Professional Documents

Culture Documents

ProductSheet MEK2500 PS2028 3 en 20201201

ProductSheet MEK2500 PS2028 3 en 20201201

Uploaded by

Papcel InstrumentOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ProductSheet MEK2500 PS2028 3 en 20201201

ProductSheet MEK2500 PS2028 3 en 20201201

Uploaded by

Papcel InstrumentCopyright:

Available Formats

Product sheet

MEK-2500 RotoForce™

Rotating Consistency Transmitter

FEATURES

▪ Rotating shear force measurement using force

balance transducer with a feedback function

▪ Versatile

▪ Reliable and well proven

▪ Precalibrated at delivery

BENEFITS

▪ Excellent accuracy, high signal to noise ratio,

and reproducibility provides best sensitivity

and very high long term stability with a

minimum of hysteresis.

Ideal for critical applications

▪ Can be used for almost all types of

consistency measurement

▪ Requires a minimum of maintenance, even in

the most demanding applications

▪ Quick and easy to start up

GENERAL / BACKGROUND The transmitter is connected with a two-wire system

The MEK-2500 is a versatile consistency transmitter for analog output. Power is supplied by a local power

that can be optimised for many different applications supply mounted in the Communication Platform.

using different components. The transmitter is A HART® Device Description (DD) enables full

suitable for applications in the entire process from the configuration of the MEK-2500 using a Universal

blow line after the digester, in screening and washing HART terminal or a PC-based AMS software.

stages, and in the bleach plant through to the The MEK-2500 is the 4th generation of rotating

machine chest before the paper machine. transmitters from BTG, and is based on the

The rotating shear force measuring method means successful and widely proven MEK rotating

the transmitter is virtually insensitive to normal transmitters, sold in more than 16.000 units. This

variations such as in fiber composition, freeness, transmitter provides even greater flexibility as a

fillers, black liquor content, flow velocity, air content, single model covers the entire consistency range, as

and pressure. well as improved stability, lower maintenance

The MEK-2500 is an intelligent, microprocessor- requirements and longer life time.

based transmitter which is fully operated using the

CPM-1300 Communication Platform. Calibration and

transmitter settings can easily be documented via a

SD- card. Use QR-code or link for more information

Communications with a Distributed Control System www.btg.com/mybtg/en/instruments/mek-2500

are made by means of a superimposed signal

according to standard HART® protocol.

BTG reserves the right to make technical improvements. Page 1

© BTG / www.btg.com ProductSheet_MEK2500_PS2028_3_En_20201201.docx

MEASURING PRINCIPLE / MEASUREMENT APPLICATION EXAMPLE

Shear force measurement using force balance BLEACH PLANT CONSISTENCY CONTROL:

principle. A shaft system is belt driven from a

synchronous electric motor. The shaft arrangement

consists of an inner-measuring shaft (4) which

rotates, within a few degrees of arc, independently of

the outer-drive shaft (3). The outer-drive shaft has a

propeller (5) which draws a continuous pulp sample

past the sensing element (6) connected to the

measuring shaft. As the sensing element in the pulp

fiber network rotates it produces a torque which

retards the measuring shaft relative to the drive shaft.

The transmitter detects the degree of retardation and

produces a feedback force to counter balance the

torque generated by the pulp fiber network. The PAPER MACHINE CONSISTENCY CONTROL:

torque/angle between the shafts is fed back and

balanced to a constant value via an electromagnetic

feedback system. The signal is then transformed to

an output signal (4-20 mA) which is calibrated and

linearized automatically against laboratory test

values. Calculations and conversions are made in

the unit’s microprocessor.

1 Electric motor

2 Gear belt transmission

3 Outer drive shaft

4 Inner measuring shaft

5 Propeller

6 Sensing element

7 Measuring chamber

8 Notched wheel on drive shaft

9 Notched wheel on inner torque shaft

10 Feedback coil

11 Pole shoe

12 Optical sensor measures angular displacement

13 Electronics

BTG reserves the right to make technical improvements. Page 2

© BTG / www.btg.com ProductSheet_MEK2500_PS2028_3_En_20201201.docx

TECHNICAL DATA / SPECIFICATIONS

Electronics:

Output signal, analog 4-20mA. Galvanically

GENERAL isolated. Current limited

Type MEK-2500 in-line rotating to min. 3.9 and max.

consistency transmitter 20.5 mA. Loop load

for pulp suspensions signal: Voltage

Manufacturer BTG Instruments AB, supply/load 24 VDC

Säffle, Sweden Output signal, digital Superimposed signal

Measuring principle Shear force over 4-20mA current loop

measurement using force according to HART®

balance transducer protocol

Consistency limits 1 – 16% fiber consistency Power consumption Max 200mA at 24VDC

Repeatability σ = 0.003% Cs Calibration sets Four separate calibration

sets, individually

Flow limits 0.5 - 5 m/s [1.6 - 16.1 fps]

programmable, and

PROCESS SPECIFICATIONS externally connectable

Process Pressure 10bar [145 psi], 16bar using a binary-coded

[230 psi] or 20bar [290 switch.

psi] depending on Alarm function Provides alarm signal on

selected transmitter low and high consistency

components levels, drive belt runtime,

Media temperature Max. 120°C / [248°F] and unstable signal.

Min. 15°C / [60°F]. Protective rating Equivalent to IP65,

Ambient temperature Transmitter: Max. 60°C / NEMA4x

[140°F] Communications Keypad and display on

Electronic box: Max. the Communication

50°C / [122°F] Platform. Universal

Material wet parts Stainless steel equiv. to HART terminal or PC

EN 1.4404/ ASTM 316L based AMS software via

or Avesta 254SMO or HART® communication

Hastelloy C depending Electric motor Squirrel cage 3-phase

on application motor, 0.3 kW 4-pole

insulation class F, wide

voltage motor, all

voltages

SAFETY & DIRECTIVES

EU-directives

Designed in accordance with relevant CE standards.

Quality Assurance

Quality-assured in accordance with ISO 9001.

YOUR LOCAL BTG OFFICE

Use QR-code or link for more information

www.btg.com/en/contact/sales-service-network

BTG reserves the right to make technical improvements. Page 3

© BTG / www.btg.com ProductSheet_MEK2500_PS2028_3_En_20201201.docx

You might also like

- RISH Delta Energy-DemandDocument8 pagesRISH Delta Energy-DemandRenato García TejadaNo ratings yet

- RAM Sequential ATPGDocument14 pagesRAM Sequential ATPGUmesh ParasharNo ratings yet

- Mek-2500 Rotoforce™: Rotating Consistency TransmitterDocument3 pagesMek-2500 Rotoforce™: Rotating Consistency TransmitterGunandar GunandarNo ratings yet

- Multi Vision 2020TG/TA: Digital Transmitters With Remote Seals For Gauge / Absolute Pressure and LevelDocument22 pagesMulti Vision 2020TG/TA: Digital Transmitters With Remote Seals For Gauge / Absolute Pressure and LevelHectorNo ratings yet

- Product Data: 8-Channel Charge Amplifier - Type 5974Document4 pagesProduct Data: 8-Channel Charge Amplifier - Type 5974jhon vargasNo ratings yet

- Epm9000 Gea12823cDocument8 pagesEpm9000 Gea12823cAulia RahmanNo ratings yet

- Catalog GTS Product 2020.R5Document24 pagesCatalog GTS Product 2020.R5markotop90No ratings yet

- ABB String Inverters: UNO-DM-3.3/3.8/4.6/5.0-TL-PLUS-US 3.3 To 5 KWDocument4 pagesABB String Inverters: UNO-DM-3.3/3.8/4.6/5.0-TL-PLUS-US 3.3 To 5 KWDS ComputersNo ratings yet

- Field Mount Flow Computer: Technology SolutionsDocument6 pagesField Mount Flow Computer: Technology SolutionsAldrin HernandezNo ratings yet

- Elmeasure Im CatalogDocument2 pagesElmeasure Im CatalogNMP Kumar UNo ratings yet

- Statcom CatologDocument6 pagesStatcom CatologPRATEEK1469WOWNo ratings yet

- Shark200 BrochureDocument8 pagesShark200 BrochureBryan Dela TorreNo ratings yet

- 4 Ziv 5ctd E2f Data Sheet English Rev 1.1Document2 pages4 Ziv 5ctd E2f Data Sheet English Rev 1.1Pablo RiscoNo ratings yet

- Jaquet T400: Speed Measurement, Switching and Indicating InstrumentsDocument4 pagesJaquet T400: Speed Measurement, Switching and Indicating InstrumentsPavel MelnikovNo ratings yet

- Ask 800Document10 pagesAsk 800eletrica.smeNo ratings yet

- Tracer-AN Series: MPPT Solar Charge ControllerDocument4 pagesTracer-AN Series: MPPT Solar Charge ControllerNkosilozwelo SibandaNo ratings yet

- E7000 - Instruction Manual - v10Document38 pagesE7000 - Instruction Manual - v10edcooNo ratings yet

- NokiaDocument2 pagesNokiaRoger Alfaro GNo ratings yet

- Sitransf Fmtransmag2 Fi01 enDocument11 pagesSitransf Fmtransmag2 Fi01 enKỳ Duyên Nguyễn ThịNo ratings yet

- NDBDocument2 pagesNDBShafiq RosmanNo ratings yet

- Leaflet Solid-State Shortwave Transmitter-2Document2 pagesLeaflet Solid-State Shortwave Transmitter-2Her GunNo ratings yet

- PB04051-06 GC2200 Power Line Transceiver Production Product BriefDocument2 pagesPB04051-06 GC2200 Power Line Transceiver Production Product BriefValiant Philosophia AveroesNo ratings yet

- Brochure Remote MonitoringDocument2 pagesBrochure Remote MonitoringJhon HernandezNo ratings yet

- Cewe Instrument Premier Product RangeDocument8 pagesCewe Instrument Premier Product Rangeye htutkyawme100% (1)

- D I G I T A L T H y R Istor Power Controllers (SCR)Document4 pagesD I G I T A L T H y R Istor Power Controllers (SCR)mubs73No ratings yet

- Cvm-E3-Mini-Wieth: Power Analyzer With Wi-Fi and Ethernet CommunicationsDocument8 pagesCvm-E3-Mini-Wieth: Power Analyzer With Wi-Fi and Ethernet CommunicationsDavid SilvestreNo ratings yet

- Datasheet RISH LM 1340Document8 pagesDatasheet RISH LM 1340PT Merapi Trans EnergiNo ratings yet

- System-20 BTU MeterDocument4 pagesSystem-20 BTU MeterLogganathan SNo ratings yet

- DC-DST4601PX Dichron Eng PDFDocument4 pagesDC-DST4601PX Dichron Eng PDFMarco GardinaliNo ratings yet

- Computer: Ac T OuDocument2 pagesComputer: Ac T OufaikNo ratings yet

- Power Clampmeter: DCM2000PDocument3 pagesPower Clampmeter: DCM2000Prama540214No ratings yet

- 0 2300 Dual Channel Monitor Datasheet 105m0340lDocument13 pages0 2300 Dual Channel Monitor Datasheet 105m0340lAdhitya ReNo ratings yet

- TriPower X10KTLM CatalogDocument2 pagesTriPower X10KTLM Cataloganashameedi98No ratings yet

- E6000 InstructionManual v27Document42 pagesE6000 InstructionManual v27rommel76No ratings yet

- ProtectorsprDocument6 pagesProtectorsprheri fauziNo ratings yet

- Elmeasure Prepaid Postpaid Meter CatalogDocument4 pagesElmeasure Prepaid Postpaid Meter CatalogSEO BDMNo ratings yet

- Schaffer 2009Document11 pagesSchaffer 2009Zhenyu YangNo ratings yet

- ds914G PDFDocument10 pagesds914G PDFhbarriosNo ratings yet

- Aclara kV2c Data SheetDocument2 pagesAclara kV2c Data SheetDonald Rey BonghanoyNo ratings yet

- IMI STI Product FT-Compact-Positioner A4 4pp AW LRDocument4 pagesIMI STI Product FT-Compact-Positioner A4 4pp AW LRCarlos BenitezNo ratings yet

- EPM 7000 Power Quality Meter - GE Grid SolutionsDocument2 pagesEPM 7000 Power Quality Meter - GE Grid SolutionsCarlos VergaraNo ratings yet

- Datasheet Microinversor YC 1200 BRDocument2 pagesDatasheet Microinversor YC 1200 BRRafael AraujoNo ratings yet

- FSC Dus132311wDocument2 pagesFSC Dus132311wFlorent YIBOKOUNo ratings yet

- Pss 2a-1c15a IMV30Document28 pagesPss 2a-1c15a IMV30schreyarNo ratings yet

- Ultrasonic Gas FlowmeterDocument6 pagesUltrasonic Gas Flowmeterhk168100% (1)

- APsystems Microinverter DS3D For Brazil DatasDocument2 pagesAPsystems Microinverter DS3D For Brazil DatasWellington PassosNo ratings yet

- Multi-Breaker Control For Complex Power Management ApplicationsDocument4 pagesMulti-Breaker Control For Complex Power Management ApplicationsMihaiNo ratings yet

- GR611MDocument4 pagesGR611MBhootNo ratings yet

- 34 ST 03 67Document22 pages34 ST 03 67Manzoor-ul- HassanNo ratings yet

- Cat12 eDocument21 pagesCat12 eFrancisco Mones RuizNo ratings yet

- 2300 Series Vibration MonitorsDocument10 pages2300 Series Vibration MonitorsAlexandraAndreeaNo ratings yet

- Gs01e20d01 01e PDFDocument58 pagesGs01e20d01 01e PDFSeikatsukaiNo ratings yet

- Single Phase Smart Meter Using DLMS/COSEM Application DataDocument2 pagesSingle Phase Smart Meter Using DLMS/COSEM Application DataBorja Lima CarrascoNo ratings yet

- Single Phase Smart Meter Using DLMS/COSEM Application DataDocument2 pagesSingle Phase Smart Meter Using DLMS/COSEM Application DataErmengarda TabordaNo ratings yet

- Nu Horizons Electronics - Portal November / December 2010 - Asia PacificDocument13 pagesNu Horizons Electronics - Portal November / December 2010 - Asia PacificNu HorizonsNo ratings yet

- AD8362 50 HZ To 2.7 GHZ 60 DB TruPwr DetectorDocument36 pagesAD8362 50 HZ To 2.7 GHZ 60 DB TruPwr DetectorJános Pál HofferNo ratings yet

- Zener MSC 3 BrochureDocument4 pagesZener MSC 3 BrochureAswanTajuddinNo ratings yet

- MT880 M DatasheetDocument2 pagesMT880 M Datasheetplavi10No ratings yet

- Sma Inverter STP25000TL JP 30Document2 pagesSma Inverter STP25000TL JP 30Gustavo FeitozaNo ratings yet

- ION8650 DatasheetDocument11 pagesION8650 DatasheetAlthaf Axel HiroshiNo ratings yet

- High-Performance D/A-Converters: Application to Digital TransceiversFrom EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNo ratings yet

- Pulp 03Document1 pagePulp 03Papcel InstrumentNo ratings yet

- KanujulaKonaKasthuri by KoppisettiDocument56 pagesKanujulaKonaKasthuri by KoppisettiPapcel InstrumentNo ratings yet

- Pulp 02Document1 pagePulp 02Papcel InstrumentNo ratings yet

- Box No 4 5Document1 pageBox No 4 5Papcel InstrumentNo ratings yet

- Pulp 06Document1 pagePulp 06Papcel InstrumentNo ratings yet

- Pulp 04Document1 pagePulp 04Papcel InstrumentNo ratings yet

- Pulp 05Document1 pagePulp 05Papcel InstrumentNo ratings yet

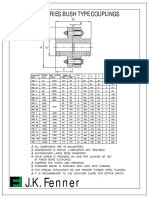

- J.K. Fenner: New Series Bush Type CouplingsDocument1 pageJ.K. Fenner: New Series Bush Type CouplingsPapcel InstrumentNo ratings yet

- OutdoorDocument1 pageOutdoorPapcel InstrumentNo ratings yet

- Box No 23 20Document1 pageBox No 23 20Papcel InstrumentNo ratings yet

- Dryer Man Hole CoverDocument1 pageDryer Man Hole CoverPapcel InstrumentNo ratings yet

- Crane BomDocument2 pagesCrane BomPapcel InstrumentNo ratings yet

- UntitledDocument1 pageUntitledPapcel InstrumentNo ratings yet

- KPDocument4 pagesKPPapcel InstrumentNo ratings yet

- Inst IO ListDocument7 pagesInst IO ListPapcel InstrumentNo ratings yet

- Box No 18 19Document1 pageBox No 18 19Papcel InstrumentNo ratings yet

- Box No 21 22 24 25Document1 pageBox No 21 22 24 25Papcel InstrumentNo ratings yet

- Approach Flow JB TerminationDocument14 pagesApproach Flow JB TerminationPapcel InstrumentNo ratings yet

- DIN-PN10 Steel Slip-On FlangesDocument3 pagesDIN-PN10 Steel Slip-On FlangesPapcel InstrumentNo ratings yet

- DIP JB TerminationDocument21 pagesDIP JB TerminationPapcel InstrumentNo ratings yet

- C66C Paper Shower-Nozzles CDocument10 pagesC66C Paper Shower-Nozzles CPapcel InstrumentNo ratings yet

- T&C BTG InstrumentsDocument2 pagesT&C BTG InstrumentsPapcel InstrumentNo ratings yet

- UntitledDocument1 pageUntitledPapcel InstrumentNo ratings yet

- UntitledDocument1 pageUntitledPapcel InstrumentNo ratings yet

- 40302500T10Z001K000 PTDocument16 pages40302500T10Z001K000 PTPapcel InstrumentNo ratings yet

- ProductSheet MBT2500 PS2027 4 en 20201124Document3 pagesProductSheet MBT2500 PS2027 4 en 20201124Papcel InstrumentNo ratings yet

- K2611 K2611 K2611 K2611: FeaturesDocument7 pagesK2611 K2611 K2611 K2611: FeaturesAndrew BanezNo ratings yet

- Wiring DiagramDocument6 pagesWiring DiagramThalita ServisNo ratings yet

- Baluff VLDTDocument96 pagesBaluff VLDTzrondjulNo ratings yet

- Lec01 - IntroductionDocument45 pagesLec01 - IntroductionYousef ZahranNo ratings yet

- TKTs Vs Calls - 14..5.2014Document31 pagesTKTs Vs Calls - 14..5.2014Ved GyanNo ratings yet

- EMI-EMC TroubleshootingDocument13 pagesEMI-EMC TroubleshootingRobert L.No ratings yet

- CarbonElectra ManualDocument30 pagesCarbonElectra ManualKorry ShepardNo ratings yet

- Noise Computational Problem and Objective Type Questions For Quiz ShowDocument39 pagesNoise Computational Problem and Objective Type Questions For Quiz ShowJhasper ManagyoNo ratings yet

- Tank Gauging TankvisionDocument31 pagesTank Gauging Tankvisionkhangduongda3No ratings yet

- 72 Pin SIMM ModulesDocument4 pages72 Pin SIMM Modulessubroto bosuNo ratings yet

- UCME Bro0208Document4 pagesUCME Bro0208surendra_patamsettyNo ratings yet

- Keyes Rotary Encoder Module Ky-040Document4 pagesKeyes Rotary Encoder Module Ky-040api-481856123No ratings yet

- Ec 2301 - Digital CommunicationDocument10 pagesEc 2301 - Digital CommunicationAadhithya PriyaNo ratings yet

- Catalogue PDFDocument12 pagesCatalogue PDFjhota_jhota84No ratings yet

- Presentation On TransformerDocument15 pagesPresentation On TransformerMandeep SinghNo ratings yet

- Transmission and Distribution Assignment Questions PDFDocument2 pagesTransmission and Distribution Assignment Questions PDFSathees KumarNo ratings yet

- Yaesu FT-8800 Summary SheetDocument1 pageYaesu FT-8800 Summary SheetJoeban R. PazaNo ratings yet

- Comparative Evaluation of SiC and Si PV Inverter Systems Based On Power Density and Efficiency As Indicators of Initial Cost and Operating RevenueDocument6 pagesComparative Evaluation of SiC and Si PV Inverter Systems Based On Power Density and Efficiency As Indicators of Initial Cost and Operating Revenueelectronic systemsNo ratings yet

- Calculation of System Noise Temperature and Noise PowerDocument13 pagesCalculation of System Noise Temperature and Noise PowerSaptarshi GhoshNo ratings yet

- Manual Cisco Router IR829Document34 pagesManual Cisco Router IR829cazobertoNo ratings yet

- Elmeasure Basic Meter Alphanor Programming GuideDocument1 pageElmeasure Basic Meter Alphanor Programming GuideP.p. Arul IlancheeranNo ratings yet

- HCNP (HCDP) Routing and Switching Training - IESN en Book-ContentDocument424 pagesHCNP (HCDP) Routing and Switching Training - IESN en Book-Contentosman uyarNo ratings yet

- Connecting The Breakout Board To The Sun Harvester Shield V1.0Document4 pagesConnecting The Breakout Board To The Sun Harvester Shield V1.0BunPământNo ratings yet

- SN 74 LVC 1 G 04Document44 pagesSN 74 LVC 1 G 04zigmund zigmundNo ratings yet

- Technical Data Sheet 5 MM Round White LED (T-1 3/4) 334-15/T1C1-4WYADocument10 pagesTechnical Data Sheet 5 MM Round White LED (T-1 3/4) 334-15/T1C1-4WYAJuan Carlos MartinezNo ratings yet

- Ursalink UR71 Industrial Cellular Router DatasheetDocument6 pagesUrsalink UR71 Industrial Cellular Router DatasheetUrsalink MarketingNo ratings yet

- About Ericsson IndiaDocument6 pagesAbout Ericsson IndiaSushobhit HarshNo ratings yet

- Modulation Part 8 of 10Document4 pagesModulation Part 8 of 10nonotjenNo ratings yet

- GPS TMG 50dB DSDocument1 pageGPS TMG 50dB DSMohamed KsimaNo ratings yet