Professional Documents

Culture Documents

Sizes Mercury & Mars (Page 1 of 4) : Figure 3A

Sizes Mercury & Mars (Page 1 of 4) : Figure 3A

Uploaded by

Freddy Arratia HerreraCopyright:

Available Formats

You might also like

- Cat D5N-D6N - Parts - 7-2010 PDFDocument33 pagesCat D5N-D6N - Parts - 7-2010 PDFzeljko100% (1)

- Alineacion CatDocument4 pagesAlineacion CatAndrea Zalamea100% (1)

- Mahindra 475 DI Total Parts ManualDocument60 pagesMahindra 475 DI Total Parts ManualSrinivas Sri100% (3)

- Quick Change Gearbox: Instructions For Installation and Operation Pictorial Parts ListDocument10 pagesQuick Change Gearbox: Instructions For Installation and Operation Pictorial Parts ListhrjeldesNo ratings yet

- Connecting Rod Bearings - Install: Table 1Document3 pagesConnecting Rod Bearings - Install: Table 1David Apaza HurtadoNo ratings yet

- Leroy Merlin - Coastal Hire Price Guide 2019 - March 2019 PDFDocument2 pagesLeroy Merlin - Coastal Hire Price Guide 2019 - March 2019 PDFMphoNhlobaneMAK-g100% (1)

- Jane SlivaDocument108 pagesJane SlivaAlberto Duran IniestraNo ratings yet

- BALEROSDocument17 pagesBALEROSjulio cesarNo ratings yet

- Service Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffectedDocument2 pagesService Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffectedAlfredoNo ratings yet

- Manual TerexDocument44 pagesManual Terexjulio100% (1)

- Flywheel Housing & AlternatorsDocument9 pagesFlywheel Housing & AlternatorsLukman ChairkiandraNo ratings yet

- MOUNTING AND ALLIGNMENT PROCEDURE FOR Z Print 2Document9 pagesMOUNTING AND ALLIGNMENT PROCEDURE FOR Z Print 2SaniNo ratings yet

- WIM-WG-001 E enDocument21 pagesWIM-WG-001 E enJhohanes OrtizNo ratings yet

- Quick Change Gearbox: Instructions For Installation and Operation Pictorial Parts ListDocument10 pagesQuick Change Gearbox: Instructions For Installation and Operation Pictorial Parts ListfejlongNo ratings yet

- TCM Torque SB96 7DDocument14 pagesTCM Torque SB96 7DИван КоньковNo ratings yet

- Manual Generador KatoDocument160 pagesManual Generador Katomass72100% (4)

- Etech MotorDocument83 pagesEtech MotorDarwin Enrique Parra VasquezNo ratings yet

- Installation Procedure: SMCS - 4050,4351Document3 pagesInstallation Procedure: SMCS - 4050,4351Enso E Rosales FNo ratings yet

- M3.0 2350 001Document6 pagesM3.0 2350 001pedro javier carrera juradoNo ratings yet

- Falk Type UbDocument12 pagesFalk Type UbJuan GalvesNo ratings yet

- 04 - 05-3657707e - Bottom Roller.Document6 pages04 - 05-3657707e - Bottom Roller.Enso RosalesNo ratings yet

- 22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Chain Chain Exchange ProcedureDocument6 pagesChain Chain Exchange Procedurecengiz kutukcuNo ratings yet

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - Installsergio blandon lNo ratings yet

- 10.manual de Instalacion y Mantenimiento, Pto (Power Take Off) PDFDocument18 pages10.manual de Instalacion y Mantenimiento, Pto (Power Take Off) PDFCamilo SanchezNo ratings yet

- Folding Ladder: Manual For Cat D9RdozerDocument27 pagesFolding Ladder: Manual For Cat D9Rdozer9879136501No ratings yet

- Pathfinder Motor HandbookDocument83 pagesPathfinder Motor Handbookchristianyankel100% (4)

- J3 Axis R-2000iCDocument14 pagesJ3 Axis R-2000iCCesar PuenteNo ratings yet

- Crankshaft Wear Sleeves and Seals: Shutdown SIS Previous ScreenDocument5 pagesCrankshaft Wear Sleeves and Seals: Shutdown SIS Previous ScreenTASHKEELNo ratings yet

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocument10 pagesWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNo ratings yet

- Gates Tb035 enDocument6 pagesGates Tb035 enMLentingNo ratings yet

- Alinieación Del GeneradorDocument5 pagesAlinieación Del Generadordamian_pelonNo ratings yet

- Caterpillar 854gDocument34 pagesCaterpillar 854gBrust Elmer ANo ratings yet

- AA03118 - Torqueo de CauchosDocument4 pagesAA03118 - Torqueo de CauchosJose A. Basanta H.No ratings yet

- Mechanical Power Take Off Rubber Block Drive Power Take Off Installation and Maintenance ManualDocument34 pagesMechanical Power Take Off Rubber Block Drive Power Take Off Installation and Maintenance ManualVituwNo ratings yet

- Mds ManualDocument20 pagesMds ManualStefanHristozovNo ratings yet

- Pistons and Connecting Rods - Install: Desmontagem e MontagemDocument3 pagesPistons and Connecting Rods - Install: Desmontagem e MontagemJefferson SilvaNo ratings yet

- Hyponic InstallationDocument7 pagesHyponic InstallationDeMen NguyenNo ratings yet

- Prime One Service ManualDocument110 pagesPrime One Service ManualberbecaruNo ratings yet

- SEBF 8174 коромысла 3500Document13 pagesSEBF 8174 коромысла 3500Евгений АбрамовNo ratings yet

- 6bearing - Remove and InstallDocument7 pages6bearing - Remove and InstallZawminhtunNo ratings yet

- Tonkaflo Pumps SS Series Installation, Operation, and Maintenance ManualDocument58 pagesTonkaflo Pumps SS Series Installation, Operation, and Maintenance ManualSmith Jonhatan Moya CarbajalNo ratings yet

- Richmond Ring & Pinion InstallationDocument8 pagesRichmond Ring & Pinion InstallationCAP History Library100% (2)

- Blackmer V-Belt Drive - Style VB Pump Models: Lgld2E, Crl2, Sgld2Document2 pagesBlackmer V-Belt Drive - Style VB Pump Models: Lgld2E, Crl2, Sgld2RAUL ARMANDO PALOMO CAMPOSNo ratings yet

- 04-Coupling 304 Motor-Gear PDFDocument12 pages04-Coupling 304 Motor-Gear PDFManuel Díaz VilloutaNo ratings yet

- EC 120 Adjustment Using The STEADYControl Adjustment Equipment - Cabin Antivibrators (AMM 53-37-00, 5-2)Document16 pagesEC 120 Adjustment Using The STEADYControl Adjustment Equipment - Cabin Antivibrators (AMM 53-37-00, 5-2)Latest RumorNo ratings yet

- tailboom assyDocument12 pagestailboom assyadulfo03455No ratings yet

- Single Bearing Generator Installation Procedures - LeTourneau, Inc.Document65 pagesSingle Bearing Generator Installation Procedures - LeTourneau, Inc.pevare100% (3)

- Petter AC1 MarineDocument33 pagesPetter AC1 Marinesergiozed0% (1)

- Drive ShaftDocument9 pagesDrive ShaftSteven AmadorNo ratings yet

- 4v69l1585e[2]Document5 pages4v69l1585e[2]bridgeNo ratings yet

- Idler Gear - Remove and InstallDocument5 pagesIdler Gear - Remove and InstallCamila Vasques Quispe100% (1)

- Suzuki GSX-R1000 2005-2006Document6 pagesSuzuki GSX-R1000 2005-2006Mr. TNo ratings yet

- Connecting Rod Bearings - Install PDFDocument3 pagesConnecting Rod Bearings - Install PDFGeorge GuerreroNo ratings yet

- M O R S E 5 X 6 Jaw Crusher ManualDocument7 pagesM O R S E 5 X 6 Jaw Crusher ManualGilberto Garnica MurilloNo ratings yet

- Caja Reductora de EngranajeDocument32 pagesCaja Reductora de EngranajeJesùs AmèsquitaNo ratings yet

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - InstallLeonardo PerezNo ratings yet

- DMA2 & DM1 Mounting & Maintenance InstructionsDocument9 pagesDMA2 & DM1 Mounting & Maintenance InstructionsMahmur AlihuddinNo ratings yet

- Service Bulletin 227B: August 28, 2001Document5 pagesService Bulletin 227B: August 28, 2001Reynaldo Bonifacio Guerra ZabaletaNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Large Gear Drives: A Good Name in IndustryDocument8 pagesLarge Gear Drives: A Good Name in IndustryFreddy Arratia HerreraNo ratings yet

- 373 140Document4 pages373 140Freddy Arratia HerreraNo ratings yet

- 373 132Document4 pages373 132Freddy Arratia HerreraNo ratings yet

- An Falla Ac DiscosDocument4 pagesAn Falla Ac DiscosFreddy Arratia HerreraNo ratings yet

- 3620Document48 pages3620JonathanPobletePerezNo ratings yet

- Specifications: Application Specification Metric EnglishDocument21 pagesSpecifications: Application Specification Metric Englishjhon greigNo ratings yet

- IDPA Gun SafetyDocument23 pagesIDPA Gun SafetyRonnieEnggingNo ratings yet

- Compressor BeltDocument4 pagesCompressor Beltlahiru0615No ratings yet

- Dokumen Error KomatsuDocument13 pagesDokumen Error KomatsuZainul Abidin100% (3)

- Youli SN-3Document19 pagesYouli SN-3Priyogo SutantiyoNo ratings yet

- P15025-Lower Well Control Valve ManualDocument5 pagesP15025-Lower Well Control Valve ManualAlex Ramirez100% (1)

- TWR / TWZ: Split System Heat Pumps Single PhaseDocument6 pagesTWR / TWZ: Split System Heat Pumps Single PhaseDavid CollinsNo ratings yet

- A Bullet Is A ProjectileDocument3 pagesA Bullet Is A ProjectileShoaib AkramNo ratings yet

- Tip Alert: Figure 2: Full-Sized Patterns: Heart Core and Front/BackDocument1 pageTip Alert: Figure 2: Full-Sized Patterns: Heart Core and Front/BackcajemarNo ratings yet

- DP Price List 2018 1Document99 pagesDP Price List 2018 1Anonymous w6GMxAPOYBNo ratings yet

- Fig 147XU Check CraneFS DS 1702 P100 1Document1 pageFig 147XU Check CraneFS DS 1702 P100 1Juan Carlos FernandezNo ratings yet

- KBA - KBB 25 MM CannonDocument6 pagesKBA - KBB 25 MM Cannondusan5stojanovic-1No ratings yet

- Cheryll Ann Jacinto LappayDocument33 pagesCheryll Ann Jacinto Lappayarun sivaNo ratings yet

- Roca Indonesia Price List Wasser VC - 03092021Document1 pageRoca Indonesia Price List Wasser VC - 03092021M RONAL FISMARNo ratings yet

- Drill CollarsDocument3 pagesDrill CollarsRambabu ChNo ratings yet

- Basic Drafting Tools and MaterialsDocument25 pagesBasic Drafting Tools and MaterialsMichelle Copones LlanesNo ratings yet

- How To Make A Wooden Folding Knife 1 PDFDocument20 pagesHow To Make A Wooden Folding Knife 1 PDFHuang KokhuiNo ratings yet

- CP Pc500lc 10m0 S N 95001 Up (Chassi)Document466 pagesCP Pc500lc 10m0 S N 95001 Up (Chassi)Cleveston Morais100% (1)

- GrindingDocument91 pagesGrindingAhmad UddinNo ratings yet

- 03 - Thermostat & Accessories - EmailDocument24 pages03 - Thermostat & Accessories - EmailTanveer AzizNo ratings yet

- Project Schedule BentayanDocument3 pagesProject Schedule Bentayanwahyu hidayatNo ratings yet

- RAB RS PepakuliaDocument2 pagesRAB RS PepakuliaDedenn aryo purnomoNo ratings yet

- URC Tarlac Tools and Materials Request Aug 18Document2 pagesURC Tarlac Tools and Materials Request Aug 18Raniel NecesitoNo ratings yet

- Uh Big Kelas 1Document3 pagesUh Big Kelas 1sdm.kaliwatesNo ratings yet

- HIGH PRESSURE HYDRAULIC PUMP CONTROL BLOCK HYDRAULIC SYSTEM EPC CNH CASE Online - AVS - PartsDocument4 pagesHIGH PRESSURE HYDRAULIC PUMP CONTROL BLOCK HYDRAULIC SYSTEM EPC CNH CASE Online - AVS - Partsamskroud brahimNo ratings yet

- Hour and Daily RoutineDocument14 pagesHour and Daily RoutineItzelNo ratings yet

Sizes Mercury & Mars (Page 1 of 4) : Figure 3A

Sizes Mercury & Mars (Page 1 of 4) : Figure 3A

Uploaded by

Freddy Arratia HerreraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sizes Mercury & Mars (Page 1 of 4) : Figure 3A

Sizes Mercury & Mars (Page 1 of 4) : Figure 3A

Uploaded by

Freddy Arratia HerreraCopyright:

Available Formats

Rexnord® Planetgear™ 7000 Speed Reducers • Scoop Mount Installation

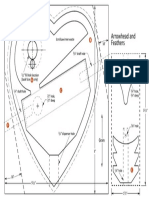

Sizes Mercury & Mars (Page 1 of 4)

INTRODUCTION

The following instructions apply to assembling scoop mounts

to Mercury & Mars Planetgear™ 7000 speed reducers. These GREASE

scoops are drilled for standard T-frame motors. Reference Table FITTING

2 (Page 4) for motor frame size capabilities and scoop mount

INPUT

part numbers. SHAFT

NOTE: Consult Rexnord for any reducer/motor combinations INPUT

that require non T-frame motors, fluid couplings or other MOUNTING

devices that require a coupling gap larger than 1/4” (6 mm). FIGURE 3A PLATE

Table of Contents

Assembly of Scoop Mount ...................................................1

Motor Alignment ................................................................2

Attaching Coupling & Coupling Guard ................................3 GREASE

Scoop Information Table .....................................................4 FITTING

INPUT

Torque Requirements for Dry Fasteners .................................5 SHAFT

INPUT

ASSEMBLY OF SCOOP MOUNT MOUNTING

FIGURE 3B PLATE

1. MSCP1 & MSCP2 - Remove 5 bolts from input shaft side as

shown in Figure 1.

MSCP18, MSCP188 & MSCP28 - Remove 8 bolts from 3. Position and loosely attach the reducer/input mounting plate

GREASE assembly to the scoop. Reference Table 1 for recommended

FITTING bolt torque values.

4. Position and attach with the appropriate fasteners the

pedestal (if required) to the motor as shown in Figure 4.

5. Loosely attach coupling to the motor shaft and the reducer

input shaft.

REMOVE 5 MOTOR

OF 8 BOLTS

VIEW OF

FIGURE 1 INPUT SHAFT END

input shaft side as shown in Figure 2. PEDESTAL

GREASE

FITTING FIGURE 4

6. Position and attach the motor/pedestal assembly to the

scoop with the recommended pedestal bolt kit as listed

in Table 2. Reference Figure 5. Reference Table 1 for

REMOVE ALL

8 BOLTS

recommended bolt torque values.

VIEW OF

FIGURE 2 INPUT SHAFT END

CAUTION: When removing all 8 bolts from the input shaft

assembly, take care not Vto break the seal between input shaft

housing and main case. If seal is broken, clean all mating

surfaces, seal with Loctite® 515 or equivalent and tighten down

to insure proper seal before proceeding any further.

2. Position input mounting plate to the input shaft side as

shown in Figures 3A and 3B (next column), and attach

with the recommended scoop bolt kit as listed in Table 1.

Reference Table 2 (Page 4) for recommended bolt torque

values. FIGURE 5

Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 158-820

Telephone: 414-342-3131 Fax: 414-937-4359 January 2008

e-mail: info@rexnord.com web: www.rexnord.com Supersedes 88-PG12

Rexnord® Planetgear™ 7000 Speed Reducers • Scoop Mount Installation

(Page 2 of 4) Sizes Mercury & Mars

MOTOR ALIGNMENT When direct coupling motors to the Planetgear 7000 reducer,

follow the four step process shown below to achieve proper

WARNING: When the Planetgear 7000 speed reducer is motor to reducer alignment. Refer to coupling manufacture

connected to a motor or driven equipment through the use of specifications to determine required alignment accuracy.

couplings, sprockets, gears or belt drives, all rotating parts must NOTE: Steps 1 to 4 may have to be repeated several times to

be properly guarded with guarding that conforms to OSHA achieve manufacturers required accuracies.

requirements to prevent personal injury or property damage.

STEP #1 (Side View Plane)

Correct for angular misalignment

in the side view plane.

STEP #2 (Side View Plane)

Correct for parallel misalignment

in the side view plane.

STEP #3 (Top View Plane)

Correct for angular misalignment

in the top view plane.

STEP #4 (Top View Plane)

Correct for parallel misalignment

in the top view plane.

158-820 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200

January 2008 Telephone: 414-342-3131 Fax: 414-937-4359

Supersedes 88-PG12 e-mail: info@rexnord.com web: www.rexnord.com

Rexnord® Planetgear™ 7000 Speed Reducers • Scoop Mount Installation

Sizes Mercury & Mars (Page 3 of 4)

ATTACHING COUPLING AND COUPLING 1. When the coupling is in place, position the coupling guard

over the coupling so that the coupling is centered inside the

GUARD guard and the opening of the guard centers on the shafts.

Mount the reducer coupling hub on the input shaft and the 2. Mark the position where the mounting holes lie on the

motor coupling hub on the motor shaft as instructed in the scoop mounting plate.

manual shipped with the coupling. If the coupling is not a

Rexnord Omega™, refer to the manufacturers literature for 3. Drill the proper size holes in the mounting plate. Tap

installation instructions. If Rexnord does not mount the motor, threads in mounting plate, 3/8” (M11) bolt size is

the couplings are mounted for shipment only. Coupling bolts recommended.

and coupling instructions are packed inside the coupling 4. Attach coupling guard to mounting plate using the correct

elements. NOTE: Prior to the installation of the element, fasteners. Refer to Table 1 for recommended bolt torques.

check both coupling hubs for the required parallel and angular

alignment; Reference Figure 6. WARNING: All rotating equipment must be properly guarded in

accordance with OSHA standards. Failure to do so may result

in personal injury or property damage.

FIGURE 6

TABLE 1 — Torque Requirements +

For Dry Fasteners (Inch)

SAE Diameter 1/4 5/16 3/8 7/16 1/2 1/16 5/8 3/4 7/8 1 1-1/8 1-1/4 1-3/8 1-1/2

General Purpose Torque (ft lb) 6 12 21 34 52 75 104 178 184 265 380 530 700 930

Grade 2

High Strength Torque (ft lb) 9 18 33 53 80 116 160 285 460 690 850 1200 1570 2080

Grade 5

Allow Steel Torque (ft lb) 13 26 47 74 114 164 225 400 650 970 1370 1940 2540 3370

Grade 8

For Dry Fasteners (Metric)

Grade Nominal Diameter M5 M6 M7 M8 M10 M12 M14 M16 M18 M20 M22 M24 M27 M30

Standard Pitch

8.8 Torque (Nm) 6.15 10.5 17.5 26 51 89 141 215 295 420 570 725 1070 1450

10.9 Torque (Nm) 8.65 15 25 36 72 125 198 305 420 590 800 1020 1510 2050

12.9 Torque (Nm) 10.4 18 29 43 87 150 240 365 500 710 960 1220 1810 2450

+ The torques shown produce a clamp load of 80% of proof load. They assume clean, dry threads with a torque coefficient of 0.2, and a coefficient of friction of 0.14.

Plated threads need only 3/4 torque shown.

Well lubricated threads need only 1/2 torque shown.

Source: Rexnord Engineering Specification: GES8-19, 04/10/79.

Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 158-820

Telephone: 414-342-3131 Fax: 414-937-4359 January 2008

e-mail: info@rexnord.com web: www.rexnord.com Supersedes 88-PG12

Rexnord® Planetgear™ 7000 Speed Reducers • Scoop Mount Installation

(Page 4 of 4) Sizes Mercury & Mars

TABLE 2 — Scoop Information (Inch)

Coupling Input Bolt Kit Bolt Kit

REDUCER Scoop Kit Motor Pedestal Scoop Plate

Guard P/N Mounting Plate (Scoop) (Pedestal)

SIZE P/N Frame Size P/N P/N

(Max Coupling Size) P/N P/N P/N

143T/145T 1884000301

MSCP1 182T/184T 1884000401 5886002280 1884000701 M003 M004

213T/215T ...

143T/145T 1884000301

MSCP18 182T/184T 1884000401 5884001401 5886002280 18844001101 M013 M004

213T/215T ...

143T/145T 1884000301

MSCP188 182T/184T 1884000401 5886006880 18844001101 M016 M004

Mercury 213T/215T ...

Mars 254T/256T 1884000501 5884001402

MSCP2 284T/286T 1884000601 5884001402 (E10) 5886002380 1884000801 M003 M005

324T ... 5884001411 (E20)

254T/256T 1884000501 5884001402

MSCP28 284T/286T 1884000601 5884001402 (E10) 5886002380 1884001201 M013 M006

324T ... 5884001411 (E20)

254T/256T 1884000501 5884001402

MSCP288 284T/286T 1884000601 5884001402 (E10) 5886006980 1884001101 M016 M006

324T ... 5884001411 (E20)

Scoop Information (Metric)

Motor Pedestal Coupling Input Bolt Kit Bolt Kit

REDUCER Scoop Kit Scoop Plate

Frame Size P/N Guard P/N Mounting Plate (Scoop) (Pedestal)

SIZE P/N P/N

(Max Coupling Size P/N P/N P/N

90SN/90LN 1884000301

100L 1886008301

MSCP1 5886002280 1884000701 M003 M004

112M 1886008401

132S/132M ...

90SN/90LN 1884000301

100L 1886008301

MSCP18 5884001401 5886002280 18844001101 M013 M004

112M 1886008401

132S/132M ...

90SN/90LN 1884000301

100L 1886008301

Mercury MSCP188 5886006880 18844001101 M016 M004

112M 1886008401

Mars

132S/132M ...

160L/160M 1884000501 5884001402

MSCP2 180M/180L 1884008501 5884001402 (E10) 5886002380 1884000801 M003 M005

200L ... 5884001411 (E20)

160L/160M 1884000501 5884001402

MSCP28 180M/180L 1884008501 5884001402 (E10) 5886002380 1884001201 M013 M006

200L ... 5884001411 (E20)

160L/160M 1884000501 5884001402

MSCP288 180M/180L 1884008501 5884001402 (E10) 5886006980 1884001101 M016 M006

200L ... 5884001411 (E20)

158-820 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200

January 2008 Telephone: 414-342-3131 Fax: 414-937-4359

Supersedes 88-PG12 e-mail: info@rexnord.com web: www.rexnord.com

You might also like

- Cat D5N-D6N - Parts - 7-2010 PDFDocument33 pagesCat D5N-D6N - Parts - 7-2010 PDFzeljko100% (1)

- Alineacion CatDocument4 pagesAlineacion CatAndrea Zalamea100% (1)

- Mahindra 475 DI Total Parts ManualDocument60 pagesMahindra 475 DI Total Parts ManualSrinivas Sri100% (3)

- Quick Change Gearbox: Instructions For Installation and Operation Pictorial Parts ListDocument10 pagesQuick Change Gearbox: Instructions For Installation and Operation Pictorial Parts ListhrjeldesNo ratings yet

- Connecting Rod Bearings - Install: Table 1Document3 pagesConnecting Rod Bearings - Install: Table 1David Apaza HurtadoNo ratings yet

- Leroy Merlin - Coastal Hire Price Guide 2019 - March 2019 PDFDocument2 pagesLeroy Merlin - Coastal Hire Price Guide 2019 - March 2019 PDFMphoNhlobaneMAK-g100% (1)

- Jane SlivaDocument108 pagesJane SlivaAlberto Duran IniestraNo ratings yet

- BALEROSDocument17 pagesBALEROSjulio cesarNo ratings yet

- Service Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffectedDocument2 pagesService Bulletin: Topic: Ident No: Supersedes: Date: Subject: Models AffectedAlfredoNo ratings yet

- Manual TerexDocument44 pagesManual Terexjulio100% (1)

- Flywheel Housing & AlternatorsDocument9 pagesFlywheel Housing & AlternatorsLukman ChairkiandraNo ratings yet

- MOUNTING AND ALLIGNMENT PROCEDURE FOR Z Print 2Document9 pagesMOUNTING AND ALLIGNMENT PROCEDURE FOR Z Print 2SaniNo ratings yet

- WIM-WG-001 E enDocument21 pagesWIM-WG-001 E enJhohanes OrtizNo ratings yet

- Quick Change Gearbox: Instructions For Installation and Operation Pictorial Parts ListDocument10 pagesQuick Change Gearbox: Instructions For Installation and Operation Pictorial Parts ListfejlongNo ratings yet

- TCM Torque SB96 7DDocument14 pagesTCM Torque SB96 7DИван КоньковNo ratings yet

- Manual Generador KatoDocument160 pagesManual Generador Katomass72100% (4)

- Etech MotorDocument83 pagesEtech MotorDarwin Enrique Parra VasquezNo ratings yet

- Installation Procedure: SMCS - 4050,4351Document3 pagesInstallation Procedure: SMCS - 4050,4351Enso E Rosales FNo ratings yet

- M3.0 2350 001Document6 pagesM3.0 2350 001pedro javier carrera juradoNo ratings yet

- Falk Type UbDocument12 pagesFalk Type UbJuan GalvesNo ratings yet

- 04 - 05-3657707e - Bottom Roller.Document6 pages04 - 05-3657707e - Bottom Roller.Enso RosalesNo ratings yet

- 22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Chain Chain Exchange ProcedureDocument6 pagesChain Chain Exchange Procedurecengiz kutukcuNo ratings yet

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - Installsergio blandon lNo ratings yet

- 10.manual de Instalacion y Mantenimiento, Pto (Power Take Off) PDFDocument18 pages10.manual de Instalacion y Mantenimiento, Pto (Power Take Off) PDFCamilo SanchezNo ratings yet

- Folding Ladder: Manual For Cat D9RdozerDocument27 pagesFolding Ladder: Manual For Cat D9Rdozer9879136501No ratings yet

- Pathfinder Motor HandbookDocument83 pagesPathfinder Motor Handbookchristianyankel100% (4)

- J3 Axis R-2000iCDocument14 pagesJ3 Axis R-2000iCCesar PuenteNo ratings yet

- Crankshaft Wear Sleeves and Seals: Shutdown SIS Previous ScreenDocument5 pagesCrankshaft Wear Sleeves and Seals: Shutdown SIS Previous ScreenTASHKEELNo ratings yet

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocument10 pagesWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNo ratings yet

- Gates Tb035 enDocument6 pagesGates Tb035 enMLentingNo ratings yet

- Alinieación Del GeneradorDocument5 pagesAlinieación Del Generadordamian_pelonNo ratings yet

- Caterpillar 854gDocument34 pagesCaterpillar 854gBrust Elmer ANo ratings yet

- AA03118 - Torqueo de CauchosDocument4 pagesAA03118 - Torqueo de CauchosJose A. Basanta H.No ratings yet

- Mechanical Power Take Off Rubber Block Drive Power Take Off Installation and Maintenance ManualDocument34 pagesMechanical Power Take Off Rubber Block Drive Power Take Off Installation and Maintenance ManualVituwNo ratings yet

- Mds ManualDocument20 pagesMds ManualStefanHristozovNo ratings yet

- Pistons and Connecting Rods - Install: Desmontagem e MontagemDocument3 pagesPistons and Connecting Rods - Install: Desmontagem e MontagemJefferson SilvaNo ratings yet

- Hyponic InstallationDocument7 pagesHyponic InstallationDeMen NguyenNo ratings yet

- Prime One Service ManualDocument110 pagesPrime One Service ManualberbecaruNo ratings yet

- SEBF 8174 коромысла 3500Document13 pagesSEBF 8174 коромысла 3500Евгений АбрамовNo ratings yet

- 6bearing - Remove and InstallDocument7 pages6bearing - Remove and InstallZawminhtunNo ratings yet

- Tonkaflo Pumps SS Series Installation, Operation, and Maintenance ManualDocument58 pagesTonkaflo Pumps SS Series Installation, Operation, and Maintenance ManualSmith Jonhatan Moya CarbajalNo ratings yet

- Richmond Ring & Pinion InstallationDocument8 pagesRichmond Ring & Pinion InstallationCAP History Library100% (2)

- Blackmer V-Belt Drive - Style VB Pump Models: Lgld2E, Crl2, Sgld2Document2 pagesBlackmer V-Belt Drive - Style VB Pump Models: Lgld2E, Crl2, Sgld2RAUL ARMANDO PALOMO CAMPOSNo ratings yet

- 04-Coupling 304 Motor-Gear PDFDocument12 pages04-Coupling 304 Motor-Gear PDFManuel Díaz VilloutaNo ratings yet

- EC 120 Adjustment Using The STEADYControl Adjustment Equipment - Cabin Antivibrators (AMM 53-37-00, 5-2)Document16 pagesEC 120 Adjustment Using The STEADYControl Adjustment Equipment - Cabin Antivibrators (AMM 53-37-00, 5-2)Latest RumorNo ratings yet

- tailboom assyDocument12 pagestailboom assyadulfo03455No ratings yet

- Single Bearing Generator Installation Procedures - LeTourneau, Inc.Document65 pagesSingle Bearing Generator Installation Procedures - LeTourneau, Inc.pevare100% (3)

- Petter AC1 MarineDocument33 pagesPetter AC1 Marinesergiozed0% (1)

- Drive ShaftDocument9 pagesDrive ShaftSteven AmadorNo ratings yet

- 4v69l1585e[2]Document5 pages4v69l1585e[2]bridgeNo ratings yet

- Idler Gear - Remove and InstallDocument5 pagesIdler Gear - Remove and InstallCamila Vasques Quispe100% (1)

- Suzuki GSX-R1000 2005-2006Document6 pagesSuzuki GSX-R1000 2005-2006Mr. TNo ratings yet

- Connecting Rod Bearings - Install PDFDocument3 pagesConnecting Rod Bearings - Install PDFGeorge GuerreroNo ratings yet

- M O R S E 5 X 6 Jaw Crusher ManualDocument7 pagesM O R S E 5 X 6 Jaw Crusher ManualGilberto Garnica MurilloNo ratings yet

- Caja Reductora de EngranajeDocument32 pagesCaja Reductora de EngranajeJesùs AmèsquitaNo ratings yet

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - InstallLeonardo PerezNo ratings yet

- DMA2 & DM1 Mounting & Maintenance InstructionsDocument9 pagesDMA2 & DM1 Mounting & Maintenance InstructionsMahmur AlihuddinNo ratings yet

- Service Bulletin 227B: August 28, 2001Document5 pagesService Bulletin 227B: August 28, 2001Reynaldo Bonifacio Guerra ZabaletaNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Large Gear Drives: A Good Name in IndustryDocument8 pagesLarge Gear Drives: A Good Name in IndustryFreddy Arratia HerreraNo ratings yet

- 373 140Document4 pages373 140Freddy Arratia HerreraNo ratings yet

- 373 132Document4 pages373 132Freddy Arratia HerreraNo ratings yet

- An Falla Ac DiscosDocument4 pagesAn Falla Ac DiscosFreddy Arratia HerreraNo ratings yet

- 3620Document48 pages3620JonathanPobletePerezNo ratings yet

- Specifications: Application Specification Metric EnglishDocument21 pagesSpecifications: Application Specification Metric Englishjhon greigNo ratings yet

- IDPA Gun SafetyDocument23 pagesIDPA Gun SafetyRonnieEnggingNo ratings yet

- Compressor BeltDocument4 pagesCompressor Beltlahiru0615No ratings yet

- Dokumen Error KomatsuDocument13 pagesDokumen Error KomatsuZainul Abidin100% (3)

- Youli SN-3Document19 pagesYouli SN-3Priyogo SutantiyoNo ratings yet

- P15025-Lower Well Control Valve ManualDocument5 pagesP15025-Lower Well Control Valve ManualAlex Ramirez100% (1)

- TWR / TWZ: Split System Heat Pumps Single PhaseDocument6 pagesTWR / TWZ: Split System Heat Pumps Single PhaseDavid CollinsNo ratings yet

- A Bullet Is A ProjectileDocument3 pagesA Bullet Is A ProjectileShoaib AkramNo ratings yet

- Tip Alert: Figure 2: Full-Sized Patterns: Heart Core and Front/BackDocument1 pageTip Alert: Figure 2: Full-Sized Patterns: Heart Core and Front/BackcajemarNo ratings yet

- DP Price List 2018 1Document99 pagesDP Price List 2018 1Anonymous w6GMxAPOYBNo ratings yet

- Fig 147XU Check CraneFS DS 1702 P100 1Document1 pageFig 147XU Check CraneFS DS 1702 P100 1Juan Carlos FernandezNo ratings yet

- KBA - KBB 25 MM CannonDocument6 pagesKBA - KBB 25 MM Cannondusan5stojanovic-1No ratings yet

- Cheryll Ann Jacinto LappayDocument33 pagesCheryll Ann Jacinto Lappayarun sivaNo ratings yet

- Roca Indonesia Price List Wasser VC - 03092021Document1 pageRoca Indonesia Price List Wasser VC - 03092021M RONAL FISMARNo ratings yet

- Drill CollarsDocument3 pagesDrill CollarsRambabu ChNo ratings yet

- Basic Drafting Tools and MaterialsDocument25 pagesBasic Drafting Tools and MaterialsMichelle Copones LlanesNo ratings yet

- How To Make A Wooden Folding Knife 1 PDFDocument20 pagesHow To Make A Wooden Folding Knife 1 PDFHuang KokhuiNo ratings yet

- CP Pc500lc 10m0 S N 95001 Up (Chassi)Document466 pagesCP Pc500lc 10m0 S N 95001 Up (Chassi)Cleveston Morais100% (1)

- GrindingDocument91 pagesGrindingAhmad UddinNo ratings yet

- 03 - Thermostat & Accessories - EmailDocument24 pages03 - Thermostat & Accessories - EmailTanveer AzizNo ratings yet

- Project Schedule BentayanDocument3 pagesProject Schedule Bentayanwahyu hidayatNo ratings yet

- RAB RS PepakuliaDocument2 pagesRAB RS PepakuliaDedenn aryo purnomoNo ratings yet

- URC Tarlac Tools and Materials Request Aug 18Document2 pagesURC Tarlac Tools and Materials Request Aug 18Raniel NecesitoNo ratings yet

- Uh Big Kelas 1Document3 pagesUh Big Kelas 1sdm.kaliwatesNo ratings yet

- HIGH PRESSURE HYDRAULIC PUMP CONTROL BLOCK HYDRAULIC SYSTEM EPC CNH CASE Online - AVS - PartsDocument4 pagesHIGH PRESSURE HYDRAULIC PUMP CONTROL BLOCK HYDRAULIC SYSTEM EPC CNH CASE Online - AVS - Partsamskroud brahimNo ratings yet

- Hour and Daily RoutineDocument14 pagesHour and Daily RoutineItzelNo ratings yet

![4v69l1585e[2]](https://imgv2-2-f.scribdassets.com/img/document/748286948/149x198/cead846d2f/1720240300?v=1)