Professional Documents

Culture Documents

Mosai Et Al., XXXX

Mosai Et Al., XXXX

Uploaded by

Mers AbeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mosai Et Al., XXXX

Mosai Et Al., XXXX

Uploaded by

Mers AbeCopyright:

Available Formats

The Recovery Of Pd(II), Ir(III) And Rh(III) From Aqueous

Solutions With Yeast-functionalised Zeolite

Alseno K. Mosai, Luke Chimuka, Ewa M. Cukrowska, Izak A. Kotzé and Hlanganani Tutu

Molecular Sciences Institute, School of Chemistry, University of the Witwatersrand, Private Bag X3, WITS,

2050, South Africa, 464646@students.wits.ac.za

Abstract

Wastewaters from platinum group metals (PGMs) processing plants can contain

substantial amounts of metals including the very PGMs. The recovery of such metals

from wastewaters can be of great value especially due to recent declines in commodity

prices. The recovery of Pd(II), Ir(III) and Rh(III) by zeolite functionalised with spent

yeast waste was studied and the effect of adsorbent dosage, pH, initial concentration,

contact time and competing ions was determined. The significant recovery of Pd(II)

and Ir(III) was achieved at pH 2, 2 mg L-1 and 10 g L-1 adsorbent dosage. The adsorption

capacity of Rh(III) increased with pH whilst that of Pd(II) and Ir(III) decreased. The

presence of competing ions led to an increase in adsorption capacity due to an adsorbent-

Fe-analyte synergistic effect. The adsorbent is suitable for significant recovery of Pd(II),

Ir(III) and Rh(III) from PGMs wastewater.

Keywords: adsorption capacity, platinum group metals, spent yeast, wastewater

Introduction In this study, the zeolite clay mineral was

The readily increasing costs of platinum group functionalised with spent brewer’s yeast waste

metals (PGMs) and declining ore grades have and used to recover Pd(II), Ir(III) and Rh(III)

been eroding the economic viability of PGMs from aqueous solutions. Thus, this study

mines around the world. As a result, some seeks to come up with a very attractive and

mining plants have closed whilst others are cheap material for the recovery of precious

still facing closure. During the processing metals.

of minerals, large amount of wastewater is

released into the environment and some Materials and methods

studies have reported that it may contain Chemicals

traces of valuable minerals such as PGMs The chemicals used were of analytical reagent

(Mosai et al., 2019). Since these metals are in grade and were purchased from Sigma

very low concentrations, the current methods Aldrich, South Africa. The 10 mg L-1 stock

used for mining cannot be used to recover the solution containing Pd(II), Ir(III) and Rh(III)

lost minerals hence, a need for cheaper and was prepared and preserved with concentrated

more efficient methods for recovery. Zeolites nitric acid. Working solutions were prepared

are negatively charged aluminium-silicate clay daily from the stock solution which was stored

minerals which have micro and mesopores in the refrigerator at 4°C when not used. The

located by water molecules and cations such as 0.01 mol L-1 HCl and NaOH were used to

Ca2+ and Mg2+ (Guaya et al., 2015). Zeolites are adjust the pH of the working solutions. The

readily available in different parts of the world spent yeast waste was collected from the Wits

and have been used as natural adsorbents Microbrewery, Johannesburg, South Africa

for the removal of metals from wastewaters using polypropylene plastic containers.

(Yuna, 2016). Other studies have indicated the

efficiency of zeolite can be improved through Functionalisation of zeolite with yeast

functionalisation with ligands that have high The collected yeast waste (40 mL) was added

affinity for target metals (Simsek et al., 2013; to 2 g zeolite in a 100 mL polypropylene

Bakatula et al., 2015). bottle and mixed for 24 h using an elliptical

238 Wolkersdorfer, Ch.; Khayrulina, E.; Polyakova, S.; Bogush, A. (Editors)

IMWA 2019 “Mine Water: Technological and Ecological Challenges”

bench-top shaker at 25°C. The contents were solution and M (g) is the mass of the yeast-

filtered using suction and the unbound yeast functionalised zeolite.

was removed by shaking the functionalised

zeolite for 5 min with deionised water. The Data treatment

contents were filtered again and the zeolite Adsorption isotherms

was dried at 25°C for 24 h. The type of adsorption between the metals and

yeast-functionalised zeolite was determined

Characterisation using the Langmuir, Freundlich and

The natural zeolite used was characterised Dubinin-Radushkevich (D-R) adsorption

with powder X-ray diffraction (PXRD) D2 isotherms. The Langmuir isotherm describes

Phaser (Bruker, Germany) to determine the monolayer adsorption of metals onto a

the mineralogy of the adsorbent and homogeneous surface with a fixed number of

X-ray fluorescence (XRF) (PAnalytical, active sites. The assumption for this isotherm

Netherlands) for chemical composition. is that the active sites have equal adsorption

The functional groups of the natural and energies (Latour, 2015). The Langmuir

functionalised zeolite were determined isotherm can be expressed as:

using Fourier transform infrared (FTIR)

C ⎛ 1 ⎞ ⎛ 1 ⎞

spectroscopy (Tensor 27, Bruker, Germany). (3)

e

= ⎜⎜ ⎟ Ce + ⎜⎜ ⎟

q q ⎟ K q ⎟

The amount of C, H and N on the natural and e ⎝ m ⎠ ⎝ L m ⎠

functionalised zeolite was determined using where qm (mg g ) is the maximum -1

varioELcube V4.0.13 (Elementar, Germany). monolayer coverage and KL (L mol-1) is the

The surface area, pore size and pore volume Langmuir isotherm constant. The affinity of

were determined using TriStar 3000 V6.05 A the metals for the adsorbent was determined

(Micrometrics, USA). using the separation factor (RL) which can

be determined from the Langmuir constant

Batch adsorption studies (KL). The affinity can be expressed as

Batch studies were conducted to determine favourable (0>RL< 1), unfavourable (RL >1),

the effect of pH (2-9), initial concentration linear adsorption (RL = 1) and irreversible

(0.5-10 mg L-1), adsorbent dosage (5-50 g adsorption (RL= 0). The RL is expressed as:

L-1), contact time (0-540 min) and competing

ions (Pt, Ru, Os, Hf, Au, Fe, Co, Ni, Ca, 1

(4)

RL =

Mg, K and Zn) on the adsorption of Pd(II), 1 + CO K L

Ir(III) and Rh(III) by yeast-functionalised

The Freundlich isotherm model describes the

zeolite. The raw zeolite was also used at the adsorption of metals onto a heterogeneous

same conditions and the adsorption was not surface where the active sites are assumed to

significant (p>0.05). The metals in the above have different energies (Bakatula et al., 2015).

conditions were shaken with the adsorbent The Freundlich isotherm can be expressed as:

to attain equilibrium and filtered. Inductively 1

coupled plasma optical emission spectroscopy (5)

(ICP-OES) (Spectro Genesis, Germany) q =K Cn e f e

was used to determine the concentration of

where Kf ((mg g-1)/(mol L-1)1/n) is Freundlich

metals. The equilibrium adsorption capacity isotherm constant and n is adsorption

(qe (µg g-1)) and adsorption efficiency of intensity.

the metals recovered by yeast-functionalised The Dubinin-Radushkevich (D-R) model

zeolite were determined using Eq. 1 and 2, is used to describe the adsorption between

respectively. metals and adsorbents onto a heterogeneous

(1) surface with Gaussian energy distribution

(Chen, 2015). The D-R model equation is as

(2) follows:

where Co and Ce (mg L-1) are the initial and

(6)

equilibrium concentrations of the metals,

respectively, V (L) is the volume of the

Wolkersdorfer, Ch.; Khayrulina, E.; Polyakova, S.; Bogush, A. (Editors) 239

IMWA 2019 “Mine Water: Technological and Ecological Challenges”

where Xm is theoretical isotherm and alumina (Al2O3) (11.6%). Since the yeast

saturation capacity (mg g−1), KDR is the waste contains high amounts of amino acids,

Dubinin-Radushkevich isotherm constant the possible interaction was through the

(mol2 (kJ2)-1), ɛ is the Polanyi constant which oxides of the zeolite and these amino acids.

can be expressed as: The FTIR spectra of the natural and functional

zeolite indicated that the functionalisation

(7) was successful since, there were N-H and C-N

bands at 1535 and 1637 cm-1, respectively on

where R is the universal gas constant (J (mol the functionalised adsorbent, indicative of

K)-1)and T is temperature (K). The mean free the amino acid groups in the yeast. Due to

energy of adsorption (Es) can be calculated the smothering of the zeolite pores by the

from KDR as shown in Eq. 8. spent yeast, the surface area and pore volume

of the adsorbent decreased whilst the pore

(8) size increased. The amount of C, H and N

increased after functionalisation due to high

amount of amino acids.

Kinetics study

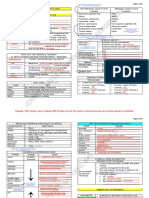

The adsorption controlling mechanism Effect of adsorbent dosage

between the metals and the adsorbent was The effect of adsorbent dosage on the

determined using pseudo first- and second- adsorption of Pd(II), Ir(III) and Rh(III) at pH

order kinetic models. The pseudo first- 2 by yeast-functionalised zeolite was studied

order model has used to describe the rate of and the results are presented in Fig. 1. The

adsorption that is controlled by the rate of adsorption capacity of the metals decreased

surface reaction in which case, the transition as the dosage increased but, the adsorption

of metals from free to adsorbed state is efficiency increased with dosage due to

considered (Rudzinski and Plazinski 2007). increased amount of binding sites. The Pd(II)

The pseudo second-order model is used to adsorption capacity was higher than that of

describe a reaction where the adsorption Ir(III) and Rh(III) thus, the yeast functional

reaction on the surface of adsorbent is the groups on zeolite had high affinity for Pd(II)

rate-controlling step (Liu, 2008). The pseudo at pH 2. The adsorption efficiencies of Pd(II)

first and second-order kinetic models can be were in the range of 69-91% as the dosage

expressed by Eq. 9 and 10, respectively: increased from 50 to 500 mg. The adsorption

efficiencies of Ir(III) were found to be 33,

(9) 54, 59, 62 and 61% at 50, 100, 200, 300 and

500 mg of yeast-functionalised zeolite,

(10) respectively and those of Rh were found to be

17,25, 35, 39 and 61%, respectively. The lower

where qt is the adsorbed amount (mg g-1) at adsorption efficiencies of Ir(III) and Rh(III)

time t, qe is the adsorbed amounts (mg g-1) at can be attributed to high oxidation states and

equilibrium and k1 is the pseudo first-order high atomic and ionic radii of the metals thus,

rate constant (min-1), k2 is the pseudo second- only a few could be taken up by the active

order rate constant (g mg-1 min-1) and k2 qe2 is sites. The recovery of the metals with yeast-

the initial adsorption rate. functionalised zeolite was in the order: Pd(II)

> Ir(III) > Rh(III).

Results and discussion

Characterisation Effect of pH

The PXRD results showed that the dominant The effect of pH on the adsorption of Pd(II),

minerals of the zeolite were clinoptilolite Ir(III) and Rh(III) by yeast-functionalised

((Na,K,Ca) 2-3 Al 3 (Al,Si) 2 Si 13 O .36 ·12H 2 O), zeolite was studied and the results (Fig.

quartz (SiO2) and sanidine (K(AlSi3O8)). The 2) indicated that the adsorption capacity

results from XRF indicated that the zeolite of Pd(II) and Ir(III) decreased as pH was

was mostly composed of silica (SiO2) (68.5%) increased due to the change of species and

adsorbent surface. At lower pH, the metals

240 Wolkersdorfer, Ch.; Khayrulina, E.; Polyakova, S.; Bogush, A. (Editors)

IMWA 2019 “Mine Water: Technological and Ecological Challenges”

180

300

160

250 Pd 140

Ir

Adsorption capacity (µg g )

-1

Rh Pd

Adsorption capacity (µg g )

120

-1

200

Ir

Rh

100

150 80

60

100

40

50

20

0 0

0 100 200 300 400 500 1 2 3 4 5 6 7 8 9 10

Mass (g) pH

Figure 1 Effect of mass on adsorption of metals Fig. 2 Effect of mass on adsorption of metals

exist as PdCl64- and IrCl63- due to high HCl for these metals which are swiftly occupied

concentration which was used to adjust the hence, no further increase in adsorption

pH. The platinum mining wastewater has was observed. The adsorption efficiencies of

high concentration of HCl which is used Pd(II) were found to be 83, 83, 81, 74 and 64%

during processing and thus, the metals exist at 0,5, 1, 2, 5 and 10 mg L-1, respectively. The

in their chloride species (Mosai et al., 2019). adsorption efficiencies for Ir(III) and Rh(III)

Since these species are negatively charged, were less than 25% beyond 2 mg L-1.

they will interact electrostatically with the The type of adsorption occurring between

positively charged surface which is due the metals and yeast-functionalised zeolite

to high concentration of hydronium ions was determined using adsorption isotherms

(H3O+). Thus at highly acidic regions, the and the data is presented in Table 1. The

amino acids will be positively charged and correlation coefficients (R2) were high for

interact strongly with negatively charged Langmuir isotherm, indicating that the

species. The adsorption capacity of Pd(II) and adsorption of the metals to the adsorbent

Ir(III) decreased as pH was increased due to was through monolayer adsorption. The

repulsions of the negatively charged hydroxide metals were removed from aqueous solutions

species and the negatively charged surface. through the metal-N interaction since,

However, the adsorption of Rh(III) increased studies have indicated that PGEs have strong

with pH. A study by Labib et al. (2018) interactions with nitrogen (Mosai et al.,

indicated that at higher pH, Rh(III) forms 2019). The maximum adsorption coverage

aqua/chloro complexes ([RhCl2(H2O)4]+ (qm) of Pd(II) onto the adsorbent was higher

and [RhCl(H2O)5]2+) which are positively than for Ir(III) and Rh(III) which can be

charged and would electrostatically interact attributed to high affinity of the active sites

with the negatively charged surface. Thus, to for Pd(II) hence, the adsorption capacity has

substantially recover Rh(III) from wastewater, been higher than that of the other metals.

pH should be adjusted. The correlation coefficients for Pd(II) were

>0.99 for all isotherms, meaning that there

Effect of initial concentration is also a possibility of adsorption on different

The effect of initial concentration on the adsorption sites or different adsorption

adsorption of Pd(II), Ir(III) and Rh(III) by the mechanisms leading to a heterogeneous

adsorbent at pH 2 was studied and the results adsorption. The mean adsorption energy (Es)

are shown in Fig. 3. The adsorption capacity of Pd(II) determined from D-R isotherm was

of Pd(II) increased with concentration from 10.12 kJ mol-1 meaning that the interaction

0.5 to 10 mg L-1 due to favourable adsorption. with the adsorbent was through chemical ion

The adsorption capacity of Ir(III) and Rh(III) exchange. The energies of Ir(III) and Rh(III)

however, increased up to 2 mg L-1 and were greater than 16 kJ mol-1 indicating that

remained fairly the same beyond this. This their interaction was possibly chemisorptive

can be attributed to the limited binding sites in nature (Youssef et al., 2008).

Wolkersdorfer, Ch.; Khayrulina, E.; Polyakova, S.; Bogush, A. (Editors) 241

IMWA 2019 “Mine Water: Technological and Ecological Challenges”

700 180

160

600

140

Adsorption capacity (µg g )

-1

500

Adsorption capacity (µg g )

-1

Pd 120

Ir

400 100

Rh

80

300

60

200

40

Pd

100 20

Ir

0 Rh

0

-20

0 2 4 6 8 10 0 100 200 300 400 500 600

Concentration (mg L )

-1

Time (min)

Fig. 3 Effect of concentration on adsorption of metals Fig. 4 Effect of time on adsorption of metals

Effect of contact time Competing ions

The effect of contact time indicated that there The effect of competing ions on the

is at first a fast rate of adsorption of the metals adsorption of Pd(II), Ir(III) and Rh(III) by

which was observed within 10 min (Fig. 4). yeast-functionalised zeolite was studied

Beyond 90 min, the increase in adsorption since, mining wastewaters contain substantial

of the metals was insignificant. Even though amounts of other metals. The results from this

the adsorption of the metals was substantial study give an indication of how the adsorbent

within 90 min, a contact time of 6 h was will behave in real wastewater. The results

selected for this study to obtain the maximum (Fig. 5) showed that the adsorption capacity

adsorption. The contact time data was used of the analytes increased in the presence of

to fit in the kinetic models and determine other ions and this can be attributed to the

the adsorption controlling mechanism. The possible synergistic interaction of the analytes

results in Table 2 showed that pseudo second- with other metals such as iron thus, leading

order described the data better since the to adsorbent-Fe-analyte interaction (Mosai

correlation coefficient (R2) was > 0.99 for all et al., 2019). The percentage increments in

the metals, indicating that the interaction of adsorption were found to be 14, 27, 58% for

the metals with the adsorbent is strong (Mosai Pd(II), Ir(III) and Rh(III), respectively. Other

et al., 2019). To further confirm that the data PGEs (Pt, Ru and Os) were substantially

was better described by pseudo second-order, removed from the aqueous solutions which

the experimental adsorption capacity (qe, is a good attribute of the adsorbent. Thus, in

exp

) was close to the pseudo second-order the presence of metals such as Fe, there is a

calculated adsorption capacity (qe) of the possibility of multilayer adsorption where

metals. When the adsorption is described the Fe is directly connected to the adsorbent

by pseudo second-order, the interaction and form bonds with the analytes. The ability

between the metals and the adsorbent is so of the adsorbent to remove metals such as

strong that the detachment of the metals is (K, Ni, Co and Zn) means that the yeast-

unlikely to happen, which is a good attribute functionalised zeolite has dual efficacy and

of the adsorbent especially when it is handled that is recovering precious metals whilst

from mining or waste sites. removing contaminants from wastewaters.

Table 1 Adsorption isotherm parameters for the adsorption of metals by yeast-functionalised zeolite

Metal Langmuir Freundlich Dubinin-Radushkevich

qm KL R2 KF n R2 Xm Es R2

(mg g-1) (L mol-1) ((mg g-1)/ (mg g-1) (kJ mol-1)

(mol L-1)1/n)

Pd(II) 0.99 53960 0.99 1308 1.37 0.99 16.7 10.12 0.99

Ir(III) 0.15 1.10x107 0.99 0.90 4.97 0.91 0.29 19.0 0.93

Rh(III) 0.052 2.75x106 0.99 0.19 7.61 0.83 0.09 22.3 0.85

242 Wolkersdorfer, Ch.; Khayrulina, E.; Polyakova, S.; Bogush, A. (Editors)

IMWA 2019 “Mine Water: Technological and Ecological Challenges”

Table 2 kinetic models parameters for the adsorption of Pd(II), Ir(III) and Rh(III) by yeast-

functionalised zeolite

Metal Pseudo first-order Pseudo-second order

qe (exp) k1 qe R2 k2 qe R2

mg g-1 min-1 mg g-1 g mg-1 min-1 mg g-1

10-3

Pd(II) 0.20 4.10 0.12 0.75 2.93 0.17 0.99

Ir(III) 0.080 1.98 0.17 0.81 4.13 0.12 0.99

Rh(III) 0.051 0.61 0.18 0.78 1.65 0.050 0.99

Adsorption capacity

Conclusion 300

The ability of zeolite functionalised with yeast 250

waste to recover Pd(II), Ir(III) and Rh(III)

Adsorption capacity (ug g )

-1

from aqueous solutions was studied. The 200

results obtained were compared to those of the

150

raw zeolite and the results were significanty

different. The raw zeolite poorly adsorbed 100

the metals but, there was a substantial change

when the functionalised zeolite was used. 50

The adsorbent was hoghly efficient at 2 mg 0

L-1 and a dosage of 10 g L-1. The adsorbent Ru Rh Pt Ir Os Pd Fe Co Ni Ca Mg K Zn Hf Au

will substantially recover Pd(II) and Ir(III) at Elements

highly acidic pH regions but the adsorption of Fig. 5 Effect of competing ions on adsorption of

Rh(III) will be more efficient at less acidic pH metals

regions due to the formation of aqua/chloro

complexes which are positively charged. The References

adsorption capacity of Pd(II) was highly Bakatula EN, Mosai AK, Tutu H (2015) Remov-

preferred more than other metals due to the al of uranium from aqueous solutions using

ability to adsorb onto different active sites ammonium-modified zeolite. S. Afr J Chem

of the adsorbent since, both Langmuir and 68(1):165-171

Freundlich described the adsorption data well. Guaya D, Valderrama C, Farran A, Armijos C,

The adsorption mechanism of all the analytes Cortina JL (2015) Simultaneous phosphate and

was best described by pseudo second-order ammonium removal from aqueous solution by a

kinetic model meaning that the interaction hydrated aluminum oxide modified natural zeo-

of the metals was strong due to chemical lite. Chem Eng J 271:204-213

adsorption. The adsorption capacities of the Yuna Z (2016) Review of the natural, modified,

analytes increased in the presence of other and synthetic zeolites for heavy metals removal

ions due to adsorbent-Fe-metal synergistic from wastewater.” Environ Eng Sci 33.7:443-454

interaction. Desorption studies were not Simsek EB, Özdemir E, Beker U (2013) Zeolite

conducted since, the used adsorbent can be supported mono-and bimetallic oxides: promis-

processed along with the new ore and thus, ing adsorbents for removal of As (V) in aqueous

no extra chemicals required for recovery. solutions. Chem Eng J 220:402-411

Hence, this will be a very cheap process.

Rudzinski W, Plazinski W (2007) Theoretical de-

Acknowledgements scription of the kinetics of solute adsorption at

heterogeneous solid/solution interfaces: On the

The authors would like to thank the National

possibility of distinguishing between the diffu-

Research Foundation (NRF) (Grant no:

sional and the surface reaction kinetics models.

108556), the University of the Witwatersrand

Appl Surf Sci 253(13):5827-5840

(Enabling grant) and the Water Research

Commission (WRC project no. K5/2589) for Latour RA (2015) The Langmuir isotherm: a com-

financial support. monly applied but misleading approach for

Wolkersdorfer, Ch.; Khayrulina, E.; Polyakova, S.; Bogush, A. (Editors) 243

IMWA 2019 “Mine Water: Technological and Ecological Challenges”

the analysis of protein adsorption behavior. J Adsorption of rhodium by modified mesopo-

Biomed Mater Res A 103(3):949-958 rous cellulose / silica sorbents : equilibrium ,

Liu, Y. (2008). New insights into pseudo-second- kinetic , and thermodynamic studies. J Porous

order kinetic equation for adsorption. Colloid Mater 25(2):383–96

Surf A: Physicochem Eng Aspects 320(1-3):275- Chen X (2015) Modeling of experimental adsorp-

278 tion isotherm data. Information 6(1):14-22

Mosai AK, Chimuka L, Cukrowska EM, Kotzé IA, Youssef AM, El-Khouly S, El-Nabarawy TH (2008)

Tutu H (2019) The recovery of Platinum (IV) Removal of Pb(II) and Cd(II) from aqueous

from aqueous solutions by hydrazine-function- solution using activated carbons from pecan

alised zeolite. Miner Eng 131:304-312 shells. Carbon Lett 9:8-13

Labib SA, Yousif AM, Ibrahim IA, Atia AA. (2018)

244 Wolkersdorfer, Ch.; Khayrulina, E.; Polyakova, S.; Bogush, A. (Editors)

You might also like

- Mtap 1 Aubf 1 Topic Reviewer Gaytano 2022 2023Document8 pagesMtap 1 Aubf 1 Topic Reviewer Gaytano 2022 2023april joy tiponesNo ratings yet

- Biosorption of PB and ZN by Non-Living Biomass of Spirulina SPDocument5 pagesBiosorption of PB and ZN by Non-Living Biomass of Spirulina SPHanylu AvilaNo ratings yet

- Verma Et Al., 2008 PDFDocument7 pagesVerma Et Al., 2008 PDFT BranizNo ratings yet

- Adsorptive Removal of PB II and CR Vi From Wastewater Using Acid Untreated Coffee HuskDocument8 pagesAdsorptive Removal of PB II and CR Vi From Wastewater Using Acid Untreated Coffee HuskEstefany ArgomedoNo ratings yet

- Amer Et AlDocument8 pagesAmer Et AlNadarlis Binti DarmawiNo ratings yet

- 2019 XANTHATED COAL AS A LEAD CATION EXCHANGER Tche QuimDocument12 pages2019 XANTHATED COAL AS A LEAD CATION EXCHANGER Tche QuimRoberto FernandezNo ratings yet

- Separation and Recovery of Rare Earth Elements From Spent nickel-metal-hydride-Gasser-EgyptDocument8 pagesSeparation and Recovery of Rare Earth Elements From Spent nickel-metal-hydride-Gasser-EgyptDaiana NavarreteNo ratings yet

- (Paperhub - Ir) 10.1021 Es0102989Document7 pages(Paperhub - Ir) 10.1021 Es0102989annahita.h.zNo ratings yet

- Chidambaram 2011Document13 pagesChidambaram 2011Ricardo Javier Gutierrez MontillaNo ratings yet

- Adsorption of Micronutrient Metal Ion Onto Struvite To Prepare SL - 2019 - ChemoDocument9 pagesAdsorption of Micronutrient Metal Ion Onto Struvite To Prepare SL - 2019 - ChemoLeynard NatividadNo ratings yet

- 1 s2.0 S0043135403007255 MainDocument7 pages1 s2.0 S0043135403007255 MainnathaloaNo ratings yet

- Materials Today: Proceedings: H. Es-Sahbany, R. Hsissou, M.L. El Hachimi, M. Allaoui, S. Nkhili, M.S. ElyoubiDocument9 pagesMaterials Today: Proceedings: H. Es-Sahbany, R. Hsissou, M.L. El Hachimi, M. Allaoui, S. Nkhili, M.S. ElyoubiVishal kambojNo ratings yet

- Food and Chemical Toxicology: Mustafa Soylak, Ayse AydinDocument7 pagesFood and Chemical Toxicology: Mustafa Soylak, Ayse Aydinlox agencyNo ratings yet

- Food and Chemical Toxicology: Mustafa Soylak, Ayse AydinDocument7 pagesFood and Chemical Toxicology: Mustafa Soylak, Ayse Aydinlox agencyNo ratings yet

- Adsorption of Several Metal Ions Onto A Model Soil Sample: Equilibrium and EPR StudiesDocument6 pagesAdsorption of Several Metal Ions Onto A Model Soil Sample: Equilibrium and EPR StudiesjhenyNo ratings yet

- Clay, Ctab, PB, Jurnal 6Document9 pagesClay, Ctab, PB, Jurnal 6SyarifahNo ratings yet

- Adsorption of Water Heavy Metals Onto Natural Clay Environmental ScienceDocument4 pagesAdsorption of Water Heavy Metals Onto Natural Clay Environmental ScienceSachin HarkalNo ratings yet

- Effect of Alkali Treatment On Heavy Metals Adsorption Capacity of Sewage SludgeDocument7 pagesEffect of Alkali Treatment On Heavy Metals Adsorption Capacity of Sewage SludgeMuhanned AljeboryNo ratings yet

- Lead and Chromium Adsorption From Water Using L-Cysteine Functionalized Magnetite (Fe O) NanoparticlesDocument15 pagesLead and Chromium Adsorption From Water Using L-Cysteine Functionalized Magnetite (Fe O) Nanoparticlesmehran janNo ratings yet

- Adsorption of Nickel in Water by Brown Algae: Laminaria Japonica and Undaria PinnatifidaDocument3 pagesAdsorption of Nickel in Water by Brown Algae: Laminaria Japonica and Undaria PinnatifidaRakesh SHNo ratings yet

- Optimization of Continuous Flow Adsorption of Heavy Metal Ions by Peganum Harmala SeedsDocument7 pagesOptimization of Continuous Flow Adsorption of Heavy Metal Ions by Peganum Harmala SeedsNórida Pájaro GómezNo ratings yet

- Research Article Lead and Copper Adsorption Behaviour by Lemna Gibba: Kinetic and Equilibrium StudiesDocument22 pagesResearch Article Lead and Copper Adsorption Behaviour by Lemna Gibba: Kinetic and Equilibrium StudiesMemoMixNo ratings yet

- Heavy Metals Removal From Industrial Wastewater by Activated Carbon Prepared From Coconut ShellDocument7 pagesHeavy Metals Removal From Industrial Wastewater by Activated Carbon Prepared From Coconut Shellanand sagarNo ratings yet

- Abdelwahab - 2007 - Kinetic and Isotherm Studies of Copper (II) Removal From Wastewater Using Various AdsorbentsDocument18 pagesAbdelwahab - 2007 - Kinetic and Isotherm Studies of Copper (II) Removal From Wastewater Using Various Adsorbentscukaasam123456No ratings yet

- New 1Document9 pagesNew 1arash.abadianNo ratings yet

- Spectrochimica Acta Part A: Molecular and Biomolecular SpectrosDocument9 pagesSpectrochimica Acta Part A: Molecular and Biomolecular SpectrosAakash VNo ratings yet

- Adsorption of ZN (II) On Activated Red Mud: Neutralized by CODocument17 pagesAdsorption of ZN (II) On Activated Red Mud: Neutralized by COisukuruNo ratings yet

- Modelling of Copper Adsorption FinalDocument21 pagesModelling of Copper Adsorption FinalaadhyaNo ratings yet

- Modelling of Copper Adsorption FinalDocument21 pagesModelling of Copper Adsorption FinalaadhyaNo ratings yet

- But 2016 Bioacumulation HVspiderDocument9 pagesBut 2016 Bioacumulation HVspiderDanilo Baltazar SedanoNo ratings yet

- Simultaneous Biosorption of Cadmium (II) and Lead (II) Ions by Pretreated Biomass of Phanerochaete ChrysosporiumDocument8 pagesSimultaneous Biosorption of Cadmium (II) and Lead (II) Ions by Pretreated Biomass of Phanerochaete ChrysosporiumWiliam CasasNo ratings yet

- Heavy Metal Sorption by Calcium Alginate Beads From Laminaria DigitataDocument8 pagesHeavy Metal Sorption by Calcium Alginate Beads From Laminaria DigitataHuman RandomNo ratings yet

- Kinetics and Equilibrium Adsorption Study of Lead (II) Onto Activated Carbon Prepared From Coconut ShellDocument7 pagesKinetics and Equilibrium Adsorption Study of Lead (II) Onto Activated Carbon Prepared From Coconut ShellsureshbabuchallariNo ratings yet

- Equilibrium Uptake, Isotherm and Kinetic Studies of CD (II) Adsorption Onto Iron Oxide Activated Red Mud From Aqueous SolutionDocument11 pagesEquilibrium Uptake, Isotherm and Kinetic Studies of CD (II) Adsorption Onto Iron Oxide Activated Red Mud From Aqueous SolutionĐỗ Quang TháiNo ratings yet

- Applied and Environmental Microbiology-1984-Tobin-821.fullDocument4 pagesApplied and Environmental Microbiology-1984-Tobin-821.fullPedro CarbajalNo ratings yet

- The Removal of Zn2+ Ions From GroundwaterDocument4 pagesThe Removal of Zn2+ Ions From GroundwaterMaria IgnatNo ratings yet

- Performance of Iron Filings and Activated Sludge As Media For Permeable Reactive Barriers To Treat Zinc Contaminated GroundwaterDocument9 pagesPerformance of Iron Filings and Activated Sludge As Media For Permeable Reactive Barriers To Treat Zinc Contaminated GroundwatersdffdsNo ratings yet

- Competitive Adsorption Characteristics of Co, Ni, and CR by IRN-77 Cation Exchange Resin in Synthesized WastewaterDocument7 pagesCompetitive Adsorption Characteristics of Co, Ni, and CR by IRN-77 Cation Exchange Resin in Synthesized WastewaternnbfieohnNo ratings yet

- Adsorção Com HDL Adsorver Vermelho Do CongoDocument6 pagesAdsorção Com HDL Adsorver Vermelho Do CongoLucas Ferreira LozNo ratings yet

- 2892 PDFDocument11 pages2892 PDFkenatejoyNo ratings yet

- Adnan Et AlDocument11 pagesAdnan Et AlAdnan SohailNo ratings yet

- Spodoptera Litura F: Antifeeding and Insect-Growth-Regulating Activity of Certain Metal Complexes TowardsDocument5 pagesSpodoptera Litura F: Antifeeding and Insect-Growth-Regulating Activity of Certain Metal Complexes TowardsAnantha LakshmiNo ratings yet

- Baybars Ali Fil, and Mustafa Korkmaz, Cengiz ÖzmetinDocument6 pagesBaybars Ali Fil, and Mustafa Korkmaz, Cengiz ÖzmetinAmmr MahmoodNo ratings yet

- Jur UtamaDocument11 pagesJur UtamaEtrinaldi Lawan CariNo ratings yet

- Tesis Referencia 1Document6 pagesTesis Referencia 1Marilu Bueno RamosNo ratings yet

- 66 Ess17020 PDFDocument9 pages66 Ess17020 PDFNórida Pájaro GómezNo ratings yet

- 1-S2.0-S1878522013000349-MainDocument9 pages1-S2.0-S1878522013000349-MainkyukyumarNo ratings yet

- Qaisar Bioresource 2013Document7 pagesQaisar Bioresource 2013iram ranaNo ratings yet

- Chemistry Lorem IpsumDocument31 pagesChemistry Lorem IpsumVestineoNo ratings yet

- Lead RemovalDocument8 pagesLead RemovalNithya RNo ratings yet

- Jurnal Hensen 1Document5 pagesJurnal Hensen 1HensenNo ratings yet

- Adebowale2020 Article AdsorptionOfLeadIonsOnMagneticDocument8 pagesAdebowale2020 Article AdsorptionOfLeadIonsOnMagneticAbisola AdeyemoNo ratings yet

- Predictions of Binary Sorption Isotherms For The Sorption of Heavy Metals by Pine Bark Using Single Isotherm DataDocument7 pagesPredictions of Binary Sorption Isotherms For The Sorption of Heavy Metals by Pine Bark Using Single Isotherm DataAyauwu LovedayNo ratings yet

- 139973-Article Text-373234-1-10-20160719Document4 pages139973-Article Text-373234-1-10-20160719JoshuaNo ratings yet

- HidroxiapatitaDocument8 pagesHidroxiapatitasherajekiNo ratings yet

- Optimization of Culture Condition For Biosorption of Lead Using Pseudomonas Aeruginosa Isolated From Gold Mining Site of Anka, Zamfara StateDocument6 pagesOptimization of Culture Condition For Biosorption of Lead Using Pseudomonas Aeruginosa Isolated From Gold Mining Site of Anka, Zamfara StateUMYU Journal of Microbiology Research (UJMR)No ratings yet

- Mathematical Modeling and Interpretation of Equilibrium Isotherms of PB (II) From Aqueous Media by Chlorella Pyrenoidosa Immobilized in Luffa CylindricaDocument20 pagesMathematical Modeling and Interpretation of Equilibrium Isotherms of PB (II) From Aqueous Media by Chlorella Pyrenoidosa Immobilized in Luffa CylindricaImane NOUACERNo ratings yet

- Pyrite PaperDocument6 pagesPyrite PaperPham Thi HoaNo ratings yet

- Sorption NavalDocument7 pagesSorption NavalNithya RNo ratings yet

- Critical Evaluation of Equilibrium Constants Involving 8-Hydroxyquinoline and Its Metal Chelates: Critical Evaluation of Equilibrium Constants in Solution: Part B: Equilibrium Constants of Liquid-Liquid Distribution SystemsFrom EverandCritical Evaluation of Equilibrium Constants Involving 8-Hydroxyquinoline and Its Metal Chelates: Critical Evaluation of Equilibrium Constants in Solution: Part B: Equilibrium Constants of Liquid-Liquid Distribution SystemsNo ratings yet

- Heavy Metals in the Environment: Origin, Interaction and RemediationFrom EverandHeavy Metals in the Environment: Origin, Interaction and RemediationRating: 5 out of 5 stars5/5 (1)

- Liu Et Al., 2019Document9 pagesLiu Et Al., 2019Mers AbeNo ratings yet

- Redfield Ratio CommentaryDocument3 pagesRedfield Ratio CommentaryMers AbeNo ratings yet

- Transitions Cheat SheetDocument1 pageTransitions Cheat SheetMers AbeNo ratings yet

- Esssential Water Chemistry I-2Document12 pagesEsssential Water Chemistry I-2Mers AbeNo ratings yet

- Module 3 - Cell Structure and FunctionsDocument7 pagesModule 3 - Cell Structure and FunctionsJade Lagada PagariganNo ratings yet

- NewItem 141 Package Odourreport 2.12.08Document57 pagesNewItem 141 Package Odourreport 2.12.08Banvari GurjarNo ratings yet

- Li MG OrganometallicsDocument62 pagesLi MG OrganometallicsArish AhmedNo ratings yet

- Bio-Based Flame Retardants When Nature Meets Fire ProtectionDocument25 pagesBio-Based Flame Retardants When Nature Meets Fire ProtectionMurillo PolettoNo ratings yet

- Safety Data Sheet: Product Name: MOBILGREASE XHP 222Document10 pagesSafety Data Sheet: Product Name: MOBILGREASE XHP 222DenisNo ratings yet

- Gen Chem NotesDocument13 pagesGen Chem NotessusontangofeliptianjayNo ratings yet

- Acid Rain: Acid Rain Is A Rain or Any Other Form of Precipitation That IsDocument13 pagesAcid Rain: Acid Rain Is A Rain or Any Other Form of Precipitation That IsThomasNo ratings yet

- Developments in Insulating Paper For Pow PDFDocument30 pagesDevelopments in Insulating Paper For Pow PDFDante FilhoNo ratings yet

- Biology Notebook: 01.03 Earth's Early Atmosphere: Key Questions and Terms NotesDocument3 pagesBiology Notebook: 01.03 Earth's Early Atmosphere: Key Questions and Terms Notessomebody once told meNo ratings yet

- Solutions For Chapter6Document14 pagesSolutions For Chapter6kyyhnwyhc6No ratings yet

- Trends in Food Science & Technology: Rongze Sun, Jiakai Lu, Alissa NoldenDocument6 pagesTrends in Food Science & Technology: Rongze Sun, Jiakai Lu, Alissa NoldendeysiNo ratings yet

- Aliapur 2009 Reference DocumentDocument15 pagesAliapur 2009 Reference DocumentBeta AnalyticNo ratings yet

- Antigen-Antibody ReactionDocument4 pagesAntigen-Antibody ReactionDr. SUVA NATHNo ratings yet

- Acids Bases and SaltsDocument51 pagesAcids Bases and SaltsKevin NdanyiNo ratings yet

- Atomic Radius Graphing ActivityDocument2 pagesAtomic Radius Graphing ActivitytweetyaarushiNo ratings yet

- Aldehydes, Ketones and Carboxylic Acids: Module - 7Document29 pagesAldehydes, Ketones and Carboxylic Acids: Module - 7TeachingTrainingCoaching KnowledgeSharingSessionNo ratings yet

- Duoline Best Practices Intervention & Chemical CompatabilityDocument5 pagesDuoline Best Practices Intervention & Chemical CompatabilityWISSAMSOULIMANNo ratings yet

- Oswaal CBSE Class 11th Syllabus Chemistry For 2022-23 ExamDocument6 pagesOswaal CBSE Class 11th Syllabus Chemistry For 2022-23 Examlparesh267No ratings yet

- (PDF) GenBio2 - Module - Week05Document69 pages(PDF) GenBio2 - Module - Week05Ramon Villota100% (1)

- Recent Progress in Silver (I) - , Gold (I) / (III) - and Palladium (II) - Nheterocyclic Carbene Complexes: A Review Towards Biological PerspectivesDocument16 pagesRecent Progress in Silver (I) - , Gold (I) / (III) - and Palladium (II) - Nheterocyclic Carbene Complexes: A Review Towards Biological PerspectivesHiram CruzNo ratings yet

- BEU-345E Nalco Engineer Test Kits II, EnglishDocument4 pagesBEU-345E Nalco Engineer Test Kits II, EnglishwilmarlabacNo ratings yet

- Monenco Consultants Limited 400 Monenco Place 801-6th Avenue S.W. Calgary, Alberta T2P 3W3Document33 pagesMonenco Consultants Limited 400 Monenco Place 801-6th Avenue S.W. Calgary, Alberta T2P 3W3nermeen ahmedNo ratings yet

- Catalyst Worksheet - SHHSDocument3 pagesCatalyst Worksheet - SHHSNerd 101No ratings yet

- Diazonium SaltDocument16 pagesDiazonium Saltshiv.anishi337No ratings yet

- Determination of Impurities in Heparin by Capillary Electrophoresis Using High Molarity Phosphate BuffersDocument8 pagesDetermination of Impurities in Heparin by Capillary Electrophoresis Using High Molarity Phosphate BuffersJosé Alberto Santos GarcíaNo ratings yet

- Schott Brochure Technical Glasses UsDocument76 pagesSchott Brochure Technical Glasses Usfirstbook1100% (1)

- Veratherm: High-Temperature Water-Based Drilling FluidDocument8 pagesVeratherm: High-Temperature Water-Based Drilling FluidSupanca Ade Putri100% (1)

- Chapter 1 PharmacologyDocument5 pagesChapter 1 PharmacologyMaria Luisa VillalunaNo ratings yet

- Safety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIDocument11 pagesSafety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIZiurelNo ratings yet