Professional Documents

Culture Documents

PEB Vs Conventional Buildings

PEB Vs Conventional Buildings

Uploaded by

shashank adigaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PEB Vs Conventional Buildings

PEB Vs Conventional Buildings

Uploaded by

shashank adigaCopyright:

Available Formats

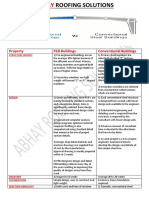

Parameter Pre Engineered Building Conventional Steel Building

Structure Weight PEB's are average 30% lighter through optimized Steel members are selected from standard hot rolled

design by tapered (varying depth) built-up sections "I" Sections, which are heavier than what is actually

with higher depths in the areas of highest stress. required by design as the members have constant

cross-sections regardless of varying magnitude of the

local (internal) stress along the member length.

Steel Strength High Tensile Steel used in PEB's having minimum (Ys) Conventional "I" & "C" sections usually have

of 345 Mpa, which contributes to reduction of Steel minimum (Ys) of 245 Mpa, resulting in higher Steel

consumption in overall. consumption.

Design of PEB's is quick & efficient as the design The Design Consultant, resulting in excess design

Design Speed time with fewer design aids available to the

process involve special dedicated international design

software, international design codes & standard Engineer, designs each conventional Steel structure

sections & connections. from scratch. Generalized computer analysis

programs require extensive input/output and design

alterations.

Clear Spans PEB's can be designed & erected with max clear span Conventional building can be for max 40 m. with high

of 100 m. with low steel qty. consumption. steel qty. consumption.

Civil Foundations Simple & economical with larger span & higher column Extremely heavier footings & more number of footing

spacing, resulting in less number of foundations along because of constraints line lower column spacing &

length & width. supports along width wise.

Erection Speed Since the connections of the components are The connections are normally complicated and differ

standard, the learning curve of erection for each from project to project, resulting in longer learning

subsequent project is faster. curves of erection for new projects.

Seismic Resistance The low-weight flexible frames offer higher resistance Rigid heavy weight structures do not perform well in

to seismic forces. seismic zones.

Safety & Responsibility Single source of supply results in total responsibility by Multiple responsibilities can result in questions on

one supplier, including design liability. PEB who is responsible when components do not fit

manufacturers can be relied upon to service their properly, insufficient material is supplied, or materials

buildings, long after they are supplied, to protect their fail to perform, particularly at the supplier/contractor

reputation. interface. The consultant carries total design liability.

Performance All components have been specified and designed Components are custom designed for a specific

specifically to act together as a system for maximum application on a specific job. Design and detailing

efficiency, precise fit, and peak performance in the errors are possible when assembling the diverse

field. components into unique buildings.

You might also like

- Pebs ManualDocument59 pagesPebs ManualThi Pham100% (6)

- Optimum Design of An Industrial Ware House: Kankuntla Ashok Y., Nirantar Shalaka R., Rajgiri Dinesh NDocument5 pagesOptimum Design of An Industrial Ware House: Kankuntla Ashok Y., Nirantar Shalaka R., Rajgiri Dinesh NAkbar Hamid100% (1)

- Seminar On " ": Pre Engineered BuildingsDocument27 pagesSeminar On " ": Pre Engineered BuildingsPrasad NbNo ratings yet

- 8-Pre-Engineered Steel BuildingsDocument168 pages8-Pre-Engineered Steel BuildingsTransportation Dept. SatyaVani100% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Typical Types of PPVC Module: Tender 'A' DrawingDocument1 pageTypical Types of PPVC Module: Tender 'A' DrawingJinxian XuNo ratings yet

- ideCAD Structural 5Document9 pagesideCAD Structural 5Gandhi HammoudNo ratings yet

- PebvsconvsteelDocument4 pagesPebvsconvsteelJose Arthur AbellaNo ratings yet

- Pre-Engineered BuildingsDocument4 pagesPre-Engineered BuildingsAhmed KhanNo ratings yet

- PEB Vs Conventional Steel BuildingsDocument3 pagesPEB Vs Conventional Steel BuildingsPacha Khan KhogyaniNo ratings yet

- Pre Engineered Buildings 410 PDFDocument7 pagesPre Engineered Buildings 410 PDFDrGanesh KameNo ratings yet

- Pre Engineered Buildings 410Document8 pagesPre Engineered Buildings 410Vinit KondapureNo ratings yet

- Property PEB Buildings Conventional Buildings: Structure WeightDocument3 pagesProperty PEB Buildings Conventional Buildings: Structure WeightpsrikanthanNo ratings yet

- PRE-ENGINEERED-BUILDING-1Document24 pagesPRE-ENGINEERED-BUILDING-1mymail.enmontallaNo ratings yet

- 02 Value Benefits of Steel ConstructionDocument7 pages02 Value Benefits of Steel ConstructionOlay KwongNo ratings yet

- Pre Engineered BuildingsDocument10 pagesPre Engineered BuildingsVelu KaruppiahNo ratings yet

- PEB Segment - IPPE Workshop - Sep17 PDFDocument33 pagesPEB Segment - IPPE Workshop - Sep17 PDFDivya PunjabiNo ratings yet

- Analysis Design of Pre-Engineered Building Using Is 8002007 International Standards-00Document40 pagesAnalysis Design of Pre-Engineered Building Using Is 8002007 International Standards-00PRATIK ATWALNo ratings yet

- Rigid Global Buildings Product ManualDocument269 pagesRigid Global Buildings Product ManualSitaramgv VenkataNo ratings yet

- PEBDocument17 pagesPEBTanuj Bhardwaj100% (1)

- PreEngineered BuildingsDocument21 pagesPreEngineered BuildingsAli Imran HaveriNo ratings yet

- Pre Engineered Buildings: We Don't Just Build, We Create..Document24 pagesPre Engineered Buildings: We Don't Just Build, We Create..Saqlain AwanNo ratings yet

- Understanding The Cost of Structural Steelwork Part 2 Design Development and DetailingDocument4 pagesUnderstanding The Cost of Structural Steelwork Part 2 Design Development and DetailingkhoohuikiangNo ratings yet

- Optimization of Industrial BuildingDocument18 pagesOptimization of Industrial BuildingEr S Thirumarai NathanNo ratings yet

- V2 I8 39 PDFDocument6 pagesV2 I8 39 PDFRamachandra Sahu100% (1)

- Bhanu PEBDocument27 pagesBhanu PEBBhanuprakash KumbarNo ratings yet

- For Printing Out - ZS-Vietnam - PEB-System-Benefits - Tech-Present - 08-2016 PDFDocument66 pagesFor Printing Out - ZS-Vietnam - PEB-System-Benefits - Tech-Present - 08-2016 PDFKimChhoungChengNo ratings yet

- Review On PEB BuildingDocument6 pagesReview On PEB BuildingMilanNo ratings yet

- Merits of SteelDocument6 pagesMerits of SteelArshdeep KaurNo ratings yet

- Analysis and Design of Pre - Engineered Building For Vehicle Parking ShedDocument23 pagesAnalysis and Design of Pre - Engineered Building For Vehicle Parking ShedEr S Thirumarai NathanNo ratings yet

- Engg. Build. DesignDocument67 pagesEngg. Build. DesignAyon SenguptaNo ratings yet

- SteelDocument99 pagesSteelEmmanuel NamkumbeNo ratings yet

- Ankit Mukati 16523004 Pre Engineered BuildingDocument33 pagesAnkit Mukati 16523004 Pre Engineered BuildingAnkit PatidarNo ratings yet

- Irjet V3i5492 PDFDocument6 pagesIrjet V3i5492 PDFM G patelNo ratings yet

- Steel and Timber Design - Chapter 1Document10 pagesSteel and Timber Design - Chapter 1Wilfredo OchavezNo ratings yet

- CE302 Chap1-3Document106 pagesCE302 Chap1-3anesu dhewaNo ratings yet

- MailerDocument8 pagesMailerGanesh KumarNo ratings yet

- "Analysis and Cost Comparative Study of Conventional IndustrialDocument4 pages"Analysis and Cost Comparative Study of Conventional IndustrialSandeep SolankiNo ratings yet

- PEB Vs Convention BuildingDocument3 pagesPEB Vs Convention BuildingSandeep SolankiNo ratings yet

- Utility Design O F Steel Truss A Review: Manoj Nallanathel Ramesh Bhaskar KishoreDocument8 pagesUtility Design O F Steel Truss A Review: Manoj Nallanathel Ramesh Bhaskar KishoreNicolas JR Palomino LlontopNo ratings yet

- TAMAYAO, John Mophet O. (Steel)Document147 pagesTAMAYAO, John Mophet O. (Steel)Josh EdilreyNo ratings yet

- Peb B D0513243Document16 pagesPeb B D0513243Daniyal AhmedNo ratings yet

- Alternative Designs For Gable Industrial Structure: (Irjet)Document7 pagesAlternative Designs For Gable Industrial Structure: (Irjet)Sinius InfracomNo ratings yet

- Pre Engineered PresentationDocument96 pagesPre Engineered PresentationBailey LoveNo ratings yet

- A Study On Design of Industrial Building-A Review: K.Prabin Kumar, D.Sunny PrakashDocument6 pagesA Study On Design of Industrial Building-A Review: K.Prabin Kumar, D.Sunny PrakashShubhamNo ratings yet

- On The Rise: Popularity of Multi-Storey Steel Frame BuildingsDocument2 pagesOn The Rise: Popularity of Multi-Storey Steel Frame BuildingsJaleel Claasen100% (1)

- Pre-Engineered Buildings: Rushank Mishra - 2008BARC012 Gyandeep Jaiswal - 2008BARC065 Akshay Gupta - 2008BARC073Document20 pagesPre-Engineered Buildings: Rushank Mishra - 2008BARC012 Gyandeep Jaiswal - 2008BARC065 Akshay Gupta - 2008BARC073agey agoy-agoyNo ratings yet

- Steel: Built To Last: Case Study No 3Document4 pagesSteel: Built To Last: Case Study No 3clam2014No ratings yet

- Pre-Engineered Metal Buildings:: Advantages and DisadvantagesDocument3 pagesPre-Engineered Metal Buildings:: Advantages and DisadvantagesJardani JovonovichNo ratings yet

- Comparative Study of Pre Engineered and Conventional Industrial BuildingDocument6 pagesComparative Study of Pre Engineered and Conventional Industrial BuildingCIVIL ENGG. SVESNo ratings yet

- Comparative Study of Pre Engineered and Conventional Industrial BuildingDocument6 pagesComparative Study of Pre Engineered and Conventional Industrial BuildingTauseef AhmadNo ratings yet

- Pre Engineered Buildings WordDocument14 pagesPre Engineered Buildings WordLalitha TammanaNo ratings yet

- PEBDocument27 pagesPEBMadan YadavNo ratings yet

- Steel Frametech BrochureDocument2 pagesSteel Frametech BrochureAqua LakeNo ratings yet

- IntroductionDocument12 pagesIntroductionJaninaRuzzleSilangNo ratings yet

- Steel DesignDocument22 pagesSteel DesignPAVANPORENo ratings yet

- Irjet V3i10147 PDFDocument5 pagesIrjet V3i10147 PDFrohithNo ratings yet

- Report Word FileDocument10 pagesReport Word FileMaricar GaculaNo ratings yet

- Seminar On " ": Pre Engineered BuildingsDocument20 pagesSeminar On " ": Pre Engineered BuildingsHari SankerNo ratings yet

- Hand Book For Steel Structure Quality Control on SiteFrom EverandHand Book For Steel Structure Quality Control on SiteNo ratings yet

- 1999v04 Column FreeDocument5 pages1999v04 Column Freeshashank adigaNo ratings yet

- Composite Beam Design 1Document15 pagesComposite Beam Design 1shashank adigaNo ratings yet

- An Overview of Pre-Engineered Building Systems in India: Saurabh A. Shah, Madhav B.KumthekarDocument6 pagesAn Overview of Pre-Engineered Building Systems in India: Saurabh A. Shah, Madhav B.Kumthekarshashank adigaNo ratings yet

- Study and Analysis of Pre-Engineering Building Structure: Sunil Kumar, Assit. Prof. G.B. BhaskarDocument3 pagesStudy and Analysis of Pre-Engineering Building Structure: Sunil Kumar, Assit. Prof. G.B. Bhaskarshashank adigaNo ratings yet

- Engineering Products BrochureDocument24 pagesEngineering Products Brochureshashank adigaNo ratings yet

- Buildings 08 00134Document24 pagesBuildings 08 00134shashank adigaNo ratings yet

- InteractiveModelingofCold FormedSteelBuildingDocument9 pagesInteractiveModelingofCold FormedSteelBuildingshashank adigaNo ratings yet

- To Study Analysis of Sandwich Beam With Ansys and Fem: July 2015Document6 pagesTo Study Analysis of Sandwich Beam With Ansys and Fem: July 2015shashank adigaNo ratings yet

- Autocad SyllabusDocument2 pagesAutocad Syllabusshashank adigaNo ratings yet

- 03 Flexural Behaviour of PrestressedDocument10 pages03 Flexural Behaviour of Prestressedshashank adigaNo ratings yet

- Analysis & Design of RCC Shear Walls in The Model Using ETABS - Skill-LyncDocument15 pagesAnalysis & Design of RCC Shear Walls in The Model Using ETABS - Skill-Lyncshashank adigaNo ratings yet

- 01 Case Study New Haven BloreDocument68 pages01 Case Study New Haven Bloreshashank adigaNo ratings yet

- 12 (Jindal University) Precast Presentation For Pepscon 2017 02 21Document96 pages12 (Jindal University) Precast Presentation For Pepscon 2017 02 21shashank adigaNo ratings yet

- Composit StructureDocument13 pagesComposit Structureshashank adigaNo ratings yet

- Analysis of Precast Building SystemDocument7 pagesAnalysis of Precast Building Systemshashank adigaNo ratings yet

- Maersk Training Centre: Well Control Training ManualDocument145 pagesMaersk Training Centre: Well Control Training ManualVladut Fagaras100% (15)

- Certificado Classic Ei2 60 1HDocument20 pagesCertificado Classic Ei2 60 1HenriquefamNo ratings yet

- Odiong Bridge FinalDocument18 pagesOdiong Bridge Finaljenor delatorreNo ratings yet

- I. Types of Windows Used in BuildingsDocument13 pagesI. Types of Windows Used in BuildingsAnshuman SinghNo ratings yet

- DS - en 1997-1 DK Na - 2010 eDocument37 pagesDS - en 1997-1 DK Na - 2010 ep_meulendijks108No ratings yet

- Stairs PresentationDocument24 pagesStairs PresentationMumtahina MouliNo ratings yet

- Problem 04 - Tower Sizing & Tray DesignDocument40 pagesProblem 04 - Tower Sizing & Tray DesignJorge Enciso AcuñaNo ratings yet

- Applicability of Precast Reinforced ConcDocument11 pagesApplicability of Precast Reinforced Concanonymousdi3noNo ratings yet

- Specifications For Plumbing, Drainage, Portable Fire Extinguishers and Hosereel PDFDocument31 pagesSpecifications For Plumbing, Drainage, Portable Fire Extinguishers and Hosereel PDFsk lukoNo ratings yet

- AKG TS Installation ManualDocument6 pagesAKG TS Installation ManualFELICIANO ROBLES RAMOSNo ratings yet

- Well PlanningDocument18 pagesWell PlanningBrahim Letaief100% (3)

- Section Through M-M: East Elevation West Elevation Front ElevatiionDocument1 pageSection Through M-M: East Elevation West Elevation Front ElevatiionAthiyo MartinNo ratings yet

- 18CV33 FLUID MECHANICS Gap AnalysisDocument1 page18CV33 FLUID MECHANICS Gap AnalysiskiranNo ratings yet

- Liahona: BuildersDocument1 pageLiahona: BuildersSheena Mae FloresNo ratings yet

- Tech Data 1PDFDocument1 pageTech Data 1PDFVJ LNo ratings yet

- 6 Ten States Standards 2004 - Chapter 30 - Design of SewersDocument12 pages6 Ten States Standards 2004 - Chapter 30 - Design of SewersCowbeak7959No ratings yet

- Question Excerpt From PD 1096 National Building Code of The PhilippinesDocument13 pagesQuestion Excerpt From PD 1096 National Building Code of The PhilippinesAmir ShaikNo ratings yet

- Chemical Composition & Mechanical Properties: e (Min.)Document4 pagesChemical Composition & Mechanical Properties: e (Min.)Joby GeorgeNo ratings yet

- DNVGL CG 0131 PDFDocument24 pagesDNVGL CG 0131 PDFLuis SousaNo ratings yet

- Manual MSB Sanitary Container 190408Document57 pagesManual MSB Sanitary Container 190408Егор ГоряевNo ratings yet

- Presentation On EarthquakeDocument20 pagesPresentation On EarthquakeManish AroraNo ratings yet

- Invent Cyberpitch Mixer PDFDocument2 pagesInvent Cyberpitch Mixer PDFCristhian Carranza CortesNo ratings yet

- Canal Embankment Stability AnalysisDocument16 pagesCanal Embankment Stability AnalysisShahnawaz ZardariNo ratings yet

- Pavement Design University of Western Australia CIVL 4121Document46 pagesPavement Design University of Western Australia CIVL 4121April IngramNo ratings yet

- Pipe Rack Design PhilosophyDocument14 pagesPipe Rack Design PhilosophyFarhan DanishNo ratings yet

- Newdirectionsposttensioningvol10a PDFDocument95 pagesNewdirectionsposttensioningvol10a PDFNOEL RODRIGUEZNo ratings yet

- 39G Performance (v3.13)Document10 pages39G Performance (v3.13)Kumar sssssNo ratings yet

- Building 114 Large Honeycomb Rev.02Document10 pagesBuilding 114 Large Honeycomb Rev.02moytabura96No ratings yet