Professional Documents

Culture Documents

Master Mf6400 WSM 10 en

Master Mf6400 WSM 10 en

Uploaded by

porcha1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Master Mf6400 WSM 10 en

Master Mf6400 WSM 10 en

Uploaded by

porcha1Copyright:

Available Formats

AUTOTRONIC 5 - Dyna-6 - Calibration

Bring the tractor up to temperature, for example:

A . Power Shuttle calibration Tractor stationary

Calibration of the Power Shuttle is mandatory when - Run the engine with the transmission lever and

the following components are changed: Power Shuttle lever in neutral and the PTO clutch

engaged.

- a Power Shuttle solenoid valve

- Measure and note the temperature.

- the solenoid valve control unit

- Then, before starting calibration, move the

- the Power Shuttle unit or one of its components

Power Shuttle lever 10 times in each direction,

- the Autotronic 5 - Transmission 1 controller leaving the lever in each position for 5 to

(CAB151) 10 seconds to bring the control unit and solenoid

valves up to the temperature of the transmis-

Given the temperature range allowed for calibration, sion.

the controllers optimise the quality of shifting by Tractor moving

continually correcting it depending on the transmission - Carry out reversing manoeuvres every 5 to

temperature. 10 seconds, in 2nd or 3rd range.

Calibration is automatic, which allows a deft and - Measure and note the temperature.

smooth quality of shifting.

The user can then, depending on requirements, adjust

the cycling of the Power Shuttle.

Conditions for calibration:

- from 35 to 45°C: optimum calibration

Preliminary steps - from 15 to 60°C: calibration authorised

If possible, the tractor should be positioned on flat

ground to carry out the calibration.

To gain entry into calibration mode, the transmission

oil temperature must be between 15°C and 60°C (59°F

and 140°F).

The temperature is measured by the sensor on the

gearbox. It can be read in 3 different ways:

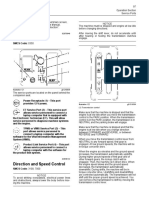

1. Direct display of the temperature on right-hand

screen of the DCC2 (for all tractors):

- Engine running

- Place the shuttle lever in neutral

- Simultaneously activate the button on the range A

shift switch and the differential lock switch for at

least 4 seconds

- The reading is displayed on the DCC2 (Fig. 1)

- The temperature reading can be switched off at

any time by pressing the DCC2 display selector

switch (CAB31)

Repeat the procedure to restore the temperature

display.

NOTE: The tractor can still be used when in temper-

ature reading mode, but the differential lock should MA-11-01519A

be disengaged.

2. Direct display of the temperature on the DOT

MATRIX screen by entering the diagnostic mode Fig. 1

(GUF224).

NOTE: The tractor can still be used when in temper-

ature reading mode.

3. Read using Wintest.

WINTEST - Issue 9.a GUF564.3

AUTOTRONIC 5 - Dyna-6 - Calibration

Automatic calibration

1. Apply the hand brake.

2. Start the engine.

3. Release the clutch pedal.

4. Increase the engine speed to 1500 rpm ± 100 with

the hand throttle lever, or by activating a memo-

rised speed (A or B).

5. Simultaneously, and at least for 3 seconds, acti-

vate:

A

- the Power Shuttle arm in raised position (manual A

declutching)

- the differential lock switch

6. The indicator lights for ranges 1 and 4 flash alter-

nately and "T" is displayed on the right-hand screen

of the DCC2 to indicate that the system is ready to

start calibration (Fig. 2).

7. Shift the Power Shuttle lever to forward position to KPH

start calibration.

8. Calibration takes approximately 2 minutes and the

indicator lights for ranges 1 and 4 flash alternately MA-11-01518A

throughout.

9. Calibration is complete when the indicator lights Fig. 2

for ranges 1 and 2 flash alternately.

10. Shift the Power Shuttle lever to neutral position to

validate the calibration. The range indicator lights

stop flashing and only the indicator light for the

range engaged comes on.

NOTE 1: At the end of calibration, Autotronic 5 errors

24 and 27 may be displayed; this does not indicate a

calibration error.

NOTE 2: To avoid calibration errors, it is important to:

- keep the engine speed set at 1500 rpm ± 100

- to keep the PowerControl lever in forward position

NOTE 3: The calibration phase is totally independent of

the possible settings for the Power Shuttle sensitivity

in the DOT MATRIX or with the potentiometer

(according to model).

GUF564.4 WINTEST - Issue 9.a

AUTOTRONIC 5 - Dyna-6 - Calibration

Validation The calibration is not correct if:

- the engine speed is not 1500 rpm ± 100

Immediate validation after calibration

- the gearbox temperature exceeds 60°C

1. Without stopping the engine.

- the Autotronic 5 label code is incorrect

2. Carry out 10 forward/reverse Power Shuttle

manoeuvres. - the Power Shuttle lever is placed in neutral position

3. Carry out 10 neutral to forward and neutral to NOTE: If the calibration fails, the incorrect parameters

reverse Power Shuttle manoeuvres. or default parameters (in the case of a new

Autotronic 5 unit) are taken into account. For this

4. Assess the quality of the shifting, which should be

reason, a new correct calibration must be carried out.

deft and smooth.

NOTE 1: Take into account the Power Shuttle progres-

sivity setting from the DOT MATRIX or using the

potentiometer (according to model). A zero setting will

allow the calibration to be validated correctly.

NOTE 2: Check that the differential lock and the front

axle are disengaged before carrying out the manoeu-

vres.

Validation of a tractor that has already been cali-

brated

NOTE: The transmission temperature must be above

15° C.

1. Start the engine.

2. The front axle must be disengaged.

3. Carry out 10 forward/reverse Power Shuttle

manoeuvres.

4. Carry out 10 neutral to forward and neutral to

reverse Power Shuttle manoeuvres.

5. Assess the quality of the shifting, which should be

deft and smooth.

NOTE: Take into account the Power Shuttle progres-

sivity setting from the DOT MATRIX or using the

potentiometer (according to model). A zero setting will

allow the calibration to be validated correctly.

Calibration faults

NOTE: A fault due to non-compliance of the conditions

required to access or maintain the calibration mode will

cause errors and poor tractor performance.

Entry into calibration mode is not provided if:

- the transmission temperature is not correct

- the engine speed is not 1500 rpm ± 100

- the Power Shuttle lever has not been placed in the

forward position

- the forward speed is not zero

- Ensure the calibration access conditions are

respected.

- Check the solenoid valve coil connections.

WINTEST - Issue 9.a GUF564.5

You might also like

- Transmission Control Unit (TCU) Calibration With 700 or Higher SoftwareDocument6 pagesTransmission Control Unit (TCU) Calibration With 700 or Higher SoftwareDavy GonzalezNo ratings yet

- Belarus MTZ 50 52 Operations MaintenancesDocument23 pagesBelarus MTZ 50 52 Operations Maintenanceslulu323283% (6)

- SuperTAPP SG RelayDocument10 pagesSuperTAPP SG RelayAtiqun NabiNo ratings yet

- Transmission Control Module (TCM) Adaptation - 8HP45 - 845re - 8HP70 - 8HP90Document5 pagesTransmission Control Module (TCM) Adaptation - 8HP45 - 845re - 8HP70 - 8HP90tejonmx67% (3)

- 745 Cat EtDocument6 pages745 Cat EtLucky advantureNo ratings yet

- UH-1H Huey Checklist V2Document2 pagesUH-1H Huey Checklist V2Jacobite Bond100% (1)

- TRANSMISSION Powershift - Calibrate: Quick Call-UpDocument5 pagesTRANSMISSION Powershift - Calibrate: Quick Call-UpAhmed ElzzaddenNo ratings yet

- Clarke Mechanical Engine Controller Alarm Verification ProcedureDocument4 pagesClarke Mechanical Engine Controller Alarm Verification ProcedureChanat MeonsiNo ratings yet

- Coal FeederDocument20 pagesCoal FeederVPORWAL50% (2)

- Pneum Act AdjDocument12 pagesPneum Act AdjFENGNo ratings yet

- Full Race Unit C-S1R Installation Manual-Feb-2023Document6 pagesFull Race Unit C-S1R Installation Manual-Feb-2023kafayaNo ratings yet

- Calibracion de EmbragguesDocument8 pagesCalibracion de EmbragguesRomeo WilliamsNo ratings yet

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Document5 pagesCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (2)

- Cola Yard 3Document11 pagesCola Yard 3pupung182No ratings yet

- Engagement Pressure For The Transmission Clutch - CalibrateDocument8 pagesEngagement Pressure For The Transmission Clutch - CalibrateVictor NunezNo ratings yet

- 5460 Hitch CalibrationDocument4 pages5460 Hitch CalibrationRichNo ratings yet

- Turbine Operation SequenceDocument3 pagesTurbine Operation SequenceTitas titasNo ratings yet

- C Y1 Y6 Manual 2020Document6 pagesC Y1 Y6 Manual 2020fathuNo ratings yet

- C K1 Manual 2020Document6 pagesC K1 Manual 2020Jon PadliNo ratings yet

- Manaul Supplement Tier-1 Alarm-Verify c134341Document2 pagesManaul Supplement Tier-1 Alarm-Verify c134341Ranses RomanNo ratings yet

- Speed Dial - Calibrate: Calibration Calibration CalibrationDocument2 pagesSpeed Dial - Calibrate: Calibration Calibration Calibrationmohamed ali100% (1)

- Sop 1 DraftDocument5 pagesSop 1 DraftSanjay GuptaNo ratings yet

- M Di 0008 PDFDocument4 pagesM Di 0008 PDFHassan raza naqviNo ratings yet

- The NAG1 (5-Speed) Automatic TransmissionDocument4 pagesThe NAG1 (5-Speed) Automatic TransmissionEdBunge100% (1)

- Detector Service ManualDocument4 pagesDetector Service Manualkhanh khanhNo ratings yet

- C K11 Manual 2020Document7 pagesC K11 Manual 2020RadNo ratings yet

- Quickshifter MAGNUM M-HS-KY Installation Manual-May-2023Document6 pagesQuickshifter MAGNUM M-HS-KY Installation Manual-May-2023kafayaNo ratings yet

- Kurimat Solar GTO - 601-700Document100 pagesKurimat Solar GTO - 601-700Mohamed AbdelbadieNo ratings yet

- Calibre Maximo FlujoDocument2 pagesCalibre Maximo FlujoRonaldo GaleanoNo ratings yet

- Kcm-Iia Instrument Panel For Marine G-Drive Engine: BulletinDocument21 pagesKcm-Iia Instrument Panel For Marine G-Drive Engine: BulletinShanish JobNo ratings yet

- JD770 Calibration of Transmission ControllerDocument3 pagesJD770 Calibration of Transmission Controllerenriquevazquez27No ratings yet

- Ajuste de La Velocidad de Movimientos Del Brazo TD40150Document6 pagesAjuste de La Velocidad de Movimientos Del Brazo TD40150RodrigoNo ratings yet

- APC200 Calibration X Operator-EDocument13 pagesAPC200 Calibration X Operator-EhoiNo ratings yet

- Pajero 1991 Cruise Control SystemDocument28 pagesPajero 1991 Cruise Control SystemnadaNo ratings yet

- Case 695Document9 pagesCase 695lapan111No ratings yet

- D-111 Bridge Control Manoeuvering Console InstructionsDocument2 pagesD-111 Bridge Control Manoeuvering Console InstructionsAkhil Raj BNo ratings yet

- Inside This Issue: Ø GeneralDocument6 pagesInside This Issue: Ø GeneralcarmaNo ratings yet

- Apc200 FredDocument4 pagesApc200 FredCao Lan100% (1)

- Air Volume Learn NissanDocument4 pagesAir Volume Learn NissanNuwan NishanthaNo ratings yet

- Section 55 - Electrical Systems - Chapter 11Document60 pagesSection 55 - Electrical Systems - Chapter 11احمد الشبراوى الشبراوىNo ratings yet

- MAGNAVALVE Mod ACDocument25 pagesMAGNAVALVE Mod ACdahora13No ratings yet

- Technical Information NoticeDocument7 pagesTechnical Information NoticejesusNo ratings yet

- SECTION 4012 Calibration ProceduresDocument28 pagesSECTION 4012 Calibration Procedureslungu mihai100% (1)

- Section 55 - Electrical System - Chapter 11: Electronic Draft Control Diagnostic Test RoutineDocument8 pagesSection 55 - Electrical System - Chapter 11: Electronic Draft Control Diagnostic Test RoutineDra MiNo ratings yet

- CMCDocument7 pagesCMCwasim_scribed100% (3)

- 19 Direct Drive ControlDocument5 pages19 Direct Drive ControlThomas BORNEYNo ratings yet

- CAT-777F-Direction and Speed ControlDocument2 pagesCAT-777F-Direction and Speed ControlCybergoNo ratings yet

- Transmission Control Module (TCM) Adaptation - 8HP45 / 845RE / 8HP50 / 8HP70 / 8HP75 / 8HP90Document6 pagesTransmission Control Module (TCM) Adaptation - 8HP45 / 845RE / 8HP50 / 8HP70 / 8HP75 / 8HP90jorge almaraz0% (1)

- Automatic Transmission For Range Rover 4 6 HSE P68Document20 pagesAutomatic Transmission For Range Rover 4 6 HSE P68Louise RogersNo ratings yet

- DYNS 30000 CalibratorDocument4 pagesDYNS 30000 Calibratorgolu201100% (2)

- Confirmation To Know That Station Had IslandedDocument10 pagesConfirmation To Know That Station Had IslandedSanjay GuptaNo ratings yet

- Calibración Gobernador 320c PDFDocument15 pagesCalibración Gobernador 320c PDFRforceIbañezNo ratings yet

- Testing and Adjusting Monitor Panel (Emms) - Special FuncDocument20 pagesTesting and Adjusting Monitor Panel (Emms) - Special FuncTú Anh NguyễnNo ratings yet

- Hawker-Siddeley HS.748 V1 ManualDocument18 pagesHawker-Siddeley HS.748 V1 Manualdani20100% (1)

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0010Document3 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0010PeterNo ratings yet

- Maintenance by Garr BhuwaDocument8 pagesMaintenance by Garr BhuwaejazNo ratings yet

- Hydrostatic System Calibration - tm13850x19 - Service ADVISOR™Document4 pagesHydrostatic System Calibration - tm13850x19 - Service ADVISOR™chrideerNo ratings yet

- Allison Features & Basic ConceptDocument7 pagesAllison Features & Basic Concepttgvnayagam100% (1)

- Overview of Cisco 1100 Series Integrated Services RoutersDocument12 pagesOverview of Cisco 1100 Series Integrated Services Routersyesid marroquinNo ratings yet

- Product Specification: SilverscapeDocument2 pagesProduct Specification: SilverscapeAhmed Fahd AmeerNo ratings yet

- B9 - High Power Contactors - EN (Web)Document108 pagesB9 - High Power Contactors - EN (Web)Fernando RapisardiNo ratings yet

- Aqua Smart ManualDocument36 pagesAqua Smart ManualDan AdamsNo ratings yet

- MWA300/330A: 3-Phase Ratio and Winding Resistance AnalyzerDocument6 pagesMWA300/330A: 3-Phase Ratio and Winding Resistance AnalyzerJavier CuzcoNo ratings yet

- Study of Reliability Analysis of CVT SystemDocument13 pagesStudy of Reliability Analysis of CVT Systemswapnil pandeNo ratings yet

- Manual de Servicio Del Aire Acondicionado LGDocument39 pagesManual de Servicio Del Aire Acondicionado LGcarlosavictoriaNo ratings yet

- 14 Factory DIP Switch Settings For Seiko DPU 414 Serial PrinterDocument2 pages14 Factory DIP Switch Settings For Seiko DPU 414 Serial PrinterRoBy RObNo ratings yet

- Warning: Symbol Identification Installation PrecautionsDocument7 pagesWarning: Symbol Identification Installation PrecautionstheunauthorisedNo ratings yet

- InsulationDocument5 pagesInsulationjaleelNo ratings yet

- Valvulas BarksdaleDocument4 pagesValvulas Barksdalends2006sNo ratings yet

- Very Simple Icroprocessor Anuary: Etienne - Sicard@Document28 pagesVery Simple Icroprocessor Anuary: Etienne - Sicard@Prakash KumarNo ratings yet

- Dana Spicer DEXT-OffhighwayCondensedSpecificationsDocument34 pagesDana Spicer DEXT-OffhighwayCondensedSpecificationsJonathan Vasquez Llaguno86% (7)

- Fastmig Sf52 Sf53 Om enDocument22 pagesFastmig Sf52 Sf53 Om enMarijan LesičakNo ratings yet

- Fault Diagnosis With DEUTZ TEM Evo System Fault D 1-1-3: Overtemperature Fault, Jacket Water at Engine OutletDocument1 pageFault Diagnosis With DEUTZ TEM Evo System Fault D 1-1-3: Overtemperature Fault, Jacket Water at Engine Outletpayman baharehNo ratings yet

- Davit Emergency Operating SystemDocument7 pagesDavit Emergency Operating Systemndagasan2000201No ratings yet

- Donaldson Ready Recokner 2018Document6 pagesDonaldson Ready Recokner 2018Hemant PanpaliyaNo ratings yet

- RM 9Document72 pagesRM 9ingen88888No ratings yet

- 104 en - Multifunction Power Supply, Large - PRA-MPS3Document23 pages104 en - Multifunction Power Supply, Large - PRA-MPS3Wilmer MojicaNo ratings yet

- Lab Manual Computer Organization and Hardware MaintenanceDocument28 pagesLab Manual Computer Organization and Hardware Maintenanceanshroy7373No ratings yet

- Modular Chiller Heat Pump EnglishDocument17 pagesModular Chiller Heat Pump EnglishAldifirNo ratings yet

- Bus Structure: Time MultiplexingDocument37 pagesBus Structure: Time MultiplexingKushal RajvanshiNo ratings yet

- Exp. 5 - Continuity Test For A Given Electrical Circuit Need For Continuity TestingDocument12 pagesExp. 5 - Continuity Test For A Given Electrical Circuit Need For Continuity Testingrishika chhibberNo ratings yet

- Coolmay TK Series User ManualDocument2 pagesCoolmay TK Series User ManualSeferino CampazNo ratings yet

- Petra UMA Touch CSD Acer Aspire V5-531-V5-571-V5-431Document103 pagesPetra UMA Touch CSD Acer Aspire V5-531-V5-571-V5-431ady putraNo ratings yet

- User Manual: Off Grid Solar Inverter 1KVA-5KVA (MHP)Document31 pagesUser Manual: Off Grid Solar Inverter 1KVA-5KVA (MHP)Nouhouyi Ali GouniNo ratings yet

- Tronic - Cy PDFDocument2 pagesTronic - Cy PDFEugenioNo ratings yet

- Weichai EngineDocument114 pagesWeichai EnginehaviettuanNo ratings yet

- IMMO System PDFDocument107 pagesIMMO System PDFBemax Roland100% (1)

- How To Make A Hulda Clark ZAPPER (See Also Bob Beck, Raymond Rife)Document4 pagesHow To Make A Hulda Clark ZAPPER (See Also Bob Beck, Raymond Rife)Carlos100% (1)