Professional Documents

Culture Documents

Projects Launching & Receiving Procedure

Projects Launching & Receiving Procedure

Uploaded by

Atif QamarCopyright:

Available Formats

You might also like

- Attachment Disturbances in Adults Treatment For Comprehensive Repair (Etc.) (Z-Library)Document477 pagesAttachment Disturbances in Adults Treatment For Comprehensive Repair (Etc.) (Z-Library)fa ab100% (8)

- Mi-17 ChecklistDocument32 pagesMi-17 Checklistpilot digital100% (11)

- Boeing 737-300 Transit CheckDocument6 pagesBoeing 737-300 Transit CheckUmer JavedNo ratings yet

- Procedures For Pigging OperationsDocument5 pagesProcedures For Pigging Operationsテレブリコ ジェファーソン78% (9)

- Pipeline Pigging ProcedureDocument22 pagesPipeline Pigging Proceduresamkarthik47100% (5)

- Concept MapDocument1 pageConcept MapLesley Joy T. BaldonadoNo ratings yet

- Iequipment (EDC) PDFDocument44 pagesIequipment (EDC) PDFAli mohammadNo ratings yet

- Block II Tech ManualDocument19 pagesBlock II Tech ManualWilliam James AbercrombieNo ratings yet

- Best Practice Guidelines: Surgical Skin PreparationDocument13 pagesBest Practice Guidelines: Surgical Skin PreparationAnwar RosyidNo ratings yet

- Establish Kinder Garden School - Develope Project ManagerDocument25 pagesEstablish Kinder Garden School - Develope Project ManagerVõ Thúy Trân0% (1)

- Att 11 - Launching and Receiving ProcedureDocument4 pagesAtt 11 - Launching and Receiving ProcedureAvdhesh YadavNo ratings yet

- IWCF Equipment اسئله Sep 18 MaerskDocument56 pagesIWCF Equipment اسئله Sep 18 MaerskAboZaidNo ratings yet

- Rxq6Ary1 Rxq8Ary1 RXQ10ARY1 RXQ12ARY1 RXQ14ARY1 RXQ16ARY1 RXQ18ARY1 RXQ20ARY1Document44 pagesRxq6Ary1 Rxq8Ary1 RXQ10ARY1 RXQ12ARY1 RXQ14ARY1 RXQ16ARY1 RXQ18ARY1 RXQ20ARY1Tangtang SatangNo ratings yet

- Owners Manual-Z Milpro Heavy Duty mk4-mk5-mk6Document19 pagesOwners Manual-Z Milpro Heavy Duty mk4-mk5-mk6João Miguel FrancoNo ratings yet

- Sofis Netherlocks InterlocksDocument12 pagesSofis Netherlocks InterlockscesarNo ratings yet

- Tcpl-1X63.75 MW Power Plant, Gummidipoondi - 1Document5 pagesTcpl-1X63.75 MW Power Plant, Gummidipoondi - 1SelvaNo ratings yet

- Pigging: Describe The Main Reasons For Launching A PigDocument6 pagesPigging: Describe The Main Reasons For Launching A PigImmanuelNo ratings yet

- X1 BASE Plus ManuelDocument8 pagesX1 BASE Plus ManuelTyler BergstromNo ratings yet

- BB-4-18/23 Quick Guide: Warnings and Safety PrecautionsDocument4 pagesBB-4-18/23 Quick Guide: Warnings and Safety PrecautionsWalter Dario LopezNo ratings yet

- sd8 Valve Overall DetailsDocument1 pagesd8 Valve Overall DetailsVEERAMANINo ratings yet

- Sop-Gtd 260613 R1Document68 pagesSop-Gtd 260613 R1antopaul2No ratings yet

- Manual - Vacuum Pump WRP25Document20 pagesManual - Vacuum Pump WRP25juaanxpoonceNo ratings yet

- SR-1 Spring Brake Valve (SD-03-4508)Document8 pagesSR-1 Spring Brake Valve (SD-03-4508)EdvinCastleNo ratings yet

- FX 6Document116 pagesFX 6Jared PérezNo ratings yet

- IWCFmDocument182 pagesIWCFmmarboudNo ratings yet

- Luxfer SOPMPV Manual Rev 3bDocument16 pagesLuxfer SOPMPV Manual Rev 3bandreicarbuneanuNo ratings yet

- D-241 Dilution & FlushingDocument1 pageD-241 Dilution & FlushingHammad HussainNo ratings yet

- Section 2 Structure and FunctionDocument9 pagesSection 2 Structure and FunctionJose SanchezNo ratings yet

- H6-Sany 135 PDFDocument17 pagesH6-Sany 135 PDFHector bustosNo ratings yet

- K35 Omx0069Document5 pagesK35 Omx0069PABLO BENJAMÍN CÉSPEDES FUENTESNo ratings yet

- 2946 1186 00 Maintenance Procedure GA 11-30 (VSD)Document9 pages2946 1186 00 Maintenance Procedure GA 11-30 (VSD)Rui FortunaNo ratings yet

- Ls400 (Deutzengine) : Cold Start Relay KitDocument10 pagesLs400 (Deutzengine) : Cold Start Relay KitALEJONo ratings yet

- MAB Separator PDFDocument2 pagesMAB Separator PDFSundarNo ratings yet

- Samsung AD 18 26 B1C Service ManualDocument37 pagesSamsung AD 18 26 B1C Service ManualdixlopNo ratings yet

- Pigging Operations Pipeline PigsDocument6 pagesPigging Operations Pipeline PigsVerghese OommenNo ratings yet

- Section Iv Main Landing GearDocument51 pagesSection Iv Main Landing GearLeonardo Alfonso Carcamo CarreñoNo ratings yet

- By Pass Type Pig ValvesDocument8 pagesBy Pass Type Pig ValvesvsajuNo ratings yet

- N2 Chain Thawing - SOP U O 48 05Document6 pagesN2 Chain Thawing - SOP U O 48 05Harmohan KaulNo ratings yet

- Sigurnosni Ventili Hidraulike 7 I 7aDocument11 pagesSigurnosni Ventili Hidraulike 7 I 7aDraganNo ratings yet

- Emitec (Groundfos) System IntroductionDocument30 pagesEmitec (Groundfos) System IntroductionЕвгений100% (2)

- Accumulator CatalogueDocument4 pagesAccumulator CatalogueDomingos BarrosNo ratings yet

- Img 0049 PDFDocument1 pageImg 0049 PDFandrewNo ratings yet

- Water Level GaugeDocument6 pagesWater Level GaugeAlexander BaziotisNo ratings yet

- Chapter 10 Steering SystemDocument17 pagesChapter 10 Steering SystemPepe AlNo ratings yet

- (Customer) 04 DX75-5B Control Valve (BCV-65) (To Print)Document8 pages(Customer) 04 DX75-5B Control Valve (BCV-65) (To Print)AimHighNo ratings yet

- Instructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air ValvesDocument15 pagesInstructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air Valvessure_iitdNo ratings yet

- CH 10 Pneumatic Control ValvesDocument20 pagesCH 10 Pneumatic Control Valvesarindam57000No ratings yet

- R55-9 1Document57 pagesR55-9 1hungNo ratings yet

- Filling LCU in ABB DDS, ElectricalDocument4 pagesFilling LCU in ABB DDS, ElectricalAndrea SnyderNo ratings yet

- Transformer Service ManualDocument11 pagesTransformer Service Manualshivaram100% (1)

- A320 Fuel SystemDocument211 pagesA320 Fuel SystemSHAKTI ASHISH KAR100% (1)

- Guide Lines-: Heavy Storm Water HandlingDocument1 pageGuide Lines-: Heavy Storm Water HandlingAnonymous 5PGSwX5No ratings yet

- 4650 and 4850 Section 70Document58 pages4650 and 4850 Section 70josephmw0308No ratings yet

- API 6A Hydraulic Actuator Operation InstructionDocument7 pagesAPI 6A Hydraulic Actuator Operation InstructionSrikanth Bammhide100% (1)

- Evk2rv 110-390 Manual enDocument13 pagesEvk2rv 110-390 Manual enKjsNo ratings yet

- Man B&W: Cylinder CoverDocument22 pagesMan B&W: Cylinder CoverRobert LuuNo ratings yet

- Figure 21-00-00-18200-00-J / SHEET 1/1 - Air Cond. Display ON A/C 201-201, 207-207Document1 pageFigure 21-00-00-18200-00-J / SHEET 1/1 - Air Cond. Display ON A/C 201-201, 207-207chinna_jetNo ratings yet

- Technical Data: The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058Document1 pageTechnical Data: The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058Dgh TeriNo ratings yet

- CV STM Sec 4 - Startup AdjDocument26 pagesCV STM Sec 4 - Startup AdjBams ArifinNo ratings yet

- DX75控制阀BCV-65 Manual EngDocument27 pagesDX75控制阀BCV-65 Manual EngAimHighNo ratings yet

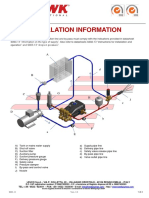

- S001-13 Installation SchemeDocument4 pagesS001-13 Installation SchemeJoe JohnsonNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Air Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811From EverandAir Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811No ratings yet

- UntitledDocument48 pagesUntitledAtif QamarNo ratings yet

- Recruitment AgenciesDocument22 pagesRecruitment AgenciesAtif Qamar100% (1)

- UntitledDocument2 pagesUntitledAtif QamarNo ratings yet

- Atif Qamar Webbased EnvironmentDocument7 pagesAtif Qamar Webbased EnvironmentAtif QamarNo ratings yet

- Alice Becker-Ho, The Language of Those in The KnowDocument4 pagesAlice Becker-Ho, The Language of Those in The KnowIntothepill Net100% (1)

- Sailing With Paul - IronsideDocument3 pagesSailing With Paul - IronsideLawrence GarnerNo ratings yet

- World Red Cross DayDocument17 pagesWorld Red Cross DayAshwani K SharmaNo ratings yet

- RemotingDocument13 pagesRemotingapi-26312742No ratings yet

- 11 Ultimate Protection Video Charitable Religious TrustsDocument12 pages11 Ultimate Protection Video Charitable Religious TrustsKing FishNo ratings yet

- Practical Work 1 EventDocument19 pagesPractical Work 1 EventNur ShakirinNo ratings yet

- (GOLD) The Examples of Final Semester TestDocument8 pages(GOLD) The Examples of Final Semester TestMetiska MunzilaNo ratings yet

- Satellite CommunicationsDocument57 pagesSatellite Communicationsheritage336No ratings yet

- LP in MusicDocument10 pagesLP in MusicContagious Joy VillapandoNo ratings yet

- The African Essentials - Presentation - O - 2019Document34 pagesThe African Essentials - Presentation - O - 2019Fatima SilvaNo ratings yet

- Hockey - Indian National Game-2compDocument21 pagesHockey - Indian National Game-2compRaj BadreNo ratings yet

- Primary Gingival Squamous Cell CarcinomaDocument7 pagesPrimary Gingival Squamous Cell CarcinomaMandyWilsonNo ratings yet

- Pgcet Environmental Engineering PaperDocument10 pagesPgcet Environmental Engineering PaperRamNo ratings yet

- Company Profile: TML Drivelines LTD (Tata Motors, Jamshedpur)Document5 pagesCompany Profile: TML Drivelines LTD (Tata Motors, Jamshedpur)Madhav NemalikantiNo ratings yet

- JD Edwards Enterpriseone Tools: Form Design Aid Guide Release 9.1.XDocument530 pagesJD Edwards Enterpriseone Tools: Form Design Aid Guide Release 9.1.XGaurav SahuNo ratings yet

- Identification and Certification of Labconco Class Ii Safety CabinetsDocument9 pagesIdentification and Certification of Labconco Class Ii Safety CabinetscobramcNo ratings yet

- Mehdi To TestDocument13 pagesMehdi To Testtestcoolvms16No ratings yet

- Small Unit Operations: PMA Core Values: Selfless Service To God and Country, Honor, ExcellenceDocument33 pagesSmall Unit Operations: PMA Core Values: Selfless Service To God and Country, Honor, ExcellenceAbay GeeNo ratings yet

- Ahad NaamahDocument2 pagesAhad NaamahedoolawNo ratings yet

- En 12245 (2022) (E)Document9 pagesEn 12245 (2022) (E)David Chirinos100% (1)

- Why Romanian Journal of Food ScienceDocument2 pagesWhy Romanian Journal of Food ScienceAna Vitelariu - RaduNo ratings yet

- Adavantages of Historical ResearchDocument2 pagesAdavantages of Historical ResearchClemence JeniferNo ratings yet

- How To Cite A Research Paper in TextDocument8 pagesHow To Cite A Research Paper in Textafnkaufhczyvbc100% (1)

- Mauro Giuliani: Etudes Instructives, Op. 100Document35 pagesMauro Giuliani: Etudes Instructives, Op. 100Thiago Camargo Juvito de Souza100% (1)

- Break Even AnalysisDocument18 pagesBreak Even AnalysisSMHE100% (10)

- Brandi PPT For BrandingDocument27 pagesBrandi PPT For BrandingShah ParinNo ratings yet

Projects Launching & Receiving Procedure

Projects Launching & Receiving Procedure

Uploaded by

Atif QamarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Projects Launching & Receiving Procedure

Projects Launching & Receiving Procedure

Uploaded by

Atif QamarCopyright:

Available Formats

LAUNCHING & RECEIVING PROCEDURE

LAUNCHING & RECEIVING

PROCEDURE

Issue 1 February 2009 Page 1 of 11

LAUNCHING & RECEIVING PROCEDURE

TABLE OF CONTENTS

1. LAUNCHER & RECEIVER SAFETY PRECAUTIONS ………………………… 4

2. TOOL BOX MEETING…………………………………………………………….. 6

3. LAUNCHING PROCEDURE……………………………………………………….7

4. RECEIVING PROCEDURE…………………………………………………….......9

5. NON- STANDARD PIGGING………………………………………………………12

Issue 1 February 2009 Page 2 of 11

LAUNCHING & RECEIVING PROCEDURE

Launcher & Receiver Safety Precautions

1. In the procedure steps below, there are several references to the need to

ensure by visual inspection or direct measurement that complete replacement

of one type of medium with another has taken place, e.g. displacing air with

liquid, displacing air with gas, etc. This is to prevent air (specifically oxygen)

from entering the pipeline that may generate increased corrosion in the

pipeline.

2. In case of a closed drain system, it is essential that the appropriate and correct

methods are used to ensure total displacement of the medium before

proceeding to the next activity in this procedure.

3. Blockages of drain and vent valves by pig cups or large quantity of debris is

possible. Similarly pressure gauges may be sometimes faulty or broken. At

least two pressure gauges shall be fitted to the barrel of the launcher / receiver

to guard against this event.

4. If there is any doubt that the barrel is not at zero pressure, close vent and drain

valves and re-pressurize the equipment. Observe very carefully the change in

pressure that is indicated, particularly during depressurizing the barrel.

5. When opening the launcher or receiver door never stand in front of the door or

at that side where the hinge is fitted. Ensure that nobody stands directly in line

with the door.

6. The receiver shall be lined up before launching a pig if the length of time that

this facility is left pressurized does not exceed one day. All launching facilities

shall be depressurized as part of the launcher sequence.

7. The receiver facilities shall be depressurized a maximum of 3-4 working hours

after receipt of pig. Where the pig receiver is sited within a station the operator

shall verify receipt of the pig and that isolation of the receiver has been properly

completed.

8. Special precautions need to be taken on receiving pyrophoric dust. Collection

and disposal of the dust shall be responsibility of the Client.

Issue 1 February 2009 Page 3 of 11

LAUNCHING & RECEIVING PROCEDURE

9. Naturally occurring radioactive material (NORM) may in some areas be

produced from the reservoir and be entrained in pigging debris. Those receivers

where NORM is presented must be identified by Client and indicated to the

pigging crew.

10. Special precautions shall be taken in circumstance where NORM is present

with particular attention being paid to personal protective equipment (PPE) and

to the handling and disposal of debris during and after recovery of the pigs.

Collection and disposal of NORM contaminated debris is the responsibility of

the Client.

Issue 1 February 2009 Page 4 of 11

LAUNCHING & RECEIVING PROCEDURE

Toolbox Meeting

Conduct toolbox meeting; ensure all concerned understand procedures and

responsibilities, emphasizing safe working practices. All attendees need to confirm

that all is understood by signing the “Attendees” sheet of the Tool Box Meeting

Form.

Issue 1 February 2009 Page 5 of 11

LAUNCHING & RECEIVING PROCEDURE

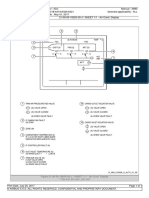

Launching Procedure

C2

C1 A

C3

P1 H P1 H

P1 H

E G1

G2

F

B

A - Main line valve

D Balance Line B - Main isolating valve

C1 - Kicker valve

D - Drain valve

E - Vent valve

F - Door

Figure 1. Typical Launcher G1, G2 - Pig alerts (pig sigs)

H - Pressure gauge

I - Pres. equalizing valve

1. Ensure kicker valves (C1+C2+C3) and isolation valves (B) are closed. *

2. Open drain valve (D) and vent valve (E) to drain and depressurize the launcher

barrel. Confirm zero pressure. Unseat bleed screw on door.*

Note 1: If no fluid flows through the bleed screw, remove bleed screw. Airflow into trap indicates

that fluid is still flowing from the trap via the drain. When the airflow stops the traps is

fully drained and the door may be opened.

Note 2: A number of older doors may not be fitted with bleed screws. In these cases additional

precautions shall be taken before opening the door, .e.g. confirm by visual observation

that draining has stopped.

3. Open door (F) in accordance with manufacturer’s procedure.*

4. Load pig into barrel, ensuring that the front driving cups are in contact with the

reducing portion of the barrel.**

5. Check door seal, clean and lightly oil mating surfaces, close door. Close drain

valve (D), ensure that door is securely locked in accordance with the

manufacturer’s procedure.*

Issue 1 February 2009 Page 6 of 11

LAUNCHING & RECEIVING PROCEDURE

6. Open the pressure equalizing valve (I), if fitted across the barrel eccentric

reducer in order to prevent the pig coming into contact with the main isolation

valve whilst pressuring up the barrel. Close drain valve (D) open kicker valve

(C2) then slowly crack valve (C3) open. As oil/gas enters air will be displaced

from the barrel through the vent valve (E).*

7. When barrel is full of product, close vent valve (E) and allow the barrel to

pressurize fully. In the case of a gaseous product air will be replaced by gas.

Continuous reading shall be taken until 100% gas is detected at the vent valve

(E).*

Note 1: Ignition sources shall be removed from the area and continuous atmospheric

monitoring within the area shall be carried out.

Note 2: In H2S designated areas the procedures for entering and working in an H2S area must

be followed. As a minimum each LIN SCAN employee needs to carry a personal H2S

detector at all times.

8. Check all pressure gauges give the same reading. Close kicker valve (C2) and

(C3).*

9. Close pressure equalizing valve (I).*

10. Set the pig signaler (G1) and (G2) open main isolating valve (B) fully. *

11. Open kicker valve (C1) fully.*

12. Slowly close main line valve (A) to force product flow through the launcher until

pig signaler (G1) trips showing that the pig has left the barrel and its traveling

through the pipeline. Reset the pig signaler.*

13. Open main line valve (A).*

14. Close kicker valve (C1).*

15. Close main isolating valve (B) and vent valve (E).*

16. Drain and depressurized as mentioned above.*

17. Close drain valve (D) and vent valve (E) clean and empty drain pit.*

* Performed by Client

** Performed by LIN SCAN

Issue 1 February 2009 Page 7 of 11

LAUNCHING & RECEIVING PROCEDURE

Receiving Procedure

C2

C1 A

C3

P1 H P1 H

P1 H

E G1

G2

F

B

A - Main line valve

D Balance Line B - Main isolating valve

C1 - Kicker valve

D - Drain valve

E - Vent valve

F - Door

Figure 2. Typical Receiver G1, G2 - Pig alerts (pigsigs)

H - Pressure gauge

I - Pres. equalizing valve

1. At the start main line valve (A) is open, main isolating valve (B) and kicker

valves (C1, C2 and C3) are closed.*

2. Ensure that drain valve (D) is closed and that the door (F) is secured as per

manufacturer procedure and that the pressure equalizing valve (I) is open.*

3. Open vent valve(s) (E).*

4. Open (C2) crack open (C3) and fill the barrel while air is being vented via (E).*

5. In the case of a gas pipeline air will be replaced by gas, continuous reading

shall be taken until 100% gas is detected at the vent valve.*

Note 1: Ignition sources shall be removed from the area and continuous atmospheric

monitoring within the area shall be carried out.

Note 2: In H2S designated areas the procedure for entering and working in an H2S area

must be followed. As a minimum each LIN SCAN employee needs to carry a

personal H2S detector at all times.

Issue 1 February 2009 Page 8 of 11

LAUNCHING & RECEIVING PROCEDURE

6. When the barrel is filled with product, close vent valves (E) and allow the barrel

to pressurize fully. Check that the barrel pressure gauge shows the same

values as the line pressure gauge.*

7. Open kicker valve (C1) fully and open main isolating valve (B). This allows fluid

to flow through the receiver.*

8. Close the main line valve (A) completely.*

9. Confirm there is no leakage from the door seal and fittings before leaving the

site.*

10. Arrival of the pig is shown initially by pig alert (G1) being activated. Pig alert

(G2) should activate shortly afterwards to show that the pig has entered the

barrel.

11. Once pig is the receiver barrel, open main line valve (A) fully.*

12. Close main isolating valve (B).*

13. Close kicker valve (C1, C2 and C3).*

14. Drain and de-pressure through drain valve (D) and vent valve(s) (E). Ensure

that the pressure equalizing line (I), if fitted across the reducer, is open. Confirm

that pressure is zero. Unseat bleed screw on door.*

15. If no fluid flows through the bleed screw, removed bleed screw, airflow into the

trap indicates that fluid is still flowing from the trap via the drain. When the

airflow stops the trap is fully drained and the door may be opened.*

Note: A number if older doors may not be fitted with bleed screws. In this case additional

precautions shall be taken before opening the door, e.g. confirm by visual observation

that drain had stopped.

16. Open door (F) and remove pig. */**

17. Clean out receiver barrel and take sample of debris, if specially required. A

sample sheet shall be completed and sent with the sample to the appropriate

laboratory. Check door seal clean and lightly oil mating surfaces.*

Issue 1 February 2009 Page 9 of 11

LAUNCHING & RECEIVING PROCEDURE

18. Close door (F) drain valve (D) and vent valve (E). Ensure door (F) is secured as

per manufacturer procedure.*

19. Empty and clean the drain pit and cross check the valve positions before

leaving the site.*

* Performed by Client

** Performed by LIN SCAN

Issue 1 February 2009 Page 10 of 11

LAUNCHING & RECEIVING PROCEDURE

Non Standard Pigging

In the event that pigging activities are required on a pipeline without permanent pig

launching/receiving facilities, the following additional requirement shall apply.

1. Temporary launching/receiving facilities shall be constructed specifically for the

project, which will ensure safe performance of the pigging activities.

2. The configuration shall be similar to that found on Figure 1, typical

launcher/receiver arrangement, contained in this document.

3. Sufficient valves shall be provided to assure isolation of the trap from the

pipeline and pressure gauge shall be installed in order to allow personnel

involved in the pigging activity to confirm the pressure in the barrel.

4. A procedure for the non-routine pigging activity shall be prepared. The

procedure shall be reviewed and approved by all parties involved prior to

commencement at work.

5. As a minimum the non-routine procedure shall include the necessary steps and

related valve movement (open/close) to assure safe launching and/or receiving

of the pig.

6. Sketches of all pertinent facilities shall be provided.

7. Special attention shall be paid to any flexible hoses used to ensure that they

are adequately anchored and pressure rated.

Issue 1 February 2009 Page 11 of 11

You might also like

- Attachment Disturbances in Adults Treatment For Comprehensive Repair (Etc.) (Z-Library)Document477 pagesAttachment Disturbances in Adults Treatment For Comprehensive Repair (Etc.) (Z-Library)fa ab100% (8)

- Mi-17 ChecklistDocument32 pagesMi-17 Checklistpilot digital100% (11)

- Boeing 737-300 Transit CheckDocument6 pagesBoeing 737-300 Transit CheckUmer JavedNo ratings yet

- Procedures For Pigging OperationsDocument5 pagesProcedures For Pigging Operationsテレブリコ ジェファーソン78% (9)

- Pipeline Pigging ProcedureDocument22 pagesPipeline Pigging Proceduresamkarthik47100% (5)

- Concept MapDocument1 pageConcept MapLesley Joy T. BaldonadoNo ratings yet

- Iequipment (EDC) PDFDocument44 pagesIequipment (EDC) PDFAli mohammadNo ratings yet

- Block II Tech ManualDocument19 pagesBlock II Tech ManualWilliam James AbercrombieNo ratings yet

- Best Practice Guidelines: Surgical Skin PreparationDocument13 pagesBest Practice Guidelines: Surgical Skin PreparationAnwar RosyidNo ratings yet

- Establish Kinder Garden School - Develope Project ManagerDocument25 pagesEstablish Kinder Garden School - Develope Project ManagerVõ Thúy Trân0% (1)

- Att 11 - Launching and Receiving ProcedureDocument4 pagesAtt 11 - Launching and Receiving ProcedureAvdhesh YadavNo ratings yet

- IWCF Equipment اسئله Sep 18 MaerskDocument56 pagesIWCF Equipment اسئله Sep 18 MaerskAboZaidNo ratings yet

- Rxq6Ary1 Rxq8Ary1 RXQ10ARY1 RXQ12ARY1 RXQ14ARY1 RXQ16ARY1 RXQ18ARY1 RXQ20ARY1Document44 pagesRxq6Ary1 Rxq8Ary1 RXQ10ARY1 RXQ12ARY1 RXQ14ARY1 RXQ16ARY1 RXQ18ARY1 RXQ20ARY1Tangtang SatangNo ratings yet

- Owners Manual-Z Milpro Heavy Duty mk4-mk5-mk6Document19 pagesOwners Manual-Z Milpro Heavy Duty mk4-mk5-mk6João Miguel FrancoNo ratings yet

- Sofis Netherlocks InterlocksDocument12 pagesSofis Netherlocks InterlockscesarNo ratings yet

- Tcpl-1X63.75 MW Power Plant, Gummidipoondi - 1Document5 pagesTcpl-1X63.75 MW Power Plant, Gummidipoondi - 1SelvaNo ratings yet

- Pigging: Describe The Main Reasons For Launching A PigDocument6 pagesPigging: Describe The Main Reasons For Launching A PigImmanuelNo ratings yet

- X1 BASE Plus ManuelDocument8 pagesX1 BASE Plus ManuelTyler BergstromNo ratings yet

- BB-4-18/23 Quick Guide: Warnings and Safety PrecautionsDocument4 pagesBB-4-18/23 Quick Guide: Warnings and Safety PrecautionsWalter Dario LopezNo ratings yet

- sd8 Valve Overall DetailsDocument1 pagesd8 Valve Overall DetailsVEERAMANINo ratings yet

- Sop-Gtd 260613 R1Document68 pagesSop-Gtd 260613 R1antopaul2No ratings yet

- Manual - Vacuum Pump WRP25Document20 pagesManual - Vacuum Pump WRP25juaanxpoonceNo ratings yet

- SR-1 Spring Brake Valve (SD-03-4508)Document8 pagesSR-1 Spring Brake Valve (SD-03-4508)EdvinCastleNo ratings yet

- FX 6Document116 pagesFX 6Jared PérezNo ratings yet

- IWCFmDocument182 pagesIWCFmmarboudNo ratings yet

- Luxfer SOPMPV Manual Rev 3bDocument16 pagesLuxfer SOPMPV Manual Rev 3bandreicarbuneanuNo ratings yet

- D-241 Dilution & FlushingDocument1 pageD-241 Dilution & FlushingHammad HussainNo ratings yet

- Section 2 Structure and FunctionDocument9 pagesSection 2 Structure and FunctionJose SanchezNo ratings yet

- H6-Sany 135 PDFDocument17 pagesH6-Sany 135 PDFHector bustosNo ratings yet

- K35 Omx0069Document5 pagesK35 Omx0069PABLO BENJAMÍN CÉSPEDES FUENTESNo ratings yet

- 2946 1186 00 Maintenance Procedure GA 11-30 (VSD)Document9 pages2946 1186 00 Maintenance Procedure GA 11-30 (VSD)Rui FortunaNo ratings yet

- Ls400 (Deutzengine) : Cold Start Relay KitDocument10 pagesLs400 (Deutzengine) : Cold Start Relay KitALEJONo ratings yet

- MAB Separator PDFDocument2 pagesMAB Separator PDFSundarNo ratings yet

- Samsung AD 18 26 B1C Service ManualDocument37 pagesSamsung AD 18 26 B1C Service ManualdixlopNo ratings yet

- Pigging Operations Pipeline PigsDocument6 pagesPigging Operations Pipeline PigsVerghese OommenNo ratings yet

- Section Iv Main Landing GearDocument51 pagesSection Iv Main Landing GearLeonardo Alfonso Carcamo CarreñoNo ratings yet

- By Pass Type Pig ValvesDocument8 pagesBy Pass Type Pig ValvesvsajuNo ratings yet

- N2 Chain Thawing - SOP U O 48 05Document6 pagesN2 Chain Thawing - SOP U O 48 05Harmohan KaulNo ratings yet

- Sigurnosni Ventili Hidraulike 7 I 7aDocument11 pagesSigurnosni Ventili Hidraulike 7 I 7aDraganNo ratings yet

- Emitec (Groundfos) System IntroductionDocument30 pagesEmitec (Groundfos) System IntroductionЕвгений100% (2)

- Accumulator CatalogueDocument4 pagesAccumulator CatalogueDomingos BarrosNo ratings yet

- Img 0049 PDFDocument1 pageImg 0049 PDFandrewNo ratings yet

- Water Level GaugeDocument6 pagesWater Level GaugeAlexander BaziotisNo ratings yet

- Chapter 10 Steering SystemDocument17 pagesChapter 10 Steering SystemPepe AlNo ratings yet

- (Customer) 04 DX75-5B Control Valve (BCV-65) (To Print)Document8 pages(Customer) 04 DX75-5B Control Valve (BCV-65) (To Print)AimHighNo ratings yet

- Instructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air ValvesDocument15 pagesInstructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air Valvessure_iitdNo ratings yet

- CH 10 Pneumatic Control ValvesDocument20 pagesCH 10 Pneumatic Control Valvesarindam57000No ratings yet

- R55-9 1Document57 pagesR55-9 1hungNo ratings yet

- Filling LCU in ABB DDS, ElectricalDocument4 pagesFilling LCU in ABB DDS, ElectricalAndrea SnyderNo ratings yet

- Transformer Service ManualDocument11 pagesTransformer Service Manualshivaram100% (1)

- A320 Fuel SystemDocument211 pagesA320 Fuel SystemSHAKTI ASHISH KAR100% (1)

- Guide Lines-: Heavy Storm Water HandlingDocument1 pageGuide Lines-: Heavy Storm Water HandlingAnonymous 5PGSwX5No ratings yet

- 4650 and 4850 Section 70Document58 pages4650 and 4850 Section 70josephmw0308No ratings yet

- API 6A Hydraulic Actuator Operation InstructionDocument7 pagesAPI 6A Hydraulic Actuator Operation InstructionSrikanth Bammhide100% (1)

- Evk2rv 110-390 Manual enDocument13 pagesEvk2rv 110-390 Manual enKjsNo ratings yet

- Man B&W: Cylinder CoverDocument22 pagesMan B&W: Cylinder CoverRobert LuuNo ratings yet

- Figure 21-00-00-18200-00-J / SHEET 1/1 - Air Cond. Display ON A/C 201-201, 207-207Document1 pageFigure 21-00-00-18200-00-J / SHEET 1/1 - Air Cond. Display ON A/C 201-201, 207-207chinna_jetNo ratings yet

- Technical Data: The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058Document1 pageTechnical Data: The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058Dgh TeriNo ratings yet

- CV STM Sec 4 - Startup AdjDocument26 pagesCV STM Sec 4 - Startup AdjBams ArifinNo ratings yet

- DX75控制阀BCV-65 Manual EngDocument27 pagesDX75控制阀BCV-65 Manual EngAimHighNo ratings yet

- S001-13 Installation SchemeDocument4 pagesS001-13 Installation SchemeJoe JohnsonNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Air Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811From EverandAir Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811No ratings yet

- UntitledDocument48 pagesUntitledAtif QamarNo ratings yet

- Recruitment AgenciesDocument22 pagesRecruitment AgenciesAtif Qamar100% (1)

- UntitledDocument2 pagesUntitledAtif QamarNo ratings yet

- Atif Qamar Webbased EnvironmentDocument7 pagesAtif Qamar Webbased EnvironmentAtif QamarNo ratings yet

- Alice Becker-Ho, The Language of Those in The KnowDocument4 pagesAlice Becker-Ho, The Language of Those in The KnowIntothepill Net100% (1)

- Sailing With Paul - IronsideDocument3 pagesSailing With Paul - IronsideLawrence GarnerNo ratings yet

- World Red Cross DayDocument17 pagesWorld Red Cross DayAshwani K SharmaNo ratings yet

- RemotingDocument13 pagesRemotingapi-26312742No ratings yet

- 11 Ultimate Protection Video Charitable Religious TrustsDocument12 pages11 Ultimate Protection Video Charitable Religious TrustsKing FishNo ratings yet

- Practical Work 1 EventDocument19 pagesPractical Work 1 EventNur ShakirinNo ratings yet

- (GOLD) The Examples of Final Semester TestDocument8 pages(GOLD) The Examples of Final Semester TestMetiska MunzilaNo ratings yet

- Satellite CommunicationsDocument57 pagesSatellite Communicationsheritage336No ratings yet

- LP in MusicDocument10 pagesLP in MusicContagious Joy VillapandoNo ratings yet

- The African Essentials - Presentation - O - 2019Document34 pagesThe African Essentials - Presentation - O - 2019Fatima SilvaNo ratings yet

- Hockey - Indian National Game-2compDocument21 pagesHockey - Indian National Game-2compRaj BadreNo ratings yet

- Primary Gingival Squamous Cell CarcinomaDocument7 pagesPrimary Gingival Squamous Cell CarcinomaMandyWilsonNo ratings yet

- Pgcet Environmental Engineering PaperDocument10 pagesPgcet Environmental Engineering PaperRamNo ratings yet

- Company Profile: TML Drivelines LTD (Tata Motors, Jamshedpur)Document5 pagesCompany Profile: TML Drivelines LTD (Tata Motors, Jamshedpur)Madhav NemalikantiNo ratings yet

- JD Edwards Enterpriseone Tools: Form Design Aid Guide Release 9.1.XDocument530 pagesJD Edwards Enterpriseone Tools: Form Design Aid Guide Release 9.1.XGaurav SahuNo ratings yet

- Identification and Certification of Labconco Class Ii Safety CabinetsDocument9 pagesIdentification and Certification of Labconco Class Ii Safety CabinetscobramcNo ratings yet

- Mehdi To TestDocument13 pagesMehdi To Testtestcoolvms16No ratings yet

- Small Unit Operations: PMA Core Values: Selfless Service To God and Country, Honor, ExcellenceDocument33 pagesSmall Unit Operations: PMA Core Values: Selfless Service To God and Country, Honor, ExcellenceAbay GeeNo ratings yet

- Ahad NaamahDocument2 pagesAhad NaamahedoolawNo ratings yet

- En 12245 (2022) (E)Document9 pagesEn 12245 (2022) (E)David Chirinos100% (1)

- Why Romanian Journal of Food ScienceDocument2 pagesWhy Romanian Journal of Food ScienceAna Vitelariu - RaduNo ratings yet

- Adavantages of Historical ResearchDocument2 pagesAdavantages of Historical ResearchClemence JeniferNo ratings yet

- How To Cite A Research Paper in TextDocument8 pagesHow To Cite A Research Paper in Textafnkaufhczyvbc100% (1)

- Mauro Giuliani: Etudes Instructives, Op. 100Document35 pagesMauro Giuliani: Etudes Instructives, Op. 100Thiago Camargo Juvito de Souza100% (1)

- Break Even AnalysisDocument18 pagesBreak Even AnalysisSMHE100% (10)

- Brandi PPT For BrandingDocument27 pagesBrandi PPT For BrandingShah ParinNo ratings yet