Professional Documents

Culture Documents

горелка

горелка

Uploaded by

Sergey shapovalovCopyright:

Available Formats

You might also like

- Year 7 Drama Marking SheetDocument2 pagesYear 7 Drama Marking Sheetruthdoyle76No ratings yet

- M-31-3 Main Engine (3-3) PDFDocument554 pagesM-31-3 Main Engine (3-3) PDFRaja SegarNo ratings yet

- Ushio ReinetsuDocument1 pageUshio Reinetsuironite100% (2)

- Project Guide CAT C9.3Document44 pagesProject Guide CAT C9.3Ngurah WidhiNo ratings yet

- Pleiger Temperature and Pressure ControlDocument8 pagesPleiger Temperature and Pressure ControlPamellaNo ratings yet

- Controller HT Jumo Dicon Touch EN.Document9 pagesController HT Jumo Dicon Touch EN.Jevgenij ChupinNo ratings yet

- 4-2953 - 55 Final Manual - Eng 05-08-11 PDFDocument225 pages4-2953 - 55 Final Manual - Eng 05-08-11 PDFVladimirNo ratings yet

- Boiler Setting ProceduresDocument19 pagesBoiler Setting Proceduressumit100% (1)

- Navigation Lights UnitDocument36 pagesNavigation Lights UnitAyman64No ratings yet

- Aa 0397a Acc20 Sulzer Rta Instruction ManualDocument141 pagesAa 0397a Acc20 Sulzer Rta Instruction ManualMahmoud KhalafNo ratings yet

- Angle Encoder & Mounting Kit Mounting Guide: MAN DieselDocument14 pagesAngle Encoder & Mounting Kit Mounting Guide: MAN DieselŞansal DikmenerNo ratings yet

- Shaftpower Operating InstructionsDocument23 pagesShaftpower Operating InstructionsThomas Liontos100% (2)

- E 5 Appendix "A"Document48 pagesE 5 Appendix "A"Braulio CvNo ratings yet

- Operating Manual: Composite Boiler CBKGDocument62 pagesOperating Manual: Composite Boiler CBKGChiriacMariusNo ratings yet

- Pages 301 To 577 From Te2342 Vol.5 Manoeuvring System-4Document277 pagesPages 301 To 577 From Te2342 Vol.5 Manoeuvring System-4Тодор ТодоровNo ratings yet

- Rse-P Ii Short Manual: W X +12.0 Bar +12.0 BarDocument81 pagesRse-P Ii Short Manual: W X +12.0 Bar +12.0 Bar徐玉坤100% (2)

- Technical Description: Type: 810.001.210Document6 pagesTechnical Description: Type: 810.001.210Radu VasilacheNo ratings yet

- Oilon Manual Burners HDocument58 pagesOilon Manual Burners HKyaw Win Tun100% (4)

- Boiler Instruction ManualDocument646 pagesBoiler Instruction ManualАлександр КосянчукNo ratings yet

- 77-107.0222 GB Rev.J User Guide FlexKraftDocument46 pages77-107.0222 GB Rev.J User Guide FlexKraftgilles vanexe100% (1)

- Salwico cs3004Document108 pagesSalwico cs3004завир мансуров100% (1)

- Aalborg KBM PDFDocument4 pagesAalborg KBM PDFkrenlanNo ratings yet

- 600 SL WS +, SLUD 1200S + 300doDocument45 pages600 SL WS +, SLUD 1200S + 300doTRANSSHELFNo ratings yet

- Trouble ShootingDocument57 pagesTrouble ShootingCem Cetiz100% (1)

- Instruction MT Gede Galunggung GamalamaDocument1,350 pagesInstruction MT Gede Galunggung Gamalamasilisyarief100% (1)

- Operating and Maintenance InstructionsDocument20 pagesOperating and Maintenance InstructionsJano Goñi100% (1)

- Rectifier Board For CS4000Document4 pagesRectifier Board For CS4000dangthutqmNo ratings yet

- Composite BoilerDocument390 pagesComposite BoilerBogdan Florin TudorofNo ratings yet

- 23 Instrumentation and AutomationDocument42 pages23 Instrumentation and AutomationAdrianzzzzNo ratings yet

- How To Collect Data For TroubleshootingDocument11 pagesHow To Collect Data For TroubleshootingcarlosNo ratings yet

- 910-001000 CS3004 Installationl USCG E1 05 2 E PDFDocument63 pages910-001000 CS3004 Installationl USCG E1 05 2 E PDFFendi MarihotNo ratings yet

- BOLLFILTER Electronic Controller Type 2200 PDFDocument34 pagesBOLLFILTER Electronic Controller Type 2200 PDFmail4ksn0% (1)

- FWG - JWSP-26-C100 - N-012053Document32 pagesFWG - JWSP-26-C100 - N-012053sridhar100% (1)

- Jowa OdmeDocument2 pagesJowa OdmeFaisal anwarNo ratings yet

- PCM-Manual 0905 AppendixDocument3 pagesPCM-Manual 0905 AppendixPamellaNo ratings yet

- CS4000 Service and Maintenance E6 10 1 E PDFDocument74 pagesCS4000 Service and Maintenance E6 10 1 E PDFOcupucNo ratings yet

- ME Bridge Manouvering System DMS2100i Manual NewDocument183 pagesME Bridge Manouvering System DMS2100i Manual NewRadoslaw PobierowskiNo ratings yet

- ABB Schalt-Und Steuerungstechnik: Hardware Intelligent Decentralized Automation SystemDocument40 pagesABB Schalt-Und Steuerungstechnik: Hardware Intelligent Decentralized Automation SystemEvandro PavesiNo ratings yet

- Alarms Description 1312-1Document325 pagesAlarms Description 1312-1александрNo ratings yet

- AALBORG Boiler ControlDocument185 pagesAALBORG Boiler ControlBatuhan ZerenerNo ratings yet

- MDocument36 pagesMmajdi2013100% (1)

- Delomatic 3, Replacement Instruction, Flash Prom, 4189340245 UK PDFDocument1 pageDelomatic 3, Replacement Instruction, Flash Prom, 4189340245 UK PDFadi merNo ratings yet

- Controller Old Model English Tib 750 GB 0711Document43 pagesController Old Model English Tib 750 GB 0711irfanWPK100% (2)

- TE2517 Vol.5BMSDocument367 pagesTE2517 Vol.5BMSdwight ferrer100% (1)

- Salwico DOS 3 Optical Detector N1115Document1 pageSalwico DOS 3 Optical Detector N1115Miguel MartinezNo ratings yet

- 15.flow Switch For Piston Cooling OilDocument10 pages15.flow Switch For Piston Cooling OilKaleb Z king webNo ratings yet

- MF-82 Instruction Manual For Boiler Plant, Volume 1 (Booklet)Document438 pagesMF-82 Instruction Manual For Boiler Plant, Volume 1 (Booklet)Thanh Nghị Bùi50% (2)

- Check and Adjustment Instructions For - Valve ClosingDocument4 pagesCheck and Adjustment Instructions For - Valve ClosingduyguNo ratings yet

- Hanla Vol1Document40 pagesHanla Vol1jasleenchhabraNo ratings yet

- Delomatic - Multi-Function System System Data: DEIF Generator Unit Control PanelDocument4 pagesDelomatic - Multi-Function System System Data: DEIF Generator Unit Control Panellukasberg100% (1)

- 8555-9201-000 D10 Parameter Trouble Shooting Jan09Document96 pages8555-9201-000 D10 Parameter Trouble Shooting Jan0915120 Tanzim NabeedNo ratings yet

- HIMAP A1 Communication EDocument51 pagesHIMAP A1 Communication Emaronnam100% (1)

- Pmi VitDocument2 pagesPmi VitOleh Temriakovych100% (2)

- CLX - XT (Model 28030 Manual (Rev 1.5)Document40 pagesCLX - XT (Model 28030 Manual (Rev 1.5)Igor DoroshchukNo ratings yet

- Damco LPU-DDocument6 pagesDamco LPU-DgeomariolisNo ratings yet

- MAN-PMI Off PDFDocument92 pagesMAN-PMI Off PDFarunNo ratings yet

- Pleiger EHS-CM2-EDocument23 pagesPleiger EHS-CM2-EIgor Khanin100% (1)

- 701 Me DoosanDocument37 pages701 Me DoosanRonald Sol Salen JordasNo ratings yet

- Incinerator: Make: Sunflame Type: OSVDocument40 pagesIncinerator: Make: Sunflame Type: OSVravilullaNo ratings yet

- MA_ALTOSONIC-V12_en_240213_4002643506_R06Document180 pagesMA_ALTOSONIC-V12_en_240213_4002643506_R06Isaias MirellesNo ratings yet

- Goodrive20 - EU Series Inverter Operation Manual - V1.4 PDFDocument163 pagesGoodrive20 - EU Series Inverter Operation Manual - V1.4 PDFIvan CardenasNo ratings yet

- ZHSC4674-461-01 Fuel Oil Service SystemDocument16 pagesZHSC4674-461-01 Fuel Oil Service SystemSergey shapovalovNo ratings yet

- ZHSC4674-400-04 Engine Room ArrangementDocument21 pagesZHSC4674-400-04 Engine Room ArrangementSergey shapovalov100% (1)

- UntitledDocument1 pageUntitledSergey shapovalovNo ratings yet

- ZHSC4674-400-01TM List of Plans & Documents of Finished Design (Machinery Part)Document7 pagesZHSC4674-400-01TM List of Plans & Documents of Finished Design (Machinery Part)Sergey shapovalovNo ratings yet

- 12-10103 Service ReportDocument6 pages12-10103 Service ReportSergey shapovalovNo ratings yet

- HiMSEN Technical Circular - Information For Combusion Diagram (Document6 pagesHiMSEN Technical Circular - Information For Combusion Diagram (Sergey shapovalovNo ratings yet

- E323-11 Standard Specification For Perforated-Plate Sieves For Testing PurposesDocument4 pagesE323-11 Standard Specification For Perforated-Plate Sieves For Testing Purposesouari.ouariNo ratings yet

- Continuous Usage Intention of Social Media As An Online Information Distribution ChannelsDocument12 pagesContinuous Usage Intention of Social Media As An Online Information Distribution Channelsapi-563385491No ratings yet

- 1g Rainbow Antimagic ColoringDocument9 pages1g Rainbow Antimagic ColoringRosanita NisviasariNo ratings yet

- Integration Strategies and New Identities in Vs Naipaul's The Mimic Men and Caryl Phillips's CambridgeDocument7 pagesIntegration Strategies and New Identities in Vs Naipaul's The Mimic Men and Caryl Phillips's CambridgeIjahss JournalNo ratings yet

- Model Course 1.07 PDFDocument75 pagesModel Course 1.07 PDFShiena CamineroNo ratings yet

- Manas Arora 3 Year - B Roll No. 3 Vastu Kala AcademyDocument12 pagesManas Arora 3 Year - B Roll No. 3 Vastu Kala AcademyManasAroraNo ratings yet

- ISA RP3.2-1960 Flange Mounted Sharp Edged Orifice Plate For Flow Measurement PDFDocument8 pagesISA RP3.2-1960 Flange Mounted Sharp Edged Orifice Plate For Flow Measurement PDFamshahNo ratings yet

- Student Performance Contract With Parents AgreementDocument1 pageStudent Performance Contract With Parents AgreementCURT KEANU VILLANUEVANo ratings yet

- Revit Programming For Beginners: Dan Mapes Senior BIM Coordinator/Developer at ME EngineersDocument17 pagesRevit Programming For Beginners: Dan Mapes Senior BIM Coordinator/Developer at ME EngineersjeanNo ratings yet

- Cloud FrameworkDocument6 pagesCloud FrameworkloversatriskNo ratings yet

- CCE Catalogue DetailedDocument28 pagesCCE Catalogue DetailedIshaan SinghNo ratings yet

- Internship Report - AmtechDocument31 pagesInternship Report - AmtechRahil ShahNo ratings yet

- Solution To Microwave Engineering Pozar Chapter 14 Exercise 17 With MATLABDocument3 pagesSolution To Microwave Engineering Pozar Chapter 14 Exercise 17 With MATLABJohn Bofarull GuixNo ratings yet

- Brkarc-2350 - 2014Document128 pagesBrkarc-2350 - 2014Sarah AnandNo ratings yet

- MTS719# 2u2s2wc-21Document2 pagesMTS719# 2u2s2wc-21glukkerNo ratings yet

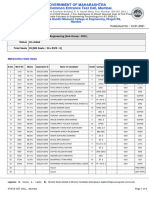

- 2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedDocument8 pages2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedAjit DeshmukhNo ratings yet

- Item Wise Rate TenderDocument5 pagesItem Wise Rate TenderB-05 ISHA PATELNo ratings yet

- Worksheet in Deloittes System Design DocumentDocument32 pagesWorksheet in Deloittes System Design Documentascentcommerce100% (1)

- Ag Test Package FormatDocument25 pagesAg Test Package FormatoparoystNo ratings yet

- MBB and DR PG Data2kDocument143 pagesMBB and DR PG Data2kYogesh PalNo ratings yet

- Heater: Hydrate PreventionDocument12 pagesHeater: Hydrate PreventionMahmoud Ahmed Ali AbdelrazikNo ratings yet

- A Practical Guide To Free-Energy' DevicesDocument73 pagesA Practical Guide To Free-Energy' DevicesJoe Seserman100% (1)

- Reasons For Diminishing Returns To A FactorDocument2 pagesReasons For Diminishing Returns To A FactorRobert AyalaNo ratings yet

- Is Codes ListDocument37 pagesIs Codes Listmoondonoo7No ratings yet

- Textbook - Thermal Physics PopleDocument26 pagesTextbook - Thermal Physics PoplecowsarechillNo ratings yet

- Unit 4 The Narrative Approach To Assessment and Counseling: StructureDocument18 pagesUnit 4 The Narrative Approach To Assessment and Counseling: Structureshweta GNo ratings yet

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- 6501i-8001i Manual de Servicio r5Document1,126 pages6501i-8001i Manual de Servicio r5marco102167% (3)

- F101-1 Client Information Form and ApprovalDocument4 pagesF101-1 Client Information Form and ApprovalgoyalpramodNo ratings yet

горелка

горелка

Uploaded by

Sergey shapovalovCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

горелка

горелка

Uploaded by

Sergey shapovalovCopyright:

Available Formats

v marine

System Manual

Part 3: Operator

2013-10-28

2-7931-8115-02 Combustion and Energy Systems

Copyright reserved

Technical Documentation SAACKE

Original Manual

The reproduction, distribution and utilization of this doc-

ument as well as the communication of its contents to

others without express authorization is prohibited. Of-

fenders will be held liable for the payment of damages.

All rights reserved in the event of the grant of a patent,

utility model or design.

SAACKE worldwide -

Technology with a Future

For more than 80 years SAACKE has set Power of innovation, technical perfec-

standards in economic, eco-friendly and tion and reliability of all products ac-

easy-to-service burner technology. count for SAACKE’s technological

First-rate engineering and continuous leadership. Competent project man-

optimization of products and systems, agement, comprehensive operational

supported by extensive in-house re- advice, and a worldwide service net-

search and development, ensure re- work stand for customer proximity and

quirements and sustain flexibility. partnership with a guaranteed future

within the industrial thermal market.

Combustion and Energy Systems

Contents se@vis marine

0 Contents

0 Contents ............................................................................................................................... 4

1 Introduction .......................................................................................................................... 7

1.1 About This Document .......................................................................................................................... 7

1.2 Symbols Used in This Documentation ................................................................................................ 7

1.3 Safety .................................................................................................................................................. 9

1.3.1 Safety Manual ..................................................................................................................................... 9

1.3.2 Warning Signs ..................................................................................................................................... 9

2 HMI (Operation and Functions) ......................................................................................... 10

2.1 Touchscreen...................................................................................................................................... 10

2.1.1 Screen Contents ................................................................................................................................ 10

2.1.2 Navigation Elements ......................................................................................................................... 15

2.1.3 Operating Controls ............................................................................................................................ 16

2.1.4 Keyboard and Keypad ....................................................................................................................... 21

3 Burner Start / Burner Stop ................................................................................................ 23

3.1 Prerequisites for Starting the Burner ................................................................................................. 23

3.2 Resetting the Burner after a Safety Shut-Off .................................................................................... 23

3.2.1 Acknowledging Alarms and Resetting Burners ................................................................................. 24

3.3 Selecting Operation Mode ................................................................................................................. 26

3.4 Starting the Burner ............................................................................................................................ 28

3.4.1 Starting Sequence – Purge ............................................................................................................... 29

3.4.2 Starting Sequence – Ignition ............................................................................................................. 30

3.5 Setting the Burner to Manual Mode (Manual Firing Rate Presetting) ...............................................30

3.6 Stopping the Burner .......................................................................................................................... 31

3.6.1 Stopping Sequence ........................................................................................................................... 31

3.7 Manual Blow-Out of the Oil Gun ....................................................................................................... 32

3.8 Controlled Shutdown ......................................................................................................................... 33

3.9 Local/Remote Operation (option) ...................................................................................................... 33

3.10 Cooling Program ............................................................................................................................... 35

4 Firing Rate Control ............................................................................................................ 36

4.1 Controlling and Limiting Burner Firing Rate ...................................................................................... 36

4.2 Defining Limits for Controlled Shutdown ........................................................................................... 39

4.3 Defining Firing Rate Limitation in Case of Cold Start ........................................................................ 41

4.4 Displaying Short-Time Trend ............................................................................................................ 42

5 Pump Control ..................................................................................................................... 43

5.1 General .............................................................................................................................................. 43

5.1.1 Pump Mode Selection ....................................................................................................................... 43

5.1.2 Pump Overviews on the HMI ............................................................................................................ 44

5.1.3 Selecting Primary Pump .................................................................................................................... 46

5.1.4 Reactivating Pump after Fault ........................................................................................................... 46

5.1.5 Reactivating Pump after Fault ........................................................................................................... 46

5.1.6 Pump Heater ..................................................................................................................................... 47

5.2 MDO/HFO Pumps ............................................................................................................................. 48

Technical Documentation

4 / 192 2-7931-8115-02 2013-10-28

se@vis marine Contents

5.2.1 Oil Line Heater for HFO Mode .......................................................................................................... 49

5.2.2 Switching off HFO Pumps (MGO flushing)........................................................................................ 50

5.3 MGO Pumps ...................................................................................................................................... 57

5.4 Ignition Oil pump ............................................................................................................................... 58

5.5 Feedwater Pumps (Optional) ............................................................................................................ 58

5.5.1 Chemical Dosing Pump (optional) ..................................................................................................... 60

5.6 Circulation Pumps (Optional) ............................................................................................................ 61

6 High-Pressure Mode (Option) ........................................................................................... 62

6.1 Enabling High-Pressure Mode .......................................................................................................... 62

6.2 Changing Settings for High-Pressure Mode ..................................................................................... 62

6.2.1 Setting Setpoint and Limits for Controlled Shutdown in High-Pressure Mode..................................63

6.2.2 Limiting Controller Output in High-Pressure Mode ........................................................................... 64

6.2.3 Setting the "Boiler Pressure" Pre-Alarm in High-Pressure Mode .....................................................66

7 Low-Pressure Mode (Option) ............................................................................................ 67

7.1 Enabling Low-Pressure Mode ........................................................................................................... 67

7.2 Changing Settings for Low-Pressure Mode ...................................................................................... 67

7.2.1 Setting Setpoint and Limits for Controlled Shutdown in Low-Pressure Mode ..................................68

7.2.2 Limiting Controller Output in Low-Pressure Mode ............................................................................ 69

7.2.3 Setting the "Boiler Pressure" Pre-Alarm in Low-Pressure Mode ......................................................70

8 IGS Mode (Option) ............................................................................................................. 71

8.1 Enabling IGS Mode ........................................................................................................................... 71

8.2 Setting the Firing Rate Limit for IGS Mode ....................................................................................... 72

9 Master/Slave Mode (Option) .............................................................................................. 73

9.1 Type 0: Boiler with equal firing rates ................................................................................................. 73

9.1.1 Selecting Single, Master and Slave .................................................................................................. 76

9.1.2 Master/Slave Overview ..................................................................................................................... 77

9.1.3 Changing the Master/Slave Settings ................................................................................................. 78

9.1.4 Setting Start/Stop Conditions for the Slave ....................................................................................... 79

9.1.5 Heat Retention Mode ........................................................................................................................ 81

9.1.6 Saving the Boiler Settings ................................................................................................................. 83

9.2 Type 1: Boiler with different firing rates ............................................................................................. 84

9.2.1 Selecting Single, Master and Slave .................................................................................................. 87

9.2.2 Master/Slave Overview ..................................................................................................................... 89

9.2.3 Changing the Master/Slave Settings ................................................................................................. 90

9.2.4 Setting Start/Stop Conditions for Master and Slave .......................................................................... 91

9.2.5 Heat Retention Mode ........................................................................................................................ 94

9.2.6 Saving the Boiler Settings ................................................................................................................. 96

10 Burner Operation ............................................................................................................... 97

11 Overviews........................................................................................................................... 99

11.1 Burner Overview.............................................................................................................................. 101

11.2 Oil-Supply Overview ........................................................................................................................ 102

11.3 Feedwater-Supply Overview ........................................................................................................... 103

11.4 Economizer Overview (EGE) .......................................................................................................... 104

Technical Documentation

2013-10-28 2-7931-8115-02 5 / 192

Contents se@vis marine

11.5 Switches and Pushbuttons .............................................................................................................. 105

11.6 Process-Values Overview ............................................................................................................... 106

11.7 Boiler Overview ............................................................................................................................... 107

11.8 Exhaust-Gas-Boiler Overview (EGB1 and EGB2) .......................................................................... 110

11.9 Master / Slave Overview ................................................................................................................. 111

12 Main Menu ........................................................................................................................ 112

12.1 User Login / Logout ......................................................................................................................... 112

12.2 Displaying the Message Archive ..................................................................................................... 117

12.3 Displaying a Trend .......................................................................................................................... 119

12.3.1 Selecting Channels for the Trend Display ....................................................................................... 119

12.3.2 Displaying a 2h Trend ..................................................................................................................... 121

12.3.3 Displaying a 24h Trend ................................................................................................................... 122

13 System Settings (System Menu) ..................................................................................... 123

13.1 Setting the Date / Time.................................................................................................................... 124

13.2 Setting the Screen Brightness ......................................................................................................... 128

13.3 Selecting the Background Color ...................................................................................................... 129

13.4 Cleaning the Display ....................................................................................................................... 129

13.5 Saving the System Settings ............................................................................................................ 130

13.6 Selecting the Language .................................................................................................................. 131

13.7 Displaying Network Settings ........................................................................................................... 132

14 Displaying Information .................................................................................................... 133

14.1 Displaying Project Data ................................................................................................................... 134

14.2 Displaying System Information ........................................................................................................ 134

14.3 Displaying and Logging Security Information (Checksums) ...........................................................135

14.4 Displaying Counter Readings (Operating Hours / Starts / Quantities) ............................................136

14.5 Maintenance Messages .................................................................................................................. 137

15 Web Server ....................................................................................................................... 138

15.1 Starting Web Visualization .............................................................................................................. 138

15.2 Downloading Data ........................................................................................................................... 139

15.3 Downloading Documents ................................................................................................................ 140

15.4 Displaying / Downloading Alarm Messages .................................................................................... 141

16 Emergency Operation...................................................................................................... 142

16.1 Safety Shut-off in Emergency Operation......................................................................................... 142

17 Messages in the Message Line ....................................................................................... 143

17.1 General Information......................................................................................................................... 143

17.2 Message Archive ............................................................................................................................. 144

17.3 Messages ........................................................................................................................................144

17.3.1 Abbreviations ................................................................................................................................... 144

17.3.2 Status Messages ............................................................................................................................. 145

17.3.3 Safety shut-offs ............................................................................................................................... 155

18 Index ................................................................................................................................. 188

Technical Documentation

6 / 192 2-7931-8115-02 2013-10-28

se@vis marine Introduction

1 Introduction

1.1 About This Document

This document describes operation of the burner management system

seavis marine, version 3.10.

It is designed for operators, technicians, and service technicians.

Help us improve our documentation!

We are always happy to receive suggestions for improving the quality of our

documentation. You will find our contact address on the back of this document.

1.2 Symbols Used in This Documentation

Especially important information in this document is emphasized by the following

symbols:

Warning!

The work safety symbol identifies safety instructions that protect against potential

lethal and severe injuries. Always observe these safety instructions and exercise

special caution while performing the corresponding tasks or procedures.

Caution!

The Caution symbol identifies all safety instructions that protect against damage or

destruction of the product and/or other system parts.

Note

This symbol indicates particularly useful information or instructions.

Other symbols used in this documentation:

Symbol Meaning

This symbol identifies an instruction.

This symbol identifies the result of an instruction.

Field Terms printed in bold identify input and display fields.

“Message“ Names of views, windows or menus are represented in quotation

marks.

Buttons on the touchscreen / on the monitor:

Buttons containing text are represented by a picture or in squared

brackets.

[Login]

If a button contains an icon, only the icon is shown.

Technical Documentation

2013-10-28 2-7931-8115-02 7 / 192

Introduction se@vis marine

Symbol Meaning

Keys on the keyboard of your PC:

<Key> If you have to press a key on the keyboard of your PC, this key is

shown in angle brackets.

If you have to execute a command on your computer, the path to

the relevant command is indicated by this arrow.

Example:

Select “Project Open project“.

In this case you have to execute the “Open project” command in

the “Project” menu.

If you have to press a series of buttons one after the other on the

HMI touch screen, the order of buttons is indicated by this arrow.

Example:

Press .

Click this icon to leave the current view.

Table 1: Symbols used in this documentation

Technical Documentation

8 / 192 2-7931-8115-02 2013-10-28

se@vis marine Introduction

1.3 Safety

The document is an integral part of the product. It must be retained for the entire

lifecycle of the product. Ensure that the document is available to personnel

responsible for the activities described. Add to the document any supplementary

information subsequently provided by SAACKE.

Note

This document is only valid in connection with the safety manual "System Manual –

Part 1: Safety" (see following section).

1.3.1 Safety Manual

Before you install the components described here, place them in service, or

operate them, you must carefully read and understand the Safety Manual.

The Safety Manual contains essentially the following information:

Information about authorized use

General safety information

Explanations of warning signs

1.3.2 Warning Signs

Warning signs have been placed on certain components. Warning signs must not

be covered or removed.

Symbol Meaning

Warning!

This symbol warns of potentially dangerous functions or situations in

the corresponding component.

Warning! Potentially lethal electrical shock!

This symbol refers to danger to life and limb due to electrical shock.

Only qualified personnel, e.g. electrical specialists, are permitted to

work on components designated in this manner, for example control

cabinets, control boxes, and devices.

Technical Documentation

2013-10-28 2-7931-8115-02 9 / 192

HMI (Operation and Functions) se@vis marine

2 HMI (Operation and Functions)

The firing plant can be controlled completely via the operating unit HMI, depending

on the configuration of the plant.

In this chapter you will learn how to operate the HMI.

2.1 Touchscreen

The control unit cabinet disposes of an operating unit HMI equipped with a

touchscreen.

To perform a function on the HMI, simply touch the corresponding element on the

screen using your finger or a touchpen. This can be a button, for instance ( ),

or a field identified by a magenta colored border ( ).

For more information on this subject see "Navigation Elements" on page 15.

V11831_310

Fig. 1: Structure of the touch screen

2.1.1 Screen Contents

The views shown on the touch screen are primarily made up of the following areas:

(A) Headline

(B) Message line

(C) Working area

(D) Footer

Technical Documentation

10 / 192 2-7931-8115-02 2013-10-28

se@vis marine HMI (Operation and Functions)

Headline

Apart from the current system data and time, the headline provides information on

the plant state, the burner states or the currently selected user level (Login), for

example.

The headline is sub-divided into several segments. Some segments may show dif-

ferent icons according to the state of the plant.

In the following figure, the different segments are numbered consecutively. During

normal plant operation, there are not always icons displayed in all segments at the

same time.

V10154_308

Fig. 2: Headline

The following table gives a detailed description of the segments and the infor-

mation displayed in the corresponding segments:

Segment Icon Description

The setting mode is activated.

1

1

The check mode is activated.

2 Maintenance required. Please contact SAACKE customer service.

Save. Modified configuration parameters must be saved. Press this button after

every change that is made.

3

Please contact SAACKE customer service.

A fault has occurred. You can find detailed information about the nature of the

4

fault in the list of alerts.

The service technician has set manually the analog input and output channels.

5 The service technician has set manually the digital input and output channels.

The service technician has set manually the analog and the digital input and

output channels.

6 Manual mode. At least one of the controllers is in manual mode.

Remote operation: The burner is being operated remotely, e.g. by the control

system. This icon is shown in combination with one of the following burner icons.

7

The burner is off.

1

The icons in this segment are only visible at user level 2.

Technical Documentation

2013-10-28 2-7931-8115-02 11 / 192

HMI (Operation and Functions) se@vis marine

Segment Icon Description

The burner is preselected. As soon as all start conditions are met, the burner is

activated.

The burner is off. The reset process is running.

The channels move to purge position.

The channels are in purge position (purge is running).

The channels move to ignition position.

The channels are in ignition position. The burner is ignited.

The burner is in operation.

The burner is in operation. Burner capacity is limited.

Controlled shutdown. The burner is automatically activated again as soon as the

pressure or temperature has reached the start-up value.

The burner is defective. The list of alerts provides information on the fault.

The burner is in operation. Load demands are set manually.

The burner is in operation. The ramp function is activated.

Blow-out of the oil gun

Emergency operation. The burner will be moved manually during emergency

8

operation.

Remote client. The remote server is activated. The HMI is accessed via a Re-

9

mote client.

… Operation modes 1 to 8

Selected fuel: 1, 2 or 3

+ Fuel 1 and 3 simultaneous firing

10 Liquid fuel. Liquid fuel, e.g. oil, is enabled for the current operation mode.

Gaseous fuel. Gaseous fuel is enabled for the current operation mode.

Flushing. The heavy fuel oil line is being flushed.

Technical Documentation

12 / 192 2-7931-8115-02 2013-10-28

se@vis marine HMI (Operation and Functions)

Segment Icon Description

The boiler is in single mode.

The boiler is in master mode.

The boiler is in slave mode.

11 The boiler is in inert gas mode.

The boiler is in high pressure mode.

The boiler is in low pressure mode.

The boiler is in keeping warm mode.

Shows the current user level. The user has logged in to level 2.

12

If the user level has a yellow background, the user will be logged out automati-

cally in less than 10 minutes.

13 System date and time

Note

If a fault icon is displayed in the headline, also take note of the message displayed

in the message line (see page 13). This message provides an indication as to the

cause of the fault.

Message Line

The message line shows the last message on the left and the message number on

the right.

V10153_308

Fig. 3: Message line

(1) Message text

(2) Message number

For further information on the messages refer to chapter "Messages in the Mes-

sage Line" on page 143.

Working Area

The working area is the area between the message line and the footer. This area

displays the data, overviews, curves etc. of the respective view.

This area also contains buttons which you can use to execute various functions.

Technical Documentation

2013-10-28 2-7931-8115-02 13 / 192

HMI (Operation and Functions) se@vis marine

V10128_308

Fig. 4: Working area (here: Main menu)

Footer

In the footer you will find various buttons ("footer buttons"), via which you can di-

rectly call the main functions of the burner management system.

V10097__308

Fig. 5: Footer

The footer provides the following buttons:

No. Button Description see

Use this button to open the main

(1) menu, which gives you access to 112

other menus.

You can use this button to call up

(2) various overviews. 2

This button opens the burner opera-

(3) tion view. 2

This button opens the controller selec-

(4) tion view. —

This button opens the list of alerts with

(5) message acknowledgment and burner 25

reset.

Table 2: Footer buttons

Technical Documentation

14 / 192 2-7931-8115-02 2013-10-28

se@vis marine HMI (Operation and Functions)

2.1.2 Navigation Elements

Various navigation elements make it easier for you to move within the menus.

V10129a_308

Fig. 6: Navigation elements

(A) Navigation path (C) Arrow keys

(B) Page number buttons

Navigation Path (Breadcrumb-Navigation)

When you open views via the main menu or the controller menu, a navigation path

(A) indicates which path you took to the current display.

V10130_308

Fig. 7: Navigation path (A)

Press an icon in the navigation path to switch directly to the associated menu level.

Page Change

In case a menu or a view consists of several pages, you may have to navigate to

the desired page. There are two possibilities for this:

Via the page number buttons (B), which will take you directly to the desired

page

Via arrow keys (C), which let you scroll to the next page or to the previous

page

Page Number Buttons

V10131_308

Fig. 8: Page number buttons (B), the current display is page 2

The button that belongs to the current page cannot be selected. It is deactivated

(here page ).

Press the button of the page you want to open.

Technical Documentation

2013-10-28 2-7931-8115-02 15 / 192

HMI (Operation and Functions) se@vis marine

Arrow keys

V10132_308

Fig. 9: Arrow keys (C)

By using the arrow buttons, browse through the pages one at a time.

Press to scroll to the previous page.

Press to scroll to the following page.

2.1.3 Operating Controls

Apart from display elements, there are also various operating controls for triggering

various functions in the working area and in the footer of the seavis marine views.

These operating controls include:

Buttons

Value fields

Status change fields

Branching elements

Pushbuttons and switches

Buttons

You can use buttons to trigger various functions. For this purpose, simply press the

corresponding button using your finger or a touchpen.

V10089a_310

Fig. 10: Deactivated button (1) compared to an enabled button (2)

Technical Documentation

16 / 192 2-7931-8115-02 2013-10-28

se@vis marine HMI (Operation and Functions)

Representation deactivated/enabled buttons

The figure above shows the difference between a deactivated button and an ena-

bled button:

(1) The icon is shown in gray and the button is displayed with a black

frame. This means the button is deactivated. Either this functions is current-

ly executing, cannot be executed right now or you are not on the required

user level.

(2) The icon is shown in color. The button is enabled and can be operat-

ed.

Button status indicators:

Some buttons in the work area have a status indicator (A). Such an indicator

shows the respective status of a function or plant element.

V10133_310

Fig. 11: Button status indicator (A)

Status indicator Function / plant element is:

Green Active

Red Faulty (warning)

White Not active (switched off)

Yellow Preselected

Value Fields / Status Change Fields

Provided you have logged in to the required user level, some fields will be shown

with a magenta frame. These fields are generally referred to as

Value fields, in which you can enter values via a numeric keypad or an al-

phanumeric keyboard.

Status change fields, in which you can enable or disable a function.

Technical Documentation

2013-10-28 2-7931-8115-02 17 / 192

HMI (Operation and Functions) se@vis marine

Value fields:

V10134_308

Fig. 12: Value fields (A)

Proceed as follows to enter a value:

Press the corresponding value field (A).

Depending on the field type, either a numeric keypad or an alphanumeric

keyboard will be displayed (see "Keyboard and Keypad " on page 21).

Enter the desired value or text using the input keyboard.

Confirm the entry with .

The value or text is accepted in the value field.

If necessary, confirm the value change with .

Status change fields:

V10010_308

Fig. 13: Enabled status change fields (A)

Technical Documentation

18 / 192 2-7931-8115-02 2013-10-28

se@vis marine HMI (Operation and Functions)

Proceed as follows to change the status of a function:

Press the corresponding status change field (A).

The field status changes.

Note

Some status change fields can adopt more than two different statuses. Press the

corresponding status change field as often as needed.

Branching Elements

In addition to the value fields there are other elements that are also displayed in a

magenta frame. These are generally referred to as branching elements. When you

press a branching element, another screen image will be displayed that provides

additional/more detailed information or in which you can trigger specific functions:

V10051_308

Fig. 14: Branching element

Press the corresponding branching element (A).

You enter the associated screen image (in our example the burner over-

view).

Switches and pushbuttons

In the overview of the switches and pushbuttons, the hardware outputs of the

channels can be turned on or off individually, if required, via switches and pushbut-

tons.

Press .

Note

The type and number of switches and pushbuttons displayed depend on the cur-

rent plant configuration.

Technical Documentation

2013-10-28 2-7931-8115-02 19 / 192

HMI (Operation and Functions) se@vis marine

Operating switches

Press on the left side the green switch to enable the hardware output of the chan-

nel.

The status indicator turns yellow. The channel is enabled.

Press on the right side the red switch to disable the hardware output of the chan-

nel.

The status indicator goes out. The channel is disabled.

Operating Pushbuttons

Press the green pushbutton as long as you want the hardware output of the chan-

nel to be enabled.

The status indicator turns yellow and the hardware channel is enabled as

long as you keep the pushbutton pressed. As soon as you release the

pushbutton, the hardware channel is disabled again.

Press the red pushbutton as long as you want the hardware output of the channel

to be disabled.

The status indicator goes out and the hardware channel is disabled as long

as you keep the pushbutton pressed. As soon as you release the pushbut-

ton, the hardware channel is enabled again.

Technical Documentation

20 / 192 2-7931-8115-02 2013-10-28

se@vis marine HMI (Operation and Functions)

2.1.4 Keyboard and Keypad

Apart from the buttons in the working area, the following elements are available at

various points:

Numeric keypad

Alphanumeric keyboard

The keypad and the keyboard can be used to enter values and texts.

Numeric Keypad

The numeric keypad is always displayed when you can enter numeric values

(e.g. for setting various controllers).

V10101_308

Fig. 15: Numeric keypad

Alphanumeric Keyboard

The alphanumeric keyboard is displayed whenever texts can be entered.

V10102_308

Fig. 16: Alphanumeric keyboard

Technical Documentation

2013-10-28 2-7931-8115-02 21 / 192

HMI (Operation and Functions) se@vis marine

Keyboard Operation

Both keyboards offer figures (figures and letters) as well as the following special

keys:

Button Function

BACK

The letter/figure entered last is deleted.

CLEAR

Any text/value that has been entered will be deleted. The key-

board will remain open for further inputs.

ECS

The keyboard is closed, values that may have been entered

will not be stored.

Shift key (only alphanumeric keyboard)

Toggles between upper-case and lower-case inputs.

Space (only alphanumeric keyboard)

Inserts a space character.

OK

The value entered is applied. The keyboard is closed.

Table 3: Special keys of input keyboards

Note

If only values between certain limit values can be entered, the limit values are dis-

played above the keyboard (min = minimum value, max = maximum value).

Technical Documentation

22 / 192 2-7931-8115-02 2013-10-28

se@vis marine Burner Start / Burner Stop

3 Burner Start / Burner Stop

3.1 Prerequisites for Starting the Burner

Before you preselect the operation mode and start the burner, make sure that the

following conditions have been met:

1. The heat generator (e.g. boiler, combustion chamber) must be prepared for

operation. Follow the instructions for the heat generator in the manufactur-

er's documentation.

2. Ensure the supply of main fuel and atomizing medium to the burner. Follow

the instructions for the fuel supply system in the manufacturer's documenta-

tion.

3. The oil pumps (manual or automatic mode) must be

running, if MDO/HFO is preselected as fuel

operational, if MGO is preselected as fuel

4. The manual rapid shut-off for the main fuel must be open.

5. The supply pressure must be applied.

6. The manual rapid shut-off for the ignition medium must be open.

7. If you want to operate the burner locally, make sure that local operation

mode has been enabled.

For information on this subject, refer to "Local/Remote Operation (option)" on

page 33.

8. No controlled shutdown may have been triggered for the burner.

If a controlled shutdown has been triggered, wait until the control values

(steam pressure, water temperature) have returned to the range for normal

controlled operation (see "Defining Limits for Controlled Shutdown" on page

39).

9. No safety shut-off may have been triggered for the burner.

If a safety shut-off has been triggered, the fault has to be remedied first. Af-

ter that, you must reset the burner (see description below).

3.2 Resetting the Burner after a Safety Shut-Off

A safety shut-off is triggered in the following situations:

Rotary cup atomizer swiveled open

Windbox temperature too high

Boiler water level too low 1

Boiler water level too low 2

Boiler pressure too high

Flue gas temperature too high

Oil temperature too low (only with heavy fuel oil – HFO)

Oil temperature too high (only with marine gas oil – MGO)

Oil pressure too high

Flame monitors 1 + 2:

– Extraneous light is detected during the purge period

– No ignition flame after first safety period

– No main flame after second safety period

– Flame goes out during operation

Monitoring period timed out

Technical Documentation

2013-10-28 2-7931-8115-02 23 / 192

Burner Start / Burner Stop se@vis marine

Primary air pressure too low

Combustion air pressure too low

"Burner quick stop" triggered on control cabinet

Oil supply faulty (incorrect valve configuration)

Combustion air fan not in operation

Rotary cup atomizer motor not in operation

Depending on the system probably even in further situations

If a safety shut-off has occurred, all the fuel valves are closed immediately.

You have to reset the automatic firing sequence controller manually to restart the

burner (see description below).

Note

The safety shut-off is also stored when the supply voltage is switched off. This

means, the automatic firing sequence controller will not restart automatically when

voltage supply is restored.

The icon will remain visible in the headline and the LED will flash rapidly. In

this case, you have to reset the automatic firing sequence controller manually as

well.

3.2.1 Acknowledging Alarms and Resetting Burners

You initially have to acknowledge all pending messages and alarms in order to re-

set the burner. Then you can reset the burner.

All messages, alarms and safety shut-offs in the system are displayed in the list of

alerts.

Proceed as follows to display them:

Press the footer button at the HMI :

Technical Documentation

24 / 192 2-7931-8115-02 2013-10-28

se@vis marine Burner Start / Burner Stop

V11817_308

Fig. 17: List of alerts

The meaning of the color markings is as follows:

Color Type

Magenta Initial value fault

Dark red Safety shut-off

Red Alarm

Yellow Alarm acknowledged but still present

Orange Alarm no longer present but still not acknowledged

Blue "Waiting for" message

Acknowledging alarm messages

When a fault has been remedied you must acknowledge the alarm message so

that it is no longer displayed.

Press .

You enter the alarm list.

When the faults have been remedied, press .

The triggered alarms are acknowledged.

Technical Documentation

2013-10-28 2-7931-8115-02 25 / 192

Burner Start / Burner Stop se@vis marine

Note

If an alarm message cannot be acknowledged successfully, the icon will

remain visible in the headline. Remedy the fault and acknowledge the alarm mes-

sage again.

Note

If an O2 alarm is triggered, you may need to acknowledge it twice before it stops

being displayed in the alarm list.

Reset burner

Once the alarm message has been acknowledged, you can reset the burner.

Press .

You enter the alarm list.

Reset the burner by pressing .

The burner is reset.

Note

If the burner could not be reset successfully, the icon will remain visible in

the headline. Remedy the fault and reset the burner again.

Note

You must not reset the burner more than 5 times successively. If even the fifth

attempt to reset the burner fails, the FSC will be locked. In this case, contact your

board engineer as probably a major problem needs to be fixed.

3.3 Selecting Operation Mode

Precondition: Burner OFF

Press the footer button at the HMI .

The burner operation section is displayed:

In the burner operation view, the current operation mode is shown in the middle (A)

and underneath of it the settings (B) for the current operation mode are displayed.

On the right you will find the button which takes you to the operation mode selec-

tion (1).

Technical Documentation

26 / 192 2-7931-8115-02 2013-10-28

se@vis marine Burner Start / Burner Stop

V10118_308

Fig. 18: Burner operation, current operation mode

(A) Current operation mode

(B) Settings for the current operation mode

No. Button Description

(1) Selecting the operation mode

Tab. 4: Buttons in the burner operation

Press .

V12119_308

Fig. 19: Selecting the Operation Mode

(A) Designation of the operation mode

(B) Fuel set for this operation mode

(C) Symbolic display of the operation mode

(D) Symbolic display of the fuel

Press the corresponding button to select the operation mode.

The status indicator of the button (E) will turn green. You can now start the

burner.

V10119b_310

Fig. 20: Status indicator

Technical Documentation

2013-10-28 2-7931-8115-02 27 / 192

Burner Start / Burner Stop se@vis marine

Note

If the operating functions of the burner are realized by switches or pushbuttons on

the control cabinet (refer to the corresponding documentation for the respective

control cabinet), buttons on the HMI may be disabled.

3.4 Starting the Burner

If the LED at the HMI

flashes slowly,

alarm messages are pending which would not prevent a burner start

is permanently lit,

alarm messages are pending which have already been acknowledged but

whose cause has not yet been remedied

flashes quickly,

a safety shut-off has occurred and the burner cannot be started

In each case, remedy the cause of the fault.

Acknowledge the alarm messages and, if necessary, reset the burner as follows:

Acknowledging alarm messages:

Press .

Resetting the burner:

Press .

If there are no further alarm messages and safety shut-offs pending, the

LED extinguishes at the HMI (otherwise repeat the process). You can now

start the burner.

Press in the footer line.

Press , to start the burner.

The burner start button (1) is disabled and the burner stop button (2) is ena-

bled.

V10089a_308

Fig. 21: Starting the burner

Technical Documentation

28 / 192 2-7931-8115-02 2013-10-28

se@vis marine Burner Start / Burner Stop

Note

If the operating controls of the burner are realized via switches or pushbuttons on

the control cabinet (see the corresponding documentation of the control cabinet),

the buttons on the HMI are generally deactivated.

The burner starts. While the burner is starting, a starting sequence is initiat-

ed in which the following steps are performed automatically:

Purge

Ignition

You can monitor the starting sequence in the burner overview at the HMI.

3.4.1 Starting Sequence – Purge

1. The combustion air fan is switched on.

2. For rotary cup atomizers in oil firing operation mode:

The drive motor of the rotary cup atomizer will be started.

3. The oil pumps will be switched on.

4. The control dampers and control valves are set to purge position.

5. As soon as the purge position has been reached, the furnace and the flue gas

channels are purged for the preset purge time.

The remaining purge time is displayed by a countdown in the burner over-

view next to the burner status icon.

6. In systems with flue gas recirculation (RECI):

Purging takes place in two phases.

In the first phase the furnace and flue gas channels are purged with the flue gas

recirculation pipe closed. At the end of the RECI Purge delay time, the flue gas re-

circulation fan is switched on and the flue gas recirculation pipe is opened. The

purge time is continued until the flue gas recirculation control damper is in the

purge position.

In the second phase the flue gas recirculation pipe is purged with the flue gas re-

circulation fan running.

7. As soon as the purge time has elapsed,

all the control dampers and control valves are moved to ignition position

only with steam pressure atomizers:

– the oil gun is moved to operating position

– the atomizer steam valve is opened.

The ignition will automatically be initiated as soon as the purge phase has

been completed.

Technical Documentation

2013-10-28 2-7931-8115-02 29 / 192

Burner Start / Burner Stop se@vis marine

3.4.2 Starting Sequence – Ignition

As soon as the ignition position has been reached, the ignition is initiated via a pilot

burner.

The ignition is initiated as follows:

1. The ignition transformer is switched on. The ignition valves are opened and

the ignition oil pump is switched on.

2. The ignition transformer is switched off as soon as the first safety time has

elapsed and the ignition flame detection will be activated.

3. After the stabilization time of the ignition flame has elapsed, the main fuel

valves will be opened.

4. The ignition valves are closed and the ignition oil pump switched off after the

second safety time. Monitoring of the main flame is activated.

The burner is now in operation and controlled operation is started, i.e. the firing

load control is enabled.

The firing rate controller modulates the burner capacity infinitely variably between

low load and full load.

3.5 Setting the Burner to Manual Mode (Manual Firing Rate Presetting)

If required, you can set the burner firing rate to a specific value between 0 % (= low

load) and 100 % (= full load). To do so, you must switch from automatic to manual

mode:

Click .

Manual mode is active for the firing rate controller. An additional field ap-

pears in the burner control view for the manual firing rate presetting (A).

V11818_308

Fig. 22: Manual firing rate presetting in burner control

Change the firing rate presetting with or as appropriate and set a value

from 0 to 100 %.

Alternatively, you can also enter the desired value directly.

Technical Documentation

30 / 192 2-7931-8115-02 2013-10-28

se@vis marine Burner Start / Burner Stop

The lower and upper limits specified in the firing rate controller (Y-MIN and Y-MAX)

are automatically observed, so no input beyond them is possible. The same ap-

plies to the lower and upper limits specified in the high and low pressure section.

The controller sets the burner to the preset firing rate.

Note

Alternatively, you can also enter the firing rate presetting directly on the firing rate

controller in the Y field.

3.6 Stopping the Burner

Press on the burner operation screen to stop the burner.

The burner stop button (2) is disabled and the burner start button (1) is ena-

bled.

V10089b_308

Fig. 23: Stopping the burner

Note

If the operating controls of the burner are realized via switches or pushbuttons on

the control cabinet (see the corresponding documentation of the control cabinet),

the buttons on the HMI are generally deactivated

The stop sequence described below is executed.

3.6.1 Stopping Sequence

1. The burner capacity is reduced to a minimum (= low load).

2. The fuel valves are closed.

3. For steam pressure atomizer burners:

If parameterized, the blow-out sequence for the oil gun is executed (see

"Manual Blow-Out of the Oil Gun" on page 32).

For rotary cup burners:

The drive motor of the rotary cup atomizer is switched off after the set delay

time has elapsed.

4. The combustion air fan is switched off after the set delay time has elapsed (if

parameterized).

5. For gas firing operation mode:

A leak test is carried out.

Technical Documentation

2013-10-28 2-7931-8115-02 31 / 192

Burner Start / Burner Stop se@vis marine

3.7 Manual Blow-Out of the Oil Gun

The oil gun of a steam pressure atomizer burner can also be blown out manually.

This is required, for example, if the burner was switched off via a safety shut-off.

The safety interlock circuits before and after fan start-up and the safety interlock

circuit for blow-out apply during the blow-out process.

Start manual blow-out as follows:

Press .

Note

If the operating controls of the burner are realized via switches or pushbuttons on

the control cabinet (see the corresponding documentation of the control cabinet),

the buttons on the HMI are generally deactivated.

1. The combustion air fan is switched on.

2. The control dampers and control valves are set to purge position.

3. As soon as the purge position has been reached, the furnace and the flue

gas channels are purged for the preset purge time.

The remaining purge time is displayed by a countdown in the burner over-

view next to the burner status icon.

4. As soon as the purge time has elapsed, all the control dampers and control

valves are moved to ignition position and the atomizer steam valve is

opened.

The ignition will automatically be initiated as soon as the purge phase has

been completed.

5. The ignition transformer is switched on and the ignition valves are opened.

6. The ignition transformer is switched off as soon as the first safety time has

elapsed, and the ignition flame detection will be activated.

7. After the stabilization time of the ignition flame has elapsed, the blowout

valve will be opened.

The following icon is displayed in the headline during manual blow-out:

8. As soon as the blow-out time has elapsed, the ignition valves, the blowout

valve and the atomizer steam valve will be closed.

9. Post-purging is started and completed after the set post-purge time.

Notes

Press to stop manual blow-out at any time.

It is not possible to start the burner during the blow-out process.

Furthermore, the status indicator in the burner operation screen shows whether the

manual blow-out sequence is active or not (green = active, white = inactive).

Technical Documentation

32 / 192 2-7931-8115-02 2013-10-28

se@vis marine Burner Start / Burner Stop

V12121a_308

Fig. 24: Burner operation screen, status indicator manual blow-out

3.8 Controlled Shutdown

The burner is shut down automatically as soon as the following situation arises:

Although the burner firing rate controller has modulated the firing rate to minimum

(= low load), the water temperature and steam pressure continue to rise so that the

preset switch-off thresholds are exceeded (see "Defining Firing Rate Limitation in

Case of Cold Start" on page 41).

In this case, the stop sequence is executed automatically (see page 31).

When the water temperature and/or steam pressure go back down to values within

the switch-on range, the burner is automatically restarted (see page 28).

3.9 Local/Remote Operation (option)

Depending on the plant configuration, you can toggle between local and remote

operation on the burner control screen. Toggling to remote operation is only possi-

ble locally.

Local operation

The burner is operated locally on the control cabinet.

Remote operation

The burner is started via a remote control and communication system.

In remote mode, the following functions can generally be performed:

– Start/stop the burner

– Preselect operating mode

You can switch to remote mode only if the system is configured for remote opera-

tion. Otherwise the relevant button is disabled on the HMI.

Note

Operation of the burners with seavis marine systems is usually done locally via

switches and hardware pushbuttons on the control cabinet. Alternatively, it is pos-

sible to operate the burner via the operating panel HMI.

If remote operation is enabled, a is displayed in front of the burner icon in

segment 7 of the header.

The status indicators (A) and the buttons (B) also indicate the current setting

(green = active , white = inactive).

Technical Documentation

2013-10-28 2-7931-8115-02 33 / 192

Burner Start / Burner Stop se@vis marine

V10090_308

Fig. 25: Toggling between local and remote operation (here: local operation ena-

bled)

Enabling local operation

Press in the burner control section.

Local operation is enabled. The header and the button status indicator (B)

show that local operation has been selected.

Enabling remote operation

Press in the burner control section.

Remote operation is enabled. The header and the button status indicator

show that remote operation has been selected.

Technical Documentation

34 / 192 2-7931-8115-02 2013-10-28

se@vis marine Burner Start / Burner Stop

3.10 Cooling Program

The cooling program starts automatically if the temperature monitor measures an

excessively high temperature in the combustion air fan when the burner is not run-

ning. For this all enable signals must be present.

V11831b_308

Fig. 26: Display of the active cooling program in the burner overview

If the cooling program is active, various icons (A) are displayed on the burner

screen showing the status of the cooling program:

Icon Cooling program status

The cooling program is active.

Cooling program error.

Phase 1:

All air-related channels are moved to the predefined purge position.

The fan is switched on.

Phase 2:

All air-related channels are moved to the MIN position. The fan re-

mains on.

Note

If the temperature monitor measures an excessively high temperature during oper-

ation, a safety shut-off occurs. The combustion air fan remains in operation until

either

the post-purging is stopped and

the started cooling program is stopped after the burner has been switched off (if

parameterizede).

Technical Documentation

2013-10-28 2-7931-8115-02 35 / 192

Firing Rate Control se@vis marine

4 Firing Rate Control

The firing rate controller adapts the boiler system to ambient conditions (such as

switching between summer and winter). You can set the following parameters:

Setpoint

Limit burner firing rate

Set a constant burner firing rate (manual mode)

This is also where you define other generally applicable values for the burner, e.g.

Firing rate limitation in case of cold-start

Limits for controlled shutdown

4.1 Controlling and Limiting Burner Firing Rate

Precondition: 6

Press .

V10220_308

Fig. 27: Firing rate controller

No. Button Description see

(1) 30

Switch to manual mode , 6

In manual mode you can enter the set-

ting value for the controller output man-

ually.

(2) —

Quick save, 6

Saves the current configuration

Technical Documentation

36 / 192 2-7931-8115-02 2013-10-28

se@vis marine Firing Rate Control

No. Button Description see

(3) Displaying short-time trend 42

Tab. 5: Buttons in the firing rate controller

Display of controller values

In the left-hand area (A) the controller is displayed with its values in analog format:

Value / Sym- Meaning

bol

W Setpoint W in bar diagram

X Actual value X in bar diagram

0.0 bar / Scaling of nominal and actual values

16.0 bar

Controller limitation active or control release withdrawn

The load controller has a maximum limit in its control range.

It is only released, if

the burner fires,

the external and internal control release have not yet occured

and

the limitations for a cold start are exceeded.

Manual mode

The controller is in manual mode

Displaying and changing controller parameters

The right-hand area (B) displays the controller parameters. At user level 6 you can

edit the controller parameters to control and limit the burner firing rate:

Value Meaning

W1 Controller setpoint

The setpoint specifies the pressure level (steam boiler) to which the

firing rate controller controls the system. The value defined here is kept

constant via the controller.

W2 Alternative setpoint (optional)

W3 External setpoint (optional)

X Actual value in bar

Y Controller setting value in %

When the controller is in manual mode , you can set the burner

firing rate manually here. To do so, enter a percentage value within the

limits Y-MIN and Y-MAX.

Technical Documentation

2013-10-28 2-7931-8115-02 37 / 192

Firing Rate Control se@vis marine

Value Meaning

Y-MIN / Lower limit (MIN) and upper limit (MAX) of controller output

Y-MAX By limiting the burner to a minimum and/or maximum firing rate you

adapt the firing system to the process or ambient conditions.

100% = maximum firing rate; 0% = base firing rate

Note:

If IGS, master/slave, high pressure or low pressure mode is configured,

the values for the upper and lower limits can only be entered in the rel-

evant mode. The values are then only displayed in the firing rate con-

troller, and cannot be changed.

Y-MAN Manual operating point for P and PD control,

if TN = 0

YR Feedback from compound YR in %

KP Proportional gain

The higher this value is, the faster the controller will regulate. However,

excessively high values will cause oscillations in the control circuit!

Negative value = reverse direction

TN Lag time

Lower values will make the controller faster, but excessively high values

will cause oscillations in the control circuit.

0 = disable lag time (I-component)

TV Derivative time

Responds to changes in the feedback value and leads to pre-control of

the controller output. Acts in conjunction with the derivative action gain

VV.

0 = disable lead time (D-component)

VV Derivative action gain

Effective only if derivative time TV > 0

AH Response threshold

If the control difference between the setpoint (W) and actual value (X) is

within the response threshold, the controller output (Y) is not changed.

This results in smoothing of the control behavior.

Be sure to enter a value > 0.0.

Save changed controller values with in the default project.

Technical Documentation

38 / 192 2-7931-8115-02 2013-10-28

se@vis marine Firing Rate Control

4.2 Defining Limits for Controlled Shutdown

If the actual steam pressure value drops below or exceeds the setpoint defined in

the firing rate controller section, an automatic burner stop or start is executed.

To do so, define the required limit values (thresholds) for automatic shutdown and

subsequent restarting of the burner in the firing rate controller:

In the firing rate controller , press to move to the second page.

V11820c_308

Fig. 28: Firing rate controller (top)

In the right-hand area (C) the limits for controlled shutdown are displayed. At user

level 6 you can edit the controller parameters.

Note

If IGS, master/slave, high pressure or low pressure mode is configured, the values

for the upper and lower limits can only be entered in the relevant mode. The values

are then only displayed in the firing rate controller, and cannot be changed.

Value Meaning

dx-STOP Burner shutdown threshold

With this value you define the limit value for automatic controlled

shutdown.

dx-START Burner startup threshold

With this value you define the limit value for subsequent burner

restart.

The limit values apply in conjunction with the setpoint W defined in the firing rate

controller:

Current value X > setpoint W + burner shutdown threshold dx-STOP = automatic

burner stop

Current value X < setpoint W + burner startup threshold dx-START = automatic

burner start

To save energy, the limit for the controlled startup should be above the controller

nominal value W (startup threshold = positive value).

This avoids unnecessary burner stops, which would lead to cooling down the boiler

because of purging while starting again. The avoidance of unnecessary burner

stops reduces strain on the boiler and saves fuel (see following example and figure

"Burner firing rate and boiler pressure optimal").