Professional Documents

Culture Documents

Overhaul Procedure For Cargo Oil Pump Turbine: A) Turbine Casing Cover

Overhaul Procedure For Cargo Oil Pump Turbine: A) Turbine Casing Cover

Uploaded by

dindin66660 ratings0% found this document useful (0 votes)

23 views3 pagesThe document provides an overview of the overhaul procedure for a cargo oil pump turbine. It outlines removing the turbine casing cover and reduction gear box cover. It then details removing the turbine rotor and wheel gear, including lifting tools, bearing caps, and thrust metals. Finally, it mentions cleaning the turbine casing, cover, gear box, and cover surfaces. The procedure emphasizes gradual, careful removal and cleaning of parts to avoid damage.

Original Description:

Original Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides an overview of the overhaul procedure for a cargo oil pump turbine. It outlines removing the turbine casing cover and reduction gear box cover. It then details removing the turbine rotor and wheel gear, including lifting tools, bearing caps, and thrust metals. Finally, it mentions cleaning the turbine casing, cover, gear box, and cover surfaces. The procedure emphasizes gradual, careful removal and cleaning of parts to avoid damage.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

23 views3 pagesOverhaul Procedure For Cargo Oil Pump Turbine: A) Turbine Casing Cover

Overhaul Procedure For Cargo Oil Pump Turbine: A) Turbine Casing Cover

Uploaded by

dindin6666The document provides an overview of the overhaul procedure for a cargo oil pump turbine. It outlines removing the turbine casing cover and reduction gear box cover. It then details removing the turbine rotor and wheel gear, including lifting tools, bearing caps, and thrust metals. Finally, it mentions cleaning the turbine casing, cover, gear box, and cover surfaces. The procedure emphasizes gradual, careful removal and cleaning of parts to avoid damage.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

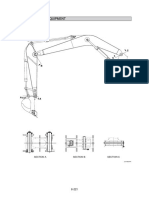

Overhaul Procedure for Cargo Oil Pump Turbine

It has been mention about overhaul procedure for Cargo oil pump turbine.

Please be careful and caution the "※" marks.

A) Turbine casing cover

1) Remove the lagging

2) Remove the gland steam drain pipe (Position is labyrinth packing)

3) Remove the taper pin and tightening bolt for turbine casing cover

4) Lifting preparation for turbine casing cover

a) Install the chain block at casing cover eye bolt

b) Install the guide bolt at 2 position bolt hole (Guide bolt is including in tools box)

5) Gradually tighten the jacking up bolts

6) Remove the turbine casing cover

※ Turbine casing cover shall be maintained vertical position and pulling out gradually.

※ Please be carful that the nozzles and labyrinth packing doesn't touch at turbine blade.

B) Reduction gear box cover

1) Remove the thermometer gauge

2) Remove the taper pin and tightening bolt

※ Must be removing the bottom flange bolt for pinion shaft, top flange and main L.O. pump

tightening bolt for wheel gear

3) Disconnect the flexible tube for trip device(2 position)

※ Check whether no remaining bolts.

4) Remove the adjusting liner for gear cover pedestal

※ Some jacking up the both side bolts and remove the adjusting liner,

and jacking up bolts make free after liner removed.

5) Gradually tighten the jacking up bolts and open the gear box cover

6) Disconnect the coupling bolts between wheel and bulkhead stuffing box

7) Remove the axial displacement sensor form bottom flange, and sensor protect by plastic bag

※ Please be careful to touch it and don't damage to sensore.

2)※

7) 4)

C) Turbine rotor and wheel gear

Please don't touch the coupling bolt(1449) and never remove it.

1) Remove the top bearing housing

2) Remove the all split pin for bearing cap

3) Install the eye nut of turbine rotor lifting tool on rotor top (Eye nut is including the tools box)

4) Install the eye nut for wheel lifting tool on gear top (Eye nut is including the tools box)

5) Prepare the chain block, and lifting perform by using turbine rotor eye nut

and wheel gear eye nut

6) Remove the bearing cap nut and bearing cap for turbine top, pinion upper and lower

※ Nut return to same position and don't mix.

※ Bearing cap use lifting bolt and remove (Lifting bolt is including the tools box)

7) Remove the thrust metal for turbine rotor

a) Remove the thrust metal(2118)

b) Turbine shaft is some lifting up(0.05~0.1mm) by chain block and remove

the thrust metal(2117)

8) Pull out the turbine rotor with pinion gear from casing

Wheel gear is turning slowly when turbine rotor pull out

※ Turbine rotor shall be maintained vertical position during pulling out.

※ Please be carful that the turbine blade doesn't touch at each part(labyrinth packing,

steam guard, oil guard and thrust collar) because those clearance are narrow.

9) Remove the bearing cap nut and bearing cap for wheel upper and lower

※ Nut return to same position and don't mix.

Bearing cap use lifting bolt and remove (Lifting bolt is including the tools box)

10) Remove the thrust metal for wheel gear

a) Remove the thrust metal(2120)

b) Turbine shaft is some lifting up(0.05~0.1mm) by chain block and remove

the thrust metal(2119)

11) Pull out the wheel gear from gear box

※ Wheel gear shall be maintained vertical position during pulling out.

D) Cleaning

1) Cleaning the surface for turbine casing & cover, reduction gear box & cover

(Use sandpaper and scotch bright)

2) Cleaning the turbine casing internal and reduction gear box internal if necessary

You might also like

- INA Repair Manual GearBOX VW-02J 210x297 en Black PDFDocument32 pagesINA Repair Manual GearBOX VW-02J 210x297 en Black PDFEmilioGastón50% (2)

- Cylinder Head 3sfeDocument27 pagesCylinder Head 3sfePham Huy83% (18)

- Vauxhall Workshop Manuals Astra H J Engine and Engine Aggregates DOHC Petrol Engine Cylinder Head Repair Instructions Valve Lash - Petrol Engine Check and Adjust PDFDocument26 pagesVauxhall Workshop Manuals Astra H J Engine and Engine Aggregates DOHC Petrol Engine Cylinder Head Repair Instructions Valve Lash - Petrol Engine Check and Adjust PDFSean Osborne0% (1)

- Repair Manual Ford DPS6 Gearbox INADocument24 pagesRepair Manual Ford DPS6 Gearbox INASamuel88% (8)

- T 176Document9 pagesT 176ashkansoheylNo ratings yet

- Toyota Corolla+c52 Shift ManualDocument221 pagesToyota Corolla+c52 Shift Manualdaswine100% (4)

- 42rle 4 Speed: RemovalDocument43 pages42rle 4 Speed: RemovalKelvin Samuel Chirinos ChirinosNo ratings yet

- SM - Volvo Ec210b LC Ec210blc ExcavatorDocument18 pagesSM - Volvo Ec210b LC Ec210blc ExcavatorNikitko Dmitry33% (3)

- Generator Rotor RemovalDocument8 pagesGenerator Rotor Removalnueste100% (1)

- 4d94e Shop ManualDocument25 pages4d94e Shop Manualyeudys100% (4)

- RB 25 HeadDocument9 pagesRB 25 HeadAlexander Dominguez0% (1)

- Remove & Install Bucket CylinderDocument8 pagesRemove & Install Bucket CylinderchanlinNo ratings yet

- Soosan Servicemanual SB GBDocument10 pagesSoosan Servicemanual SB GBvanNo ratings yet

- Drilling Engineering Year 2 Tutorial Questions For ExamDocument55 pagesDrilling Engineering Year 2 Tutorial Questions For Examshanecarl100% (1)

- Overhaul Procedure For Cargo Oil PumpDocument1 pageOverhaul Procedure For Cargo Oil Pumpdindin6666No ratings yet

- Timing Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalDocument7 pagesTiming Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalPablo FernandezNo ratings yet

- Manual Desarmado y Armado - Bomba Cat 3406Document39 pagesManual Desarmado y Armado - Bomba Cat 3406Gallego Carlos100% (1)

- Assembly and Disassembly of Screw Type CompressorDocument16 pagesAssembly and Disassembly of Screw Type Compressorhitesh bhoiNo ratings yet

- Desensamble de Caja de Transferencia Hilux Vf2cmDocument20 pagesDesensamble de Caja de Transferencia Hilux Vf2cmromuloNo ratings yet

- EC210 - Track Motor, DisassemblyDocument14 pagesEC210 - Track Motor, DisassemblyPreett Rajin MenabungNo ratings yet

- Remove and Install Torque Divider 3113-010Document19 pagesRemove and Install Torque Divider 3113-010Milton Hernandez PérezNo ratings yet

- O. Crankcase DisassemblyDocument14 pagesO. Crankcase DisassemblyRinso PietersmaNo ratings yet

- 2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci ÓnDocument8 pages2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci Óncarlos Gutierrez De La HozNo ratings yet

- D Transmission2010Document37 pagesD Transmission2010Akrae AcrNo ratings yet

- Toyota Matrix L4 2008Document16 pagesToyota Matrix L4 2008Gesco EscobarNo ratings yet

- SOP Reach Stacker01Document7 pagesSOP Reach Stacker01vozefjadav100% (1)

- Dismantling and Assembling Output ShaftDocument10 pagesDismantling and Assembling Output ShaftBalogh SzabolcsNo ratings yet

- Steering Axle: Safety Precautions Maintenance and RepairDocument9 pagesSteering Axle: Safety Precautions Maintenance and RepairPhilip Peter HanssenNo ratings yet

- Maag Gear Box Wpu 182fDocument188 pagesMaag Gear Box Wpu 182fMahmoud Mohammad60% (5)

- Centrifugal Pump Dismantling ProcedureDocument1 pageCentrifugal Pump Dismantling ProcedureBv RaoNo ratings yet

- Hyundai 999Document55 pagesHyundai 999Said GedeonNo ratings yet

- 841 - Pdfsam - SM PC300LC, HD-8 A90001, A87001 Up CEBM018701Document80 pages841 - Pdfsam - SM PC300LC, HD-8 A90001, A87001 Up CEBM018701jaime bolivarNo ratings yet

- Impak 2Document11 pagesImpak 2Vasudev AgrawalNo ratings yet

- 07K Manifold IEIMVB1 IEIMVB2 Install GuideDocument18 pages07K Manifold IEIMVB1 IEIMVB2 Install GuideEmmanuel HernandezNo ratings yet

- Disassembling: 1. Fix SUPPLY PumpDocument10 pagesDisassembling: 1. Fix SUPPLY PumpSatria Fajri100% (1)

- XL Series Actuators 1: Installation, Operating and Maintenance InstructionsDocument8 pagesXL Series Actuators 1: Installation, Operating and Maintenance InstructionsFranco M. CaverzanNo ratings yet

- Caterpillar Cat 245B EXCAVATOR (Prefix 1SJ) Service Repair Manual (1SJ00001-00712)Document24 pagesCaterpillar Cat 245B EXCAVATOR (Prefix 1SJ) Service Repair Manual (1SJ00001-00712)rpoy9396615No ratings yet

- Group 11 Work Equipment: 1. StructureDocument4 pagesGroup 11 Work Equipment: 1. StructureJorge Iván Villaseñor LozanoNo ratings yet

- Acura TSX Sport Wagon L4-2.4L 2011 Timing Chain: Service and RepairDocument11 pagesAcura TSX Sport Wagon L4-2.4L 2011 Timing Chain: Service and RepairCarlos Gunter Tamayo MoralesNo ratings yet

- Remove and Install StickDocument5 pagesRemove and Install StickYurii ChinovNo ratings yet

- Sti Timing Belt InstructionsDocument19 pagesSti Timing Belt InstructionsPablo DpNo ratings yet

- Fork Strip ExtractDocument24 pagesFork Strip Extract张连杉No ratings yet

- EW210D - Axle, RemovingDocument4 pagesEW210D - Axle, RemovingMaintenance KPBNo ratings yet

- Timing Chain: Service and Repair RemovalDocument4 pagesTiming Chain: Service and Repair RemovalCris MOnteroNo ratings yet

- Fuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Document9 pagesFuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Hammam al HammamNo ratings yet

- Fuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Document9 pagesFuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Hammam al HammamNo ratings yet

- Group 11 Work EquipmentDocument4 pagesGroup 11 Work EquipmentTaha RdmanNo ratings yet

- Remo TBDocument5 pagesRemo TBTyler MacNo ratings yet

- 2013-2015 FIT CTD Cartridge Rebuild - Bike Help Center - FOXDocument36 pages2013-2015 FIT CTD Cartridge Rebuild - Bike Help Center - FOXYadi RomaNo ratings yet

- Military 14 Bolt Axle ManualDocument29 pagesMilitary 14 Bolt Axle ManualCAP History Library67% (6)

- Powerfist 208cc Disassembly InstructionsDocument12 pagesPowerfist 208cc Disassembly Instructionscristiandawson0No ratings yet

- 2012 Fork Service ManualDocument36 pages2012 Fork Service ManualFer SabidongNo ratings yet

- 6.0L Turbo Rebuild Instructions PDFDocument5 pages6.0L Turbo Rebuild Instructions PDFW MoralesNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Tugas FISIKA IDocument3 pagesTugas FISIKA Idindin6666No ratings yet

- Sealant For Thermal Spray CoatingsDocument2 pagesSealant For Thermal Spray Coatingsdindin6666No ratings yet

- Decoking Control Valve: Www. 195 West Ryan Road Oak Creek, WI 53154 414-764-7500Document6 pagesDecoking Control Valve: Www. 195 West Ryan Road Oak Creek, WI 53154 414-764-7500dindin6666No ratings yet

- Rayan Erdi Rabbani CVDocument1 pageRayan Erdi Rabbani CVdindin6666No ratings yet

- Surat DocumentDocument4 pagesSurat Documentdindin6666No ratings yet

- Fabrication Impeller, Wear Ring Impeller & Nut Impeller P103P509BDocument4 pagesFabrication Impeller, Wear Ring Impeller & Nut Impeller P103P509Bdindin6666No ratings yet

- P21-0161 Final Report Acm 315 Kw-LoherDocument19 pagesP21-0161 Final Report Acm 315 Kw-Loherdindin6666No ratings yet

- Datasheet Drawing CombitubeDocument4 pagesDatasheet Drawing Combitubedindin6666No ratings yet

- Turbine Auxiliaries - Arrangement of Turbine Auxiliaries - ALL ABOUT POWER PLANTDocument14 pagesTurbine Auxiliaries - Arrangement of Turbine Auxiliaries - ALL ABOUT POWER PLANTKolahalam Rakeshraju100% (1)

- Linear Bar Grille - FullDocument7 pagesLinear Bar Grille - Fullntt_121987No ratings yet

- Prestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 13Document76 pagesPrestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 13Carlos Alberto Pacheco SierraNo ratings yet

- An Overview and Thermal Analysis of Vehicle Exhaust GasketDocument7 pagesAn Overview and Thermal Analysis of Vehicle Exhaust Gasketmrcamre.plcNo ratings yet

- GB MA BA WA 2.5 Stand-2020-01Document37 pagesGB MA BA WA 2.5 Stand-2020-01NickNo ratings yet

- FTM HFV HiltiDocument5 pagesFTM HFV HiltiPrabartak Das100% (1)

- Kinetics of Electrode Reactions (Ch. 3)Document21 pagesKinetics of Electrode Reactions (Ch. 3)GIRMA SELALE GELETANo ratings yet

- Matrix Methods For Optical LayoutDocument133 pagesMatrix Methods For Optical LayoutAmaniDarwishNo ratings yet

- Fundamentals of Solidification in Aluminum Castings: Geoffrey K. SigworthDocument14 pagesFundamentals of Solidification in Aluminum Castings: Geoffrey K. SigworthMohmal AhmedNo ratings yet

- STE Electronics MELCsDocument4 pagesSTE Electronics MELCsNathalie Garmeles MiñosaNo ratings yet

- CBSE CBSE Class 9 NCERT Solution Science Force Laws of MotionDocument16 pagesCBSE CBSE Class 9 NCERT Solution Science Force Laws of MotiondashNo ratings yet

- HeatTransferApplicationLibraryManual PDFDocument1,020 pagesHeatTransferApplicationLibraryManual PDFhend faiadNo ratings yet

- Pressure-Enthalpy Diagrams: Aturation Ubcooling AND UperheatDocument35 pagesPressure-Enthalpy Diagrams: Aturation Ubcooling AND UperheatAbdul RahmanNo ratings yet

- Steen e Ken 1989Document20 pagesSteen e Ken 1989suryakantNo ratings yet

- Cont OvenDocument10 pagesCont OvenSengupta VivekNo ratings yet

- Dhina Pratama Febri PPT OtjDocument15 pagesDhina Pratama Febri PPT Otjyapp GndnNo ratings yet

- Layout Inspection Result Sheet: PQE:01:F07 (PG 1 /)Document3 pagesLayout Inspection Result Sheet: PQE:01:F07 (PG 1 /)Fortune FireNo ratings yet

- 3 Gaseous Exchange Through The Respiratory Membrane.Document23 pages3 Gaseous Exchange Through The Respiratory Membrane.Ahmed AliNo ratings yet

- Boiler Water TestDocument8 pagesBoiler Water TestMohammad Jahid AlamNo ratings yet

- Shallow Hazards: Shallow Drilling Hazard AssessmentDocument5 pagesShallow Hazards: Shallow Drilling Hazard AssessmentTiffany DacinoNo ratings yet

- Settlement CalculationDocument3 pagesSettlement Calculationjibeesh cm100% (2)

- Gyroscopic Forces Modeled in AnsysDocument92 pagesGyroscopic Forces Modeled in AnsysGiuseppe Failla100% (1)

- WELDING SPREADER Electrode KALMAR PDFDocument1 pageWELDING SPREADER Electrode KALMAR PDFArtin HykoNo ratings yet

- Slender Walls (James E. Amrhein)Document3 pagesSlender Walls (James E. Amrhein)Cesar RjszvlNo ratings yet

- Winprop PDFDocument296 pagesWinprop PDFNabajit BaruahNo ratings yet

- Deflection of Beams - Chapter 12Document17 pagesDeflection of Beams - Chapter 12ezoramajnunNo ratings yet

- Analisa Karakteristik Getaran Pada Mesin Asphalt Mixing Plant Tipe Apollo An1Document7 pagesAnalisa Karakteristik Getaran Pada Mesin Asphalt Mixing Plant Tipe Apollo An1wilson sebastianNo ratings yet

- Exam Style Answers 31 Asal Physics CBDocument2 pagesExam Style Answers 31 Asal Physics CBAnshul ShahNo ratings yet

- Mathcad - 2019 SoilTypeDocument6 pagesMathcad - 2019 SoilTypeMikael Rafael KusnadiNo ratings yet