Professional Documents

Culture Documents

HI-TECH Laser Cutting For Electric Motors Development: Aussafer Due

HI-TECH Laser Cutting For Electric Motors Development: Aussafer Due

Uploaded by

Yusuf KarimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HI-TECH Laser Cutting For Electric Motors Development: Aussafer Due

HI-TECH Laser Cutting For Electric Motors Development: Aussafer Due

Uploaded by

Yusuf KarimCopyright:

Available Formats

Q$'6$3',CY%>$9*$#?

$)%@DY%@A@@

1-$4*)+4

)*!+,-.-!,/01 !20 -,34/56578 ) *996:3*-:5/1 ) ;,*-<!,0 1<996:,!1.9!5;:6, *0=,!-5!:*6 *

!"#$% ! %&'($)*")+,-% ! %!./012!%-,3$)%45**+67%8")%$-$4*)+4%#"*")3%'$($-"9#$6*:%&533,8$)%;5$

&'($)*")+,- >599-+$)3%T)"L-$

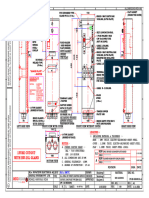

HI-TECH laser cutting for electric motors

development: Aussafer Due

!"#$%&'("

" # $ % & ' (

Translate

Aussafer Due is partner of excellence for the development and

manufacturing of laser cut

laminations and of stator/rotor core stacks, by means of 10

Find

fiber laser machines (the biggest subcontracting division in

Italy), providing a highly customized service upon customers’

Search

precise needs, besides offering a range of additional services.

Technology, innovation, precision and a highly

specialized technical team represent the highlights that ! !"#$%&'($)!*+!*,)

have always characterized Aussafer Due. A strategic asset that -).%/)**)'

has allowed the company to become a national and

international reference reality in the metalworking sector, with

specific focus on the electric motor enabled by a business

unit fully dedicated to the realization of prototypes, preseries, The magazine

and special rotor and stator cores, through laser cutting of

electrical steel laminations. The cores are realized by standard

welding processes, or BACKLACK bonding.

The advantages of BACKLACK technology is better precision,

stiffness and vibration performance, and the possibility of very 6<=%/ 6<@%/%B,C 6<D%/%B,)4E

>$9*$#?$) @A@@ @A@@

complex shapes. Aussafer Due can deliver to its customer both @A@@

loose laminations and rotor/stator cores.

F$G33*,6'

A customized service that permits to collaborate with

customers in the product development phase, directly

dialoguing with technical and R&D offices, Universities, Find your TAG

Research and Development Centres, for the implementation of

the realistic prototype. &$)"39,4$ %,5*"#,*+"6

Aussafer Due also supports its customers in repairing and

refurbishment of big rotating electrical machines, like

,5*"#"*+($

,5*"#"*+($%+6'53*)C

alternators, hydro and wind generators.

For these activities, its customers can rely on Aussafer Reverse ?,**$)+$3 %2E+6,

Engineering Service, that enables the acquirement of the 4"#9"6$6*3 %2"(+'/DH

drawing from a physical part.

'$3+76 % 1/B"?+-+*C

$I4+$64C %$-$4*)+4%4,)

$-$4*)+4%#"?+-+*C

$-$4*)+4%#"*")

$-$4*)+4%#"*")3 %$-$4*)+4%>JK

$-$4*)+4%($E+4-$

$-$4*)+4%($E+4-$3

1-$4*)+L4,*+"6

$-$4*)"#"?+-+*C %$6$)7C%*),63+*+"6

MNOP/Q1NR1 %E,+)9+6%*$4E6"-"7C

.64$6*+($3 %+6'54*+"6%#"*")

+6($3*#$6*3

S"+6*%($6*5)$

#,658,4*5)+67

Laser Technology advantages compared to traditional methods

B,658,4*5)+67%+6'53*)C

#,33/

• no stamping tool required

• cost effectiveness and short lead times for geometry

9)"'54*+"6

and product changes

T,)*6$)3E+9 %9"G$)*),+6

• short time to market for realizing a functional

prototype 9)"*"*C9$ %9)"*"*C9$3

),G%#,*$)+,-3 %N$4E,)7$%>C3*$#

Aussafer Due added value and competitive edge )$3$,)4E

Strongly oriented to innovation, Aussafer Due avails itself of N$3$,)4E%,6'

state-of-the-art process technologies, in compliance with '$($-"9#$6*

Industry 4.0, with 10 fiber laser cutting machines (i.e. 3$#+4"6'54*")3 %3+#5-,*+"6

the biggest subcontracting laser cutting department in Italy), >*,)*/59 %353*,+6,?+-+*C

customized on its own specifications. As outstanding is the

353*,+6,?-$%#"?+-+*C %*$3*+67

broad range of warehoused materials available in stock: silicon

*),+6+67

steels in thicknesses from 0.1 to 1 mm, with magnetic

properties and grades from M230 to M800, also NO (NO10,

NO20 etc.), on different insulations (C3, C5, C6), BACKLACK,

cold rolled and hot rolled pole sheets (TF and TG), too.

Outstanding level quality for the most demanding sectors

ISO 9001:2015-certified and with its own quality system,

Aussafer Due guarantees final quality and accuracy with in-

process tests and checks carried out by its entrusted in-house

laboratory, equipped with 3 innovative coordinate measuring

machines (CMM).

The in-depth experience and the competences gained allow the

company to manufacture several motor typologies:

asynchronous motors (IM), internal permanent magnet

synchronous motors (IPMSM) also with rotor cage, surface

mounted permanent

magnet synchronous motors (SM-PMSM), synchronous

reluctance motors (SynRM), linear motors, alternators and

generators, also segmented. Executions manufactured for

numerous customers spread worldwide, operating in various

sectors, for applications in automotive and racing ambit (hydro

and wind generators), traction motors, CNC machine

tools, CNC spindles, renewable energies, automation, naval and

aerospace industry, oil & gas.

!"#$ "%&&'()*+,%) -'&)*+.%/+-'012'/132& -'&)*+.%//124

٠ أعجبني

" # $ % & ' (

Previous article Next article

Vignati Group, complex technical Electric mobility is glamour

components

U%1-$4*)+4%B"*")%167+6$$)+67%V%0$46+4E$%F5"($%>9,<%&--%N+7E*3%N$3$)($'<%N$7+3*$)$'%"I4$:%K+,%1)+*)$,%@D%/%@ADWX%B+-,6<%>E,)$%4,9+*,-

85--C%9,+'/59:%WYAAAYAAA%15)"3<%0,Z%4"'$Y%K&0%65#?$)%,6'%16)"-#$6*%+6%*E$%B+-,6%N$7+3*$)%"8%2"#9,6+$3:%AAXW=[\ADWD% +

You might also like

- Algorithmic Problem Solving by Roland Backhouse PDFDocument178 pagesAlgorithmic Problem Solving by Roland Backhouse PDFמוחמד טאהא60% (5)

- Advising Sheet 4-Year 10-11Document2 pagesAdvising Sheet 4-Year 10-11Kristin PaulsNo ratings yet

- Presentation Slides STRASSER Shearwalls and Diaphragms WDS 190516Document90 pagesPresentation Slides STRASSER Shearwalls and Diaphragms WDS 190516Pl TorrNo ratings yet

- Igs TP 010 1&2Document13 pagesIgs TP 010 1&2mahotkatNo ratings yet

- Long Term ConstructionDocument6 pagesLong Term ConstructionFrl RizalNo ratings yet

- Bangladesh Machine Tools Factory (BMTF)Document7 pagesBangladesh Machine Tools Factory (BMTF)Kaniz AlmasNo ratings yet

- IGS-PL-003 (2) : Neddle & Gauge ValvesDocument5 pagesIGS-PL-003 (2) : Neddle & Gauge ValvesMehdi orojluNo ratings yet

- IGS-PL-005 (1) : Sencing Tube LinesDocument4 pagesIGS-PL-005 (1) : Sencing Tube LinesMehdi orojluNo ratings yet

- National Savings Certificates (IX Issue) Amendment Rules, 2013.Document5 pagesNational Savings Certificates (IX Issue) Amendment Rules, 2013.Latest Laws TeamNo ratings yet

- Screenshot 2022-02-01 at 8.04.43 AMDocument1 pageScreenshot 2022-02-01 at 8.04.43 AMArshia GoelNo ratings yet

- The New American Civil War - New EuropeDocument5 pagesThe New American Civil War - New EuropemartinscodellerNo ratings yet

- Imat Günü RehberiDocument8 pagesImat Günü RehberiMert Tan Tari100% (1)

- Latihan Analisis Dengan Wireless - Dicoding IndonesiaDocument7 pagesLatihan Analisis Dengan Wireless - Dicoding IndonesiaRizki MarchellNo ratings yet

- The Market For Foreign Exchange: Chapter FiveDocument7 pagesThe Market For Foreign Exchange: Chapter FivechristieNo ratings yet

- SEMIKRON DataSheet SKKT 27 07897231Document4 pagesSEMIKRON DataSheet SKKT 27 07897231DEVI PRASAD GREENSECURENo ratings yet

- SKDH146 16 L75Document2 pagesSKDH146 16 L75Ercan CesurNo ratings yet

- General Accounting 1 - A7.3Document753 pagesGeneral Accounting 1 - A7.3Etienne Cronje100% (1)

- French Mem Spring 2017Document2 pagesFrench Mem Spring 2017frlancedesignNo ratings yet

- The International Monetary System: Chapter TwoDocument10 pagesThe International Monetary System: Chapter TwochristieNo ratings yet

- IGS-TP-014-3 (0) : Polyethylene Shrinkable Sleeve Part 3Document13 pagesIGS-TP-014-3 (0) : Polyethylene Shrinkable Sleeve Part 3madx44No ratings yet

- Tecnicas de SQL Injection - Un RepasoDocument44 pagesTecnicas de SQL Injection - Un RepasoJuan Carlos RiveraNo ratings yet

- Lc420eun SDV3Document35 pagesLc420eun SDV3M QidosNo ratings yet

- TSP20100915 SpritzerDocument4 pagesTSP20100915 Spritzerlimml63No ratings yet

- Screenshot 2022-10-29 at 17.22.35Document28 pagesScreenshot 2022-10-29 at 17.22.35Dounia LamghariNo ratings yet

- Search Books, Presentations, Business, Academics... : Scribd Explore Community Upload A DocumentDocument46 pagesSearch Books, Presentations, Business, Academics... : Scribd Explore Community Upload A DocumentJoseph HajdukNo ratings yet

- SEMIKRON DataSheet SKKT 72 07897371Document4 pagesSEMIKRON DataSheet SKKT 72 07897371Ali özkanlıNo ratings yet

- PerceptionDocument24 pagesPerceptionParth PatelNo ratings yet

- Lambbbb PDFDocument8 pagesLambbbb PDFNaciri AnouarNo ratings yet

- #Eská Republika 800 142 669: Technical SalesDocument4 pages#Eská Republika 800 142 669: Technical SalesRudolf ArochNo ratings yet

- Vitra RootDocument48 pagesVitra Rootmounier.fahadNo ratings yet

- BRZ Electrical Wiring DiagramDocument404 pagesBRZ Electrical Wiring DiagramBagas Hanadi YudoNo ratings yet

- SKKT 72, SKKH 72, SKKT 72B: ThyristorDocument4 pagesSKKT 72, SKKH 72, SKKT 72B: ThyristorAn Trần Huỳnh PhúNo ratings yet

- ArquitecturaDocument187 pagesArquitecturaRosales PachecoNo ratings yet

- Utilit E, Utilisabilit E, Acceptabilit E: Interpr Eter Les Relations Entre Trois Dimensions de L' Evaluation Des EIAHDocument14 pagesUtilit E, Utilisabilit E, Acceptabilit E: Interpr Eter Les Relations Entre Trois Dimensions de L' Evaluation Des EIAHmehdiNo ratings yet

- United States (866) 531-6285: Technical SalesDocument5 pagesUnited States (866) 531-6285: Technical Salesdilor19No ratings yet

- M PL 22 2Document14 pagesM PL 22 2yaabalfazl24No ratings yet

- Welding-Test ISO 5817 PDFDocument19 pagesWelding-Test ISO 5817 PDFHumberto Ernesto Di CiccioNo ratings yet

- Nemco Compressor Oil ISO VG 100, 150Document9 pagesNemco Compressor Oil ISO VG 100, 150hendro suprianto nugrohoNo ratings yet

- Kts - Everdigm RD - Ecd35 - 40 (Eng)Document2 pagesKts - Everdigm RD - Ecd35 - 40 (Eng)E Abadt DL100% (1)

- Human Resource ManagementDocument28 pagesHuman Resource ManagementMonica DagaNo ratings yet

- HomeDocument1 pageHomeArinze ChisomNo ratings yet

- Tag&Rename 3.4 User Manual PDFDocument40 pagesTag&Rename 3.4 User Manual PDFtml3nrNo ratings yet

- Tis 739 2555Document25 pagesTis 739 2555Renz Roger BuendichoNo ratings yet

- MEP Planning Mannual-5-7Document3 pagesMEP Planning Mannual-5-7mohamed nouhNo ratings yet

- Texturado para EstucosDocument33 pagesTexturado para EstucosMarceloing1976No ratings yet

- Gyrocompass Navigat X MK1 ManualDocument180 pagesGyrocompass Navigat X MK1 Manualregaccfr3No ratings yet

- 2mag Mix 4 MsDocument1 page2mag Mix 4 MskulathuiyerNo ratings yet

- 2mag Mix 4 Ms PDFDocument1 page2mag Mix 4 Ms PDFkulathuiyerNo ratings yet

- Elregaily 20Document7 pagesElregaily 20giribabukandeNo ratings yet

- Three Reasons Why Signal Processing Is The Career of The FutureDocument2 pagesThree Reasons Why Signal Processing Is The Career of The Futurecoep05No ratings yet

- Vijamukhi - The IL DisassemblerDocument541 pagesVijamukhi - The IL Disassemblervs_crniNo ratings yet

- A Note On The Derivation of The Derivatives of Invariants of Stretch Tensor To The Right Cauchy-GreenDocument5 pagesA Note On The Derivation of The Derivatives of Invariants of Stretch Tensor To The Right Cauchy-GreenZAARAOUI MohamedNo ratings yet

- Barsmanual Russian 2019july A4 PDFDocument1 pageBarsmanual Russian 2019july A4 PDFАвтопідбір UANo ratings yet

- 1.1 Review of Functions - MTH 191, Section 05, Spring 2022 WebAssignDocument1 page1.1 Review of Functions - MTH 191, Section 05, Spring 2022 WebAssignL. AbedNo ratings yet

- PL - 2100 2Document3 pagesPL - 2100 2AlineNo ratings yet

- CF9001 General Service ManualDocument177 pagesCF9001 General Service ManualMarck JunoNo ratings yet

- Divided States: Strategic Divisions in EU-Russia RelationsFrom EverandDivided States: Strategic Divisions in EU-Russia RelationsNo ratings yet

- Design of a Single Well Bioreactor-Incubator System with Sterile Nutrient Media SupplyFrom EverandDesign of a Single Well Bioreactor-Incubator System with Sterile Nutrient Media SupplyNo ratings yet

- Exhibitors + Products: Offline AttendanceDocument1 pageExhibitors + Products: Offline AttendanceYusuf KarimNo ratings yet

- Thank You: Your Subscription From Google Ireland Limited On Google Play Continues and You've Been Charged.Document2 pagesThank You: Your Subscription From Google Ireland Limited On Google Play Continues and You've Been Charged.Yusuf KarimNo ratings yet

- Siltlc: CoryeghDocument3 pagesSiltlc: CoryeghYusuf KarimNo ratings yet

- Cefla Sorbini T20/ 2MF: Send InquiryDocument1 pageCefla Sorbini T20/ 2MF: Send InquiryYusuf KarimNo ratings yet

- 2 Ways To Avail Our Services 2 Ways To Avail Our Services: QuestionsDocument1 page2 Ways To Avail Our Services 2 Ways To Avail Our Services: QuestionsYusuf KarimNo ratings yet

- High-Quality E-Motor Lamination and E-Core Stacks: Key Technologies. We'Ve Mastered Them AllDocument1 pageHigh-Quality E-Motor Lamination and E-Core Stacks: Key Technologies. We'Ve Mastered Them AllYusuf KarimNo ratings yet

- Sales Order: Order No From Order Date No of Packages Payment Term Index System India PVT LTDDocument1 pageSales Order: Order No From Order Date No of Packages Payment Term Index System India PVT LTDYusuf KarimNo ratings yet

- Assen NL: Attention, Please!Document1 pageAssen NL: Attention, Please!Yusuf KarimNo ratings yet

- Credit/debit Card: Cash: by Visiting One of Our: Click Here Sales Shops Cash Collection PartnersDocument1 pageCredit/debit Card: Cash: by Visiting One of Our: Click Here Sales Shops Cash Collection PartnersYusuf KarimNo ratings yet

- UntitledDocument1 pageUntitledYusuf KarimNo ratings yet

- 2018 SH-ACL LC-3015Fb 4-Fold Decoiler, Infeed System and Leveling / Cutting MachineDocument1 page2018 SH-ACL LC-3015Fb 4-Fold Decoiler, Infeed System and Leveling / Cutting MachineYusuf KarimNo ratings yet

- मतदाता सूचना/Voter InformationDocument1 pageमतदाता सूचना/Voter InformationYusuf KarimNo ratings yet

- UntitledDocument1 pageUntitledYusuf KarimNo ratings yet

- Daily Progress Report: SI Number: RIG PDSI#403/DS1500.EDocument71 pagesDaily Progress Report: SI Number: RIG PDSI#403/DS1500.EAgung Tri SugihartoNo ratings yet

- IndustrialDocument2 pagesIndustrialPedro LopesNo ratings yet

- Copper-Nickel Alloys, Properties and ApplicationsDocument28 pagesCopper-Nickel Alloys, Properties and Applicationsismail hakimNo ratings yet

- Ashby, Michael F. - Materials Selection in Mechanical Design-Elsevier (2011)Document22 pagesAshby, Michael F. - Materials Selection in Mechanical Design-Elsevier (2011)ritzky fachriNo ratings yet

- NCP Reverse Engineering Capabilities & RafDocument21 pagesNCP Reverse Engineering Capabilities & Rafnevin KhedooNo ratings yet

- Welding of Medium - High Carbon Steels and Special Steels - Education Center - KOBELCO - KOBE STEEL, LTD.Document4 pagesWelding of Medium - High Carbon Steels and Special Steels - Education Center - KOBELCO - KOBE STEEL, LTD.ds5aqdnaver.comNo ratings yet

- 1 DesignDocument54 pages1 DesignDr. Aung Ko LattNo ratings yet

- Complete BOP Stack SpaceoutDocument10 pagesComplete BOP Stack SpaceoutAderobaki GbengaNo ratings yet

- Manual PR Seal Gasket Dryer Comeesa Line 1 EdiDocument4 pagesManual PR Seal Gasket Dryer Comeesa Line 1 EdiRizal SetiawanNo ratings yet

- Multichoice Paper OneDocument4 pagesMultichoice Paper OneAhmed ShakirNo ratings yet

- Sarissa Tabletop SystemDocument12 pagesSarissa Tabletop Systemeuclideb40No ratings yet

- Elastotet Windshield PU 230Document2 pagesElastotet Windshield PU 230victorNo ratings yet

- Plastering: Ashwin JoshiDocument15 pagesPlastering: Ashwin JoshiVarunNo ratings yet

- Different Paper and UseDocument6 pagesDifferent Paper and UsePavan SamudralaNo ratings yet

- Float ClearDocument2 pagesFloat ClearynmoihcppwlkaizbciNo ratings yet

- Proto - Welds - Application - iXRDDocument4 pagesProto - Welds - Application - iXRDcelestino biasottoNo ratings yet

- FOSROCTechnicalBulletin CuringCompoundsDocument6 pagesFOSROCTechnicalBulletin CuringCompoundsmalak hindiNo ratings yet

- Capstan and Turret Lathe NotesDocument10 pagesCapstan and Turret Lathe NotesR.PalaniNo ratings yet

- Introducción WPS ISODocument41 pagesIntroducción WPS ISOCarlos Eduardo Castillo LanderosNo ratings yet

- Check ListDocument3 pagesCheck Listdipl labNo ratings yet

- Konkreto SP561 TDSDocument2 pagesKonkreto SP561 TDSuchennaNo ratings yet

- 4D Printing Part1Document4 pages4D Printing Part1raghavaraoNo ratings yet

- Book FrictionStir WeldingDocument239 pagesBook FrictionStir WeldingKaushik SenguptaNo ratings yet

- 4Document7 pages4امجد عباس حاجم بريديNo ratings yet

- 3.1 1P SL CutoutDocument1 page3.1 1P SL CutoutSalman AlyazouriNo ratings yet

- Polyfluo 523XF TDSDocument1 pagePolyfluo 523XF TDSsangtnguyenNo ratings yet

- Fence BOMDocument5 pagesFence BOMMercy GomezNo ratings yet

- aa81368e345707e221d018f149fe283a (1) (2)Document342 pagesaa81368e345707e221d018f149fe283a (1) (2)love buddhdev100% (1)

- Nanocomposites N B Singh Full ChapterDocument67 pagesNanocomposites N B Singh Full Chapterjustin.downs797100% (14)

- Tuff Stuff: Item #1284 & #1285Document3 pagesTuff Stuff: Item #1284 & #1285joeyNo ratings yet