Professional Documents

Culture Documents

Nissan and BMW

Nissan and BMW

Uploaded by

Akhundjanov RakhimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nissan and BMW

Nissan and BMW

Uploaded by

Akhundjanov RakhimCopyright:

Available Formats

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION > [VK56DE]

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Trouble Diagnosis Introduction INFOID:0000000003787653

INTRODUCTION

The engine has an ECM to control major systems such as fuel con-

trol, ignition control, idle air control system, etc. The ECM accepts

input signals from sensors and instantly drives actuators. It is essen-

tial that both input and output signals are proper and stable. At the

same time, it is important that there are no malfunctions such as vac-

uum leaks, fouled spark plugs, or other malfunctions with the engine.

MEF036D

It is much more difficult to diagnose an incident that occurs intermit-

tently rather than continuously. Most intermittent incidents are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

SEF233G

A visual check only may not find the cause of the incidents. A road

test with CONSULT-III (or GST) or a circuit tester connected should

be performed. Follow the Work Flow on "WORK FLOW" .

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such incidents, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A Diagnostic Worksheet like the example

on "Worksheet Sample" should be used.

Start your diagnosis by looking for conventional malfunctions first.

This will help troubleshoot driveability malfunctions on an electroni-

SEF234G

cally controlled engine vehicle.

WORK FLOW

Revision: November 2008 EC-8 2009 Titan

P0132, P0152 A/F SENSOR 1

< COMPONENT DIAGNOSIS > [VK56DE]

Check the following.

• Harness connectors E5, F14

• IPDM E/R harness connector E119

• 15A fuse

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors.

4.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between A/F sensor 1 terminal and ECM terminal as follows.

Refer to Wiring Diagram.

A/F sensor 1 terminal ECM terminal

1 35

Bank1

2 56

1 16

Bank 2

2 75

Continuity should exist.

4. Check harness continuity between the following terminals and ground.

Refer to Wiring Diagram.

Bank 1 Bank 2

A/F sensor 1 terminal ECM terminal A/F sensor 1 terminal ECM terminal

1 35 1 16

2 56 2 75

Continuity should not exist.

5. Also check harness for short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK INTERMITTENT INCIDENT

Perform GI-35, "How to Check Terminal" and GI-38, "Intermittent Incident".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace.

6.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace malfunctioning air fuel ratio (A/F) sensor 1.

CAUTION:

• Discard any air fuel ratio (A/F) sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new air fuel ratio (A/F) sensor, clean exhaust system threads (using Oxygen Sensor

Thread Cleaner tool J-43897-18 or J-43897-12) and approved anti-seize lubricant.

>> INSPECTION END

Revision: November 2008 EC-150 2009 Titan

P0139, P0159 HO2S2

< COMPONENT DIAGNOSIS > [VK56DE]

P0139, P0159 HO2S2

A

Component Description INFOID:0000000003787788

The heated oxygen sensor 2, after three way catalyst (manifold), EC

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2. C

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions. D

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

SEF327R E

On Board Diagnosis Logic INFOID:0000000003787789

The heated oxygen sensor 2 has a much longer switching time F

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxy-

gen storage capacity of the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

G

sensor 2, ECM monitors whether the switching response of the sen-

sor's voltage is faster than specified during the various driving condi-

tion such as fuel-cut.

H

SEF302U I

DTC No. Trouble diagnosis name DTC detecting condition Possible cause J

P0139 • Harness or connectors

0139 (The sensor circuit is open or shorted)

(Bank 1) Heated oxygen sensor 2 It takes more time for the sensor to respond be- • Heated oxygen sensor 2 K

P0159 circuit slow response tween rich and lean than the specified time. • Fuel pressure

0159 • Fuel injector

(Bank 2) • Intake air leaks

L

DTC Confirmation Procedure INFOID:0000000003787790

NOTE: M

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next step.

1. Turn ignition swich OFF and wait at least 10 seconds. N

2. Turn ignition swich ON.

3. Turn ignition swich OFF and wait at least 10 seconds.

O

WITH CONSULT-III

TESTING CONDITION:

For better results, perform “DTC WORK SUPPORT” at a temperature of 0 to 30 °C (32 to 86 °F).

P

1. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

2. Start engine and warm it up to the normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

5. Let engine idle for 1 minute.

6. Make sure that “COOLAN TEMP/S” indicates more than 70°C (158°F).

Revision: November 2008 EC-169 2009 Titan

P0222, P0223 APP SENSOR

< COMPONENT DIAGNOSIS > [VK56DE]

P0222, P0223 APP SENSOR

Component Description INFOID:0000000003787810

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The throttle position sensor has the two sensors. These sensors are

a kind of potentiometers which transform the throttle valve position

into output voltage, and emit the voltage signal to the ECM. In addi-

tion, these sensors detect the opening and closing speed of the

throttle valve and feed the voltage signals to the ECM. The ECM

judges the current opening angle of the throttle valve from these sig-

nals and the ECM controls the throttle control motor to make the

throttle valve opening angle properly in response to driving condi-

PBIB0145E

tion.

On Board Diagnosis Logic INFOID:0000000003787811

These self-diagnoses have the one trip detection logic.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0222 Throttle position sensor An excessively low voltage from the TP sensor • Harness or connectors

0222 1 circuit low input 1 is sent to ECM. (TP sensor 1 circuit is open or shorted.)

(APP sensor 2 circuit is shorted.)

• Electric throttle control actuator

P0223 Throttle position sensor An excessively high voltage from the TP sensor (TP sensor 1)

0223 1 circuit high input 1 is sent to ECM. • Accelerator pedal position sensor

(APP sensor 2)

FAIL-SAFE MODE

When the malfunction is detected, ECM enters fail-safe mode and the MIL lights up.

Engine operation condition in fail-safe mode

The ECM controls the electric throttle control actuator in regulating the throttle opening in order for the idle position to be within +10

degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal condition.

So, the acceleration will be poor.

DTC Confirmation Procedure INFOID:0000000003787812

NOTE:

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next step.

1. Turn ignition swich OFF and wait at least 10 seconds.

2. Turn ignition swich ON.

3. Turn ignition swich OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8V at idle.

1. Start engine and let it idle for 1 second.

2. Check DTC.

3. If DTC is detected, go to EC-190, "Diagnosis Procedure".

Diagnosis Procedure INFOID:0000000003787813

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Revision: November 2008 EC-190 2009 Titan

P0335 CKP SENSOR (POS)

< COMPONENT DIAGNOSIS > [VK56DE]

P0335 CKP SENSOR (POS)

Component Description INFOID:0000000003787823

The crankshaft position sensor (POS) is located on the A/T assem-

bly facing the gear teeth (cogs) of the signal plate. It detects the fluc-

tuation of the engine revolution.

The sensor consists of a permanent magnet and Hall IC.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor

changes.

The ECM receives the voltage signal and detects the fluctuation of

PBIB0562E

the engine revolution.

ECM receives the signals as shown in the figure.

PBIB3459E

On Board Diagnosis Logic INFOID:0000000003787824

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

• The crankshaft position sensor (POS) signal

is not detected by the ECM during the first

few seconds of engine cranking.

• Harness or connectors

• The proper pulse signal from the crankshaft

P0335 Crankshaft position sen- (The sensor circuit is open or shorted)

position sensor (POS) is not sent to ECM

0335 sor (POS) circuit • Crankshaft position sensor (POS)

while the engine is running.

• Signal plate

• The crankshaft position sensor (POS) signal

is not in the normal pattern during engine run-

ning.

DTC Confirmation Procedure INFOID:0000000003787825

NOTE:

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next step.

1. Turn ignition swich OFF and wait at least 10 seconds.

2. Turn ignition swich ON.

3. Turn ignition swich OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5V with igni-

tion switch ON.

1. Crank engine for at least 2 seconds and run it for at least 5 seconds at idle speed.

2. Check 1st DTC.

3. If 1st trip DTC is detected, go to EC-204, "Diagnosis Procedure".

Diagnosis Procedure INFOID:0000000003787826

1.CHECK GROUND CONNECTIONS

Revision: November 2008 EC-204 2009 Titan

P0442 EVAP CONTROL SYSTEM

< COMPONENT DIAGNOSIS > [VK56DE]

P0442 EVAP CONTROL SYSTEM

A

On Board Diagnosis Logic INFOID:0000000003787843

This diagnosis detects leaks in the EVAP purge line using engine intake manifold vacuum. EC

If pressure does not increase, the ECM will check for leaks in the line between the fuel tank and EVAP canister

purge volume control solenoid valve, under the following “Vacuum test” conditions.

The EVAP canister vent control valve is closed to shut the EVAP purge line off. The EVAP canister purge vol-

ume control solenoid valve will then be opened to depressurize the EVAP purge line using intake manifold C

vacuum. After this occurs, the EVAP canister purge volume control solenoid valve will be closed.

PBIB3640E

I

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

• Incorrect fuel tank vacuum relief valve

• Incorrect fuel filler cap used J

• Fuel filler cap remains open or fails to close.

• Foreign matter caught in fuel filler cap.

• Leak is in line between intake manifold and EVAP

canister purge volume control solenoid valve. K

• Foreign matter caught in EVAP canister vent con-

trol valve.

• EVAP canister or fuel tank leaks

• EVAP purge line (pipe and rubber tube) leaks

L

• EVAP purge line rubber tube bent

EVAP control system EVAP control system has a leak, EVAP

P0442 • Loose or disconnected rubber tube

small leak detected control system does not operate prop-

0442 • EVAP canister vent control valve and the circuit

(negative pressure) erly. M

• EVAP canister purge volume control solenoid

valve and the circuit

• Fuel tank temperature sensor

• Drain filter N

• O-ring of EVAP canister vent control valve is

missing or damaged

• EVAP canister is saturated with water

• EVAP control system pressure sensor O

• Fuel level sensor and the circuit

• Refueling EVAP vapor cut valve

• ORVR system leaks

P

CAUTION:

• Use only a genuine NISSAN fuel filler cap as a replacement. If an incorrect fuel filler cap is used, the

MIL may come on.

• If the fuel filler cap is not tightened properly, the MIL may come on.

• Use only a genuine NISSAN rubber tube as a replacement.

Revision: November 2008 EC-221 2009 Titan

P1140, P1145 IVT CONTROL POSITION SENSOR

< COMPONENT DIAGNOSIS > [VK56DE]

>> INSPECTION END

A

Component Inspection INFOID:0000000003787941

INTAKE VALVE TIMING CONTROL POSITION SENSOR

EC

1. Disconnect intake valve timing control position sensor harness connector.

2. Loosen the fixing bolt of the sensor.

3. Remove the sensor. C

4. Visually check the sensor for chipping.

F

SEF362Z

5. Check resistance as shown below. G

Terminal No. (Polarity) Resistance Ω [at 25°C (77°F)]

3 (+) - 1 (-) H

2 (+) - 1 (-) Except 0 or ∞

3 (+) - 2 (-)

I

6. If NG, replace intake valve timing control position sensor. Refer

to EC-487.

JMBIA0600ZZ J

Revision: November 2008 EC-301 2009 Titan

P1551, P1552 BATTERY CURRENT SENSOR

< COMPONENT DIAGNOSIS > [VK56DE]

P1551, P1552 BATTERY CURRENT SENSOR

A

Component Description INFOID:0000000003787977

The power generation voltage variable control enables fuel con- EC

sumption to be decreased by reducing the engine load which is

caused by the power generation of the generator. The battery cur-

rent sensor (1) is installed to the battery cable at the negative termi-

nal. The sensor measures the charging/discharging current of the C

battery. Based on the sensor signal, ECM judges whether or not the

power generation voltage variable control is performed. When per-

forming the power generation voltage variable control, ECM calcu- D

lates the target power generation voltage based on the sensor

signal. And ECM sends the calculated value as the power genera-

tion command value to IPDM E/R. For the details of the power gen-

eration voltage variable control, refer to CHG-6, "System

BBIA0744E E

Description".

: Vehicle front

CAUTION: F

Do not connect the electrical component or the ground wire directly to the battery terminal. The con-

nection causes the malfunction of the power generation voltage variable control, and then the battery

discharge may occur.

G

On Board Diagnosis Logic INFOID:0000000003787978

The MIL will not light up for these self-diagnoses. H

NOTE:

If DTC P1551 or P1552 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

Refer to EC-292.

I

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1551 Battery current sensor circuit An excessively low voltage from the sensor

1551 low input is sent to ECM. • Harness or connectors J

(The sensor circuit is open or shorted.)

P1552 Battery current sensor circuit An excessively high voltage from the sensor • Battery current sensor

1552 high input is sent to ECM.

K

DTC Confirmation Procedure INFOID:0000000003787979

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next step. L

1. Turn ignition swich OFF and wait at least 10 seconds.

2. Turn ignition swich ON.

M

3. Turn ignition swich OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8V with ignition

N

switch ON

1. Turn ignition switch ON.

2. Wait at least 10 seconds.

3. Check 1st trip DTC. O

4. If 1st trip DTC is detected, go to EC-323, "Diagnosis Procedure".

Diagnosis Procedure INFOID:0000000003787980

P

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body.

Revision: November 2008 EC-323 2009 Titan

P2101 ELECTRIC THROTTLE CONTROL FUNCTION

< COMPONENT DIAGNOSIS > [VK56DE]

2. Check if foreign matter is caught between the throttle valve and

the housing. A

OK or NG

OK >> GO TO 11.

NG >> Remove the foreign matter and clean the electric throttle EC

control actuator inside.

BBIA0364E

11.CHECK THROTTLE CONTROL MOTOR D

Refer to EC-355, "Component Inspection".

OK or NG E

OK >> GO TO 12.

NG >> GO TO 13.

12.CHECK INTERMITTENT INCIDENT F

Refer to GI-35, "How to Check Terminal" and GI-38, "Intermittent Incident".

OK or NG

G

OK >> GO TO 13.

NG >> Repair or replace harness or connectors.

13.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR H

1. Replace the electric throttle control actuator.

2. Perform EC-22, "Throttle Valve Closed Position Learning".

3. Perform EC-23, "Idle Air Volume Learning". I

>> INSPECTION END

J

Component Inspection INFOID:0000000003788019

THROTTLE CONTROL MOTOR

K

1. Disconnect electric throttle control actuator harness connector.

2. Check resistance between terminals 5 and 6.

L

Resistance: Approximately 1 - 15 Ω [at 25 °C (77°F)]

3. If NG, replace electric throttle control actuator and go to next

step. M

4. Perform EC-22, "Throttle Valve Closed Position Learning".

5. Perform EC-23, "Idle Air Volume Learning".

N

PBIB2066E

Revision: November 2008 EC-355 2009 Titan

P2138 APP SENSOR

< COMPONENT DIAGNOSIS > [VK56DE]

P2138 APP SENSOR

A

Component Description INFOID:0000000003788044

The accelerator pedal position sensor is installed on the upper end EC

of the accelerator pedal assembly. The sensor detects the accelera-

tor position and sends a signal to the ECM.

Accelerator pedal position sensor has two sensors. These sensors

are a kind of potentiometers which transform the accelerator pedal C

position into output voltage, and emit the voltage signal to the ECM.

In addition, these sensors detect the opening and closing speed of

the accelerator pedal and feed the voltage signals to the ECM. The D

ECM judges the current opening angle of the accelerator pedal from

these signals and controls the throttle control motor based on these

signals.

Idle position of the accelerator pedal is determined by the ECM

PBIB1741E E

receiving the signal from the accelerator pedal position sensor. The ECM uses this signal for the engine oper-

ation such as fuel cut.

F

On Board Diagnosis Logic INFOID:0000000003788045

This self-diagnosis has the one trip detection logic.

NOTE: G

If DTC P2138 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to

EC-292.

H

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

• Harness or connector

(APP sensor 1 and 2 circuit is open or I

Accelerator pedal position Rationally incorrect voltage is sent to ECM shorted.)

P2138

sensor circuit range/per- compared with the signals from APP sensor 1 (TP sensor circuit is shorted.)

2138

formance and APP sensor 2. • Accelerator pedal position sensor 1 and 2

• Electric throttle control actuator J

(TP sensor)

FAIL-SAFE MODE

When the malfunction is detected, ECM enters fail-safe mode and the MIL lights up. K

Engine operating condition in fail-safe mode

L

The ECM controls the electric throttle control actuator in regulating the throttle opening in order for the idle position to be within +10

degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal condition.

So, the acceleration will be poor. M

DTC Confirmation Procedure INFOID:0000000003788046

NOTE: N

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next step.

1. Turn ignition swich OFF and wait at least 10 seconds. O

2. Turn ignition swich ON.

3. Turn ignition swich OFF and wait at least 10 seconds.

TESTING CONDITION: P

Before performing the following procedure, confirm that battery voltage is more than 8V at idle.

1. Start engine and let it idle for 1 second.

2. Check DTC.

3. If DTC is detected, go to EC-372, "Diagnosis Procedure".

Revision: November 2008 EC-371 2009 Titan

ELECTRICAL LOAD SIGNAL

< COMPONENT DIAGNOSIS > [VK56DE]

ELECTRICAL LOAD SIGNAL

Description INFOID:0000000003788060

The electrical load signal (Headlamp switch signal, etc.) is transferred through the CAN communication line

from BCM to ECM via IPDM E/R.

Diagnosis Procedure INFOID:0000000003788061

1.CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-I

1. Turn ignition switch ON.

2. Connect CONSULT-III and select “DATA MONITOR” mode.

3. Select “LOAD SIGNAL” and check indication under the following conditions.

Condition Indication

Rear window defogger switch: ON ON

Rear window defogger switch: OFF OFF

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2.CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

Check “LOAD SIGNAL” indication under the following conditions.

Condition Indication

Lighting switch: ON at 2nd position ON

Lighting switch: OFF OFF

OK or NG

OK >> GO TO 3.

NG >> GO TO 5.

3.CHECK HEATER FAN SIGNAL CIRCUIT OVERALL FUNCTION

Select “HEATER FAN SW” and check indication under the following conditions.

Condition Indication

Heater fan control switch: ON ON

Heater fan control switch: OFF OFF

OK or NG

OK >> INSPECTION END

NG >> GO TO 6.

4.CHECK REAR WINDOW DEFOGGER SYSTEM

Refer to DEF-47, "Filament Check".

>> INSPECTION END

5.CHECK HEADLAMP SYSTEM

Refer to EXL-137, "Removal and Installation".

>> INSPECTION END

6.CHECK HEATER FAN CONTROL SYSTEM

Refer to HAC-17, "CONSULT-III Function (HVAC)" (with automatic air conditioner) or HAC-112, "CONSULT-III

Function (HVAC)" (with manual air conditioner).

Revision: November 2008 EC-388 2009 Titan

ECM

< ECU DIAGNOSIS > [VK56DE]

ECU DIAGNOSIS A

ECM

CONSULT-III Reference Value in Data Monitor Mode INFOID:0000000003788078

EC

Remarks:

z Specification data are reference values.

z Specification data are output/input values which are detected or supplied by the ECM at the connector. C

* Specification data may not be directly related to their components signals/values/operations.

i.e. Adjust ignition timing with a timing light before monitoring IGN TIMING, because the monitor may show the specification data in spite of the

ignition timing not being adjusted to the specification data. This IGN TIMING monitors the data calculated by the ECM according to the signals

input from the camshaft position sensor and other ignition timing related sensors. D

MONITOR ITEM CONDITION SPECIFICATION

• Run engine and compare CONSULT-III value with the tachometer indica- Almost the same speed as the

ENG SPEED

tion. tachometer indication.

E

MAS A/F SE-B1 See EC-79.

B/FUEL SCHDL See EC-79.

A/F ALPHA-B1 F

See EC-79.

A/F ALPHA-B2

COOLAN TEMP/S • Engine: After warming up More than 70°C (158°F)

A/F SEN1 (B1) G

• Engine: After warming up Maintaining engine speed at 2,000 rpm Fluctuates around 2.2 V

A/F SEN1 (B2)

• Revving engine from idle to 3,000 rpm quickly after the following conditions

HO2S2 (B1) are met. H

0 - 0.3V ←→ Approx. 0.6 - 1.0V

HO2S2 (B2) • After keeping engine speed between 3,500 and 4,000 rpm for 1 minute and

at idle for 1 minute under no load

• Revving engine from idle to 3,000 rpm quickly after the following conditions I

are met.

HO2S2 MNTR (B1)

- Engine: After warming up LEAN ←→ RICH

HO2S2 MNTR (B2)

- Keeping engine speed between 3,500 and 4,000 rpm for 1 minute and at

idle for 1 minute under no load J

• Turn drive wheels and compare CONSULT-III value with the speedometer Almost the same speed as the

VHCL SPEED SE

indication. speedometer indication

BATTERY VOLT • Ignition switch: ON (Engine stopped) 11 - 14V K

• Ignition switch: ON Accelerator pedal: Fully released 0.5 - 1.0V

ACCEL SEN 1

(Engine stopped) Accelerator pedal: Fully depressed 4.2 - 4.8V

L

• Ignition switch: ON Accelerator pedal: Fully released 0.5 - 1.0V

ACCEL SEN 2*1 (Engine stopped) Accelerator pedal: Fully depressed 4.2 - 4.8V

TP SEN 1-B1

• Ignition switch: ON Accelerator pedal: Fully released More than 0.36V M

(Engine stopped)

TP SEN 2-B1 Accelerator pedal: Fully depressed Less than 4.75V

• Selector lever: D

EVAP SYS PRES • Ignition switch: ON Approx. 1.8 - 4.8V

N

START SIGNAL • Ignition switch: ON → START → ON OFF → ON → OFF

• Ignition switch: ON Accelerator pedal: Fully released ON

CLSD THL POS

(Engine stopped) Accelerator pedal: Slightly depressed OFF O

Air conditioner switch: OFF OFF

• Engine: After warming up, idle the

AIR COND SIG Air conditioner switch: ON

engine ON

(Compressor: Operates.) P

Shift lever: P or N ON

P/N POSI SW • Ignition switch: ON

Shift lever: Except above OFF

Steering wheel: Not being turned

• Engine: After warming up, idle the OFF

PW/ST SIGNAL (Forward direction)

engine

Steering wheel: Being turned ON

Revision: November 2008 EC-415 2009 Titan

ECM

< ECU DIAGNOSIS > [VK56DE]

EC

O

AABIA0017GB

Fail-Safe Chart INFOID:0000000003788082 P

When the DTC listed below is detected, the ECM enters fail-safe mode and the MIL lights up.

Revision: November 2008 EC-447 2009 Titan

ECM

< ECU DIAGNOSIS > [VK56DE]

DTC No. Detected items Engine operating condition in fail-safe mode

P0102 Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0103

P0117 Engine coolant tempera- Engine coolant temperature will be determined by ECM based on the following condition.

P0118 ture sensor circuit CONSULT-III displays the engine coolant temperature decided by ECM.

Engine coolant temperature decided

Condition

(CONSULT-III display)

Just as ignition switch is turned ON

40°C (104°F)

or START

Approx. 4 minutes or more after

80°C (176°F)

engine starting.

40 - 80°C (104 - 176°F)

Except as shown above

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling

fan operates while engine is running.

P0122 Throttle position sensor The ECM controls the electric throttle control actuator in regulating the throttle opening in

P0123 order for the idle position to be within +10 degrees.

P0222 The ECM regulates the opening speed of the throttle valve to be slower than the normal

P0223 condition.

P2135 So, the acceleration will be poor.

P0643 Sensor power supply ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2100 Throttle control motor relay ECM stops the electric throttle control actuator control, throttle valve is maintained at a

P2103 fixed opening (approx. 5 degrees) by the return spring.

P2101 Electric throttle control ECM stops the electric throttle control actuator control, throttle valve is maintained at a

function fixed opening (approx. 5 degrees) by the return spring.

P2118 Throttle control motor ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2119 Electric throttle control ac- (When electric throttle control actuator does not function properly due to the return spring

tuator malfunction:)

ECM controls the electric throttle actuator by regulating the throttle opening around the

idle position. The engine speed will not rise more than 2,000 rpm.

(When throttle valve opening angle in fail-safe mode is not in specified range:)

ECM controls the electric throttle control actuator by regulating the throttle opening to 20

degrees or less.

(When ECM detects the throttle valve is stuck open:)

While the vehicle is driving, it slows down gradually by fuel cut. After the vehicle stops, the

engine stalls.

The engine can restart in N or P position, and engine speed will not exceed 1,000 rpm or

more.

P2122 Accelerator pedal position The ECM controls the electric throttle control actuator in regulating the throttle opening in

P2123 sensor order for the idle position to be within +10 degrees.

P2127 The ECM regulates the opening speed of the throttle valve to be slower than the normal

P2128 condition.

P2138 So, the acceleration will be poor.

• When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when there

is malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected

as NG for 5 trips, ECM warns the driver that engine control system malfunctions and MIL circuit is open by

means of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected and demands the

driver to repair the malfunction.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Revision: November 2008 EC-448 2009 Titan

INTAKE VALVE TIMING CONTROL

< ON-VEHICLE REPAIR > [VK56DE]

Intake Valve Timing Control Position Sensor (LH) INFOID:0000000003788099

A

REMOVAL

1. Remove engine room cover using power tool. Refer to EM-24, "Removal and Installation".

EC

2. Remove air duct and resonator assembly. Refer to EM-25, "Removal and Installation".

3. Disconnect intake valve timing control position sensor connector (LH).

4. Remove intake valve timing control position sensor (LH) (1) from C

Intake valve timing control solenoid valve cover (LH) (3).

AWBIA0141ZZ

F

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: G

Replace the O-ring (2) of the intake valve timing control position sensor with a new one, then lubricate

O-ring with engine oil before installing.

H

Intake valve timing control position sensor bolt : 9.6 N·m (0.98 kg-m, 85 in-lb)

Intake Valve Timing Control Position Sensor (RH) INFOID:0000000003788100

I

REMOVAL

1. Remove engine room cover using power tool. Refer to EM-24, "Removal and Installation".

J

2. Disconnect intake valve timing control position sensor connector (RH).

3. Remove intake valve timing control position sensor (RH) (1)

from Intake valve timing control solenoid valve cover (RH) (3).

K

AWBIA0143ZZ

INSTALLATION N

Installation is in the reverse order of removal.

CAUTION:

Replace the O-ring (2) of the intake valve timing control position sensor with a new one, then lubricate O

O-ring with engine oil before installing.

Intake valve timing control position sensor bolt : 9.6 N·m (0.98 kg-m, 85 in-lb)

P

Camshaft Position Sensor (PHASE) INFOID:0000000003788101

REMOVAL

1. Remove engine room cover using power tool. Refer to EM-24, "Removal and Installation".

2. Remove air duct and resonator assembly. Refer to EM-25, "Removal and Installation".

3. Disconnect camshaft position sensor connector.

Revision: November 2008 EC-487 2009 Titan

You might also like

- Hegner Manual PDFDocument19 pagesHegner Manual PDFOsairManassan0% (3)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- P0222, P0223 TP SENSOR: DTC LogicDocument3 pagesP0222, P0223 TP SENSOR: DTC LogicWillie AustineNo ratings yet

- Xtrail P2135Document9 pagesXtrail P2135Dircios100% (3)

- P0100 Mass Air Flow CircuitDocument7 pagesP0100 Mass Air Flow CircuitDaniel rodriguez alayoNo ratings yet

- Livina AT PDFDocument293 pagesLivina AT PDFAndika100% (1)

- ESP ManualDocument39 pagesESP Manualwwe_himanshu88% (8)

- Service - WEM SS 501 (Inglés)Document42 pagesService - WEM SS 501 (Inglés)Valentim100% (3)

- Inex User ManualDocument132 pagesInex User Manualduck dvdNo ratings yet

- Cip 0133Document4 pagesCip 0133alan lantiguaNo ratings yet

- DTC P0182, P0183 FTT SENSOR Component DescriptionDocument4 pagesDTC P0182, P0183 FTT SENSOR Component DescriptionWillie AustineNo ratings yet

- GEK28158c-Gas Turbine Flame Detector SystemsDocument6 pagesGEK28158c-Gas Turbine Flame Detector Systemskarim karimNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P2135Document4 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P2135PeterNo ratings yet

- Sentra 2003 1.8 P1121Document9 pagesSentra 2003 1.8 P1121Dircios100% (1)

- DTC P0325 Knock Sensor 1 Circuit MalfunctionDocument3 pagesDTC P0325 Knock Sensor 1 Circuit MalfunctionErln LimaNo ratings yet

- LACETTI Engine (71-100) - 1.8DDocument30 pagesLACETTI Engine (71-100) - 1.8DDangLuyenNo ratings yet

- Injector Solenoid Circuit - Test (RENR5096)Document7 pagesInjector Solenoid Circuit - Test (RENR5096)Josip MiškovićNo ratings yet

- O2 and A/F Sensor Diagnosis: Section 7Document44 pagesO2 and A/F Sensor Diagnosis: Section 7sungjoo75No ratings yet

- Kenr6200 01Document2 pagesKenr6200 01Rodrigo Santibañez100% (1)

- Switches: ARC ON/OFF SwitchDocument10 pagesSwitches: ARC ON/OFF Switchkusnan kusnanNo ratings yet

- Circuit Inspection DTC P0100/31 Mass Air Flow Circuit MalfunctionDocument6 pagesCircuit Inspection DTC P0100/31 Mass Air Flow Circuit MalfunctionMiguel ruizNo ratings yet

- Description: 2Gr-Fe Engine Control System - Sfi SystemDocument6 pagesDescription: 2Gr-Fe Engine Control System - Sfi Systemkavidush123No ratings yet

- Electrical M07 Sensors enDocument28 pagesElectrical M07 Sensors enFredy Manrique AstoNo ratings yet

- Cummins QSB6.7 and QSB4.5 With CM850 ECM - Components TestingDocument15 pagesCummins QSB6.7 and QSB4.5 With CM850 ECM - Components TestingAnders Hedlöf100% (6)

- Chapter Electric Fuel Injection SystemDocument92 pagesChapter Electric Fuel Injection Systemcamionetanissanz20No ratings yet

- DTC 51Document4 pagesDTC 51victorNo ratings yet

- Knock Sensor For Toyota NZE EngineDocument3 pagesKnock Sensor For Toyota NZE EngineTalleban TalNo ratings yet

- DTC P0500 Corolla Altis 2006Document3 pagesDTC P0500 Corolla Altis 2006ardi agusman100% (2)

- 2JZ-GE Transmission Diagnostics PDFDocument55 pages2JZ-GE Transmission Diagnostics PDFJesus Cheremo100% (3)

- REPAIR MANUAL Celica 2zz - P0325Document3 pagesREPAIR MANUAL Celica 2zz - P0325carlos alberto jimenez pallaresNo ratings yet

- P Johnstone: Jackaroo TipsDocument5 pagesP Johnstone: Jackaroo TipsJimmy Brian KaifitiNo ratings yet

- P0710Document5 pagesP0710David RosadoNo ratings yet

- CMP (Phase) MuranoDocument8 pagesCMP (Phase) MuranoGuillermo RojasNo ratings yet

- Manual de Serviço Injeção EletrônicaDocument87 pagesManual de Serviço Injeção EletrônicaMarcos MedradoNo ratings yet

- Structure and Operation: 3. Electronic Control Unit Connection DiagramDocument86 pagesStructure and Operation: 3. Electronic Control Unit Connection DiagramAung Hlaing Min MyanmarNo ratings yet

- U241e TransaxleDocument4 pagesU241e Transaxleromelr100% (1)

- General Description of MV Switchgear: Unit 3Document51 pagesGeneral Description of MV Switchgear: Unit 3sherifmoussaNo ratings yet

- Диагностика датчиков давления Катапиллер С4.4Document7 pagesДиагностика датчиков давления Катапиллер С4.4Aleksey ZhmaevNo ratings yet

- WT 200 Water Transducer: Component DescriptionDocument16 pagesWT 200 Water Transducer: Component Descriptionmilad100% (1)

- P2714Document10 pagesP2714Jose Francisco GuzmánNo ratings yet

- GIS CB Time TestingDocument26 pagesGIS CB Time TestingVISHAL TELANGNo ratings yet

- Cip 0135Document3 pagesCip 0135alan lantiguaNo ratings yet

- Description: PrintDocument8 pagesDescription: PrintAUTOSCOPE DIAGNOSIS PERUNo ratings yet

- 15 Diagnóstico de Componentes IntegralesDocument18 pages15 Diagnóstico de Componentes IntegralesmongongoNo ratings yet

- 1 Electric Injection System - Chery Tiggo T11Document87 pages1 Electric Injection System - Chery Tiggo T11limadacarlosNo ratings yet

- G3608Document2 pagesG3608mauricioNo ratings yet

- CodigosDocument6 pagesCodigosAdán Castro GallegosNo ratings yet

- DTC P0510 Closed Throttle Position Switch Malfunction: Circuit DescriptionDocument4 pagesDTC P0510 Closed Throttle Position Switch Malfunction: Circuit DescriptionGEME MSDFNo ratings yet

- Emanagebasicoperation PDFDocument23 pagesEmanagebasicoperation PDFanthony dizonNo ratings yet

- DTC P0743 Torque Converter Clutch Circuit ElectricalDocument4 pagesDTC P0743 Torque Converter Clutch Circuit ElectricalErln LimaNo ratings yet

- P 1300 Toyota Automatic TransmissionDocument6 pagesP 1300 Toyota Automatic TransmissionSuksan Sananmuang100% (1)

- B1435 Cool Air Bypass Damper Position SensorDocument4 pagesB1435 Cool Air Bypass Damper Position SensorVũ Nguyễn Minh100% (1)

- DTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionDocument9 pagesDTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionAndres AriasNo ratings yet

- Inspection Procedure - Toyota Service Information - 103544Document3 pagesInspection Procedure - Toyota Service Information - 103544irwan ekoNo ratings yet

- Trouble Diagnosis Trouble Diagnosi Blower Motor Circuit: To EsmDocument6 pagesTrouble Diagnosis Trouble Diagnosi Blower Motor Circuit: To EsmAlex RonNo ratings yet

- Jfe 582Document94 pagesJfe 582Antonio Colmenares100% (1)

- Dodge 2001 Computer CodesDocument9 pagesDodge 2001 Computer Codespaul_a_rodriguezNo ratings yet

- Panasonic PT 52lcx66Document83 pagesPanasonic PT 52lcx66ferdialvascribdNo ratings yet

- Emergency Stop Switch Circuit - Test (RENR5096)Document3 pagesEmergency Stop Switch Circuit - Test (RENR5096)Josip MiškovićNo ratings yet

- General Information: Checks & RepairsDocument24 pagesGeneral Information: Checks & RepairsChristian BedoyaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- CAT Position Switches and Multiple Limit SwitchDocument144 pagesCAT Position Switches and Multiple Limit SwitchzeuszktNo ratings yet

- Groups 80: ElectricityDocument50 pagesGroups 80: ElectricityMarius BorcauNo ratings yet

- KH-200A. User Manual. Dry-CleaningDocument44 pagesKH-200A. User Manual. Dry-CleaningYARYU LEKNo ratings yet

- TR12 Tripping Relays AlphaDocument16 pagesTR12 Tripping Relays AlphaDEADMAN100% (1)

- Gas Pressure SwitchDocument6 pagesGas Pressure SwitchMahussienyNo ratings yet

- LM Mil HDBK 454B 151030Document208 pagesLM Mil HDBK 454B 151030SivaramSubramanianNo ratings yet

- ABB Switch DisconnectorDocument3 pagesABB Switch DisconnectorSher Bahadur VermaNo ratings yet

- MPR-414F MPR-414FS: Instruction ManualDocument29 pagesMPR-414F MPR-414FS: Instruction ManualAnonymous D8ay3BMJ5No ratings yet

- Notice de Réparation RI9724 - 02 PDFDocument224 pagesNotice de Réparation RI9724 - 02 PDFBaciu NicolaeNo ratings yet

- Safety Solenoid Valve Nominal Width RP 1/2 - RP 2 SV SV-D Sv-DleDocument8 pagesSafety Solenoid Valve Nominal Width RP 1/2 - RP 2 SV SV-D Sv-DleAgustantoNo ratings yet

- Models:: Forma Scientific, Inc. P.O. Box 649 Marietta, Ohio 45750Document38 pagesModels:: Forma Scientific, Inc. P.O. Box 649 Marietta, Ohio 45750Ezsilvasilva SilvaNo ratings yet

- IQ4 Pipeline Installation and Maintenance GuideDocument64 pagesIQ4 Pipeline Installation and Maintenance Guidewatwiboon praemongkolNo ratings yet

- Scanclimber SC1300 Wheel Chassis - 0Document7 pagesScanclimber SC1300 Wheel Chassis - 0Boruida MachineryNo ratings yet

- SF 200 Hardware Deployment ManualDocument20 pagesSF 200 Hardware Deployment ManualZeus OmegaNo ratings yet

- Uenr25330001Document8 pagesUenr25330001William carlos Trujillo cruzNo ratings yet

- 440r Manual and Parts ListDocument90 pages440r Manual and Parts ListBlessing OjeaburuNo ratings yet

- SX 36 ManualDocument16 pagesSX 36 ManualAndreyna BreaNo ratings yet

- E5en H OnromDocument374 pagesE5en H OnromAderly GarciaNo ratings yet

- 2013 Polaris Ranger Owner ManualDocument100 pages2013 Polaris Ranger Owner ManualMark StewartNo ratings yet

- Hyundai-Cat 4390037 PDFDocument24 pagesHyundai-Cat 4390037 PDFbagus fauziNo ratings yet

- Checklist c172n PDFDocument2 pagesChecklist c172n PDFAbiy TadeseNo ratings yet

- Diagrama Electrico 631KDocument6 pagesDiagrama Electrico 631Kjaciel_tobaNo ratings yet

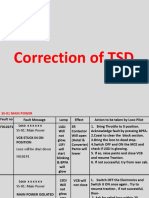

- TSD CorrectionDocument212 pagesTSD CorrectionKSHITIJ PRATAP SINGH0% (1)

- Training Report On Control Relay PanelDocument50 pagesTraining Report On Control Relay PanelShubham Pal75% (4)

- Daikin RemoteDocument0 pagesDaikin Remotebookslover1No ratings yet

- Kalendar Kursus 1 Jangka Pendek 2017Document18 pagesKalendar Kursus 1 Jangka Pendek 2017SenyumSajerNo ratings yet