Professional Documents

Culture Documents

Submittal Data Sheet

Submittal Data Sheet

Uploaded by

ErickOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

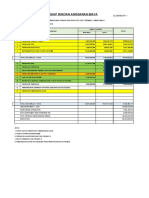

Submittal Data Sheet

Submittal Data Sheet

Uploaded by

ErickCopyright:

Available Formats

Submittal Data Sheet

Job or Customer:

Engineer:

Contractor:

Submitted by:

Date

Approved by:

Date

Order No:

Date

Specification:

Installation Date:

< STANDARDS >

D1784, F437,

introduction

IPEX BlazeMaster® pipe and fittings are designed specifically for fire sprinkler

F438, F439,

F442

systems. They are made from a specialty thermoplastic known chemically

as post-chlorinated polyvinyl chloride (CPVC). IPEX BlazeMaster pipe and

fittings provide unique advantages in sprinkler installations including superior

1821 hydraulics, ease of joining, increased hanger spacing in comparison to other

1887

thermoplastics and ease of assembly. They also are based on a technology

with a continuous and proven service history of more than 40 years.

C199 P-M

Fire Performance

BlazeMaster is made with CPVC which offers an even greater fire safety profile

than PVC. Like PVC, CPVC will not independently support combustion, and as

such will not burn once the flame source is removed. CPVC’s ignition resistance

is demonstrated by its flash ignition temperature of 900°F.

CPVC also has a low flame spread. In addition, it provides outstanding smoke

characteristics. In testing conducted to CAN/ULC S102.2, CPVC showed a

13, 13R

13D, 90A flame spread of less than 15, and a smoke-developed classification of 15. And,

24 like PVC, CPVC has a fuel contribution of 0.

BlazeMaster® is manufactured by IPEX USA LLC. and distributed in Canada by IPEX Inc.

BlazeMaster® is a registered trademark of the Lubrizol Corporation.

Canada: Website: ipexna.com • Toll Free: 866-473-9462

© 2019 IPEX DS BlazeMaster:C 1 of 8

Submittal Data Sheet

material properties availability

Physical & Thermal Properties of BlazeMaster CPVC Description Size (in)

Property CPVC ASTM Pipe 3/4 to 3”

Specific Gravity 1.55 D792 Fittings

IZOD Impact Strength Tee (Soc) 3/4” to 3”

3.0 D256A

(ft. lbs./inch, notched) 3/4” to 3” x 3/4”

Reducing Tee (Soc)

Modulus of Elasticity, @ 73°F, psi 4.23 x 105 D638 3” x 3/4” to 2-1/2”

Ultimate Tensile Strength, psi 8,400 D638 Sprinkler Head Adapter Tee 3/4” to 2” x 3/4”

Compressive Strength, psi 9,600 D695 (Soc x Soc x SST FPT) 2” x 1/2”

Poisson’s Ratio .35 - .38 - Sprinkler Head Adapter Tee

1/2” x 1/2” 1”

(FPT x FPT x Soc)

Working Stress @ 73°F, psi 2,000 D1598

90° Elbow (Soc) 3/4” - 3”

Hazen-Williams C Factor 150 _

Sprinkler head Adapter 90° Elbow 3/4” to 1-1/4” x 1/2” to

Coefficient of Linear Expansion

3.4 x 10-5 D696 (Soc x SST FPT) 3/4”

in./(in.°F)

45° Elbow (Soc) 3/4” to 3”

Thermal Conductivity BTU/hr./

0.95 C177 Cross (Soc) 3/4” to 2-1/2”

ft.2/°F/in.

Limiting Oxygen Index 60% D2863 Coupling (Soc) 3/4” to 3”

Electrical Conductivity Non Conductor Grooved Adapter Coupling

1-1/4” to 3”

(Soc x Groove)

Female Adaptor (Soc x SST FPT) 3/4” to 2”

Sprinkler Head Adaptor 3/4” to 1-1/4” x 1/2” to

(Soc x SST FPT) 3/4”

Sprinkler Head Adaptor

3/4” to 1” x 1/2”

(Sp x SST FPT)

Reducer Bushing (Spig x Soc) 1” to 3” x 3/4” to 2-1/2”

Cap (Soc) 3/4” to 3”

Union (Soc) 3/4” to 2”

One Piece Flange (Soc) 3/4” to 3”

Canada: Website: ipexna.com • Toll Free: 866-473-9462

© 2019 IPEX DS BlazeMaster:C 2 of 8

Handling & Installation Procedures

Outdoor Installations nominal size of the pipe diameter.

IPEX BlazeMaster pipe and fittings are not listed for exposed, Apply a heavy, even coat of cement

outdoor applications. to the outside pipe end. Apply a

medium coat to the fitting socket.

Pipe sizes 1-1/4” (32 mm) and above

Joining IPEX BlazeMaster Pipe and Fittings with shall always receive a second

Red One Step Solvent Cement cement application on the pipe

end. (Apply cement on the pipe

Note: BlazeMaster BM-5 One Step Cement requires no cleaner

end, in the fitting socket, and on

or primer. Refer to individual manufacturers’ installation

the pipe again.) Only use solvent

instructions.

cements that have been specifically

investigated and tested for use with

Cutting BlazeMaster CPVC systems and

approved by the pipe and fitting

IPEX BlazeMaster pipe can be easily cut with a sharp ratchet

manufacturer. Too much cement

cutter (except at temperatures

can cause clogged waterways. Do

below 10ºC (50ºF)), a wheel-type

not allow excess cement to puddle in

plastic tubing cutter, a power saw

the pipe and fitting assembly.

or a fine toothed saw. To ensure

the pipe is cut square, a miter box Special care shall be exercised when

is recommended when using a saw. assembling BlazeMaster systems in

A square cut provides the surface extremely low temperatures (below

of the pipe with maximum bonding 4°C (40ºF)) or extremely high temperatures (above 38°C (100ºF)).

area. If any indication of damage or Extra set time shall be allowed in colder temperatures. When

cracking is evident at the pipe end, cementing pipe and fittings in extremely cold temperatures,

cut off at least 50.8 mm (2”) beyond make certain that the cement has not “gelled”. Gelled cement

any visible crack. must be discarded. In extremely hot temperatures, make sure

both surfaces to be joined are still wet with cement when

putting them together.

Deburring

Burrs and filings can prevent proper

contact between pipe and fitting Assembly

during assembly, and must be After applying cement, immediately insert the pipe into

removed from the outside and the the fitting socket, while rotating the pipe one-quarter turn.

inside of the pipe. A chamfering Properly align the fitting for the installation at this time. Pipe

tool or a file is suitable for this must bottom to the stop. Hold the assembly for 10 to 15

purpose. A slight bevel shall be placed at seconds to ensure initial bonding. A bead of cement should be

the end of the pipe to ease entry of the pipe evident around the pipe and fitting juncture. If this bead is not

into the socket and minimize the chances of continuous around the socket shoulder, it may indicate that

wiping solvent cement from the fitting during insufficient cement was applied.

insertion.

Fitting Preparation

Using a clean, dry rag, wipe loose dirt and moisture from the

fitting socket and pipe end. Moisture can slow the cure time

and at this stage of assembly, excessive water can reduce

joint strength. Check the dry fit of the pipe and fitting. The pipe

should enter the fitting socket easily 1/4 to 3/4 of the way. At

this stage, the pipe should not bottom out in the socket.

Solvent Cement Application

Joining surfaces shall be penetrated and softened. Cement

shall be applied (worked into pipe) with an applicator half the

Canada: Website: ipexna.com • Toll Free: 866-473-9462

© 2019 IPEX DS BlazeMaster:C 3 of 8

Handling & Installation Procedures

If insufficient cement is applied, the fitting must be cut out and

discarded. Table I: 552 kPa (225 psi) Test Pressure (maximum)

Ambient Temperature During Cure Period

Cement in excess of the bead can be wiped off with a rag.

Care shall be exercised when installing sprinkler heads. Pipe Size Temperature

Sprinkler head fittings shall be allowed to cure for a minimum of

16°C to 49°C > 4.4°C >17.8°C

30 minutes prior to installing the sprinkler head. When installing inches mm

sprinkler heads, be sure to anchor or hold the pipe drop (60°F to 120°F) (> 40°F) (> 0°F)

securely to avoid rotating the pipe in previously cemented 3/4 20 1 hr 4 hrs 48 hrs

connections. Previously cemented fittings shall also be 1 25 1-1/2 hrs 4 hrs 48 hrs

permitted to cure for a minimum of 30 minutes.

1-1/4 32 & 40 3 hrs 32 hrs 10 days

Warning: Sprinkler heads shall be installed only after all the 2 50 8 hrs 48 hrs Note 1

CPVC pipe and fittings, including the sprinkler head adapters,

are solvent welded to the piping and allowed to cure for 2-1/2 & 3 65 & 80 24 hrs 96 hrs Note 1

a minimum of 30 minutes. Sprinkler head fittings should be

Note: Cure times indicated in Table 1 are to be used for all

visually inspected and probed with a wooden dowel to ensure

that the water way and threads are clear of any excess LPCB approved pipe and fitting joints.

cement. Once the installation is complete and cured per Table

I, II or III, the system shall be hydrostatically tested. Sprinklers Table II: 1379 kPa (200 psi) Test Pressure (maximum)

shall not be installed in the fittings prior to the fittings being Ambient Temperature During Cure Period

cemented in place.

Pipe Size Temperature

Note: Safety and Health Precautions. Prior to using CPVC

solvent cements, review and follow all precautions found on 16°C to 49°C > 4.4°C >17.8°C

inches mm

the container labels, material safety data sheet, and Standard (60°F to 120°F) (> 40°F) (> 0°F)

Practice for Safe Handling ASTM F 402. 3/4 20 45 mins 1-1/2 hrs 48 hrs

1 25 45 mins 1-1/2 hrs 48 hrs

Set and Cure Times 1-1/4 32 & 40 1-1/2 hrs 16 hrs 10 days

Solvent cement set and cure 2 50 6 hrs 36 hrs Note 1

times are a function of pipe size,

2-1/2 & 3 65 & 80 8 hrs 72 hrs Note 1

temperature, relative humidity,

and tightness of fit. Curing time

is faster for drier environments, Table III: 690 kPa (100 psi) Test Pressure (maximum)

smaller pipe sizes, higher Ambient Temperature During Cure Period

temperatures and tighter fits.

The assembly must be allowed Pipe Size Temperature

to set, without any stress on

the joint, for 1 to 5 minutes, 16°C to 49°C > 4.4°C >17.8°C

inches mm

depending on pipe size and temperature. Following initial (60°F to 120°F) (> 40°F) (> 0°F)

set period, the assembly can be handled carefully, avoiding 3/4 20 15 mins 15 mins 30 mins

significant stresses to the joint. Refer to the following tables for

1 25 15 mins 30 mins 30 mins

minimum cure times prior to pressure testing.

1-1/4 32 & 40 15 mins 30 mins 2 hrs

Note: For these sizes, the solvent cement can be applied at

temperatures below -17.8°C (0°F), however, the sprinkler system

temperature must be raised to a temperature of 0°C (32°F) or

above and allowed to cure per the above recommendations

prior to pressure testing.

Canada: Website: ipexna.com • Toll Free: 866-473-9462

© 2019 IPEX DS BlazeMaster:C 4 of 8

Handling & Installation Procedures

Threaded Connections Flanged Connections

IPEX BlazeMaster CPVC female threaded adapters or flanges Flange Make-Up: Once a flange is joined to pipe, the method

are listed for connecting a BlazeMaster fire sprinkler system to for joining two flanges is as follows:

other materials, valves, and appurtenances.

1. Piping runs joined to the flanges must be installed in a

A thread sealant shall be used in making threaded straight line position to the flange to avoid stress at

connections. TFE (Teflon®) thread tape is the recommended the flange due to misalignment. Piping must also be

sealant. Some thread sealants other than TFE thread tape secured and supported to prevent lateral movement

contain solvents or other materials that may be damaging to that can create stress and damage the flange.

CPVC. Contact your authorized IPEX BlazeMaster distributor

or IPEX Representative for approved thread sealants. Use of 2. With gasket in place, align the bolt holes of the

thread sealants other than those approved by IPEX will void mating flanges by rotating the ring into position.

the warranty on the IPEX BlazeMaster system. (Consideration should be given to alignment of One-

Piece Flange prior to joining with pipe.)

Care shall be exercised when transitioning between IPEX

BlazeMaster pipe and fittings and metal. Care must be taken 3. Insert all bolts, washers (two standard flat washers per

to avoid over-torquing. Refer to section on instructions for bolt), and nuts.

torque requirements.

4. Make sure the faces of the mating surfaces are flush

The following is the recommended method of installation to against gasket prior to bolting down the flanges.

ensure a sound connection.

5. Tighten the nuts by hand until they are snug. Establish

a) Begin by applying 2 to 3 wraps of TFE (Teflon ) thread

® uniform pressure over the flange face by tightening

tape. the bolts in 5 ft. lb. (6.8 M Kg) increments according

to the sequence shown in Figure 8: Bol Tightening

b) Tighten the sprinkler head into the adapter taking Sequence following a 180° opposing sequence.

care not to cross-thread the fitting. (Recommended

torque values 15-25 ft/lbs) 6. Care must be taken to avoid “bending” the flange

when joining a flange to a “raised face” flange, or a

c) Two to three turns beyond finger-tight is all that wafer-style valve. Do not use bolts to bring together

improperly mated flanges.

is required to make a sound plastic threaded

connection. Caution: Over-torquing will damage the flange. Torque

given is for dry, non-lubricated bolt, standard washers,

CAUTION: Over-tightening will damage both the pipe and neoprene 3.18 mm (1/8º) thick full face gasket. If lubricant

the fitting. (non-petroleum based) is used, torque levels may vary.

Actual field conditions may require a variation in these

recommendations.

Recommended Bolt Torque

Figure 8: Flange Size Bolt Diameter Torque

Bolt Tightening

inches mm inches mm ft lbs M Kg

Sequence

3/4 - 1-1/2 19.05 - 38.10 1/2 12.70 10 - 15 13.6 - 20.3

2-3 50.80 - 76.20 5/8 15.88 20 - 30 27.1 - 40.7

Canada: Website: ipexna.com • Toll Free: 866-473-9462

© 2019 IPEX DS BlazeMaster:C 5 of 8

Handling & Installation Procedures

Grooved Coupling Adapters Penetrating Fire Rated Walls and Partitions

The following procedures are recommended for proper Before penetrating fire rated walls and partitions, consult

assembly of the Grooved Coupling Adapter. READ THESE building codes and authorities having jurisdiction in your area.

INSTRUCTIONS CAREFULLY BEFORE BEGINNING INSTALLATION. Several classified through-penetration firestop systems are

approved for use with CPVC pipe. Consult IPEX representative

1. Inspect the fittings and pipe to insure that they are for further information. Warning: Some firestop sealants or wrap

sufficiently free from indentations, projections or roll- strips contain solvents or plasticizers that may be damaging to

marks on the gasket seating areas of the fitting and CPVC. Always consult the manufacturer of the firestop material

pipe. The pipe should be squarely cut with any loose for compatibility with IPEX BlazeMaster CPVC pipe and fittings.

scale, paint and/or dirt must be removed from the

groove and seating surface. Use a standard grade E*,

EPDM compound that is suitable for wet fire sprinkler Earthquake Bracing

service. A flexible coupling shall be used with grooved Since IPEX BlazeMaster CPVC pipe is more ductile than

coupling adapters. Caution: Use of rigid style couplings metallic sprinkler pipe, it has a greater capacity to withstand

may damage the grooved coupling adapter. Consult the earthquake damage. In areas subject to earthquakes,

coupling manufacturer for proper selection. BlazeMaster fire sprinkler systems shall be designed and

braced in accordance with local codes or NFPA 13, Section 6-4

*See manufacturer for temperature ratings.

(1999 Edition).

2. Make sure the gasket is clean and free of any cracks,

When it is required to earthquake brace BlazeMaster piping,

cuts or other defects which may cause leaks. Lubricate

it is important to use fittings, fasteners or clamps that do not

the gasket with a vegetable soap-based gasket

have sharp edges or apply excessive compressive forces

lubricant. Caution: Use of petroleum based lubricants

sufficient to distort the pipe.

will damage the gasket and adapter resulting in stress

failure of the CPVC adapter. A gasket/joint lubricant is

recommended to prevent pinching the gasket and to Pressure Testing

assist in seating the gasket during the alignment process.

Once an installation is completed and cured, per the previous

Apply the appropriate lubricant to the gasket lips and

recommendations, the system should be hydrostatically (water)

exterior surface of the gasket.

pressure tested at 1379 kPa (200 psi), Table II, for 2 hours (or

3. Place the gasket over the metal pipe ends, being sure at 345 kPa (50 psi) in excess of the maximum pressure, Table

gasket lip does not overhang the pipe end. Insert I, when the maximum pressure to be maintained in the system

the CPVC grooved coupling adapter into the gasket. is in excess of 1034 kPa (150 psi) in accordance with the

Make sure that the gasket is centered between the two requirements established by NFPA Standard 13, Section 10-2.2.1

grooves. No portion of the gasket should extend into the (1999 Edition). Sprinkler systems in one- and two-family dwellings

grooves. Caution: Make sure the gasket is not pinched and mobile homes may be tested at line pressure, Table III in

between the pipe and the fitting. accordance with the requirements established by NFPA 13D,

Section 1-5.4 (1999 Edition). When pressure testing, the sprinkler

4. Place the metal housing over the gasket, making sure system shall be slowly filled with water and the air bled from

the metal housing key is into the grooves on the metal the highest and farthest sprinkler heads before pressure testing

pipe and the CPVC coupling adapter. Insert the bolts is applied. Air must be removed from piping systems (plastic

and tighten by hand. Tighten the bolts alternately and or metal) to prevent it from being locked in the system when

equally until the bolt pads are touching metal-to-metal. pressure is applied. Entrapped air can generate excessive

In completing a proper joint, the gasket is also slightly surge pressures that are potentially damaging, regardless of

compressed, adding to the strength of the seal from the the piping materials used. Air or compressed gas should never

gasket’s durometer. be used for pressure testing. If a leak is found, the fitting must

be cut out and discarded. A new section can be installed using

5. Inspect the joints before and after pressure testing. Look couplings or a union. Unions should be used in accessible areas

for gaps between the bolt pads and for housing keys only.

that are not inside the grooves.

Canada: Website: ipexna.com • Toll Free: 866-473-9462

© 2019 IPEX DS BlazeMaster:C 6 of 8

Specifications

Scope Material

This specification sheet covers IPEX Inc. requirements for for BlazeMaster CPVC SDR 13.5 Pipe are made from Lubrizol Inc.

3/4” through 3” (20 mm – 75 mm) BlazeMaster CPVC SDR 13.5 Chlorinated Polyvinyl Chloride (CPVC) raw material having

Pipe for wet pipe automatic sprinkler systems, having a rated a cell class of 23447 as defined in ASTM Standard D 1784

working pressure of 175 psi (1205 kPa) at 150°F (66°C) or 315 psi “Standard Specification for Rigid Polyvinyl Chloride (PVC)

(2172 kPa) at 73°F (22°C) and BlazeMaster CPVC Schedule 80 and Chlorinated Polyvinyl Chloride (CPVC) Compounds”. The

Fittings. The fittings, for wet pipe automatic sprinkler systems, compound is listed with NSF for potable water service.

having a rated working pressure of 175 psi (1205 kPa) at 150°F

(66°C) or 315 psi (2172 kPa) @ 73°F (22°C). These products The material has been tested in accordance with CAN/ULC

meet or exceed performance standards set by the American Standard S102.2M88 “Standard Method of Test for Surface

National Standards Institute (ANSI), the American Society for Burning Characteristics of Flooring, Floor Covering, and

Testing and Materials (ASTM), Factory Mutual Research (FM), Miscellaneous Materials and Assemblies” with the following

National Fire Protection Agency (NFPA), NSF International (NSF), results: Flame Spread 5 / Smoke Development 5-15.

Underwriters Laboratories Inc., and Underwriters’ Laboratories

BlazeMaster Schedule 80 Fittings are made from Lubrizol Inc.

of Canada (ULC).

Chlorinated Polyvinyl Chloride (CPVC) raw material having

Underwriters’ Laboratories of Canada lists BlazeMaster CPVC a cell class of 23447 as defined in ASTM Standard D 1784

Schedule 80 Fittings and BlazeMaster CPVC SDR 13.5 Pipe for “Standard Specification for Rigid Polyvinyl Chloride (PVC)

use in the following applications; Residential occupancies as and Chlorinated Polyvinyl Chloride (CPVC) Compounds”. The

defined in the Standard for Sprinkler Systems in One and Two- compound is listed with NSF for potable water service.

Family Dwellings, NFPA 13D.

Multiple residential as defined in NFPA 13R. Marking

BlazeMaster Schedule 80 Fittings and BlazeMaster CPVC SDR

Light-hazard occupancies as defined in the Standard for 13.5 Pipe are made from Lubrizol Inc. Chlorinated Polyvinyl

Installation of Sprinkler Systems, NFPA 13. BlazeMaster CPVC Chloride (CPVC) raw material having a cell class of 23447 as

Schedule 80 Fittings and BlazeMaster CPVC SDR 13.5 Pipe can defined in ASTM Standard D 1784 “Standard Specification

be used for both concealed and exposed installations. Refer to for Rigid Polyvinyl Chloride (PVC) and Chlorinated Polyvinyl

Ipex literature for any limitations. Chloride (CPVC) Compounds”. The compound is listed with NSF

for potable water service.

Dimensions

IPEX BlazeMaster pipe is produced in SDR 13.5 dimensions to

the specifications of ASTM F442. Fittings are produced to ASTM

F437, F438 pr F439 specifications depending on the size and

configuration.

Canada: Website: ipexna.com • Toll Free: 866-473-9462

© 2019 IPEX DS BlazeMaster:C 7 of 8

About IPEX

About the IPEX Group of Companies

As leading suppliers of thermoplastic piping systems, the IPEX Group of Companies provides our

customers with some of the world’s largest and most comprehensive product lines. All IPEX products

are backed by more than 50 years of experience. With state-of-the-art manufacturing facilities and

distribution centers across North America, we have established a reputation for product innovation,

quality, end-user focus and performance.

Markets served by IPEX group products are:

• Electrical systems

• Telecommunications and utility piping systems

• Tuyaux et raccords en PVC, PVCC, PP, PVDF, PE, ABS et PEX

• Industrial process piping systems

• Municipal pressure and gravity piping systems

• Plumbing and mechanical piping systems

• PE Electrofusion systems for gas and water

• Industrial, plumbing and electrical cements

• Irrigation systems

BlazeMaster® is manufactured by IPEX USA LLC. and distributed in Canada by IPEX Inc.

BlazeMaster® is a registered trademark of the Lubrizol Corporation.

This literature is published in good faith and is believed to be reliable. However, it does not represent

and/or warrant in any manner the information and suggestions contained in this brochure. Data

presented is the result of laboratory tests and field experience.

A policy of ongoing product improvement is maintained. This may result in modifications of features

and/or specifications without notice.

Canada: Website: ipexna.com • Toll Free: 866-473-9462

© 2019 IPEX DS BlazeMaster:C 8 of 8

You might also like

- CG-2019022-00 Brahma Single Waterway MonitorDocument1 pageCG-2019022-00 Brahma Single Waterway MonitorErickNo ratings yet

- TM-1840 AVEVA Catalogue (2.1) Piping Catalogues and Specifications Rev 6.0Document296 pagesTM-1840 AVEVA Catalogue (2.1) Piping Catalogues and Specifications Rev 6.0Vivek Vinayakumar100% (7)

- MIS-M-DS-04045 Closed Drain Drum Data Sheet-BDocument3 pagesMIS-M-DS-04045 Closed Drain Drum Data Sheet-Bhappale2002No ratings yet

- ADocument55 pagesAdon bowo'sNo ratings yet

- PSP Uppwd La Mep Hvac 31Document81 pagesPSP Uppwd La Mep Hvac 31Arise UP ProjectsNo ratings yet

- Offer No 763 DTD 10.03.23Document6 pagesOffer No 763 DTD 10.03.23Shahab Z AhmedNo ratings yet

- CuClad Laminates Data SheetDocument4 pagesCuClad Laminates Data SheetDenis CarlosNo ratings yet

- Taconic TSM-DS3M - All The T's and I'sDocument7 pagesTaconic TSM-DS3M - All The T's and I'sjackNo ratings yet

- Torch SealDocument2 pagesTorch Sealmk779900mkNo ratings yet

- Driscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetDocument2 pagesDriscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetmariannyNo ratings yet

- PE Media Densidad PresionesDocument2 pagesPE Media Densidad Presionesfffae123No ratings yet

- Diclad Series: Ptfe/Woven Fiberglass LaminatesDocument5 pagesDiclad Series: Ptfe/Woven Fiberglass LaminatesmaamriaNo ratings yet

- TRL19002 - Thermal heat transfer finite element analysis of flange conne...Document11 pagesTRL19002 - Thermal heat transfer finite element analysis of flange conne...Anonymous bySKOTNo ratings yet

- Use of Electric Downhole Heaters To Prevent Wax Build-Up, Offshore, West AfricaDocument19 pagesUse of Electric Downhole Heaters To Prevent Wax Build-Up, Offshore, West AfricaEnder HernandezNo ratings yet

- TDS Hips 2551Document3 pagesTDS Hips 2551jokotrianto13No ratings yet

- Technical Data Sheet: TMS-SCE-2X and TMS-SCE-3XDocument4 pagesTechnical Data Sheet: TMS-SCE-2X and TMS-SCE-3XdakidofdaboomNo ratings yet

- Proofex Torchseal 3P and 4P UAEDocument2 pagesProofex Torchseal 3P and 4P UAEhbangash2022No ratings yet

- WP025LDf TDS 062022Document1 pageWP025LDf TDS 062022rallabhandiSKNo ratings yet

- Banner Termistores QTIDocument2 pagesBanner Termistores QTIAugusto RadaelliNo ratings yet

- Pyroclad X1: Selection & Specification DataDocument6 pagesPyroclad X1: Selection & Specification DataDuongthithuydungNo ratings yet

- Engineering Manual: XXX - XXX.XXXDocument12 pagesEngineering Manual: XXX - XXX.XXXsezio81No ratings yet

- Manual Tecnico de Tuberias de PVC y CPVC-GFDocument48 pagesManual Tecnico de Tuberias de PVC y CPVC-GFluis claudio c, vieiraNo ratings yet

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Document2 pagesEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNo ratings yet

- JR CSF 09 Plumbing - IronDocument139 pagesJR CSF 09 Plumbing - Ironkhairul mizanNo ratings yet

- Simpson EtDocument3 pagesSimpson EtJohn McClaneNo ratings yet

- NEPRO Conduit Pvc1Document16 pagesNEPRO Conduit Pvc1chaouch.najehNo ratings yet

- Pipe FittingsDocument5 pagesPipe FittingsAutieri AutieriNo ratings yet

- DRISCOPLEX 6500 Tubería y AccesoriosDocument7 pagesDRISCOPLEX 6500 Tubería y AccesoriosBrayan CJNo ratings yet

- Polyflame Garden - I & IIDocument2 pagesPolyflame Garden - I & IIAbdul Jaleel MohammedNo ratings yet

- Premierflex 3000Document2 pagesPremierflex 3000mk779900mkNo ratings yet

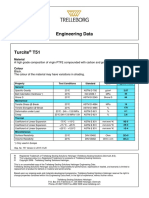

- Turcite T51 Engineering DataDocument1 pageTurcite T51 Engineering DataAntonio Rivera VillavicencioNo ratings yet

- Model WS Specific Application Window Sprinklers Horizontal and Pendent Vertical Sidewall 5.6 K-Factor General DescriptionDocument8 pagesModel WS Specific Application Window Sprinklers Horizontal and Pendent Vertical Sidewall 5.6 K-Factor General DescriptionLe DucNo ratings yet

- Window Sprinkler ProtectionDocument8 pagesWindow Sprinkler ProtectionatotiNo ratings yet

- Technical Data: 1. DescriptionDocument5 pagesTechnical Data: 1. DescriptionIskandar Zulkarnain HasibuanNo ratings yet

- Driscoplex 3100 Series Pipe Data Sheet: Property Unit Test Procedure Typical ValueDocument2 pagesDriscoplex 3100 Series Pipe Data Sheet: Property Unit Test Procedure Typical ValuemariannyNo ratings yet

- Fletchers Product-Info-Sheet-Drainage-batten-Rev0Document2 pagesFletchers Product-Info-Sheet-Drainage-batten-Rev0kresho sNo ratings yet

- Transtech Certified Fire Rated EnclosuresDocument2 pagesTranstech Certified Fire Rated EnclosuresIRCON RAPDRP Electrical ProjectsNo ratings yet

- Series LFII Residential Flush Pendent Sprinklers 4.2 K-FactorDocument8 pagesSeries LFII Residential Flush Pendent Sprinklers 4.2 K-FactorAchraf BoudayaNo ratings yet

- TECAPEI Natural (Sabic Ultem 1000 Series) 14Document1 pageTECAPEI Natural (Sabic Ultem 1000 Series) 14kgrier8966No ratings yet

- Delta PTDocument6 pagesDelta PTWK SinnNo ratings yet

- Duraplus ABS Data Sheet IpexDocument21 pagesDuraplus ABS Data Sheet IpexdodgeraganNo ratings yet

- Nexans XT Medium Voltage Single Core...Document15 pagesNexans XT Medium Voltage Single Core...Mathias CanalesNo ratings yet

- Uponor Dop Klett CPR 20 Ic 251 V 001Document3 pagesUponor Dop Klett CPR 20 Ic 251 V 001jamppajoo2No ratings yet

- EU Data Sheet Chainflex CF880Document7 pagesEU Data Sheet Chainflex CF880gaconlonton410No ratings yet

- 3M Corrosion Prevention Sealing Tape 9143FR Technical Data SheetDocument3 pages3M Corrosion Prevention Sealing Tape 9143FR Technical Data SheetRinti ArnoNo ratings yet

- k11 2Document6 pagesk11 2jeshupunkNo ratings yet

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungNo ratings yet

- Dielectric Resonators: General OverviewDocument4 pagesDielectric Resonators: General Overviewlamia97No ratings yet

- G-FIRE Figure 705 Grooved Flexible Coupling 1 Inch To 12 Inch (DN25 To DN300) - TFP1840 - 08 - 2022Document5 pagesG-FIRE Figure 705 Grooved Flexible Coupling 1 Inch To 12 Inch (DN25 To DN300) - TFP1840 - 08 - 2022Leila DinizNo ratings yet

- DPF VT1222 TyV 4.1.0. REV3 PDFDocument6 pagesDPF VT1222 TyV 4.1.0. REV3 PDFPavlo Fabres SierraltaNo ratings yet

- 4660 CNG PDFDocument2 pages4660 CNG PDFdsanabraNo ratings yet

- RF-35TC: Thermally Conductive Low Loss LaminateDocument4 pagesRF-35TC: Thermally Conductive Low Loss LaminateElectronic BoyNo ratings yet

- Detector de Calor para Zonas de Riesgo Modelo HDDocument2 pagesDetector de Calor para Zonas de Riesgo Modelo HDfuegoygas010611No ratings yet

- FirePro - Vinayaka Enterprises - HZL - 2m3 Storage Tank Area - Design Proposal - Offer 136 - 09.12.2019Document12 pagesFirePro - Vinayaka Enterprises - HZL - 2m3 Storage Tank Area - Design Proposal - Offer 136 - 09.12.2019ananthu.uNo ratings yet

- Firelock V34, K8.0 Model V3428 Quick Response: See Victaulic Publication 10.01 For More DetailsDocument4 pagesFirelock V34, K8.0 Model V3428 Quick Response: See Victaulic Publication 10.01 For More DetailscesarNo ratings yet

- Fiberlon HDDocument2 pagesFiberlon HDMohamed AmeenNo ratings yet

- EU Data Sheet Chainflex CF890Document8 pagesEU Data Sheet Chainflex CF890gaconlonton410No ratings yet

- TFP620 05 2014Document8 pagesTFP620 05 2014Furkan KadıNo ratings yet

- Betafoam XpsDocument2 pagesBetafoam Xpsirfan vpNo ratings yet

- ABS Cycolac X37Document3 pagesABS Cycolac X37countzeroaslNo ratings yet

- 18-Acoples Elastomericos LovejoyDocument70 pages18-Acoples Elastomericos LovejoyERIKSON EGUSQUIZANo ratings yet

- Tds Ral 7037 Haa Hfhr02s8Document1 pageTds Ral 7037 Haa Hfhr02s8Jaskaran SinghNo ratings yet

- PP Compound 1196nn DatasheetDocument1 pagePP Compound 1196nn Datasheetphanplastic299No ratings yet

- MSS SP 44 2019Document58 pagesMSS SP 44 2019Erick100% (1)

- Osyexp and Pibvexp Explosion Proof Supervisory SwitchDocument2 pagesOsyexp and Pibvexp Explosion Proof Supervisory SwitchErickNo ratings yet

- Fire Protection Systems: Mechanical Technical Manual SeriesDocument38 pagesFire Protection Systems: Mechanical Technical Manual SeriesErickNo ratings yet

- PS120Document4 pagesPS120ErickNo ratings yet

- PCMPKDocument3 pagesPCMPKErickNo ratings yet

- PCMSRMDocument3 pagesPCMSRMErickNo ratings yet

- Tubería AWWA C900Document3 pagesTubería AWWA C900ErickNo ratings yet

- SERIES 7000/8000: 3 Piece Full Port " - 12"Document8 pagesSERIES 7000/8000: 3 Piece Full Port " - 12"ErickNo ratings yet

- Pipe Restrainers 1000CDocument4 pagesPipe Restrainers 1000CErickNo ratings yet

- VCF01 - 350PSI Flanged Swing Check ValveDocument1 pageVCF01 - 350PSI Flanged Swing Check ValveErickNo ratings yet

- VCG01 - 350PSI Grooved-End Swing Check ValveDocument2 pagesVCG01 - 350PSI Grooved-End Swing Check ValveErickNo ratings yet

- Flowcom - Bridada y BridadaDocument1 pageFlowcom - Bridada y BridadaErickNo ratings yet

- Technical Data: Concentrate Control Valve Applications, Priming Connections and TrimsDocument8 pagesTechnical Data: Concentrate Control Valve Applications, Priming Connections and TrimsErickNo ratings yet

- Flowcom - Ranurada y BridadaDocument1 pageFlowcom - Ranurada y BridadaErickNo ratings yet

- VBW12121 - 300PSI Wafer Butterfly ValveDocument1 pageVBW12121 - 300PSI Wafer Butterfly ValveErickNo ratings yet

- Fittings For Grooved-End Pipe: FIG. 7060 FIG. 7076Document1 pageFittings For Grooved-End Pipe: FIG. 7060 FIG. 7076ErickNo ratings yet

- Flowcom - Ranurada y RanuradaDocument1 pageFlowcom - Ranurada y RanuradaErickNo ratings yet

- Product Specifications: Hole-Cut SystemDocument1 pageProduct Specifications: Hole-Cut SystemErickNo ratings yet

- VBG12121-300PSI Grooved-End Butterfly ValveDocument2 pagesVBG12121-300PSI Grooved-End Butterfly ValveErickNo ratings yet

- Fittings For Grooved-End Pipe: FIG. 7050 FIG. 7051 FIG. 7052 7052iDocument1 pageFittings For Grooved-End Pipe: FIG. 7050 FIG. 7051 FIG. 7052 7052iErickNo ratings yet

- Technical Data: Foam MakersDocument4 pagesTechnical Data: Foam MakersErickNo ratings yet

- Installation, Operation & Maintenance Manual - Original VersionDocument11 pagesInstallation, Operation & Maintenance Manual - Original VersionAli AafaaqNo ratings yet

- JSA For Blinding and De-Blinding (Opening Process Equipment)Document11 pagesJSA For Blinding and De-Blinding (Opening Process Equipment)Thái Đạo Phạm Lê100% (1)

- 701, 702 Oil Burners: Replacement PartsDocument2 pages701, 702 Oil Burners: Replacement PartsHerbert Quispe RjsNo ratings yet

- Technical Considerations in Selecting and Configuring Welded Vacuum ChambersDocument7 pagesTechnical Considerations in Selecting and Configuring Welded Vacuum ChambersVpc Ingeniería SANo ratings yet

- F607RWDocument1 pageF607RWEli Antonio Cruz FloresNo ratings yet

- Suzuki Gsx-R150/S150 Tis Full System R-77S Carbon End: 1. Product InformationDocument5 pagesSuzuki Gsx-R150/S150 Tis Full System R-77S Carbon End: 1. Product InformationCasual CasualNo ratings yet

- PDFDocument22 pagesPDFManjunath AithalNo ratings yet

- BOQ Fire SystemDocument90 pagesBOQ Fire SystemDSAKNo ratings yet

- SF - Domestic Water PipingDocument16 pagesSF - Domestic Water PipingJahat AtencioNo ratings yet

- Flex InstallDocument5 pagesFlex Installlinga007No ratings yet

- Stress Analysis of Column Piping System Using Caesar IIDocument7 pagesStress Analysis of Column Piping System Using Caesar IIHmd Mokhtari100% (1)

- UWT - Rotonivo - ManualDocument32 pagesUWT - Rotonivo - ManualTibe HoubrixNo ratings yet

- Anatomy Sluice GateDocument13 pagesAnatomy Sluice GateSohaib Ahmad MushtaqNo ratings yet

- 47 564L - VMS64 - SubmittalDocument2 pages47 564L - VMS64 - SubmittalVINOD PAULNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Metallic Pipes and Fittings - 0Document30 pagesMetallic Pipes and Fittings - 0majeedrumani0% (1)

- 2063 72040 Tipicos InstrumentacionDocument42 pages2063 72040 Tipicos InstrumentacionZillur RahmanNo ratings yet

- TODO Catalogo Tecnico 2Document67 pagesTODO Catalogo Tecnico 2Abrar HussainNo ratings yet

- Bin Activator Palamatic ProcessDocument1 pageBin Activator Palamatic ProcessMauro TognocchiNo ratings yet

- Awwa c501-1992 铸铁闸阀Document24 pagesAwwa c501-1992 铸铁闸阀allauScribd0% (1)

- Axial Expansion Joints enDocument16 pagesAxial Expansion Joints enbandithaguru6338No ratings yet

- Encoder WDG 40S: Wachendorff Automation ... Systems and EncodersDocument11 pagesEncoder WDG 40S: Wachendorff Automation ... Systems and EncodersPierre ClouNo ratings yet

- Do List PDFDocument83 pagesDo List PDFNathan Daniels100% (1)

- 03d001a BDocument4 pages03d001a BRasha AbdullahNo ratings yet

- Specification For T: 1 16.05.2020 Revised SC VB SJG 0 27.08.2015 First Issue NV US SVKDocument24 pagesSpecification For T: 1 16.05.2020 Revised SC VB SJG 0 27.08.2015 First Issue NV US SVKvishal bhamreNo ratings yet

- Erm-A Weather Louver: Materials Surface Finish AccessoriesDocument2 pagesErm-A Weather Louver: Materials Surface Finish AccessoriesLai WeikinNo ratings yet

- WeamcoMetric CatalogDocument83 pagesWeamcoMetric CatalogPustinjak SaharicNo ratings yet