Professional Documents

Culture Documents

Hydraulic Hammer Rental Service Checklist

Hydraulic Hammer Rental Service Checklist

Uploaded by

Faisal BackrieOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Hammer Rental Service Checklist

Hydraulic Hammer Rental Service Checklist

Uploaded by

Faisal BackrieCopyright:

Available Formats

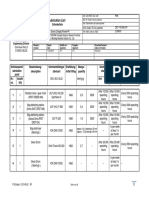

Hydraulic Hammer

Rental Service Checklist

RENTAL Inspection: Rental OUT:

Return (Check-In)

Customer:

Field Visit - Only

Hammer: Model Sn

Date:

Machine:Model Sn

Inspector/Technician:

Hours

Hammer: Model Sn

Dealer

Machine:Model Sn

Reference/Contract #

Hours

1) Customer Comments/Reports - Note & repair as necessary:

2) General Walk-Around - Note any damage/observations, Confirm original equipment.

3) Confirm Customer Greasing - Check for correct grease: inspect tool outside of lower bushing, grease

fittings, grease in autolube canister, damaged lines, etc...Correct problems.

Confirm Auto-lube dial settings are correct (Blue Red )

4) Clean - Remove all dirt, grease, oil. Replace safety/warning decals as necessary.

5) Tool - Remove/Inspect - Note heavy galling, heat signatures, cracks, retainer slot damage, etc...Debur

retainer pin slot area. Inspect piston/tool striking faces for damage.

Cat tool

Total Length Measured inches or mm (circle one)

6) Tool Retaining Pins - Excessive wear, cracks, etc...

7) Lower Bushing Inspection - Indicate action taken:

OK (Reused in place)

Rotated 90 degrees.

Replaced

8) Inspection of Lines/Connections - Loose, leaks, routing, secured, and/or otherwise damaged

9) Major Service Required? - Check whether hammer is due for 1000hr or annual service.

Scheduled date:

10) Operate Hammer - Check for proper operation, leaks, etc...Measure operating pressure every 250 hours

or quarterly (3 months). (H45-H100:Low Pressure Circuit, H115s-H180s:Operating Pressure)

Pressure measured: psi or kPa (circle one)

11) Grease - Use correct hammer paste, fill and check autolube system if installed.

12) Additional Comments:

13) READY to Rent (Check-in Complete) Initials Date

Caterpillar Form No. 01-040356-00 (2501)

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- JCB VM115 Single Drum RollerDocument9 pagesJCB VM115 Single Drum Roller江柄宏100% (1)

- Fuel Truck Operator's Daily ChecklistDocument1 pageFuel Truck Operator's Daily ChecklistTFattah0% (1)

- Rammer Hammer Service Manual: Read/DownloadDocument2 pagesRammer Hammer Service Manual: Read/DownloadАндрей Алипьев25% (4)

- AT2512C Eng 01 953804Document2 pagesAT2512C Eng 01 953804Victor Hugo Benitez PaezNo ratings yet

- Ontario Grade 11 PhysicsDocument14 pagesOntario Grade 11 Physicssandeep_walia14990% (1)

- 03-04-19 Service Report SCK20Document2 pages03-04-19 Service Report SCK20abdelghani abdelhadiNo ratings yet

- Mac25 Maintenance Section 2Document27 pagesMac25 Maintenance Section 2Wahyu SriharjaNo ratings yet

- Bulldozer MonthlyDocument1 pageBulldozer MonthlyFlorfloresta Alfa OneNo ratings yet

- Inspection: AIR Winch Ingersoll RandDocument19 pagesInspection: AIR Winch Ingersoll RandAbdou BoucheritNo ratings yet

- Inspección Equipo BM 2000 2200 - 2013 - enDocument3 pagesInspección Equipo BM 2000 2200 - 2013 - enCesarNo ratings yet

- Trial Doosan GET DX220 (20ton Class)Document21 pagesTrial Doosan GET DX220 (20ton Class)Irul UmamNo ratings yet

- Check Book (GB) PDFDocument43 pagesCheck Book (GB) PDFY.EbadiNo ratings yet

- Certificate of Thorough Examination: Safe Working Load (S)Document1 pageCertificate of Thorough Examination: Safe Working Load (S)AlthafHussain100% (1)

- Format WoDocument13 pagesFormat WoRofie Tritho MNo ratings yet

- Chklist HEXDocument3 pagesChklist HEXluisNo ratings yet

- Cvse 0014Document1 pageCvse 0014法璋No ratings yet

- 40 F032 120E Crane (Crawler) Inspection Daily RevBDocument1 page40 F032 120E Crane (Crawler) Inspection Daily RevBrashid7930% (1)

- WORKORDAHDocument1 pageWORKORDAHrjoyner100No ratings yet

- Format SampleDocument8 pagesFormat SampleBalraj BawaNo ratings yet

- Procedure Manual: Edition 10Document104 pagesProcedure Manual: Edition 102222222222222-242735100% (1)

- Toyota PickupDocument11 pagesToyota Pickupalexberhane3No ratings yet

- 105 MaintenanceDocument29 pages105 MaintenanceokovalskiNo ratings yet

- Asc 20n 0649 c1 (Block Cutting Machine)Document1 pageAsc 20n 0649 c1 (Block Cutting Machine)AkhilNo ratings yet

- WELDING MACHINE ChecklistDocument1 pageWELDING MACHINE Checklistsakthi venkatNo ratings yet

- Utm - 1Document2 pagesUtm - 1Kaushal GandhiNo ratings yet

- Delivery Report Form ExcavatorDocument1 pageDelivery Report Form ExcavatorAkbarNo ratings yet

- 09-05-19 Service Report SCK10Document2 pages09-05-19 Service Report SCK10abdelghani abdelhadiNo ratings yet

- Tower Light Almeer 101Document2 pagesTower Light Almeer 101groshan20No ratings yet

- Toyota Multi Point Inspection: Item SpecsDocument3 pagesToyota Multi Point Inspection: Item SpecsSantiago EspinosaNo ratings yet

- Hammer Rental Checklists v080414Document2 pagesHammer Rental Checklists v080414liva rakotondrasoaNo ratings yet

- Far ZBN41205Document4 pagesFar ZBN41205yeremia kristianNo ratings yet

- At22 MaintenanceDocument37 pagesAt22 MaintenancefabuleukalengaNo ratings yet

- Gear InspectionDocument6 pagesGear Inspectionbh hbNo ratings yet

- KUC Procedure Manual Ed9 SELA1208-03 PDFDocument89 pagesKUC Procedure Manual Ed9 SELA1208-03 PDFsebastian100% (1)

- Customer Service Report PE 1 SignedDocument1 pageCustomer Service Report PE 1 SignedAfzal BaigNo ratings yet

- 10000inox IngDocument184 pages10000inox IngAlberto Sobreira Lima NetoNo ratings yet

- Hercules 10000Document46 pagesHercules 10000Rafael LudwigNo ratings yet

- VD 267Document1 pageVD 267sami abdulNo ratings yet

- HC15 Manual PDFDocument24 pagesHC15 Manual PDFnstefosNo ratings yet

- Pipe Insulation: Qa / QC FormDocument1 pagePipe Insulation: Qa / QC FormShyam Sundar GayenNo ratings yet

- QC Form 6Document1 pageQC Form 6rashid ahmadiNo ratings yet

- C15 Additional Part Bushing Cam ShaftDocument7 pagesC15 Additional Part Bushing Cam ShaftYeremiaNo ratings yet

- Failure Analysis Report: SIMS InformationDocument13 pagesFailure Analysis Report: SIMS InformationHasby PotterNo ratings yet

- Form-I-010 Welding Machine Inspection Form: Carry-In CertificateDocument1 pageForm-I-010 Welding Machine Inspection Form: Carry-In CertificateAdhy DarmawanNo ratings yet

- Loaders: Start-Up Inspection / Warranty RegistrationDocument1 pageLoaders: Start-Up Inspection / Warranty RegistrationCesar Chu AcevedoNo ratings yet

- 19-F12 Mobile Crane Daily Inspection ChecklistDocument2 pages19-F12 Mobile Crane Daily Inspection ChecklistSn AhsanNo ratings yet

- Machine Inspection Form ExcavatorDocument27 pagesMachine Inspection Form ExcavatorAwanNo ratings yet

- JKJ166 PH1A A2Document4 pagesJKJ166 PH1A A2wanjo608No ratings yet

- TSB 2021 MAT 03036 XUV700 MT AT Diesel PDI CheckList 11aac0241 20243412959Document8 pagesTSB 2021 MAT 03036 XUV700 MT AT Diesel PDI CheckList 11aac0241 20243412959manukrishnan245No ratings yet

- Reports and FormsDocument11 pagesReports and FormsRodolfo Mata LoeraNo ratings yet

- Presentation For EngineersDocument116 pagesPresentation For EngineersChalana UshanNo ratings yet

- H Tong Maintenance ManualDocument8 pagesH Tong Maintenance ManualBahman MatouriNo ratings yet

- Structural Damage Report Form: SDR NoDocument2 pagesStructural Damage Report Form: SDR NoDewin Silva100% (1)

- Industrial Training: Exposure To Weld Shop Maruti Suzuki India LimitedDocument23 pagesIndustrial Training: Exposure To Weld Shop Maruti Suzuki India LimitedAnkush ChauhanNo ratings yet

- (Form GNQ 19) Pump Pre Commissioning Checklist 1Document2 pages(Form GNQ 19) Pump Pre Commissioning Checklist 1eugene mejidanaNo ratings yet

- LAMP. 4. 4. Draft Lifting Plan ProcedureDocument12 pagesLAMP. 4. 4. Draft Lifting Plan ProcedureKONSULTAN RELOKASI RTGNo ratings yet

- Ohs-Pr-09-10-F03 (A) Machine Guard ChecklistDocument7 pagesOhs-Pr-09-10-F03 (A) Machine Guard ChecklistSiddiquiNo ratings yet

- Z-619 Sinoma Chengdu - Lubrication ListDocument6 pagesZ-619 Sinoma Chengdu - Lubrication ListNazar KhanNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Mar-16 MechSajid ShaikhNo ratings yet

- Tuesb Site Testing Document Rev 0001Document8 pagesTuesb Site Testing Document Rev 0001rosalNo ratings yet

- Buyer: OwnerDocument27 pagesBuyer: OwnerDaniel TostaNo ratings yet

- Practice Manager Job Description - Oct 2019Document3 pagesPractice Manager Job Description - Oct 2019M LubisNo ratings yet

- Project Proposal of Maratua Homestay Scheme ResearchDocument6 pagesProject Proposal of Maratua Homestay Scheme ResearchAndre Prakoso100% (1)

- Easily Process Your Prints From 135 Film With The SP500Document2 pagesEasily Process Your Prints From 135 Film With The SP500Bosko HerorNo ratings yet

- Qualitative Marketing Research - Brac UniversityDocument33 pagesQualitative Marketing Research - Brac UniversityJahidur_rahimNo ratings yet

- MDR Backlog Ldia090 - 4gDocument1 pageMDR Backlog Ldia090 - 4gJakoba FetindrainibeNo ratings yet

- Relatia Dintre Dependenta de Internet Sentimentul de Singuratate Si Suportul Social Perceput in Randul Adolescentilor Libre 1 PDFDocument11 pagesRelatia Dintre Dependenta de Internet Sentimentul de Singuratate Si Suportul Social Perceput in Randul Adolescentilor Libre 1 PDFAna-Maria ChiricNo ratings yet

- Sap Service Description For Managed Services Ams English v04 2016Document16 pagesSap Service Description For Managed Services Ams English v04 2016Karthick MNo ratings yet

- Chapter 9 ResumeDocument6 pagesChapter 9 Resumetira sundayNo ratings yet

- Load Dispatch Centre: By-Siddharth KumarDocument16 pagesLoad Dispatch Centre: By-Siddharth KumarSIDDHARTHNo ratings yet

- SiteScope ManualDocument291 pagesSiteScope ManualrijugNo ratings yet

- DHC Order - Section 59 Claim AmendmentsDocument35 pagesDHC Order - Section 59 Claim AmendmentsM VridhiNo ratings yet

- Constantinos A. Doxiadis - The Man and His WorkDocument23 pagesConstantinos A. Doxiadis - The Man and His WorkLutche Amor HostalleroNo ratings yet

- M3-Social Media Text AnalyticsDocument19 pagesM3-Social Media Text AnalyticsKHAN SANA PARVEENNo ratings yet

- Kindergarten Catch-Up PlanDocument1 pageKindergarten Catch-Up PlanJudy Mae Bernabe ManaloNo ratings yet

- Law On Public Officers 05.06.14Document27 pagesLaw On Public Officers 05.06.14Imman DCPNo ratings yet

- Scope of Work For Canopy Replacement of DRS/MRS: 1.0 GeneralDocument9 pagesScope of Work For Canopy Replacement of DRS/MRS: 1.0 GeneralDevang PatelNo ratings yet

- Crop Flipkart Labels 13 Feb 2024-05-29Document5 pagesCrop Flipkart Labels 13 Feb 2024-05-2904vijilNo ratings yet

- Skippers United Pacific Vs Doza DIGESTDocument2 pagesSkippers United Pacific Vs Doza DIGESTHarold ApostolNo ratings yet

- "Pab Rules": Denr - Emb XiDocument38 pages"Pab Rules": Denr - Emb XiLeslie Balneg RubinNo ratings yet

- Media-Services Provider Los Gatos, California Reed Hastings Marc Randolph Scotts Valley, California OTTDocument2 pagesMedia-Services Provider Los Gatos, California Reed Hastings Marc Randolph Scotts Valley, California OTTpapa shunkuNo ratings yet

- Endashaw Hareru Et Al 2022 Alcohol Use Disorder and Its Associated Factors Among Residents in Southern Ethiopia DuringDocument11 pagesEndashaw Hareru Et Al 2022 Alcohol Use Disorder and Its Associated Factors Among Residents in Southern Ethiopia DuringchalachewNo ratings yet

- TP-20 For Protective RelaysDocument20 pagesTP-20 For Protective RelayssathiyaseelanNo ratings yet

- Carpio-Morales v. CA Case DigestDocument2 pagesCarpio-Morales v. CA Case DigestLIERANo ratings yet

- Ashghal Issue11 EngDocument32 pagesAshghal Issue11 Engmanojj65No ratings yet

- EN - Summer - 2013 - V-2012-08-17 - 1Document17 pagesEN - Summer - 2013 - V-2012-08-17 - 1chaudharyv100% (1)

- Use-Case Model: Adding Detail With Operation Contracts Detail With Operation ContractsDocument12 pagesUse-Case Model: Adding Detail With Operation Contracts Detail With Operation Contractsadhi321No ratings yet

- 2013 Get Organized Challenge WorkbookDocument22 pages2013 Get Organized Challenge WorkbookJennifer Collins100% (4)

- Cable Sizing PrincipleDocument7 pagesCable Sizing PrincipleYouwan LeeNo ratings yet