Professional Documents

Culture Documents

1.2550 60Wcrv8: Chemical Composition

1.2550 60Wcrv8: Chemical Composition

Uploaded by

novkovic1984Copyright:

Available Formats

You might also like

- 10 Columns (Students) CDocument47 pages10 Columns (Students) Cmarwahusni195No ratings yet

- Processing of Bopp FilmDocument49 pagesProcessing of Bopp FilmHassan Ali Khan78% (9)

- Sae J2295-2016Document28 pagesSae J2295-2016Andris ZaharovNo ratings yet

- Werkstoff 1.5217 (20MnV6)Document2 pagesWerkstoff 1.5217 (20MnV6)alextentwentyNo ratings yet

- Gom Inspect Introduction Seminar sw2019 895 007 ENDocument67 pagesGom Inspect Introduction Seminar sw2019 895 007 ENnovkovic1984No ratings yet

- Domestic Gas PipingDocument30 pagesDomestic Gas Pipingmitasyahu50% (2)

- 1.2210 115crv3Document2 pages1.2210 115crv3Eduardo DelfinoNo ratings yet

- 1.2344 X40Crmov5-1: Chemical CompositionDocument2 pages1.2344 X40Crmov5-1: Chemical CompositionolcayakbulutNo ratings yet

- Technical Card Gruppo Lucefin Revision 2013 All Rights ReservedDocument1 pageTechnical Card Gruppo Lucefin Revision 2013 All Rights Reservednovkovic1984No ratings yet

- Assab Steels 705M Machinery Steel: Metal, Ferrous Metal, Alloy SteelDocument2 pagesAssab Steels 705M Machinery Steel: Metal, Ferrous Metal, Alloy SteelMuhammad FikriNo ratings yet

- Aisi 01 Din 2: It1Il - TtttiDocument1 pageAisi 01 Din 2: It1Il - TtttiFebri SSNo ratings yet

- 1.7225 en PDFDocument2 pages1.7225 en PDFTheodoros AtheridisNo ratings yet

- 1.8550 34cralni7 Ni50: Chemical CompositionDocument2 pages1.8550 34cralni7 Ni50: Chemical CompositionMichel PortalNo ratings yet

- GB Formadur2083Document1 pageGB Formadur2083ayman emmadNo ratings yet

- 1 2344 PDFDocument2 pages1 2344 PDFtayefehNo ratings yet

- Technical Card Gruppo Lucefin Revision 2013 All Rights ReservedDocument1 pageTechnical Card Gruppo Lucefin Revision 2013 All Rights ReservedArjun PrajapatiNo ratings yet

- FMTD TrapDocument2 pagesFMTD Trapakash tiwariNo ratings yet

- 1.2344 en PDFDocument2 pages1.2344 en PDFMarín HernándezNo ratings yet

- Aisi A2 Data SheetDocument1 pageAisi A2 Data SheetShivuNo ratings yet

- 1.2738 40CrMnNiMo8-6-4 PDFDocument2 pages1.2738 40CrMnNiMo8-6-4 PDFTACO CompositesNo ratings yet

- Technical Card Gruppo Lucefin Revision 2014 All Rights ReservedDocument2 pagesTechnical Card Gruppo Lucefin Revision 2014 All Rights ReservedDaniel RiverosNo ratings yet

- (%) Tempering Graph: Typical AnalysisDocument1 page(%) Tempering Graph: Typical AnalysisHicham KorichiNo ratings yet

- Heating Up Basten 2006 PDFDocument52 pagesHeating Up Basten 2006 PDFmustafNo ratings yet

- Quality 40nicrmov16 Ku: Lucefin GroupDocument1 pageQuality 40nicrmov16 Ku: Lucefin Groupkbwoniu123No ratings yet

- Aisi M2 DIN 3343: 770-860 Furnace FurnaceDocument1 pageAisi M2 DIN 3343: 770-860 Furnace FurnaceMichel MancillaNo ratings yet

- 2083X40Cr14Document1 page2083X40Cr14D K NaskarNo ratings yet

- X22CrMoV 12-1Document2 pagesX22CrMoV 12-1Prasad RvsNo ratings yet

- 1.3505 100cr6 PDFDocument1 page1.3505 100cr6 PDFmcNo ratings yet

- 39nicrmo3 en 10083-3: 2006: End Quench Hardenability Test TemperingDocument1 page39nicrmo3 en 10083-3: 2006: End Quench Hardenability Test Temperingvo thanh lamNo ratings yet

- 1.2510 100Mncrw4 Z3C: Chemical CompositionDocument2 pages1.2510 100Mncrw4 Z3C: Chemical CompositionLeonardoNo ratings yet

- 32crmov12-10 : Steel GradeDocument5 pages32crmov12-10 : Steel Gradereza haghjooNo ratings yet

- 1.2842 enDocument2 pages1.2842 enCosmin IonutNo ratings yet

- Precipitation Hardening Stainless Steel: Voestalpine High Performance Metals (Australia) Pty LTDDocument3 pagesPrecipitation Hardening Stainless Steel: Voestalpine High Performance Metals (Australia) Pty LTDAtlantic Heat Treat ShopNo ratings yet

- Quality 1.2080 Chemical Composition: Lucefin GroupDocument1 pageQuality 1.2080 Chemical Composition: Lucefin GroupMSc Kostic MilosNo ratings yet

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- Bearing Steel 100Cr6 AUSA - 2Document3 pagesBearing Steel 100Cr6 AUSA - 2suresh kumarNo ratings yet

- 1 3243hs652513 PDFDocument1 page1 3243hs652513 PDFmarko9292No ratings yet

- Powder Metallurgy HSS: Chemical CompositionDocument4 pagesPowder Metallurgy HSS: Chemical CompositionSama UmateNo ratings yet

- Oil-Hardening Cold Work Tool Steels (0 Series) : Recommended Heat Treating Practice Recommended Processing SequenceDocument6 pagesOil-Hardening Cold Work Tool Steels (0 Series) : Recommended Heat Treating Practice Recommended Processing SequenceJonathan JuarezNo ratings yet

- CaseHard AISI8620Document2 pagesCaseHard AISI8620Anonymous B3I6zYNhqdNo ratings yet

- Drying Out and Heating-Up of Refractory LiningsDocument59 pagesDrying Out and Heating-Up of Refractory LiningsmustafNo ratings yet

- Cement Kiln Refractory Heat Up PDFDocument24 pagesCement Kiln Refractory Heat Up PDFMin Zayar100% (1)

- 1 3207hs104310Document1 page1 3207hs104310marko9292No ratings yet

- Through-Hardening Low Alloy Steel Bar 4340: Colour Code: Jade (Band) - MarigoldDocument3 pagesThrough-Hardening Low Alloy Steel Bar 4340: Colour Code: Jade (Band) - Marigoldl_aguilar_mNo ratings yet

- 20NiCrMoS2 2Document1 page20NiCrMoS2 2Bogdan CraciunNo ratings yet

- Astm A105Document1 pageAstm A105Isaac SamuelNo ratings yet

- 16Mncr5: Steel GradeDocument3 pages16Mncr5: Steel GradePaul Praveen PeterNo ratings yet

- ATA Heet: LSS Chipper KnifeDocument2 pagesATA Heet: LSS Chipper KnifeX800XL100% (1)

- Hardness HRC As A Function of Holding Time at Different Working Temperature Working Temperature Working TemperatureDocument1 pageHardness HRC As A Function of Holding Time at Different Working Temperature Working Temperature Working Temperaturemarko9292No ratings yet

- 1.2379 en PDFDocument2 pages1.2379 en PDFVasileSpireaNo ratings yet

- 90 MN CR V8Document1 page90 MN CR V8arunajay724No ratings yet

- Assab 709 enDocument4 pagesAssab 709 enTri YNo ratings yet

- SAE1045Document2 pagesSAE1045novale.basura2906100% (1)

- Sae 4140 ACTDocument1 pageSae 4140 ACTOSCARNo ratings yet

- Hardness HRC As A Function of Holding Time at Different Working Temperature Working Temperature Working TemperatureDocument1 pageHardness HRC As A Function of Holding Time at Different Working Temperature Working Temperature Working Temperaturemarko9292No ratings yet

- Vapor Power Cycles: Prof. Osama A. El Masry Mechanical Engineering Dept. Alexandria UniversityDocument45 pagesVapor Power Cycles: Prof. Osama A. El Masry Mechanical Engineering Dept. Alexandria UniversitySaad GhouriNo ratings yet

- ATA Heet: LSS D2Document2 pagesATA Heet: LSS D2X800XLNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetreza amiriniaNo ratings yet

- 1.8159 51Crv4 NCV: Chemical CompositionDocument2 pages1.8159 51Crv4 NCV: Chemical CompositionParth AuradkarNo ratings yet

- 39NiCrMo3 PDFDocument2 pages39NiCrMo3 PDFAmy GriffinNo ratings yet

- High Speed Hard Turning of Aisi S1 (60Wcrv8) Cold Work Tool SteelDocument18 pagesHigh Speed Hard Turning of Aisi S1 (60Wcrv8) Cold Work Tool Steelnovkovic1984No ratings yet

- Ansys All You Need To Know About Hardware For SimulationDocument36 pagesAnsys All You Need To Know About Hardware For Simulationnovkovic1984No ratings yet

- Technical Card Gruppo Lucefin Revision 2013 All Rights ReservedDocument2 pagesTechnical Card Gruppo Lucefin Revision 2013 All Rights Reservednovkovic1984No ratings yet

- Wire Rope Vibration Damper: Stainless SteelDocument3 pagesWire Rope Vibration Damper: Stainless Steelnovkovic1984No ratings yet

- WC357 Gear Deburring Brochure - RGB - 2-16Document6 pagesWC357 Gear Deburring Brochure - RGB - 2-16novkovic1984No ratings yet

- CNC Machines, Types, Tools, Applications and ImportanceDocument23 pagesCNC Machines, Types, Tools, Applications and Importancenovkovic1984No ratings yet

- Montecha - Бренд водичDocument19 pagesMontecha - Бренд водичnovkovic1984No ratings yet

- Deep Drawing Process: A Brief Overview: September 2015Document6 pagesDeep Drawing Process: A Brief Overview: September 2015novkovic1984No ratings yet

- Aluminium Alloy en Aw 6060 Material Data Sheet AlumincoDocument9 pagesAluminium Alloy en Aw 6060 Material Data Sheet Aluminconovkovic1984No ratings yet

- Assfalg Catalog Deburring - Chamfering 2019 (EN)Document64 pagesAssfalg Catalog Deburring - Chamfering 2019 (EN)novkovic1984No ratings yet

- Deburring Underestimated TaskDocument3 pagesDeburring Underestimated Tasknovkovic1984No ratings yet

- Young. Premium. Fun: The All New TiagoDocument2 pagesYoung. Premium. Fun: The All New Tiagonovkovic1984No ratings yet

- Heli-Coil Catalog HC2000 Rev12 PDFDocument40 pagesHeli-Coil Catalog HC2000 Rev12 PDFnovkovic1984No ratings yet

- 2018 Nissan Kicks enDocument8 pages2018 Nissan Kicks ennovkovic1984No ratings yet

- Vrsta Alata Tip Alata VarijantaDocument2 pagesVrsta Alata Tip Alata Varijantanovkovic1984No ratings yet

- Deburring Underestimated TaskDocument4 pagesDeburring Underestimated Tasknovkovic1984No ratings yet

- Maryland Metrics Thread Data ChartsDocument3 pagesMaryland Metrics Thread Data Chartsnovkovic1984No ratings yet

- DXF Import&Export Ver2Document5 pagesDXF Import&Export Ver2novkovic1984No ratings yet

- ᎌਦߙถࡼறමၫ఼ޱᇷআᒦቦ A Precision CNC Turn-Mill Machining Center with Gear Hobbing CapabilityDocument9 pagesᎌਦߙถࡼறමၫ఼ޱᇷআᒦቦ A Precision CNC Turn-Mill Machining Center with Gear Hobbing Capabilitynovkovic1984No ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984No ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984No ratings yet

- Iso 13715 PDFDocument2 pagesIso 13715 PDFnovkovic1984No ratings yet

- 20160323110453-11SMn30 (9SMn28)Document1 page20160323110453-11SMn30 (9SMn28)novkovic1984No ratings yet

- 20160323010442-C50E (Ck50)Document2 pages20160323010442-C50E (Ck50)novkovic1984No ratings yet

- 3 EPS Universal Gas Barrier New 2017Document1 page3 EPS Universal Gas Barrier New 2017trottersitNo ratings yet

- Concealed Wiring Open Wiring: Two Types of Wiring MethodsDocument3 pagesConcealed Wiring Open Wiring: Two Types of Wiring MethodsMark Jay TalisayonNo ratings yet

- Sheet-Metal Forming Processes: Haipan SalamDocument86 pagesSheet-Metal Forming Processes: Haipan Salamprasetyokolik-1No ratings yet

- Mason: SL# Vehicle/Equipment Act - No Commodities UOM Norm / M.day Remarks 1Document1 pageMason: SL# Vehicle/Equipment Act - No Commodities UOM Norm / M.day Remarks 1John Mark EvangelistaNo ratings yet

- IBR Thickness CalculationDocument21 pagesIBR Thickness CalculationAmit BansalNo ratings yet

- L-Bolt Anchor Bolts: Simpson Strong-Tie Wood Construction Connectors - Canadian Limit States DesignDocument1 pageL-Bolt Anchor Bolts: Simpson Strong-Tie Wood Construction Connectors - Canadian Limit States DesignHakan EzcanNo ratings yet

- Toate SolutiileDocument10 pagesToate SolutiileDanijelNo ratings yet

- 09 Pressure Sustaining Valve CPSVDocument2 pages09 Pressure Sustaining Valve CPSVCamilo AyalaNo ratings yet

- Box Culvert - ISDocument14 pagesBox Culvert - ISShyamontika Choudhury ChakrabartiNo ratings yet

- FRP Vs Rotomolded Plastic TanksDocument3 pagesFRP Vs Rotomolded Plastic TanksKimberly ConleyNo ratings yet

- Prysmian GeneralCable Marine Cat 2017Document94 pagesPrysmian GeneralCable Marine Cat 2017NghiemNo ratings yet

- MOTS-12 Welding and NDE of WeldsDocument1 pageMOTS-12 Welding and NDE of Weldsryan.sNo ratings yet

- Second Floor Plan: Bureau of DesignDocument1 pageSecond Floor Plan: Bureau of DesignDominador Ladot Heraña Jr.No ratings yet

- PIP ARC01015 (Architechtural & Building Utilities Design Criteria) PDFDocument39 pagesPIP ARC01015 (Architechtural & Building Utilities Design Criteria) PDF이동욱No ratings yet

- Aluminium Composite Panels - Alucobond SingaporeDocument7 pagesAluminium Composite Panels - Alucobond Singaporemitchel johsonNo ratings yet

- SAILMA Grades Steel Plates & SheetsDocument2 pagesSAILMA Grades Steel Plates & SheetsElumalai SrinivasanNo ratings yet

- Checklist of Material Submission (Concrete)Document10 pagesChecklist of Material Submission (Concrete)Yau Ka Ki Jacky0% (1)

- POSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Document1 pagePOSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Murti WisnuNo ratings yet

- Selection of Bolting Materials, Carbon and Alloy Steel For PDocument7 pagesSelection of Bolting Materials, Carbon and Alloy Steel For PswatkoolNo ratings yet

- CHAPTER 4 Draft PROPOSED OF HIGH ABSORBING CONCRETE SLAB FOR FLOOD PREVENTION Pages 1 19 1Document8 pagesCHAPTER 4 Draft PROPOSED OF HIGH ABSORBING CONCRETE SLAB FOR FLOOD PREVENTION Pages 1 19 1jason mr.perfect11No ratings yet

- Meeting Data Center Temperature RequirementsDocument5 pagesMeeting Data Center Temperature Requirementsaneev_aNo ratings yet

- Aluminium Form Work (Mivan) : Sl. No Description YES NO N/A Remarks Layout and MarkingDocument4 pagesAluminium Form Work (Mivan) : Sl. No Description YES NO N/A Remarks Layout and Markinganbunilavan50% (2)

- 000-Za-E-M09411 - A Ms For Cable Glanding and TerminationDocument28 pages000-Za-E-M09411 - A Ms For Cable Glanding and Terminationsyam prasad100% (1)

- Ansi-Bhma 156.15-2021 HHDocument1 pageAnsi-Bhma 156.15-2021 HHRey Eduard Q. UmelNo ratings yet

- Lesson No. 3 in Machine Design 1Document10 pagesLesson No. 3 in Machine Design 1Carl JavierNo ratings yet

- PVP2014-28958 Writing and Reviewing FEA Reports Under ASME Div 1 and 2 Design PDFDocument5 pagesPVP2014-28958 Writing and Reviewing FEA Reports Under ASME Div 1 and 2 Design PDFmatteo_1234No ratings yet

1.2550 60Wcrv8: Chemical Composition

1.2550 60Wcrv8: Chemical Composition

Uploaded by

novkovic1984Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.2550 60Wcrv8: Chemical Composition

1.2550 60Wcrv8: Chemical Composition

Uploaded by

novkovic1984Copyright:

Available Formats

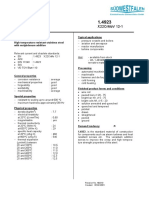

1.

2550 60WCrV8

Chemical Composition :

C Si Mn P S Cr V W

Min. % 0.55 0.70 0.15 0.90 0.10 1.70

Max. % 0.65 1.00 0.45 0.030 0.030 1.20 0.20 2.20

Material Code :

DIN ASTM JIS GOST

1.2550 S1 - 6ChV2S

60WCrV8

Properties :

Oil hardenable, medium carbon with tungsten alloyed shock resistant cold work tool steel, high resistant to impacts

with excellent toughness and wear resistance, high fatigue strength, good edge-holding ability, high hardenability,

dimensional stability.

Applications :

Highly stressed applications, blanking dies for cutting sheets up to 12 mm thickness, heavy duty cold piercing punches,

cutting, punching and blanking tools for heavy plates, cold forming tools, tablet compression tools, shear blades for

cold and hot works, woodworking tools, chipping knives, shank tools for pneumatic equipment, deburring and coining

tools, hot work tools for low thermal stresses, ejectors, chopping blades and milling cutters, upsetting tools, flash trim-

ming and splitting dies, industrial knives, hot swaging dies, pneumatic chisels, solid embossing dies, cold and hot punch-

ing tools.

Physical Properties :

Density : at 20 °C 8,00 kg/dm3 Thermal expansion between : 20 °C and... °C, 10-6 m/(mK)

Thermal conductivity : at 20 °C 25,0 W/(m.K)

100 °C 200 °C 300 °C 400 °C 500 °C

11,0 12,5 13,0 13,5 14,0

Heat Treatment :

Annealing : 710 - 750 °C

Hardness after annealing : Max. 225 HB

Stress relieving : Approx. 650 °C

Hot forming : 1050 - 850 °C

Hardening : 870 - 910 °C

Quenching media : Oil

Hardness after quenching : 58 - 62 HRC

Hardness after tempering :

100 °C 200 °C 300 °C 400 °C

60 HRC 59 HRC 56 HRC 53 HRC

ÖZ ÇELÝK TÝCARET LTD.ÞTÝ.

Heat Treatment Sequence

1000

900 Hardening

800

700

Preheat stage

Temperature, °C

600

500

Oil

400

Cooling in furnace Tempering to

300 working hardness

200

Air cooling

100

Stress relieving

0

Time Cleaning / Hardness test

Time - Temperature - Transformation Diagram Tempering Diagram

1200 70

Austenitizing 890 °C

1100 66

1000 62

900 58

Hardness, HRC

Ac1e

54

Temperature, °C

800

Ac1b

700 P 100 100

50

100 100

A+K 5

600 46

500 42

60WCrV8

400 38

Ms Zw Heat treatment :

300 34

2 90 94 910 °C / Oil

40

13

200 24

30

30

M 5 6 6

7

15 0 100 200 300 400 500 600 700 800

300

100

Tempering temperature, °C

765 762 762 673 585 437 409 279 243 258

0

1 10 102 103 104 105 106

Seconds

1 10 100 1000 10000

Time Minutes

Stock Sizes

Round Bars mm

12.5 16.5 18.5 20.5 22.5 25.5 28.5 30.5 32.8 35.8 38.8 40.8 45.8 50.8 55.8

60.8 71 81 91

You might also like

- 10 Columns (Students) CDocument47 pages10 Columns (Students) Cmarwahusni195No ratings yet

- Processing of Bopp FilmDocument49 pagesProcessing of Bopp FilmHassan Ali Khan78% (9)

- Sae J2295-2016Document28 pagesSae J2295-2016Andris ZaharovNo ratings yet

- Werkstoff 1.5217 (20MnV6)Document2 pagesWerkstoff 1.5217 (20MnV6)alextentwentyNo ratings yet

- Gom Inspect Introduction Seminar sw2019 895 007 ENDocument67 pagesGom Inspect Introduction Seminar sw2019 895 007 ENnovkovic1984No ratings yet

- Domestic Gas PipingDocument30 pagesDomestic Gas Pipingmitasyahu50% (2)

- 1.2210 115crv3Document2 pages1.2210 115crv3Eduardo DelfinoNo ratings yet

- 1.2344 X40Crmov5-1: Chemical CompositionDocument2 pages1.2344 X40Crmov5-1: Chemical CompositionolcayakbulutNo ratings yet

- Technical Card Gruppo Lucefin Revision 2013 All Rights ReservedDocument1 pageTechnical Card Gruppo Lucefin Revision 2013 All Rights Reservednovkovic1984No ratings yet

- Assab Steels 705M Machinery Steel: Metal, Ferrous Metal, Alloy SteelDocument2 pagesAssab Steels 705M Machinery Steel: Metal, Ferrous Metal, Alloy SteelMuhammad FikriNo ratings yet

- Aisi 01 Din 2: It1Il - TtttiDocument1 pageAisi 01 Din 2: It1Il - TtttiFebri SSNo ratings yet

- 1.7225 en PDFDocument2 pages1.7225 en PDFTheodoros AtheridisNo ratings yet

- 1.8550 34cralni7 Ni50: Chemical CompositionDocument2 pages1.8550 34cralni7 Ni50: Chemical CompositionMichel PortalNo ratings yet

- GB Formadur2083Document1 pageGB Formadur2083ayman emmadNo ratings yet

- 1 2344 PDFDocument2 pages1 2344 PDFtayefehNo ratings yet

- Technical Card Gruppo Lucefin Revision 2013 All Rights ReservedDocument1 pageTechnical Card Gruppo Lucefin Revision 2013 All Rights ReservedArjun PrajapatiNo ratings yet

- FMTD TrapDocument2 pagesFMTD Trapakash tiwariNo ratings yet

- 1.2344 en PDFDocument2 pages1.2344 en PDFMarín HernándezNo ratings yet

- Aisi A2 Data SheetDocument1 pageAisi A2 Data SheetShivuNo ratings yet

- 1.2738 40CrMnNiMo8-6-4 PDFDocument2 pages1.2738 40CrMnNiMo8-6-4 PDFTACO CompositesNo ratings yet

- Technical Card Gruppo Lucefin Revision 2014 All Rights ReservedDocument2 pagesTechnical Card Gruppo Lucefin Revision 2014 All Rights ReservedDaniel RiverosNo ratings yet

- (%) Tempering Graph: Typical AnalysisDocument1 page(%) Tempering Graph: Typical AnalysisHicham KorichiNo ratings yet

- Heating Up Basten 2006 PDFDocument52 pagesHeating Up Basten 2006 PDFmustafNo ratings yet

- Quality 40nicrmov16 Ku: Lucefin GroupDocument1 pageQuality 40nicrmov16 Ku: Lucefin Groupkbwoniu123No ratings yet

- Aisi M2 DIN 3343: 770-860 Furnace FurnaceDocument1 pageAisi M2 DIN 3343: 770-860 Furnace FurnaceMichel MancillaNo ratings yet

- 2083X40Cr14Document1 page2083X40Cr14D K NaskarNo ratings yet

- X22CrMoV 12-1Document2 pagesX22CrMoV 12-1Prasad RvsNo ratings yet

- 1.3505 100cr6 PDFDocument1 page1.3505 100cr6 PDFmcNo ratings yet

- 39nicrmo3 en 10083-3: 2006: End Quench Hardenability Test TemperingDocument1 page39nicrmo3 en 10083-3: 2006: End Quench Hardenability Test Temperingvo thanh lamNo ratings yet

- 1.2510 100Mncrw4 Z3C: Chemical CompositionDocument2 pages1.2510 100Mncrw4 Z3C: Chemical CompositionLeonardoNo ratings yet

- 32crmov12-10 : Steel GradeDocument5 pages32crmov12-10 : Steel Gradereza haghjooNo ratings yet

- 1.2842 enDocument2 pages1.2842 enCosmin IonutNo ratings yet

- Precipitation Hardening Stainless Steel: Voestalpine High Performance Metals (Australia) Pty LTDDocument3 pagesPrecipitation Hardening Stainless Steel: Voestalpine High Performance Metals (Australia) Pty LTDAtlantic Heat Treat ShopNo ratings yet

- Quality 1.2080 Chemical Composition: Lucefin GroupDocument1 pageQuality 1.2080 Chemical Composition: Lucefin GroupMSc Kostic MilosNo ratings yet

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- Bearing Steel 100Cr6 AUSA - 2Document3 pagesBearing Steel 100Cr6 AUSA - 2suresh kumarNo ratings yet

- 1 3243hs652513 PDFDocument1 page1 3243hs652513 PDFmarko9292No ratings yet

- Powder Metallurgy HSS: Chemical CompositionDocument4 pagesPowder Metallurgy HSS: Chemical CompositionSama UmateNo ratings yet

- Oil-Hardening Cold Work Tool Steels (0 Series) : Recommended Heat Treating Practice Recommended Processing SequenceDocument6 pagesOil-Hardening Cold Work Tool Steels (0 Series) : Recommended Heat Treating Practice Recommended Processing SequenceJonathan JuarezNo ratings yet

- CaseHard AISI8620Document2 pagesCaseHard AISI8620Anonymous B3I6zYNhqdNo ratings yet

- Drying Out and Heating-Up of Refractory LiningsDocument59 pagesDrying Out and Heating-Up of Refractory LiningsmustafNo ratings yet

- Cement Kiln Refractory Heat Up PDFDocument24 pagesCement Kiln Refractory Heat Up PDFMin Zayar100% (1)

- 1 3207hs104310Document1 page1 3207hs104310marko9292No ratings yet

- Through-Hardening Low Alloy Steel Bar 4340: Colour Code: Jade (Band) - MarigoldDocument3 pagesThrough-Hardening Low Alloy Steel Bar 4340: Colour Code: Jade (Band) - Marigoldl_aguilar_mNo ratings yet

- 20NiCrMoS2 2Document1 page20NiCrMoS2 2Bogdan CraciunNo ratings yet

- Astm A105Document1 pageAstm A105Isaac SamuelNo ratings yet

- 16Mncr5: Steel GradeDocument3 pages16Mncr5: Steel GradePaul Praveen PeterNo ratings yet

- ATA Heet: LSS Chipper KnifeDocument2 pagesATA Heet: LSS Chipper KnifeX800XL100% (1)

- Hardness HRC As A Function of Holding Time at Different Working Temperature Working Temperature Working TemperatureDocument1 pageHardness HRC As A Function of Holding Time at Different Working Temperature Working Temperature Working Temperaturemarko9292No ratings yet

- 1.2379 en PDFDocument2 pages1.2379 en PDFVasileSpireaNo ratings yet

- 90 MN CR V8Document1 page90 MN CR V8arunajay724No ratings yet

- Assab 709 enDocument4 pagesAssab 709 enTri YNo ratings yet

- SAE1045Document2 pagesSAE1045novale.basura2906100% (1)

- Sae 4140 ACTDocument1 pageSae 4140 ACTOSCARNo ratings yet

- Hardness HRC As A Function of Holding Time at Different Working Temperature Working Temperature Working TemperatureDocument1 pageHardness HRC As A Function of Holding Time at Different Working Temperature Working Temperature Working Temperaturemarko9292No ratings yet

- Vapor Power Cycles: Prof. Osama A. El Masry Mechanical Engineering Dept. Alexandria UniversityDocument45 pagesVapor Power Cycles: Prof. Osama A. El Masry Mechanical Engineering Dept. Alexandria UniversitySaad GhouriNo ratings yet

- ATA Heet: LSS D2Document2 pagesATA Heet: LSS D2X800XLNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetreza amiriniaNo ratings yet

- 1.8159 51Crv4 NCV: Chemical CompositionDocument2 pages1.8159 51Crv4 NCV: Chemical CompositionParth AuradkarNo ratings yet

- 39NiCrMo3 PDFDocument2 pages39NiCrMo3 PDFAmy GriffinNo ratings yet

- High Speed Hard Turning of Aisi S1 (60Wcrv8) Cold Work Tool SteelDocument18 pagesHigh Speed Hard Turning of Aisi S1 (60Wcrv8) Cold Work Tool Steelnovkovic1984No ratings yet

- Ansys All You Need To Know About Hardware For SimulationDocument36 pagesAnsys All You Need To Know About Hardware For Simulationnovkovic1984No ratings yet

- Technical Card Gruppo Lucefin Revision 2013 All Rights ReservedDocument2 pagesTechnical Card Gruppo Lucefin Revision 2013 All Rights Reservednovkovic1984No ratings yet

- Wire Rope Vibration Damper: Stainless SteelDocument3 pagesWire Rope Vibration Damper: Stainless Steelnovkovic1984No ratings yet

- WC357 Gear Deburring Brochure - RGB - 2-16Document6 pagesWC357 Gear Deburring Brochure - RGB - 2-16novkovic1984No ratings yet

- CNC Machines, Types, Tools, Applications and ImportanceDocument23 pagesCNC Machines, Types, Tools, Applications and Importancenovkovic1984No ratings yet

- Montecha - Бренд водичDocument19 pagesMontecha - Бренд водичnovkovic1984No ratings yet

- Deep Drawing Process: A Brief Overview: September 2015Document6 pagesDeep Drawing Process: A Brief Overview: September 2015novkovic1984No ratings yet

- Aluminium Alloy en Aw 6060 Material Data Sheet AlumincoDocument9 pagesAluminium Alloy en Aw 6060 Material Data Sheet Aluminconovkovic1984No ratings yet

- Assfalg Catalog Deburring - Chamfering 2019 (EN)Document64 pagesAssfalg Catalog Deburring - Chamfering 2019 (EN)novkovic1984No ratings yet

- Deburring Underestimated TaskDocument3 pagesDeburring Underestimated Tasknovkovic1984No ratings yet

- Young. Premium. Fun: The All New TiagoDocument2 pagesYoung. Premium. Fun: The All New Tiagonovkovic1984No ratings yet

- Heli-Coil Catalog HC2000 Rev12 PDFDocument40 pagesHeli-Coil Catalog HC2000 Rev12 PDFnovkovic1984No ratings yet

- 2018 Nissan Kicks enDocument8 pages2018 Nissan Kicks ennovkovic1984No ratings yet

- Vrsta Alata Tip Alata VarijantaDocument2 pagesVrsta Alata Tip Alata Varijantanovkovic1984No ratings yet

- Deburring Underestimated TaskDocument4 pagesDeburring Underestimated Tasknovkovic1984No ratings yet

- Maryland Metrics Thread Data ChartsDocument3 pagesMaryland Metrics Thread Data Chartsnovkovic1984No ratings yet

- DXF Import&Export Ver2Document5 pagesDXF Import&Export Ver2novkovic1984No ratings yet

- ᎌਦߙถࡼறමၫ఼ޱᇷআᒦቦ A Precision CNC Turn-Mill Machining Center with Gear Hobbing CapabilityDocument9 pagesᎌਦߙถࡼறමၫ఼ޱᇷআᒦቦ A Precision CNC Turn-Mill Machining Center with Gear Hobbing Capabilitynovkovic1984No ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984No ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984No ratings yet

- Iso 13715 PDFDocument2 pagesIso 13715 PDFnovkovic1984No ratings yet

- 20160323110453-11SMn30 (9SMn28)Document1 page20160323110453-11SMn30 (9SMn28)novkovic1984No ratings yet

- 20160323010442-C50E (Ck50)Document2 pages20160323010442-C50E (Ck50)novkovic1984No ratings yet

- 3 EPS Universal Gas Barrier New 2017Document1 page3 EPS Universal Gas Barrier New 2017trottersitNo ratings yet

- Concealed Wiring Open Wiring: Two Types of Wiring MethodsDocument3 pagesConcealed Wiring Open Wiring: Two Types of Wiring MethodsMark Jay TalisayonNo ratings yet

- Sheet-Metal Forming Processes: Haipan SalamDocument86 pagesSheet-Metal Forming Processes: Haipan Salamprasetyokolik-1No ratings yet

- Mason: SL# Vehicle/Equipment Act - No Commodities UOM Norm / M.day Remarks 1Document1 pageMason: SL# Vehicle/Equipment Act - No Commodities UOM Norm / M.day Remarks 1John Mark EvangelistaNo ratings yet

- IBR Thickness CalculationDocument21 pagesIBR Thickness CalculationAmit BansalNo ratings yet

- L-Bolt Anchor Bolts: Simpson Strong-Tie Wood Construction Connectors - Canadian Limit States DesignDocument1 pageL-Bolt Anchor Bolts: Simpson Strong-Tie Wood Construction Connectors - Canadian Limit States DesignHakan EzcanNo ratings yet

- Toate SolutiileDocument10 pagesToate SolutiileDanijelNo ratings yet

- 09 Pressure Sustaining Valve CPSVDocument2 pages09 Pressure Sustaining Valve CPSVCamilo AyalaNo ratings yet

- Box Culvert - ISDocument14 pagesBox Culvert - ISShyamontika Choudhury ChakrabartiNo ratings yet

- FRP Vs Rotomolded Plastic TanksDocument3 pagesFRP Vs Rotomolded Plastic TanksKimberly ConleyNo ratings yet

- Prysmian GeneralCable Marine Cat 2017Document94 pagesPrysmian GeneralCable Marine Cat 2017NghiemNo ratings yet

- MOTS-12 Welding and NDE of WeldsDocument1 pageMOTS-12 Welding and NDE of Weldsryan.sNo ratings yet

- Second Floor Plan: Bureau of DesignDocument1 pageSecond Floor Plan: Bureau of DesignDominador Ladot Heraña Jr.No ratings yet

- PIP ARC01015 (Architechtural & Building Utilities Design Criteria) PDFDocument39 pagesPIP ARC01015 (Architechtural & Building Utilities Design Criteria) PDF이동욱No ratings yet

- Aluminium Composite Panels - Alucobond SingaporeDocument7 pagesAluminium Composite Panels - Alucobond Singaporemitchel johsonNo ratings yet

- SAILMA Grades Steel Plates & SheetsDocument2 pagesSAILMA Grades Steel Plates & SheetsElumalai SrinivasanNo ratings yet

- Checklist of Material Submission (Concrete)Document10 pagesChecklist of Material Submission (Concrete)Yau Ka Ki Jacky0% (1)

- POSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Document1 pagePOSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Murti WisnuNo ratings yet

- Selection of Bolting Materials, Carbon and Alloy Steel For PDocument7 pagesSelection of Bolting Materials, Carbon and Alloy Steel For PswatkoolNo ratings yet

- CHAPTER 4 Draft PROPOSED OF HIGH ABSORBING CONCRETE SLAB FOR FLOOD PREVENTION Pages 1 19 1Document8 pagesCHAPTER 4 Draft PROPOSED OF HIGH ABSORBING CONCRETE SLAB FOR FLOOD PREVENTION Pages 1 19 1jason mr.perfect11No ratings yet

- Meeting Data Center Temperature RequirementsDocument5 pagesMeeting Data Center Temperature Requirementsaneev_aNo ratings yet

- Aluminium Form Work (Mivan) : Sl. No Description YES NO N/A Remarks Layout and MarkingDocument4 pagesAluminium Form Work (Mivan) : Sl. No Description YES NO N/A Remarks Layout and Markinganbunilavan50% (2)

- 000-Za-E-M09411 - A Ms For Cable Glanding and TerminationDocument28 pages000-Za-E-M09411 - A Ms For Cable Glanding and Terminationsyam prasad100% (1)

- Ansi-Bhma 156.15-2021 HHDocument1 pageAnsi-Bhma 156.15-2021 HHRey Eduard Q. UmelNo ratings yet

- Lesson No. 3 in Machine Design 1Document10 pagesLesson No. 3 in Machine Design 1Carl JavierNo ratings yet

- PVP2014-28958 Writing and Reviewing FEA Reports Under ASME Div 1 and 2 Design PDFDocument5 pagesPVP2014-28958 Writing and Reviewing FEA Reports Under ASME Div 1 and 2 Design PDFmatteo_1234No ratings yet