Professional Documents

Culture Documents

Reactor - 1.5KL (Batch) Design Data

Reactor - 1.5KL (Batch) Design Data

Uploaded by

Naam Ka KyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reactor - 1.5KL (Batch) Design Data

Reactor - 1.5KL (Batch) Design Data

Uploaded by

Naam Ka KyaCopyright:

Available Formats

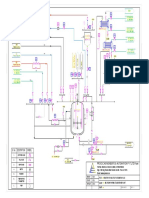

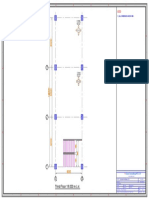

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Equipment Information ........................................................................................................................................... 2

Design Data........................................................................................................................................................... 3

Materials of Construction ......................................................................................................................................... 4

Summary of Effective Design Pressures in kgf/mm² g Vs Temperature in °C ................................................................. 5

Radiography Details................................................................................................................................................ 7

Wind Load Calculation - Design 1, Corr. .................................................................................................................... 8

Seismic Load Calculation - Design 1, Corr.................................................................................................................. 9

Dished End (Front) - Design 1, Corr. (Int. Pr.) ..........................................................................................................10

Main Shell - Design 1, Corr. (Int. Pr.) ...................................................................................................................... 11

Dished End (Rear) - Design 1, Corr. (Int. Pr.) ...........................................................................................................12

Limpet (Main Shell) - Design 1, Corr. ....................................................................................................................... 13

Limpet (Main Shell) - Design 1, Corr. ....................................................................................................................... 15

Limpet (Dish Rear) - Design 1, Corr. ........................................................................................................................ 17

Limpet (Dish Rear) - Design 1, Corr. ........................................................................................................................ 19

Lug Support - Design 1, Corr. (Wind) ...................................................................................................................... 21

Lug Support - Design 1, Corr. (Seismic) ................................................................................................................... 24

Top Bearing .......................................................................................................................................................... 27

Bottom Bearing ..................................................................................................................................................... 28

Shaft ...................................................................................................................................................................30

Impeller (1) - , ...................................................................................................................................................... 32

Lifting Lugs .......................................................................................................................................................... 33

Foundation Load Data............................................................................................................................................ 35

Center of Gravity Data ...........................................................................................................................................36

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 1 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

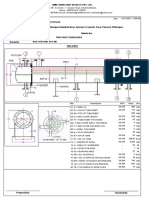

Equipment Information

Customer REACTOR -1.5KL (BATCH)

Project RUSAN PHARMA

Location AMIR TANKS & VESSELS PVT.LTD.

Plant

Design Code ASME VIII Div.1, 19

Equipment Name REACTOR-1.5KL

Equipment Type Reaction Vessel

Equipment Class N.A.

Equipment Category N.A.

Reference Drawing No ---

Service Other Service/Other Service

Support Type Lug Supports

Design & Reviewal:

Designed By

Design Date 02/11/2021 11:20:53

Checked By

Approved By

Revision R00

Inspection & Approval:

Inspection Agency ---

Reviewed By ---

Equipment Data:

Front end Dished End

Front end flanged False

Rear end Dished End

Rear end flanged False

Shell ID 1200 mm

Shell OD 1210 mm

Length, Shell (W.L. to W.L) / Overall 1500 / 2077.1 mm

Jacketing Data:

Jacketing system Shell & Bottom End

Jacket type Limpet Jacketed

Agitator Data:

Power 3 hp (MKS)

RPM 50

Duty Factor 2

Diameter of shaft 55.33 mm

Free Length of shaft 1834.7 mm

No of impellers 1

Propped False

Other Data:

Fabricated weight ( corr / uncorr ) 420.9 / 530.8 kgf

Empty weight + external weights ( corr / uncorr ) 631.8 / 742.5 kgf

Estimated operating weight ( corr / uncorr ) 738.5 / 849.1 kgf

Estimated hydrotest weight ( corr / uncorr ) 738.5 / 849.1 kgf

130

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 2 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Design Data

(1) Process Details:

Shell Side Jacket Side

Media Density kg/m³ Media Density kg/m³

Oprg Process 1000 Process 1000

Design 1 1000 1000

Hydrotest Water 1000 Water 1000

Pneumatic

(2) Pressure: kgf/mm² g

Shell Side Jacket Side

Int. Ext. Int. Ext.

Input Pr. MAWP Input Pr. Input Pr. MAWP Input Pr.

Oprg 0.01055 0.01055 0 0.02 0.02 0

Design 1 0.03 0.03 0 0.05 0.05 0

(3) Test Pressure: kgf/mm² g

Shell Side Jacket Side

Based On

Input Pr. MAWP MAP Input Pr. MAWP MAP

Hydrotest 0.03947 0.03947 0.03947 0.06923 0.06923 0.06923

Pneumatic

(4) Temperature: °C

Shell Side Jacket Side

Min. MDMT. Max. Min. MDMT. Max

Oprg 20 20 120 20 20 120

Design 1 40 40 160 21.67 21.67 160

Hydrotest 21.67 21.67 45 21.67 21.67 45

Pneumatic

(5) Allowances: mm

Shell Side Jacket Side

Int. Ext. Int. Ext.

Corrosion 1.5 0.0 0.0 0.0

Polishing 0 0 0 0

(6) Radiography & Joint Efficiency:

Shell Side Jacket Side

Joint

Radiography Joint Efficiency Radiography

Efficiency

Shell Nil 0.7 Nil 0.7

Head Nil 0.7 Nil 0.7

130

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 3 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Materials of Construction

1. Body Material:

Shell Side Jacket Side

Shell / Channel SA-240 GR. 316L Plate [UNS: S31603] SA-240 GR. 304 Plate [UNS: S30400]

Shell / Channel alternate

Head SA-240 GR. 316L Plate [UNS: S31603] SA-240 GR. 304 Plate [UNS: S30400]

Head alternate

Body flange SA-240 GR. 316L Plate [UNS: S31603] SA-240 GR. 304 Plate [UNS: S30400]

Body flange cover SA-240 GR. 316L Plate [UNS: S31603] SA-240 GR. 304 Plate [UNS: S30400]

Liner

2. Nozzle Connections:

Shell Side Jacket Side

SA-312 GR. TP316 Smls. & wld. pipe SA-312 GR. TP304 Smls. & wld. pipe

Nozzle neck

[UNS: S31600] [UNS: S30400]

SA-182 GR. F316 Forgings [UNS: SA-182 GR. F304 Forgings [UNS:

Flange=< NPS 40

S31600] S30400]

Cover flange SA-240 GR. 316 Plate [UNS: S31600] SA-240 GR. 304 Plate [UNS: S30400]

SA-312 GR. TP316 Smls. & wld. pipe SA-312 GR. TP304 Smls. & wld. pipe

Nozzle neck

[UNS: S31600] [UNS: S30400]

SA-182 GR. F316 Forgings [UNS: SA-182 GR. F304 Forgings [UNS:

Flange > NPS 40;

S31600] S30400]

Cover flange=< NPS 200 SA-240 GR. 316 Plate [UNS: S31600] SA-240 GR. 304 Plate [UNS: S30400]

SA-312 GR. TP316 Smls. & wld. pipe SA-312 GR. TP304 Smls. & wld. pipe

Nozzle neck

[UNS: S31600] [UNS: S30400]

SA-182 GR. F316 Forgings [UNS: SA-182 GR. F304 Forgings [UNS:

Flange=> NPS 350

S31600] S30400]

Cover flange SA-240 GR. 316 Plate [UNS: S31600] SA-240 GR. 304 Plate [UNS: S30400]

SA-182 GR. F316 Forgings [UNS: SA-182 GR. F304 Forgings [UNS:

Pad flange

S31600] S30400]

Pad flange cover SA-240 GR. 316 Plate [UNS: S31600] SA-240 GR. 304 Plate [UNS: S30400]

Manhole flange SA-240 GR. 316 Plate [UNS: S31600] SA-240 GR. 304 Plate [UNS: S30400]

Manhole cover SA-240 GR. 316 Plate [UNS: S31600] SA-240 GR. 304 Plate [UNS: S30400]

Reinforcement pad SA-240 GR. 316L Plate [UNS: S31603] SA-240 GR. 304 Plate [UNS: S30400]

External bolt SA-193 GR. B7 Bolting [UNS: G41400] SA-193 GR. B7 Bolting [UNS: G41400]

External gasket Asbestos Free (AF 120) Asbestos Free (AF 120)

Stiffener SA-240 GR. 316L Plate [UNS: S31603] SA-240 GR. 304 Plate [UNS: S30400]

Lifting lug IS-2062 GR. A Plate, bar, shapes IS-2062 GR. A Plate, bar, shapes

Support IS-2062 GR. A Plate, bar, shapes IS-2062 GR. A Plate, bar, shapes

SA-36 / IS-1363,67 Bolting [UNS: SA-36 / IS-1363,67 Bolting [UNS:

Anchor bolt

K02600] K02600]

3. Agitator:

Shaft SA-479 GR. 316 Bar [UNS: S31600]

Impeller SA-240 GR. 316 Plate [UNS: S31600]

Internal coupling SA-479 GR. 316 Bar [UNS: S31600]

Housing SA-479 GR. 316 Bar [UNS: S31600]

Housing cover SA-240 GR. 316 Plate [UNS: S31600]

4. Insulation & Cladding:

Mat. / Density / Thk. N.A. / kg/m³ / mm

Mat. / Thk. N.A. / mm

130

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 4 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Summary of Effective Design Pressures in kgf/mm² g Vs Temperature in °C

Inside pr. Liquid Effective pr.

Sr. No. Item name Temp.

+ve -ve pr. +ve -ve

1 Dished End (Front) 160 0.03 0 0 0.03 0

2 Main Shell 160 0.03 0 0 0.03 0

3 Dished End (Rear) 160 0.03 0 0 0.03 0

4 Limpet (Main Shell) 160 0.05 0 0.00008 0.05008 0

5 Limpet (Dish Rear) 160 0.05 0 0.00008 0.05008 0

00

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 5 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Item Wise Weight Summary

Empty wt Volume Filled wt

Sr. No. Item name Item size

kgf m³ kgf

Torispherical End CR = 1200, KR =

1 Dished End (Front) 83.76 0.224 83.76

120, 6 Nom / 5.4 Min Thk, SF = 50

2 Main Shell 1210 OD x 5 Thk, 1500 Lg 227.1 1.696 227.1

Torispherical End CR = 1200, KR =

3 Dished End (Rear) 83.76 0.224 83.76

120, 6 Nom / 5.4 Min Thk, SF = 50

4 Limpet (Main Shell) 80 OD x 02 Thk, 40544 Lg, 81.51 0.09196 173.5

5 Limpet (Dish Rear) 80 OD x 02 Thk, 6475 Lg, 13.02 0.01469 27.71

170 Long x 165 Wide x 12 Thk, 4

6 Bolting Plate 10.66 0 10.66

Nos.

165 Long x 150 Wide x 12 Thk, 8

7 Gusset Plate 18.81 0 18.81

Nos.

8 Anchor Bolt Anchor - M20 x 200 Lg, 4 Nos. 1.99 0 1.99

9 Support Pad 210 Long x 220 Wide x 5 Thk, 4 Nos. 7.392 0 7.392

10 Motor 3 HP x 1450 RPM 50 0 50

11 Gear Box 3 HP x 29 Red. Ratio 50 0 50

12 Coupling Flexible Coupled - B2A 6.14 0 6.14

13 Bearing Housing 157 OD x 40.5 Thk, 280 Lg 33.2 0.00127 33.2

14 Top Bearing SKF - Taper Roller 32007X 0.02243 0 0.02243

15 Bottom Bearing SKF - Taper Roller 30209 0.04893 0 0.04893

16 Shaft Seal Mechanical Seal 10 0 10

17 Shaft 55.334 OD x 2509.705 Lg 48.28 0 48.28

18 Impeller (1) Anchor - Sweep Dia 1160 x 2 Blades 14 0 14

19 Lifting Lugs 120 Long x 70 Wide x 12 Thk, 2 Nos. 1.596 0 1.596

20 Pad (Lifting Lugs) 70 Long x 170 Wide x 6 Thk, 2 Nos. 1.142 0 1.142

∑ 530.8 ∑ 637.4

00

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 6 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Radiography Details

Design Code : ASME VIII Div.1, 19

Chamber name Sh Design Data

Applicable Service Other Service

Lethal Service? False

Reference code clause

Selected Radiography level Nil

Category

Sr. No. Item Type Joint Info

A B C D

Radiography Nil Nil Nil

1 Shells Joint Type Type 1 Type 1 Type 1

Joint Eff. 0.7 0.7

Radiography Nil Nil Nil

2 Heads Joint Type Type 1 Type 1 Type 1

Joint Eff. 0.7 0.7

Radiography Nil Nil Nil Nil

3 Nozzles < 10" Nb Joint Type Type 1 Type 1 Type 7 Type 7

Joint Eff. 0.7 0.7

Radiography Nil Nil Nil Nil

4 Nozzles > 10" Nb Joint Type Type 1 Type 1 Type 7 Type 7

Joint Eff. 0.7 0.7

100

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 7 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Wind Load Calculation - Design 1, Corr.

Design Code: Wind [IS:875, 15]

1. Design Conditions:

Basic wind speed (Section 5.2) Vb 50 m/s

Expected life of equipment ( Section 5.3.1 ) 25 Years

Probability factor (Risk coeff.) ( Section 5.3.1 ) K1 0.902

Terrain category ( Section 5.3.2 ) Category 2

Topography factor ( Section 5.3.3 ) K3 1.3

Cyclonic region imp. factor ( Section 5.3.4 ) K4 1.15

Force coefficient (Shape factor) Cf 0.8

2. Calculation of Forces and Moments:

Equivalent diameter De 1920 mm

Overall length of equipment L 2077.1 mm

Height of C.G. of equipment Hcg 920 mm

Size and height factor ( Section 5.3.2 ) K2 0.98

Effective transverse cross-sectional area

= De x L A 3987951.6 mm²

Effective wind speed

= K1 x K2 x K3 x K4 x Vb Vz 66.06 m/s

Wind pressure

= 6E-08 x Vz 2 Pz 0.00026 kgf/mm²

Longitudinal force

= Cf x A x Pz F 835.4 kgf

Support elevation H 0 mm

Turning moment

= F x ( Hcg - H ) M 768532.4 kgf-mm

501

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 8 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Seismic Load Calculation - Design 1, Corr.

Design Code: Seismic [IS:1893, 02]

1. Design Conditions:

Weight of equipment Wo 738.5 kgf

Importance factor (Table-6 , 2002) I 1.5

Soil profile type Stiff Soil Profile (SD)

Foundation type RCC footings + Tie Beams

Damping factor 5

Seismic zone Zone III

Seismic zone factor (Table-2 , 2002) Z 0.16

Response reduction factor (Table-7 , 2002) R 2.9

Spectral accelerations coeff. (Fig. 2 , 2002) Sa / g 2.5, Use max value

Damping correction factor (Table-3 , 2002) Cf 1

Seismic coefficient (Clause-6.4.2 , 2002)

= 0.5 x Z x I x Cf x ( Sa / g ) x ( 1 / R )

= 0.5 x 0.16 x 1.5 x 1 x 2.5 x ( 1 / 2.9 ) Ah 0.103

2. Calculation of Forces and Moments:

Elevation of support H 0 mm

Height of C.G. of equipment Hcg 536.8 mm

Seismic base shear force

= Ah x Wo

= 0.103 x 738.5 Vb 76.39 kgf

Seismic moment of support

= Vb x ( Hcg - H )

= 76.39 x ( 536.8 - 0 ) M 41004.6 kgf-mm

101

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 9 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Dished End (Front) - Design 1, Corr. (Int. Pr.)

Item Type: Design of Torispherical Head (Internal Pressure)

Design Code: ASME VIII Div.1, 19

1. Design Conditions:

Design pressure (internal) Pi 0.03 kgf/mm² g

Design temperature T 160 °C

Material of construction SA-240 GR. 316L Plate [UNS: S31603]

Max. allowable stress @ design temp. S 11.6 kgf/mm²

Radiography Nil

Joint efficiency E 0.7

Inside diameter of shell ID 1203 mm

Crown radius CR 1201.5 mm

Knuckle radius KR 121.5 mm

Nominal thickness 6 mm

Nominal thickness required as per TEMA N.A mm

Internal allowance, corrosion + polishing 1.5 mm

External allowance, corrosion + polishing 0 mm

Thinning allowance / Under tolerance 0.6 mm

Available thickness 3.9 mm

2. Design Calculation as Per UG 32 e / Appendix 1-4 (d):

Factor [M]

= ( 1 / 4 ) x [ 3 + SQRT [ CR / KR ] ]

= ( 1 / 4 ) x [ 3 + SQRT [ 1201.5 / 121.5 ] ]

= 1.536

Thickness for internal pressure [t]

= M x Pi x CR / ( 2 x S x E - 0.2 x Pi )

= 1.536 x 0.03 x 1201.5 / ( 2 x 11.6 x 0.7 - 0.2 x 0.03 )

= 3.411 mm

Since available thickness is more than design thickness, design is safe.

101

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 10 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Main Shell - Design 1, Corr. (Int. Pr.)

Item Type: Shell (Internal Pressure)

Design Code: ASME VIII Div.1, 19

1. Design Conditions:

Design pressure (internal) Pi 0.03 kgf/mm² g

Design temperature T 160 °C

Material of construction SA-240 GR. 316L Plate [UNS: S31603]

Max. allowable stress at design temp. S 11.6 kgf/mm²

Radiography Nil

Joint efficiency long. seam Ec 0.7

Outside diameter OD 1210 mm

Inside radius ( corroded ) R 601.5 mm

Shell length L 1500 mm

Nominal thickness 5 mm

Nominal thickness required as per TEMA N.A. mm

Internal allowance, corrosion + polishing 1.5 mm

External allowance, corrosion + polishing 0 mm

Thickness under tolerance 0 mm

Available thickness 3.5 mm

2. Design Calculation as Per UG-27:

Thickness of shell under internal pressure [ti]

= Pi x R / ( S x E - 0.6 x Pi )

= 0.03 x 601.5 / ( 11.6 x 0.7 - 0.6 x 0.03 )

= 2.227 mm

Since available thickness is more than design thickness, design is safe.

102

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 11 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Dished End (Rear) - Design 1, Corr. (Int. Pr.)

Item Type: Design of Torispherical Head (Internal Pressure)

Design Code: ASME VIII Div.1, 19

1. Design Conditions:

Design pressure (internal) Pi 0.03 kgf/mm² g

Design temperature T 160 °C

Material of construction SA-240 GR. 316L Plate [UNS: S31603]

Max. allowable stress @ design temp. S 11.6 kgf/mm²

Radiography Nil

Joint efficiency E 0.7

Inside diameter of shell ID 1203 mm

Crown radius CR 1201.5 mm

Knuckle radius KR 121.5 mm

Nominal thickness 6 mm

Nominal thickness required as per TEMA N.A mm

Internal allowance, corrosion + polishing 1.5 mm

External allowance, corrosion + polishing 0 mm

Thinning allowance / Under tolerance 0.6 mm

Available thickness 3.9 mm

2. Design Calculation as Per UG 32 e / Appendix 1-4 (d):

Factor [M]

= ( 1 / 4 ) x [ 3 + SQRT [ CR / KR ] ]

= ( 1 / 4 ) x [ 3 + SQRT [ 1201.5 / 121.5 ] ]

= 1.536

Thickness for internal pressure [t]

= M x Pi x CR / ( 2 x S x E - 0.2 x Pi )

= 1.536 x 0.03 x 1201.5 / ( 2 x 11.6 x 0.7 - 0.2 x 0.03 )

= 3.411 mm

Since available thickness is more than design thickness, design is safe.

101

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 12 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Limpet (Main Shell) - Design 1, Corr.

Item Type: Design of Limpet Coil

Design Code: ASME VIII Div.1, 19

1. Shell Side Data:

Material of construction SA-240 GR. 316L Plate [UNS: S31603]

Design pressure (internal) Ps 0.03 kgf/mm² g

Design temperature Ts 160 °C

Max. allowable stress @ design temp. Ss 11.6 kgf/mm²

Outside diameter OD1 1210 mm

Inside diameter ID1 1203 mm

Provided thickness ts 3.5 mm

Internal allowance, corrosion + polishing 1.5 mm

External allowance, corrosion + polishing 0 mm

2. Limpet Side Data:

Material of construction SA-240 GR. 304 Plate [UNS: S30400]

Design pressure (internal) Pj 0.05008 kgf/mm² g

Design temperature Tj 160 °C

Max. allowable stress @ design temp. Sj 13.2 kgf/mm²

Outside diameter OD 80 mm

Inside diameter ID 76 mm

Provided thickness tj 2 mm

Nominal thickness 2 mm

Internal allowance, corrosion + polishing 0 mm

External allowance, corrosion + polishing 0 mm

Limpet coil pitch p 120 mm

Number of limpet coil turns (approx.) Nt 10

Refer to Appendixes:

3. Longitudinal Tensile Stress in Shell:

S’

= 0.5 x Ps x OD1 / ( 2 x ts )

= 0.5 x 0.03 x 1210 / ( 2 x 3.5 )

= 2.593 kgf/mm²

F

= 1.5 x Ss - S'

= 1.5 x 11.6 - 2.593

= 17.21

Factor K

= 101.4

P’

=F/K

= 17.21 / 101.4

= 0.17 kgf/mm² g

provided shell thickness is sufficient.

4. Check for Coil Thickness:

Coil thickness [tj]

= 0.5 x Pj x ID / ( Sj x 0.7 - 0.6 x Pj )

= 0.5 x 0.05008 x 76 / ( 13.2 x 0.7 - 0.6 x 0.05008 )

= 0.207 mm

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 13 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

provided coil thickness is sufficient.

101

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 14 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Limpet (Main Shell) - Design 1, Corr.

Item Type: Design of Limpet Coil

Design Code: IS 2825, Refer to Appendix P-3

1. Shell Side Data:

Material of construction SA-240 GR. 316L Plate [UNS: S31603]

Design pressure (internal) Ps 0.03 kgf/mm² g

Design temperature Ts 160 °C

Max. allowable stress @ design temp. Ss 11.6 kgf/mm²

Outside diameter OD1 1210 mm

Inside diameter ID1 1203 mm

Provided thickness ts 3.5 mm

Internal allowance, corrosion + polishing 1.5 mm

External allowance, corrosion + polishing 0 mm

2. Limpet Side Data:

Material of construction SA-240 GR. 304 Plate [UNS: S30400]

Design pressure (internal) Pj 0.05008 kgf/mm² g

Design temperature Tj 160 °C

Max. allowable stress @ design temp. Sj 13.2 kgf/mm²

Outside diameter OD 80 mm

Inside diameter ID 76 mm

Provided thickness tj 2 mm

Nominal thickness 2 mm

Internal allowance, corrosion + polishing 0 mm

External allowance, corrosion + polishing 0 mm

Limpet coil pitch p 120 mm

Number of limpet coil turns (approx.) Nt 10

3. Stresses in Coil:

Hoop stress [Fcc]

= Pj x ID / ( 2 x tj x 0.7 )

= 0.05008 x 76 / ( 2 x 2 x 0.7 )

= 1.359 kgf/mm²

Longitudinal tensile stress [Fcl]

= Pj x ID / ( 4 x tj x 0.7 + 2.5 x ts x 0.85 )

= 0.05008 x 76 / ( 4 x 2 x 0.85 + 2.5 x 3.5 x 0.85 )

= 0.294 kgf/mm² is less than Ss

4. Stresses in Shell:

Hoop stress [Fst]

= [ Ps x ID1 / ( 2 x ts x 0.7 ) ] + Fcl

= [ 0.03 x 1203 / ( 2 x 3.5 x 0.7 ) ] + 0.294

= 7.66 kgf/mm² is less than Ss

Longitudinal tensile stress due to shell pressure [Fs2]

= Ps x ID1 / ( 4 x ts x 0.85 )

= 0.03 x 1203 / ( 4 x 3.5 x 0.85 )

= 2.578 kgf/mm²

Long. tensile stress due to coil pressure [Fs3]

= Pj x ID / ( 2 x ts x 0.85 )

= 0.05008 x 76 / ( 2 x 3.5 x 0.85 )

= 0.544 kgf/mm²

Long. tensile stress due to bending [Fs4]

= 2 x ( Pj - Ps ) x OD 2 / ( 3 x ts 2 )

= 2 x ( 0.05008 - 0.03 ) x 80 2 / ( 3 x 3.5 2 )

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 15 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

= 6.994 kgf/mm²

Total longitudinal tensile stress [Fsl]

= Fs2 + Fs3 + Fs4

= 2.578 + 0.544 + 6.994

= 10.12 kgf/mm² is less than 1.5 x Ss

5. Equivalent Stress at Coil to Shell Junction:

Equivalent stress at coil to shell junction [Fe]

= ( Fsl 2 + Fst 2 + Fcl 2 - Fsl x Fst - Fst x Fcl - Fcl x Fsl ) 0.5

= ( 10.12 2 + 7.66 2 + 0.294 2 - 10.12 x 7.66 - 7.66 x 0.294 - 0.294 x 10.12 ) 0.5

= 8.853 kgf/mm² is less than 2 x Ss

provided shell thickness is sufficient.

6. Check for Coil Thickness:

Coil thickness [tj]

= 0.5 x Pj x ID / ( Sj x 0.85 - Pj )

= 0.5 x 0.05008 x 76 / ( 13.2 x 0.85 - 0.05008 )

= 0.103 mm

provided coil thickness is sufficient.

121

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 16 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Limpet (Dish Rear) - Design 1, Corr.

Item Type: Design of Limpet Coil

Design Code: ASME VIII Div.1, 19

1. Shell Side Data:

Material of construction SA-240 GR. 316L Plate [UNS: S31603]

Design pressure (internal) Ps 0.03 kgf/mm² g

Design temperature Ts 160 °C

Max. allowable stress @ design temp. Ss 11.6 kgf/mm²

Outside diameter OD1 1212 mm

Inside diameter ID1 1203 mm

Provided thickness ts 4.5 mm

Internal allowance, corrosion + polishing 1.5 mm

External allowance, corrosion + polishing 0 mm

2. Limpet Side Data:

Material of construction SA-240 GR. 304 Plate [UNS: S30400]

Design pressure (internal) Pj 0.05008 kgf/mm² g

Design temperature Tj 160 °C

Max. allowable stress @ design temp. Sj 13.2 kgf/mm²

Outside diameter OD 80 mm

Inside diameter ID 76 mm

Provided thickness tj 2 mm

Nominal thickness 2 mm

Internal allowance, corrosion + polishing 0 mm

External allowance, corrosion + polishing 0 mm

Limpet coil pitch p 120 mm

Number of limpet coil turns (approx.) Nt 3

Refer to Appendixes:

3. Longitudinal Tensile Stress in Shell:

S’

= 0.5 x Ps x OD1 / ( 2 x ts )

= 0.5 x 0.03 x 1212 / ( 2 x 4.5 )

= 2.331 kgf/mm²

F

= 1.5 x Ss - S'

= 1.5 x 11.6 - 2.331

= 17.47

Factor K

= 101.4

P’

=F/K

= 17.47 / 101.4

= 0.172 kgf/mm² g

provided shell thickness is sufficient.

4. Check for Coil Thickness:

Coil thickness [tj]

= 0.5 x Pj x ID / ( Sj x 0.7 - 0.6 x Pj )

= 0.5 x 0.05008 x 76 / ( 13.2 x 0.7 - 0.6 x 0.05008 )

= 0.207 mm

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 17 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

provided coil thickness is sufficient.

101

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 18 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Limpet (Dish Rear) - Design 1, Corr.

Item Type: Design of Limpet Coil

Design Code: IS 2825, Refer to Appendix P-3

1. Shell Side Data:

Material of construction SA-240 GR. 316L Plate [UNS: S31603]

Design pressure (internal) Ps 0.03 kgf/mm² g

Design temperature Ts 160 °C

Max. allowable stress @ design temp. Ss 11.6 kgf/mm²

Outside diameter OD1 1212 mm

Inside diameter ID1 1203 mm

Provided thickness ts 4.5 mm

Internal allowance, corrosion + polishing 1.5 mm

External allowance, corrosion + polishing 0 mm

2. Limpet Side Data:

Material of construction SA-240 GR. 304 Plate [UNS: S30400]

Design pressure (internal) Pj 0.05008 kgf/mm² g

Design temperature Tj 160 °C

Max. allowable stress @ design temp. Sj 13.2 kgf/mm²

Outside diameter OD 80 mm

Inside diameter ID 76 mm

Provided thickness tj 2 mm

Nominal thickness 2 mm

Internal allowance, corrosion + polishing 0 mm

External allowance, corrosion + polishing 0 mm

Limpet coil pitch p 120 mm

Number of limpet coil turns (approx.) Nt 3

3. Stresses in Coil:

Hoop stress [Fcc]

= Pj x ID / ( 2 x tj x 0.7 )

= 0.05008 x 76 / ( 2 x 2 x 0.7 )

= 1.359 kgf/mm²

Longitudinal tensile stress [Fcl]

= Pj x ID / ( 4 x tj x 0.7 + 2.5 x ts x 0.85 )

= 0.05008 x 76 / ( 4 x 2 x 0.85 + 2.5 x 4.5 x 0.85 )

= 0.259 kgf/mm² is less than Ss

4. Stresses in Shell:

Hoop stress [Fst]

= [ Ps x ID1 / ( 4 x ts x 0.7 ) ] + Fcl

= [ 0.03 x 1203 / ( 4 x 4.5 x 0.7 ) ] + 0.259

= 3.124 kgf/mm² is less than Ss

Longitudinal tensile stress due to shell pressure [Fs2]

= Ps x ID1 / ( 4 x ts x 0.85 )

= 0.03 x 1203 / ( 4 x 4.5 x 0.85 )

= 2.005 kgf/mm²

Long. tensile stress due to coil pressure [Fs3]

= Pj x ID / ( 2 x ts x 0.85 )

= 0.05008 x 76 / ( 2 x 4.5 x 0.85 )

= 0.423 kgf/mm²

Long. tensile stress due to bending [Fs4]

= 2 x ( Pj - Ps ) x OD 2 / ( 3 x ts 2 )

= 2 x ( 0.05008 - 0.03 ) x 80 2 / ( 3 x 4.5 2 )

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 19 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

= 4.231 kgf/mm²

Total longitudinal tensile stress [Fsl]

= Fs2 + Fs3 + Fs4

= 2.005 + 0.423 + 4.231

= 6.659 kgf/mm² is less than 1.5 x Ss

5. Equivalent Stress at Coil to Shell Junction:

Equivalent stress at coil to shell junction [Fe]

= ( Fsl 2 + Fst 2 + Fcl 2 - Fsl x Fst - Fst x Fcl - Fcl x Fsl ) 0.5

= ( 6.659 2 + 3.124 2 + 0.259 2 - 6.659 x 3.124 - 3.124 x 0.259 - 0.259 x 6.659 ) 0.5

= 5.552 kgf/mm² is less than 2 x Ss

provided shell thickness is sufficient.

6. Check for Coil Thickness:

Coil thickness [tj]

= 0.5 x Pj x ID / ( Sj x 0.85 - Pj )

= 0.5 x 0.05008 x 76 / ( 13.2 x 0.85 - 0.05008 )

= 0.103 mm

provided coil thickness is sufficient.

121

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 20 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Lug Support - Design 1, Corr. (Wind)

Item Type: Lug Support Design

Design Code: P V Design Manual, D.R. Moss

1. Lug Data:

M.O.C IS-2062 GR. A Plate, bar, shapes

No. of support N 4

Base plate width b1 170 mm

Base plate depth Lb 165 mm

Thickness of base plate tb 12 mm

Allowable bending stress Sb 22.97 kgf/mm²

2. Bolt Data:

M.O.C SA-36 / IS-1363,67 Bolting [UNS: K02600]

No. of bolt / lug Nb 1

Bolt diameter db 20 mm

PCD D 1470 mm

Diameter of bolt hole 24 mm

Allowable tensile stress Fs 10.69 kgf/mm²

3. Gusset Data:

Thickness tg 12 mm

Height h 150 mm

Gusset angle θ 52.52

Gusset depth at top Lc 50 mm

Number of gussets n 2

Distance between gussets b 130 mm

4. Shell Data:

Material SA-240 GR. 316L Plate [UNS: S31603]

OD diameter OD 1210 mm

Inside diameter ID 1203 mm

Thickness available ts 3.5 mm

5. Pad Data:

Material SA-240 GR. 316L Plate [UNS: S31603]

Thickness tp 5 mm

Width W 210 mm

Length L 220 mm

6. Load And Moment (Wind):

Max. overturning moment M 768532.4 kgf-mm

Design weight of vessel Wt 420.9 kgf

7. Design of Anchor Bolts:

Total uplift force on bolts [T]

= [ 4 x M / ( D x N ) ] - Wt / N

= [ 4 x 768532.4 / ( 1470 x 4 ) ] - 420.9 / 4

= 417.6 kgf

Required area of bolts [Am]

= MAX [ ( T / Fs ) , 0 ]

= MAX [ ( 417.6 / 10.69 ) , 0 ]

= 39.07 mm²

Available area of bolts [Ab]

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 21 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

= Ar x Nb ........................................................................................ where, Ar = 217.1 mm², is root area of bolt

= 217.1 x 1

= 217.1 mm²

Since Ab > Am, bolts provided are sufficient

8. Gusset Design:

Reaction force at each support [Q]

= [ 4 x M / ( D x N ) ] + Wt / N

= [ 4 x 768532.4 / ( 1470 x 4 ) ] + 420.9 / 4

= 628 kgf

Maximum axial force in gusset [P1]

=Q/n

= 628 / 2

= 314 kgf

Allowable compr. stress in gusset [Sg]

= 18000 / [ 1 + 12 x ( h’ / tg ) 2 / 18000 ] ....................................... where, h’ = 189 mm

= 18000 / [ 1 + 12 x ( 189 / 12 ) 2 / 18000 ]

= 15445.4 psi

= 10.86 kgf/mm²

Required thickness of gusset [tg’]

= 2 x P1 x ( 3 x a - Lb ) / [ Sg x Lb 2 x ( sin θ ) 2 ]

= 2 x 314 x ( 3 x 125 - 165 ) / [ 10.86 x ( 165 ) 2 x ( sin 52.52 ) 2 ]

= 0.708 mm

9. Base Plate Design:

Bending moment [Mb]

= Q x b1 / 6

= 628 x 170 / 6

= 17794.7 kgf-mm

Bearing pressure [bp]

= Q / ( w x b1 ) ............................................................................... where, w = 99 mm

= 628 / ( 99 x 170 )

= 0.03732 kgf/mm²

Bending moment due to bearing pressure [Mb’]

= bp x b 2 / 10

= 0.03732 x 130 2 / 10

= 63.07 kgf-mm

Required thickness of base plate between chairs [tb’]

= SQRT { 6 x MAX [ Mb , Mb' ] / [ ( Lb - db ) x Sb ] }

= SQRT { 6 x MAX [ 17794.7 , 63.07 ] / [ ( 165 - 20 ) x 22.97 ] }

= 5.742 mm

10. Check for Compression Plate:

Equivalent radial load [f]

=Qxa/(nxh)

= 628 x 125 / ( 2 x 150 )

= 261.7 kgf

Angle between supports []

=2x/N

=2x/4

= 1.571 rad

Internal bending moment coefficient [Kr]

= 0.5 x [ 1 / ( 0.5 x ) - cot ( 0.5 x ) ]

= 0.5 x [ 1 / ( 0. 5 x 1.571 ) - cot ( 0.5 x 1.571 ) ]

= 0.137

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 22 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Internal bending moment [Mc]

= 0.5 x Kr x f x OD

= 0.5 x 0.137 x 261.7 x 1210

= 21629.7 kgf-mm

Bending stress induced [fb]

= Mo / Zc

= 21629.7 / 1343.3

= 16.1 kgf/mm² ......................................................................... < Sb = 22.97 kgf/mm²

Since, induced stress fb < allow. stress Sb in shell material, design is safe.

102

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 23 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Lug Support - Design 1, Corr. (Seismic)

Item Type: Lug Support Design

Design Code: P V Design Manual, D.R. Moss

1. Lug Data:

M.O.C IS-2062 GR. A Plate, bar, shapes

No. of support N 4

Base plate width b1 170 mm

Base plate depth Lb 165 mm

Thickness of base plate tb 12 mm

Allowable bending stress Sb 22.97 kgf/mm²

2. Bolt Data:

M.O.C SA-36 / IS-1363,67 Bolting [UNS: K02600]

No. of bolt / lug Nb 1

Bolt diameter db 20 mm

PCD D 1470 mm

Diameter of bolt hole 24 mm

Allowable tensile stress Fs 10.69 kgf/mm²

3. Gusset Data:

Thickness tg 12 mm

Height h 150 mm

Gusset angle θ 52.52

Gusset depth at top Lc 50 mm

Number of gussets n 2

Distance between gussets b 130 mm

4. Shell Data:

Material SA-240 GR. 316L Plate [UNS: S31603]

OD diameter OD 1210 mm

Inside diameter ID 1203 mm

Thickness available ts 3.5 mm

5. Pad Data:

Material SA-240 GR. 316L Plate [UNS: S31603]

Thickness tp 5 mm

Width W 210 mm

Length L 220 mm

6. Load And Moment (Seismic):

Max. overturning moment M 41004.6 kgf-mm

Design weight of vessel Wt 738.5 kgf

7. Design of Anchor Bolts:

Total uplift force on bolts [T]

= [ 4 x M / ( D x N ) ] - Wt / N

= [ 4 x 41004.6 / ( 1470 x 4 ) ] - 738.5 / 4

= -156.7 kgf

Required area of bolts [Am]

= MAX [ ( T / Fs ) , 0 ]

= MAX [ ( -156.7 / 10.69 ) , 0 ]

= 0 mm²

Available area of bolts [Ab]

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 24 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

= Ar x Nb ........................................................................................ where, Ar = 217.1 mm², is root area of bolt

= 217.1 x 1

= 217.1 mm²

Since Ab > Am, bolts provided are sufficient

8. Gusset Design:

Reaction force at each support [Q]

= [ 4 x M / ( D x N ) ] + Wt / N

= [ 4 x 41004.6 / ( 1470 x 4 ) ] + 738.5 / 4

= 212.5 kgf

Maximum axial force in gusset [P1]

=Q/n

= 212.5 / 2

= 106.3 kgf

Allowable compr. stress in gusset [Sg]

= 18000 / [ 1 + 12 x ( h’ / tg ) 2 / 18000 ] ....................................... where, h’ = 189 mm

= 18000 / [ 1 + 12 x ( 189 / 12 ) 2 / 18000 ]

= 15445.4 psi

= 10.86 kgf/mm²

Required thickness of gusset [tg’]

= 2 x P1 x ( 3 x a - Lb ) / [ Sg x Lb 2 x ( sin θ ) 2 ]

= 2 x 106.3 x ( 3 x 125 - 165 ) / [ 10.86 x ( 165 ) 2 x ( sin 52.52 ) 2 ]

= 0.24 mm

9. Base Plate Design:

Bending moment [Mb]

= Q x b1 / 6

= 212.5 x 170 / 6

= 6021.2 kgf-mm

Bearing pressure [bp]

= Q / ( w x b1 ) ............................................................................... where, w = 99 mm

= 212.5 / ( 99 x 170 )

= 0.01263 kgf/mm²

Bending moment due to bearing pressure [Mb’]

= bp x b 2 / 10

= 0.01263 x 130 2 / 10

= 21.34 kgf-mm

Required thickness of base plate between chairs [tb’]

= SQRT { 6 x MAX [ Mb , Mb' ] / [ ( Lb - db ) x Sb ] }

= SQRT { 6 x MAX [ 6021.2 , 21.34 ] / [ ( 165 - 20 ) x 22.97 ] }

= 3.34 mm

10. Check for Compression Plate:

Equivalent radial load [f]

=Qxa/(nxh)

= 212.5 x 125 / ( 2 x 150 )

= 88.55 kgf

Angle between supports []

=2x/N

=2x/4

= 1.571 rad

Internal bending moment coefficient [Kr]

= 0.5 x [ 1 / ( 0.5 x ) - cot ( 0.5 x ) ]

= 0.5 x [ 1 / ( 0. 5 x 1.571 ) - cot ( 0.5 x 1.571 ) ]

= 0.137

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 25 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Internal bending moment [Mc]

= 0.5 x Kr x f x OD

= 0.5 x 0.137 x 88.55 x 1210

= 7318.8 kgf-mm

Bending stress induced [fb]

= Mo / Zc

= 7318.8 / 1343.3

= 5.448 kgf/mm² ......................................................................... < Sb = 22.97 kgf/mm²

Since, induced stress fb < allow. stress Sb in shell material, design is safe.

102

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 26 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Top Bearing

Item Type: Bearing Design and Selection

1. Bearing Data:

Make SKF

Type of bearing Taper Roller

Bearing Designation 32007X

Nominal Dia d 35 mm

Static load Pstat 54000 N

Dynamic load Pdyn 42900 N

Y0 0.7

Y1 1.3

E 0.46

Weight Wt 0.02243 N

2. Loads and Operating Parameters:

Radial load Fr 761.9 kgf

Axial load Fa 68.42 kgf

Revolutions RPM 50

Operating hours / day Hr 8 hrs

Expected operating life Yr 4 years

3. Calculations:

Life in million revolutions [Lf]

= RPM x ( 60 x Hr ) x ( 30 x 12 Yr ) x 1E-06

= 50 x ( 60 x 8 ) x ( 30 x 12 x 4) x 1E-06

= 34.56 million revolutions

Effective load on bearing [Feff]

= Fr + Y1 x Fa

= 761.9 + 1.3 x 68.42

= 850.8 kgf

Dynamic load on bearing [Fdyn]

= Feff x Lf a ................................................................................... where, a = 1/3 for ball bearings

and, a = 3/10 for taper and spherical bearings

= 850.8 x 34.56 0.333 kgf

= 2462.7 kgf

Since Fdyn < Pdyn , the selected bearing is safe for operation

100

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 27 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Bottom Bearing

Item Type: Bearing Design and Selection

1. Bearing Data:

Make SKF

Type of bearing Taper Roller

Bearing Designation 30209

Nominal Dia d 45 mm

Static load Pstat 76500 N

Dynamic load Pdyn 66000 N

Y0 0.8

Y1 1.5

E 0.4

Weight Wt 0.04893 N

2. Loads and Operating Parameters:

Radial load Fr 663.1 kgf

Axial load Fa 68.42 kgf

Revolutions RPM 50

Operating hours / day Hr 8 hrs

Expected operating life Yr 4 years

3. Calculations:

Life in million revolutions [Lf]

= RPM x ( 60 x Hr ) x ( 30 x 12 Yr ) x 1E-06

= 50 x ( 60 x 8 ) x ( 30 x 12 x 4) x 1E-06

= 34.56 million revolutions

Effective load on bearing [Feff]

= Fr + Y1 x Fa

= 663.1 + 1.5 x 68.42

= 765.7 kgf

Dynamic load on bearing [Fdyn]

= Feff x Lf a ................................................................................... where, a = 1/3 for ball bearings

and, a = 3/10 for taper and spherical bearings

= 765.7 x 34.56 0.333 kgf

= 2216.3 kgf

Since Fdyn < Pdyn , the selected bearing is safe for operation

100

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 28 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Coupling Data:

Make

Type Flexible Coupled

Designation B2A

Torque capacity 52.6 kgf-mm

Outside diameter 130 mm

Inside diameter 32 mm

Hub diameter 68 mm

Flange thickness 25.5 mm

No of pins 6

Gap between cplgs 3 mm

Clearance for pin removal 70 mm

100

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 29 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Shaft

Item Type: Agitator Shaft with Intermediate Bearing Housing

1. Shaft Data:

Power P 3 hp (MKS)

Pumping capacity (RPM) RPM 50

Service (Duty) factor sf 2

Material of impeller SA-479 GR. 316 Bar [UNS: S31600]

0.2% Proof stress Sy 21.09 kgf/mm²

Allowable stress Sa 14.05 kgf/mm²

Young’s modulus Es 18912.6 kgf/mm²

Weight density rho 7999.5 kg/m³

Shaft OD OD 55.33 mm

Shaft ID ID 0 mm

Total length 2509.7 mm

Allowance CA 0 mm

Shaft is propped at bottom False

Distance between bearings A 225 mm

Overhanging length L 1834.7 mm

Type of shaft seal Mechanical Seal

Distance of packing Y 300 mm

Allowable deflection at packing 0.5 mm

2. Impeller Torque, Forces and Moments:

Impeller Length, Power, Radius, Torque, Force, Moment,

L(i) P(i) Rb(i) Tm(i) F(i) M(i)

Hub No

mm hp (MKS) mm kgf-mm kgf kgf-mm

1 1734.7 3 580 42986.4 98.82 171422.5

∑ P=3 Tm = 42986.4 F = 98.82 M = 171422.5

Formulae used in the above table:

Tm(i) = [ 736 x 60 x HP(i) / ( 9.81 x 2 x x RPM ) ] kgf-m = [ 716440.6 x P(i) / RPM ] kgf-mm

F(i) = Tm(i) / ( 0.75 x Rb ) kgf

M(i) = F(i) x L(i) kgf-mm

3. Check for Equivalent Bending Moment:

Reaction at top bearing [R1]

=M/A

= 171422.5 / 225

= 761.9 kgf

Reaction at bottom bearing [R2]

= F - R1

= 98.82 - 761.9

= -663.1 kgf

Induced equivalent moment in shaft [Me]

= ( M 2 + 0.75 x Tm 2 ) 0.5

= ( 171422.5 2 + 0.75 x 42986.4 2 ) 0.5

= 175418.2 kgf-mm

Stress induced in shaft [Fy]

= ( 32 x sf x Me x D1 ) / [ x ( D1 4 - ID 4 ) ] .......................... where, assumed D1 = 55.33 mm

= ( 32 x 2 x 175418.2 x 55.33 ) / [ x ( 55.33 4 - 0 4 ) ]

= 21.09 kgf/mm²

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 30 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Since induced stress (Fy) <= yield stress (Sy), shaft diameter required for equivalent bending is D1 = 55.33 mm.

4. Check for Continuous Working Stress:

Stress assumed in shaft [Fq]

= ( 16 x sf x Tm x D2 ) / [ x ( D2 4 - ID 4 ) ] .......................... where, assumed D2 = 31.47 mm

= ( 16 x 2 x 42986.4 x 31.47 ) / [ x ( 31.47 4 - 0 4 ) ]

= 14.05 kgf/mm²

Since induced stress (Fq) <= allowable stress (Sa), shaft diameter required for torsion is D2 = 31.47 mm.

5. Shaft Deflection at Impellers:

M.I. of shaft [MI]

= x ( OD 4 - ID 4 ) / 64

= x ( 55.33 4 - 0 4 ) / 64

= 460203.5 mm 4

Deflection of shaft centre, mm Deflection at edge of blade, mm

Impeller

Ds(i) 7 x Ds(i) / 3

1 21.46 50.08

Formula used in the above table:

Ds(i) = [ F x L( x ( 3 x L - L(i) ) ] / ( 6 x Es x MI1 )

6 (a). Critical Speed of Shaft:

Critical speed of shaft [Ns]

= [ 60 / ( 2 x ) ] x SQRT [ 8 x Es x MI x g / ( ws x L 4 ) ] ... where, g = 9810 mm/s 2 & ws = 0.01924 kgf/mm

= [ 60 / ( 2 x ) ] x SQRT [ 8 x 18912.6 x 460203.5 x 9810 / (0.01924 x 1834.7 4 ) ]

= 534.6 rpm

6 (b). Critical Speed of Attachments (Blades, CPLGS ETC.):

Sr. No. Wt(i), kgf L(i), mm Nc(i), rpm

1 2509.7 534.6

Formula used in the above table:

Nc(i) = [ 60 / ( 2 x ) ] x SQRT { 3 x Es x MI x g / [ Wt(i) x L(i) 2 x ( A + L(i) ) ] }

6 (c). Critical Speed of The System:

Critical speed of the entire shaft system [Nc]

= 1 / SQRT { [ 1 / Ns 2 ] + [ 1 / Nc(1) 2 ] + [ 1 / Nc(2) 2 ] + [ 1 / Nc(3) 2 ] + [ 1 / Nc(4) 2 ] + [ 1 / Nc(5) 2 ] }

= 399.1 rpm

7. Provided Shaft Diameter 55.33

Provided shaft diameter should be at least equal to MAX [ D1, D2 ] + CA i.e., MAX [ 55.33, 31.47 ] + 0 mm.

210

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 31 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Impeller (1) - ,

Item Type: Design of Impeller Blade with Stiffener

Design Code: ASME VIII Div.1, 19

1. Design Data:

Power P 3 hp (MKS)

Pumping capacity (RPM) RPM 50

Service (Duty) factor sf 2

Material of impeller SA-240 GR. 316 Plate [UNS: S31600]

0.2% Proof stress Sy 21.09 kgf/mm²

Young’s modulus Es 18912.6 kgf/mm²

Weight density 7999.5 kg/m³

Allowance CA 1.5 mm

2. Shaft Data:

Shaft OD at Impeller OD 55.33 mm

Total length L 1734.7 mm

3. Blade Data:

Type of impeller Anchor

Impeller radius R 580 mm

Distance of impeller from bottom bearing c 1734.7 mm

No of blades Nb 2 mm

Width of blade w 100 mm

Blade thickness tb 12 mm

Blade angle 0°

4. Calculation of Blade Thickness

Torsional moment on shaft [Tm]

= 736 x 60 x H.P. / ( 9.81 x 2 x x RPM ) kg-m

= 716440.6 x P / RPM kgf-mm

= 716440.6 x 3 / 50

= 42986.4 kgf-mm

Effective force on blade [Fm]

= Tm / ( 0.75 x Rb )

= 42986.4 / ( 0.75 x 580 )

= 98.82 kgf

Minimum blade thickness required [tb]

= SQRT [ 6 x sf x Tm / ( Nb x d x Sa ) ]

= SQRT [ 6 x 2 x 42986.4 / ( 2 x 100 x 21.09 ) ]

= 11.06 mm

Since the calculated thickness 11.06 mm is less that provided thickness 12 mm of blade, blade thickness is adequate.

100

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 32 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Lifting Lugs

Item Type: Design of Lifting Lug

Design Code: P V Design Manual, D.R. Moss

1. Lifting Lug Data:

Material IS-2062 GR. A Plate, bar, shapes

Length of lug LL 70 mm

Width of lug A 120 mm

Thickness of lug plate TL 12 mm

Straight length B1 10 mm

Radius at tip R3 605 mm

Pin Hole diameter D1 40 mm

Lug to vessel weld size W1 6 mm

Min yield stress Sy 25.52 kgf/mm²

Allowable tensile stress ( 2 / 3 x Sy ) St 17.01 kgf/mm²

Allowable bending stress ( 1.5 x St ) Sb 22.97 kgf/mm²

Allowable shear stress (0.6 x St ) Ss 10.21 kgf/mm²

2. Design Loads:

Total design lift weight Wt 530.8 kgf

Number of lifting lugs N 2

Jerk load factor j 1.5

3. Calculation of Reference Dimensions:

Dimension [ L1 ] Dimension [ L2 ]

= LL - B1 - R3 = L1 / SIN ( 1 )

= 70 - 10 - 35 = 25 / SIN ( 0.395 )

= 25 mm = 65 mm

Dimension [ LT ] Angle [ 2 ]

= LL - R3 = ASIN ( R3 / L2 )

= 70 - 35 = ASIN ( 35 / 65 )

= 35 mm = 0.569 radians

Angle [ 1 ] Angle [ 3 ]

= ATAN ( 2 x L1 / A ) = 1 + 2

= ATAN ( 2 x 25 / 120 ) = 0.395 + 0.569

= 0.395 radians = 0.963 radians

Dimension [ L3 ]

= R3 / SIN ( 3 )

= 35 / SIN ( 0.963 )

= 42.62 mm

4. Design of Lug Plate:

Effective design load on each lug [ P ] Required min. thickness of lug plate for shear [ t2 ]

= j x Wt / N = P / [ ( R3 - 0.5 x D1) x ss ]

= 1.5 x 530.8 / 2 = 597.1 / [ ( 35 - 0.5 x 40 ) x 10.21 ]

= 597.1 kgf = 3.899 mm

Required min. thickness of lug plate for bending [ t1 ] Required min. thickness of lug plate for tension [ t3 ]

= 6 x P x LT / ( A 2 x Sb ) = P / [ ( 2 x L3 - D1 ) x ss ]

= 6 x 597.1 x 35 / ( 120 2 x 22.97 ) = 597.1 / [ ( 2 x 42.62 - 40 ) x 17.01 ]

= 0.379 mm = 0.776 mm

5. Calculation of Stresses in Lug Plate Welds:

Bending stress in weld [ f1 ] Max. shear stress in weld [ f2 ]

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 33 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

= 6 x P x LT / [ 2 x LL2 ] =P/[2xA]

= 6 x 597.1 x 35 / ( 2 x 70 2 ) = 597.1 / ( 2 x 120 )

= 12.8 kgf/mm = 2.488 kgf/mm

Min. Size of lug plate weld [ w1 ]

= MAX ( f1 , 2 x f2 ) / ( 0.707 x Ss )

= MAX ( 12.8 , 2 x 2.488 ) / ( 0.707 x 10.21 )

= 1.773 mm

100

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 34 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Foundation Load Data

Weight

Wind Seismic

( kgf )

Sr. Shear Moment

Mode Condn

No. ( kgf ) ( kgf-m ) Shear Moment

Empty Filled

( kgf ) ( kgf-m )

Tran. Long. Tran. Long.

1 Oprg Corr. 631.8 738.5 835.4 835.4 768.5 768.5 76.39 41

2 Design 1 Corr. 631.8 738.5 835.4 835.4 768.5 768.5 76.39 41

3 Oprg Uncorr. 742.5 849.1 835.4 835.4 768.5 768.5 87.84 53.16

4 Design 1 Uncorr. 742.5 849.1 835.4 835.4 768.5 768.5 87.84 53.16

004

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 35 of 36

Amir Tanks & Vessels Pvt Ltd Sawer Raod, India, 452002

9302556009 Email: amirtanks@rediffmail.com

REACTOR -1.5KL (BATCH) Rev: R00 / 02/11/2021 11:20:53

/ AMIR TANKS & VESSELS

RUSAN PHARMA REACTOR-1.5KL

PVT.LTD.

Center of Gravity Data

Empty Operating / Filled

Sr.No. Mode Condition Wt. C.G. Wt. C.G.

( kgf ) ( mm ) ( kgf ) ( mm )

1 Oprg Corr. 631.8 920 738.5 536.8

2 Design 1 Corr. 631.8 920 738.5 536.8

3 Oprg Uncorr. 742.5 920 849.1 605.2

4 Design 1 Uncorr. 742.5 920 849.1 605.2

004

CademPVD 21.12 by CADEM Softwares, Pune | www.cadem.net 36 of 36

You might also like

- Lab Report 5. Investigating The Hydraulic JumpDocument12 pagesLab Report 5. Investigating The Hydraulic Jumpfazeen100% (1)

- PR1978 Workbook July-24-2017Document1,085 pagesPR1978 Workbook July-24-2017rewqNo ratings yet

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanNo ratings yet

- Sfa 5.18 PDFDocument28 pagesSfa 5.18 PDFFranqui Fernandes100% (1)

- Arz 104 Wood 125141Document1 pageArz 104 Wood 125141youcef islaNo ratings yet

- Vessel Volume Calculator GuideDocument18 pagesVessel Volume Calculator GuideDavit GizawNo ratings yet

- Astm F436.04 PDFDocument6 pagesAstm F436.04 PDFWelington Volpatto MoraisNo ratings yet

- Pump and Line Calculation Sheet: Company NameDocument1 pagePump and Line Calculation Sheet: Company NameganeshdhageNo ratings yet

- (How To) Calculate The Required Blower Capacity For FBD - Pharma EngineeringDocument11 pages(How To) Calculate The Required Blower Capacity For FBD - Pharma EngineeringTerrence Terry BhengoeNo ratings yet

- Agitated Vessel Heat TransferDocument7 pagesAgitated Vessel Heat TransferalokbdasNo ratings yet

- 7-12-0011 Rev 5Document1 page7-12-0011 Rev 5cynideNo ratings yet

- Typical Fouling FactorDocument3 pagesTypical Fouling FactorMasoudNo ratings yet

- Rationalise List Welding ConsumablesDocument19 pagesRationalise List Welding ConsumablesMayank SadaniNo ratings yet

- DCP Nde DV 297 HLT 01Document7 pagesDCP Nde DV 297 HLT 01Chandrasekhar mishraNo ratings yet

- SAP FILTER-May-2020-1200Dia-Rev - PDocument4 pagesSAP FILTER-May-2020-1200Dia-Rev - PHasmukh DaveNo ratings yet

- Reid Vapour PressureDocument2 pagesReid Vapour PressureShazia Nazz Malik100% (1)

- Cone Layout Development by Marking and Calculation Method With Practical ExampleDocument12 pagesCone Layout Development by Marking and Calculation Method With Practical ExampleOkayNo ratings yet

- Input From Simulation Result From Table or Chart AssumptionDocument31 pagesInput From Simulation Result From Table or Chart AssumptionMohamed Mamdouh AbdelHameed100% (1)

- Instructed By: Hossein Sadeghi: An Introduction To Welded Tanks For Oil Storage, Api Standard 650Document287 pagesInstructed By: Hossein Sadeghi: An Introduction To Welded Tanks For Oil Storage, Api Standard 650Tania HuqNo ratings yet

- E 106Document1 pageE 106Bith SMGNo ratings yet

- VERIFICATIONDocument3 pagesVERIFICATIONshaishavNo ratings yet

- Darcy Weisbatch Calculation PDFDocument2 pagesDarcy Weisbatch Calculation PDFSaputraNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityYASH PAREKH100% (1)

- 1 Process VesselsDocument4 pages1 Process VesselsARIANA NICOLE RELIGIOSONo ratings yet

- CH-RA3 Page 2Document1 pageCH-RA3 Page 2Sonya LoveraNo ratings yet

- Valve Sizing SelectionDocument15 pagesValve Sizing Selectionbari100% (1)

- Dish CalculationDocument2 pagesDish CalculationRyan Goh Chuang HongNo ratings yet

- Strake CalculationDocument1 pageStrake CalculationABIDEEN BAMNENo ratings yet

- Lip NozzleDocument2 pagesLip NozzleSajal KulshresthaNo ratings yet

- Pid Engtech Pilot Plants v04pdfDocument20 pagesPid Engtech Pilot Plants v04pdfFaizan SarangNo ratings yet

- Equivalent Length of A Reducer - Google SearchDocument3 pagesEquivalent Length of A Reducer - Google SearchzoksiNo ratings yet

- Sizing of Temperature Control Units: For Reactor ApplicationsDocument22 pagesSizing of Temperature Control Units: For Reactor ApplicationsFernando Stuar Campos MendozaNo ratings yet

- Grand Prix Engg.: Tag No. 90-EH-02Document6 pagesGrand Prix Engg.: Tag No. 90-EH-02Abhay UpadhyayNo ratings yet

- Boilers and Condensers YuanDocument77 pagesBoilers and Condensers YuanDaniel SetyadiNo ratings yet

- Tube Expander-Tools PDFDocument120 pagesTube Expander-Tools PDFmarceilinus devaluantoNo ratings yet

- Pollution Control in Oil, Gas and Chemical PlantsDocument15 pagesPollution Control in Oil, Gas and Chemical PlantsPRAFULKUMAR PARMARNo ratings yet

- Pressure Vessel Design Excel Sheet Basic Designing Non Critical PDocument1 pagePressure Vessel Design Excel Sheet Basic Designing Non Critical PKaramYassNo ratings yet

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BAgus MarpaungNo ratings yet

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Document15 pagesAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)HyungTae JangNo ratings yet

- Specification of Rotameters: S.NO. Description SpecificationsDocument2 pagesSpecification of Rotameters: S.NO. Description Specificationssushant_jhawerNo ratings yet

- Ultipor HT For Hot Liquid ServiceDocument2 pagesUltipor HT For Hot Liquid ServiceMustafa DaoudNo ratings yet

- Asme Section Viii ChecklistDocument4 pagesAsme Section Viii ChecklistLalit WaghodeNo ratings yet

- F&D Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageF&D Head Design Tool: Pressure Vessel Engineering LTDMauricio KookcNo ratings yet

- TDC 1150Document3 pagesTDC 1150shazanNo ratings yet

- Dish Head TypesDocument6 pagesDish Head TypesJohn MaldonadoNo ratings yet

- Installing Chemcad Building A Spreadsheet Inputting Data: Process Design Laboratory Fall 15Document36 pagesInstalling Chemcad Building A Spreadsheet Inputting Data: Process Design Laboratory Fall 15Justin D. BrownNo ratings yet

- New Heat Exchaner Design - 5mwDocument20 pagesNew Heat Exchaner Design - 5mwDaniel Perez0% (1)

- Orifice SizingDocument2 pagesOrifice SizingAvinav Kumar100% (1)

- CN - Heat Tracing Calcualtion: Calculation Note D3-NGD PRO 024 NG-018Document1 pageCN - Heat Tracing Calcualtion: Calculation Note D3-NGD PRO 024 NG-018EmamokeNo ratings yet

- Distillation Column InternalsDocument7 pagesDistillation Column InternalsRicardo BecNo ratings yet

- Data Sheet P-0560 - Hot Oil Drain Tank Sump PumpDocument2 pagesData Sheet P-0560 - Hot Oil Drain Tank Sump Pumpcygnus marine panamaNo ratings yet

- Filter Design Data (24 Oct20)Document2 pagesFilter Design Data (24 Oct20)Hedi Ben MohamedNo ratings yet

- Pressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmDocument4 pagesPressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmMuh FarhanNo ratings yet

- Bolt TighteningDocument13 pagesBolt Tighteningwali banNo ratings yet

- VP 3209 e 031a 02 0013 Rev.dDocument254 pagesVP 3209 e 031a 02 0013 Rev.dSuryaprakashNo ratings yet

- V1121 FLPC MS Ga 6024017 PDFDocument219 pagesV1121 FLPC MS Ga 6024017 PDFDarshan PanchalNo ratings yet

- Joint Efficiency PDFDocument6 pagesJoint Efficiency PDFRayvaldooNo ratings yet

- Balaji S - Static Equipment Design - 7 Years - Resume - NEWDocument5 pagesBalaji S - Static Equipment Design - 7 Years - Resume - NEWkanchanabalajiNo ratings yet

- FAUDI Aviation Diesel - Products-ENDocument25 pagesFAUDI Aviation Diesel - Products-ENAttila HontváriNo ratings yet

- ASTM B619 B619M 17aDocument6 pagesASTM B619 B619M 17aAbdülHak ÖZkaraNo ratings yet

- IO List For CHPDocument16 pagesIO List For CHPPranav Sharma2No ratings yet

- A.P.C.System & Products Pvt. LTDDocument1 pageA.P.C.System & Products Pvt. LTDSudipto MajumderNo ratings yet

- TOC PMTxx43-ENG FLODocument8 pagesTOC PMTxx43-ENG FLONaam Ka KyaNo ratings yet

- PAT Automation PID-ModelDocument1 pagePAT Automation PID-ModelNaam Ka KyaNo ratings yet

- TOC PMTxx02-ENG ASYDocument10 pagesTOC PMTxx02-ENG ASYNaam Ka KyaNo ratings yet

- 00 Ground Floor-0.000-Rev-1.00-M.LvlDocument1 page00 Ground Floor-0.000-Rev-1.00-M.LvlNaam Ka KyaNo ratings yet

- 05 Terrace Floor-30.000-Rev-1.00-M.LvlDocument1 page05 Terrace Floor-30.000-Rev-1.00-M.LvlNaam Ka KyaNo ratings yet

- TOC PMTxx10-ENG ADTDocument14 pagesTOC PMTxx10-ENG ADTNaam Ka KyaNo ratings yet

- Ground Floor Layout 1Document1 pageGround Floor Layout 1Naam Ka KyaNo ratings yet

- 03 Third Floor-18.000-Rev-1.00-M.LvlDocument1 page03 Third Floor-18.000-Rev-1.00-M.LvlNaam Ka KyaNo ratings yet

- Cpme Mechanical Design DataDocument134 pagesCpme Mechanical Design DataNaam Ka KyaNo ratings yet

- Greentherm Price ListDocument5 pagesGreentherm Price ListNaam Ka KyaNo ratings yet

- ATV RUS LIM RCT 001 - MergedDocument5 pagesATV RUS LIM RCT 001 - MergedNaam Ka KyaNo ratings yet

- Cpme Tharmal Desing DataDocument3 pagesCpme Tharmal Desing DataNaam Ka KyaNo ratings yet

- Condenser 44m2Document5 pagesCondenser 44m2Naam Ka KyaNo ratings yet

- 2nd Year Syllabus NEPDocument68 pages2nd Year Syllabus NEPshiva prakashNo ratings yet

- Empirical Investigation of High-Frequency Ground Wave PropagationDocument11 pagesEmpirical Investigation of High-Frequency Ground Wave PropagationtkNo ratings yet

- Kinetic and Potential Energy WorksheetDocument3 pagesKinetic and Potential Energy WorksheetAvril NavarroNo ratings yet

- 3 Holes-Uni Hydraulic Piston Pumps: Pump Type Code Pressure Max Speed WeightDocument4 pages3 Holes-Uni Hydraulic Piston Pumps: Pump Type Code Pressure Max Speed Weightrodolfo rodríguezNo ratings yet

- Toric Iol: Dr. Ankit GuptaDocument28 pagesToric Iol: Dr. Ankit GuptaArif MohammadNo ratings yet

- Extension Springs Torsion Spring: Active Coils (N)Document9 pagesExtension Springs Torsion Spring: Active Coils (N)Pidathala Raghu Vamsi ReddyNo ratings yet

- ASTM D 2216-05 Standard Test Methods For Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass PDFDocument7 pagesASTM D 2216-05 Standard Test Methods For Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass PDFHamza QayyumNo ratings yet

- Ceiling Speakers Calculator SheetDocument1 pageCeiling Speakers Calculator SheetIhab A OsmanNo ratings yet

- MCQ DomDocument15 pagesMCQ DomprabhaakarNo ratings yet

- Unit 9 Integration of Elementary FunctionsDocument21 pagesUnit 9 Integration of Elementary Functionscooooool1927No ratings yet

- Borehole (200x200mm)Document34 pagesBorehole (200x200mm)azwanNo ratings yet

- 740-Upd8 Global Warming Swindle PresentationDocument11 pages740-Upd8 Global Warming Swindle PresentationDipanjan DasNo ratings yet

- SIUE Exit ExamDocument9 pagesSIUE Exit ExamXXXXNo ratings yet

- Certification: Construction and Study of Miniature TrebuchetDocument38 pagesCertification: Construction and Study of Miniature TrebuchetAavash PokhrelNo ratings yet

- Technical Guide For Solar Thermal SystemsDocument197 pagesTechnical Guide For Solar Thermal SystemsArvin ArviniNo ratings yet

- Physics SensorsDocument7 pagesPhysics SensorsPragti ChauhanNo ratings yet

- Homework - Chapter 8Document12 pagesHomework - Chapter 8SpringSpaethNo ratings yet

- Reservoir Properties CorrelationDocument33 pagesReservoir Properties CorrelationNiaz HussanNo ratings yet

- Maths Set-1 Class 10 Boards 2022-23Document12 pagesMaths Set-1 Class 10 Boards 2022-23Eashan K GiriNo ratings yet

- Cellulosic Fiber Loose-Fill Thermal Insulation: Standard Specification ForDocument11 pagesCellulosic Fiber Loose-Fill Thermal Insulation: Standard Specification ForingluisalejoNo ratings yet

- Wire Drawing: Group 3Document6 pagesWire Drawing: Group 3Pratik AcharyaNo ratings yet

- Pipe Friction Loss CalculationDocument5 pagesPipe Friction Loss Calculationapi-26699613100% (6)

- Ministry of Education Yangon Technological University Department of Civil EngineeringDocument72 pagesMinistry of Education Yangon Technological University Department of Civil EngineeringCho WaiNo ratings yet

- CITATION HTT /L 1033Document2 pagesCITATION HTT /L 1033Ahmad NajibNo ratings yet

- Chemistry in Microstructured ReactorsDocument41 pagesChemistry in Microstructured ReactorsMatteo RizzottoNo ratings yet

- Trunnion CalculationsDocument2 pagesTrunnion Calculationspmech consultantNo ratings yet

- Tarun Summer Internship Report FormattedDocument52 pagesTarun Summer Internship Report FormattedGOVIND SINGHNo ratings yet

- Cancelled: Unified Facilities Criteria (Ufc)Document196 pagesCancelled: Unified Facilities Criteria (Ufc)khawarNo ratings yet