit eka putraNo ratings yet

- Basic Electrical and Electronics EngineeringDocument8 pagesBasic Electrical and Electronics EngineeringNagendra PrasadNo ratings yet