Professional Documents

Culture Documents

Manual CM Ia en

Manual CM Ia en

Uploaded by

Jose Luis GallegoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual CM Ia en

Manual CM Ia en

Uploaded by

Jose Luis GallegoCopyright:

Available Formats

CM-IA SERIES

JP FLUID CONTROL

SOLENOID VALVES

2/2-WAY

INDIRECT OPERATED

NORMALLY CLOSED

COMPACT

ENERGY EFFICIENT

Solenoid Valve CM-IA-series

The CM-IA is an indirect operated 2/2-way solenoid Series Compact (CM)

valve, specially designed for installations where

Function 2/2 way

compactness and energy efficiency is important. The

valve is normally closed. The solenoid valve requires a Operation Indirect operated (I)

differential pressure of 0.5 bar for proper operation. The Position Normally closed (A)

pipe connections are 3/8”, 1/2" (12 mm orifice), or 3/4"

Body Brass (B)

(20 mm orifice). The body material is made of brass with

Pipe: Orifice: Kv-value:

a NBR, EPDM or FKM seal. The CM-IA solenoid valves are

Pipe (inch) & 3/8" (038) 12 mm (012) 2.05 m3/hr

compatible with all coils from the CS4-series. Orifice (mm) &

Kv-value (m3/hr) 1/2" (012) 12 mm (012) 2.05 m3/hr

Example of product code 3/4" (034) 20 mm (020) 5.1 m3/hr

Response time in ms

70/300 (3/8",1/2") 80/800 (3/4")

(Open/Close)

NBR (N) -10..80°C

Seal &

EPDM (E) -30..130°C

Media Temperature

FKM (F) -10..120°C

Thread BSPP / NPT (N)

Ambient Temperature Max 50°C

Min. Press. Difference 0.5 bar

Dimensions Max. Operating pressure 16/12 bar (AC/DC)

Coil series CS4

380V AC 50Hz (380AC)

230V AC 50/60Hz (230AC)

120V AC 60Hz (120AC)

Voltage

24V DC (024DC)

24V AC 50/60Hz (024AC)

12V DC (012DC)

Insulation Class Class F

Power 6 W / 8 VA

Duty Cycle 100% ED

Connector EN 175301-803 (DIN 43650 Type B)

Protection Class IP 65 (with cable plug)

2 2

Circuit Diagram

1 1

Pipe connection Dimensions LxBxH1xH2 (mm)

3/8" 62 x 43 x 84 x 98

1/2" 62 x 43 x 84 x 98

3/4" 80 x 56 x 94 x 107

MANUAL-CM-IA-EN v1.2 www.jpfluidcontrol.com 1

CM-IA SERIES

JP FLUID CONTROL

SOLENOID VALVES

400

1. TECHNICAL SPECIFICATIONS

350

1.1. Principle of operation

A solenoid valve is a valve for neutral, clean liquids and gases, which is 300

electrically controlled with the aid of a solenoid. 2/2 way means that the

valve has two ports (input / output) and two positions (closed / open).

The valve is normally closed, this means that the valve is closed when de- 250

Flow rate (l/min)

energized.

Indirect operated solenoid valves use the differential pressure of the 200

medium on the ports to open and close the orifice. A minimum

differential pressure of 0.5 bar is required for proper operation.

Furthermore, they can control a high flow rate with a relatively small 150

solenoid coil. They can be used in only one flow direction. This type of

solenoid valves is used in systems where the pressure is above 0.5 bar

and a large orifice is desired. Indirect operated valves open slower than 100

direct operated valves and require a minimum differential pressure, but

are well suited for high flow rates.

50

1.2. Area of application

Body material 0

0.5

1.5

2.5

3.5

4.5

5.5

6.5

7.5

8.5

9.5

11.5

12.5

13.5

10.5

14.5

15.5

The CM-IA type is provided with a brass body (ASTM #37800).

dp (bar)

Diaphragm

The CM-IA series is available with several materials. Depending on the 3/8" - 1/2" 3/4"

application the correct diaphragm should be selected. In the following

table a concise overview is presented of compatible media. 1.4. Duty cycle

Diaphragm Temperature Allowed media Not allowed The solenoid valve is suitable for continuous use. High switching

FKM -10°C.120°C Most fuels and Glycol-based frequencies and high pressures can reduce the lifespan.

oils, cold water, brake fluids,

detergents, ammonia gas, hot 1.5. Compliance

compressed air. water and steam,

low molecular The coils are CE marked and comply with the LVD Directive (2006/95/EC)

weight organic and EMC Directive (2004/108/EC), provided that the cables and

acids (such as connectors are properly connected.

acetic acid).

EPDM -30°C.130°C Water and Oils, fats, fuels, 1.6. Type label

steam, alcohol. solvents.

The coil properties are displayed on a label on the coil. A second label is

NBR -10°C.80°C Neutral media, Fuels, strong

provided with the valve that shows all relevant valve parameters. This

like air, cold acids, brake fluid.

label must be attached to the other side of the coil. In the figure below,

water, hydraulic

an example is shown.

oil.

1.3. Flow chart

In the flow chart, the flow of water from 20°C is shown as a function of

the positive pressure difference across the valve. The flow rate is

expressed in liters per minute and the pressure in bar. The graph shows

valves with different orifice (mm).

MANUAL-CM-IA-EN v1.2 www.jpfluidcontrol.com 2

CM-IA SERIES

JP FLUID CONTROL

SOLENOID VALVES

► Damage caused by improper use, falling, improper operating

COIL conditions or other reasons, can cause that the solenoid valve

is not functioning properly. Correct transport, proper storage

and installation, and proper use and maintenance, are

essential for reliable and error-free operation.

► Check the compatibility of the medium used, temperature

JP FLUID CONTROL PRODUCTC ODE and other operating conditions with the materials and

(Series & Volta g e ) specifications of the product. It is the responsibility of the

CS4-230AC

VOLTAGE & FREQUENC Y

230V~50Hz user to select the right product for the application.

C E-MARKERING

IP-65 ► The product may not function properly as a result of dirt,

BESC HERMINGSGRAAD wear, damage (for example, by dropping) or improper use.

Therefore, the product should not be used in applications

where a malfunction can cause danger or damage.

VALVE ► This product is not intended or approved for medical

applications, food and/or application in gas appliances.

► Solenoid valves can only be used with clean liquids or gases.

It is recommended to install a filter before the solenoid valve.

JP FLUID CONTROL ► Check the compatibility of the medium used, temperature

CM-IA034B200E PRODUCTC ODE

and other operating conditions with the materials and

Normally Closed POSITION

Pipe: 3/4"

specifications of the product.

PIPE CONNECTION

Seal: EPDM SEAL MATERIAL ► Never exceed the limits for pressure, temperature or voltage

Orifice: 20 mm ORIFICE as indicated on the product and/or in the technical

Pressure (AC /DC): documentation.

0 - (16 /12 ) bar MAXIMUM PRESSURE ► The temperature of a solenoid valve coil can rise during

operation; this is normal. Overheating will cause smoke and a

burning smell. In this case, the power supply must

immediately be disconnected.

1.7. Exploded view ► Warning: a valve opens and closes quickly. Improper use can

cause pressure transients (fluid hammer) in the pipes with

In the figure below is an exploded drawing of the CM-IA series displayed. possible damage as a consequence.

# Part ► It is not allowed to change the construction of the valve.

► Beware of electric shock when working with electrical

1 SS 302

equipment.

2 SS 302

3 PA

5

Epoxy

Spring steel

3. INSTALLATION AND MAINTENANCE

6 Top: 430F

Rest: Brass #37800 1.1. Safety instructions before starting

7 NBR/EPDM

/FKM ► It is recommended to install the product in a dry

8 430F & SS 302 environment. In moist environments, make sure that no

9 SS 302 moisture can penetrate the coil, actuator or connector. Install

10 Brass #37800

the solenoid valve in a safe way to avoid electric shock,

burning or other injuries. Ensure that the solenoid valve is

11 SS 302

installed in an area with adequate ventilation to facilitate

12 NBR/EPDM heat dissipation. Make sure the solenoid valve is not in

/FKM contact with or in the vicinity of flammable materials. Ensure

13 Brass #37800

that the product is protected from frost. Frost may damage

the product and/or block the moving parts, causing the

product to malfunction.

► Maintenance may only be performed when the system is not

pressurized, electrically disconnected and cooled down.

► Turn off the power supply before performing any work on the

solenoid valve to prevent the risk of electrical shock and to

prevent activation of the solenoid valve.

► The product is only safe when properly installed and operated

by qualified persons. Please read the safety instructions and

technical documentation carefully before installation, use or

servicing.

► Always make sure to start the installation safely after

installation or maintenance.

► Water hammer is a typical consequence of a high flow rate

and pressure in pipes with small diameters. There are several

solutions to this problem:

► Reduce the pressure with a pressure reducing

2. GENERAL SAFETY INSTRUCTIONS valve before the solenoid valve.

► Increase the pipe diameter if possible.

► This product is not a safety device and may not be used as ► Dampen the water hammer by using a flexible

such. hose or buffer before the solenoid valve.

MANUAL-CM-IA-EN v1.2 www.jpfluidcontrol.com 3

CM-IA SERIES

JP FLUID CONTROL

SOLENOID VALVES

1.2. Installation

Clean fluids and gases

The solenoid valve can be used in combination with clean liquids or

gases. Check if there is any dirt in the piping or valve before installing. It

is recommended to install a filter (500 µm) before the solenoid valve.

OUT

IN

Mounting the valve

Be aware of the direction of flow of the medium when installing the Check the flow direction with the help of the indications on the

valve. Solenoid valves with an arrow on the housing must be connected valve body.

in the indicated direction. The pipes on both sides of the valve must be

securely fastened. Use a wrench for both valve and pipe while tightening

to prevent unnecessary stresses in the system. The solenoid valve must

be fixed via the provided connection points. Only exert force at the

designated areas on the body such as the hexagon; never to the coil or

armature. Avoid vibration in the pipes. Use a suitable sealant for

threaded connections of the solenoid valve. Avoid the entry of thread

sealing material in the valve, this can lead to malfunctioning of the valve.

Position

It is recommended to install the solenoid in vertical position with the coil

facing upwards. This reduces the probability of the collection of debris in

the solenoid valve. When the solenoid valve is mounted at an angle, it is

recommended to deviate maximally 90° from the vertical position.

Only exert force at the designated faces, never at the coil or

armature.

Installation of the coil

► Make sure the coil is labeled with the valve characteristics. The

device can be damaged by using unsuitable tools.

► The temperature of the coil increases during use, this is normal.

Overheating will cause smoke and a burning smell. In this case, the

power supply must be shut down immediately.

► The coil can be rotated if the coil nut is loosened. After the

determination of the correct position, the nut should be fastened

with a torque of 5Nm.

Maximum angle 90°.

MANUAL-CM-IA-EN v1.2 www.jpfluidcontrol.com 4

CM-IA SERIES

JP FLUID CONTROL

SOLENOID VALVES

Installation of the cable plug

► Always connect the ground (3), which is provided with a

residual current device at voltages above 50V. Never use

liquid or gas piping for grounding electrical equipment. The

power supply is connected to terminals (1) and (2). The

polarity does not matter.

► Verify the voltage and frequency before connecting the coil.

► When mounting the connector, make sure that no moisture

can ingress between the coil and connector. The connector

screws should be fastened with a torque of 0.5Nm.

Connecting the power supply

► Never connect power to the coil when it is not attached to the

solenoid valve! The coil may burn out.

► Only connect power if you are sure that there is no pressure

in the system and no hazardous situations can occur.

4. SPARE PARTS

The wear parts of the solenoid valve can be replaced with a repair kit

(plunger, plunger spring, diaphragm, diaphragm spring, o-ring).

Product code Orifice Diaphragm

CM-IA-120N-REV 12mm NBR

CM-IA-120E-REV 12mm EPDM

CM-IA-120F-REV 12mm FKM

3 1 CM-IA-200N-REV 20mm NBR

2 CM-IA-200E-REV 20mm EPDM

1 2 CM-IA-200F-REV 20mm FKM

3

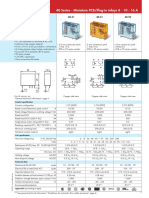

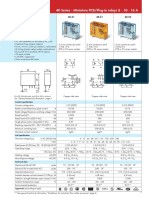

The product code of the coil is as follows:

Product code Voltage

CS4-380AC 380V AC 50Hz

CS4-230AC 230V AC 50Hz

CS4-120AC 120V AC 60Hz

CS4-024AC 24V AC 50Hz

CS4-024DC 24V DC

CS4-012DC 12V DC

5. DISPOSAL

The removal of the product should be performed in accordance with the

applicable laws. Keep in mind the media that are still present in the valve.

This manual can be downloaded from www.jpfluidcontrol.com Modifications

reserved © JP Fluid Control

This document has been prepared with great care. JP Fluid control assumes no responsibility for any

Connector: EN 175301-803 Type B (formerly DIN 43650B). errors that may appear in this document. No rights can be derived from this document

The poles (1) and (2) should be connected to the power supply, polarity

is not important. Pole (3) is connected to the ground. Connect the

connector carefully to avoid ingress of moisture. Ensure that drops

cannot slip along the cable and enter the connector .

MANUAL-CM-IA-EN v1.2 www.jpfluidcontrol.com 5

You might also like

- HydrostaticDocument9 pagesHydrostaticSWARAJ PAWARNo ratings yet

- Manual ST Da enDocument5 pagesManual ST Da enSky FooNo ratings yet

- Solenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally ClosedDocument5 pagesSolenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally ClosedVicente Moll ZamoranoNo ratings yet

- Manual TW enDocument5 pagesManual TW enRobertoNo ratings yet

- CATEN - 58Series-Finder RelayDocument11 pagesCATEN - 58Series-Finder RelayjaneeshNo ratings yet

- DZ158 CatalogueDocument4 pagesDZ158 CatalogueThinura SamarawickramaNo ratings yet

- Finder Catalogo 95.15.2SMA - Relay Socket, Through Hole, Through Hole, 8 PinsDocument16 pagesFinder Catalogo 95.15.2SMA - Relay Socket, Through Hole, Through Hole, 8 PinsJMSNo ratings yet

- Direct Acting: Solenoid Valve 2/2 - NC (Normally Closed) G 1/4Document2 pagesDirect Acting: Solenoid Valve 2/2 - NC (Normally Closed) G 1/4aqma2No ratings yet

- Finder Relays Series 62Document9 pagesFinder Relays Series 62Thong Dang SyNo ratings yet

- Fellbach EV-500 Namur NewDocument4 pagesFellbach EV-500 Namur Newman2mu2001No ratings yet

- S58ENDocument12 pagesS58ENValerija SilinaNo ratings yet

- выключатель массы ДАФ 105 S250 - FT04ENDocument4 pagesвыключатель массы ДАФ 105 S250 - FT04ENВячеслав ШапочкаNo ratings yet

- Finder 41 Series RelayDocument6 pagesFinder 41 Series RelayInderjeet chouhanNo ratings yet

- S62ENDocument16 pagesS62ENzakaria alhosinyNo ratings yet

- Relais FINDER - 4C.02Document8 pagesRelais FINDER - 4C.02Menet HenriNo ratings yet

- Datasheet Micro Solenoid Valve Series v367 v03b Asco en 5377170Document2 pagesDatasheet Micro Solenoid Valve Series v367 v03b Asco en 5377170jackzhang7608No ratings yet

- Singleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundDocument6 pagesSingleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundRafael CocãoNo ratings yet

- Product Data Sheet: Dehnguard® Modular For North America DG Mu 3py 208 3W+G (908 300)Document1 pageProduct Data Sheet: Dehnguard® Modular For North America DG Mu 3py 208 3W+G (908 300)leonardomarinNo ratings yet

- Finder Relays Series 40 PDFDocument8 pagesFinder Relays Series 40 PDFCosmin ConstantinescuNo ratings yet

- Finder Relays Series 40 PDFDocument8 pagesFinder Relays Series 40 PDFqwertysasNo ratings yet

- Features: 40 Series - Miniature PCB/Plug-in Relays 8 - 10 - 16 ADocument16 pagesFeatures: 40 Series - Miniature PCB/Plug-in Relays 8 - 10 - 16 ADante LupuNo ratings yet

- Miniature Circuit Breaker - S200M - 1P - B - 10 Ampere: Product-DetailsDocument6 pagesMiniature Circuit Breaker - S200M - 1P - B - 10 Ampere: Product-DetailsYurivilca Yurivilca GianmarcoNo ratings yet

- Acs - Catálogo InglêsDocument3 pagesAcs - Catálogo InglêsPaulo SergioNo ratings yet

- Surge Protection Device - TT-2-PE/S1-M-24DC - 2920638: Key Commercial DataDocument7 pagesSurge Protection Device - TT-2-PE/S1-M-24DC - 2920638: Key Commercial DataKurnia PratamaNo ratings yet

- General Purpose Relay: TA, TR Series Part Number DescriptionDocument17 pagesGeneral Purpose Relay: TA, TR Series Part Number DescriptionMIKENo ratings yet

- 3PA - 3PB Series Specifications・How to Order・Dimensions (0.6MB)Document18 pages3PA - 3PB Series Specifications・How to Order・Dimensions (0.6MB)Fasta DriveNo ratings yet

- Finder Relays Series 4CDocument5 pagesFinder Relays Series 4CJavid SalamovNo ratings yet

- Datasheet 6281-Ev 120127 EngDocument6 pagesDatasheet 6281-Ev 120127 EngsalimiyounessNo ratings yet

- Features: 55 Series - General Purpose Relays 7 - 10 ADocument6 pagesFeatures: 55 Series - General Purpose Relays 7 - 10 AAdetunji TaiwoNo ratings yet

- Miniature Circuit Breaker - S200M - 1P - C - 6 Ampere: Product-DetailsDocument5 pagesMiniature Circuit Breaker - S200M - 1P - C - 6 Ampere: Product-DetailssyamnjNo ratings yet

- Aotai Welding Catalogue 2023Document140 pagesAotai Welding Catalogue 2023Noki AfandiNo ratings yet

- 13,14. 60.13 Series FinderDocument12 pages13,14. 60.13 Series FinderTaQuangDucNo ratings yet

- Songchuan 303-1203846Document5 pagesSongchuan 303-1203846Fabz LimaNo ratings yet

- SafetydnDocument5 pagesSafetydnDigital ModelsNo ratings yet

- Valvula Piezotronic Atex Serie 630 AscoDocument4 pagesValvula Piezotronic Atex Serie 630 AscoBase SistemasNo ratings yet

- Features: 60 Series - General Purpose Relays 6 - 10 ADocument6 pagesFeatures: 60 Series - General Purpose Relays 6 - 10 AAdetunji TaiwoNo ratings yet

- BY1K Screw Clamp Terminal BlocksDocument20 pagesBY1K Screw Clamp Terminal Blocksphong vi100% (1)

- Relay 44 SeriesDocument12 pagesRelay 44 SeriesDanielNo ratings yet

- Sanyou Relays: Miniature High Power RelayDocument3 pagesSanyou Relays: Miniature High Power RelayTV Cinaqui ContiNo ratings yet

- Finder Relays Series 60 PDFDocument6 pagesFinder Relays Series 60 PDFElenilson SampaioNo ratings yet

- Features: 60 Series - General Purpose Relays 6 - 10 ADocument12 pagesFeatures: 60 Series - General Purpose Relays 6 - 10 ANguyen Duc HoaiNo ratings yet

- Ficha Tecnica Reles Termicos Lsis InglesDocument7 pagesFicha Tecnica Reles Termicos Lsis InglesMarcos CenturionNo ratings yet

- SX310 WTE Diode PDFDocument4 pagesSX310 WTE Diode PDFHưng HQNo ratings yet

- Rele FinderDocument14 pagesRele FinderVictor MonteagudoNo ratings yet

- 1-2 Major Component Specifications (B) Outdoor UnitDocument1 page1-2 Major Component Specifications (B) Outdoor UnitmudhaffarNo ratings yet

- Phoenix Contact - Relay Module - Rif-1-Rpt-ldp-24dc - 2x21 - 2903334Document5 pagesPhoenix Contact - Relay Module - Rif-1-Rpt-ldp-24dc - 2x21 - 2903334alexender2kNo ratings yet

- 210 прямого действияDocument2 pages210 прямого действияAlexanderNo ratings yet

- Moeller Datasheet DILET11-M-A 048886Document5 pagesMoeller Datasheet DILET11-M-A 048886sebastian peña abreuNo ratings yet

- D ft1208dj ft1208mj ft1204mj ft1204dj ft1208bj ft1208nj ft1204bj TDocument6 pagesD ft1208dj ft1208mj ft1204mj ft1204dj ft1208bj ft1208nj ft1204bj TMindSet MarcosNo ratings yet

- Sima Electronics Automotive Relays: Ordering InformationDocument2 pagesSima Electronics Automotive Relays: Ordering InformationJHelfNo ratings yet

- 2CDS211001R0324 sh201 c32Document4 pages2CDS211001R0324 sh201 c32Youth Power SolutionNo ratings yet

- Model: Maa: Lightning Surge Protectors For Electronics Equipment M-RESTER Lightning Surge Protector For Power Supply UseDocument3 pagesModel: Maa: Lightning Surge Protectors For Electronics Equipment M-RESTER Lightning Surge Protector For Power Supply Usejohn doeNo ratings yet

- GV240 Series: Advanced Switching SolutionsDocument7 pagesGV240 Series: Advanced Switching SolutionsBiagio PadulaNo ratings yet

- MR Single Pole Contactors1 PDFDocument4 pagesMR Single Pole Contactors1 PDFdip461No ratings yet

- Schrack Power PCB Relay U/UB (V23148) : General Purpose Relays PCB RelaysDocument3 pagesSchrack Power PCB Relay U/UB (V23148) : General Purpose Relays PCB Relaysremus popescuNo ratings yet

- Catalog of HAILI Welder MMA MIG TIG and Plasma CutterDocument41 pagesCatalog of HAILI Welder MMA MIG TIG and Plasma CutterHugo AlvarezNo ratings yet

- Ultra-slim PCB Relays (EMR or SSR) 0.1 - 0.2 - 2 - 6 A: SеriesDocument14 pagesUltra-slim PCB Relays (EMR or SSR) 0.1 - 0.2 - 2 - 6 A: SеriesRaymond CruzinNo ratings yet

- Pds 300Document4 pagesPds 300zbalzaNo ratings yet

- Miniature Circuit Breaker - S200M - 4P - C - 16 Ampere: Product-DetailsDocument5 pagesMiniature Circuit Breaker - S200M - 4P - C - 16 Ampere: Product-Detailsliron2312396No ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Service and Maintenance D9Document84 pagesService and Maintenance D9abduallah muhammadNo ratings yet

- High Efficiency 2.45 GHZ Low Power Hybrid Junction Rectifier For RF Energy HarvestingDocument4 pagesHigh Efficiency 2.45 GHZ Low Power Hybrid Junction Rectifier For RF Energy HarvestingPrakash SunnyNo ratings yet

- Lab Sheet Refrigeration (Second Law of Thermodynamic)Document10 pagesLab Sheet Refrigeration (Second Law of Thermodynamic)JIJENDERKUMAR A/L VIJAYAN MoeNo ratings yet

- The Greenhouse Effect & Greenhouse GasesDocument13 pagesThe Greenhouse Effect & Greenhouse GasesRanjeet SinghNo ratings yet

- Science 7 Q3 Periodic Exam Blooms Taxo With Answer KeyDocument8 pagesScience 7 Q3 Periodic Exam Blooms Taxo With Answer KeyPantz Revibes PastorNo ratings yet

- Particles and Radiation Questions and Answers in One FileDocument71 pagesParticles and Radiation Questions and Answers in One FileFin BrickmanNo ratings yet

- Govind (HVAC Technician) KSA Wup CCDocument6 pagesGovind (HVAC Technician) KSA Wup CCftimum1No ratings yet

- Why Do Airplanes With Turbofan Engines Have To Fly Higher Than The Ones With Turboprop - QuoraDocument4 pagesWhy Do Airplanes With Turbofan Engines Have To Fly Higher Than The Ones With Turboprop - QuoraAmir BahramiNo ratings yet

- Primary 5 Science Unit 4 Changing States of WaterDocument3 pagesPrimary 5 Science Unit 4 Changing States of WaterMonika DamanikNo ratings yet

- General Purpose Relay: TA, TR Series Part Number DescriptionDocument17 pagesGeneral Purpose Relay: TA, TR Series Part Number DescriptionMIKENo ratings yet

- Morocco Construction Market SizeDocument14 pagesMorocco Construction Market SizeTarik MarrahaNo ratings yet

- Ote Outotec Vibrating Compactor Eng WebDocument4 pagesOte Outotec Vibrating Compactor Eng WebGupta AnacoolzNo ratings yet

- Dec-16 Log Sheet PHDocument296 pagesDec-16 Log Sheet PHDinesh GowdNo ratings yet

- P2200 030697 ManualDocument16 pagesP2200 030697 Manualsebastien.bertrand.001No ratings yet

- Postgraduate Certificate MEP Cources PGCDocument12 pagesPostgraduate Certificate MEP Cources PGCemmanuel ochigboNo ratings yet

- Aersurface Ug v20060-101-174Document74 pagesAersurface Ug v20060-101-174Mile RomeroNo ratings yet

- 24V, High Current Synchronous Step-Down Converter: The Future of Analog IC TechnologyDocument20 pages24V, High Current Synchronous Step-Down Converter: The Future of Analog IC Technologymohammad zulkifliNo ratings yet

- Hej 3DDocument3 pagesHej 3Dhugo renzo chavez bernuyNo ratings yet

- Leed Practise Exams - Pool DDocument52 pagesLeed Practise Exams - Pool DTabish SuhailNo ratings yet

- Cheat Sheet AOS 3Document1 pageCheat Sheet AOS 3Samana GulzariNo ratings yet

- Concepts of Physics Course OutlineDocument6 pagesConcepts of Physics Course OutlineChance...No ratings yet

- Green Hydrogen - Standards, Certifications, and LabelsDocument14 pagesGreen Hydrogen - Standards, Certifications, and LabelsKapil NarulaNo ratings yet

- Week 7Document27 pagesWeek 7EmoryNo ratings yet

- New Microsoft PowerPoint Presentationseminar 1Document25 pagesNew Microsoft PowerPoint Presentationseminar 1Racii magarNo ratings yet

- ENA Forum MembershipDocument4 pagesENA Forum MembershipA14 SungNo ratings yet

- Ethylene Plants: Coke & Coke-Tar Separation From QO & QWDocument4 pagesEthylene Plants: Coke & Coke-Tar Separation From QO & QWerickNo ratings yet

- LP2100Document1 pageLP2100kaungmyatkyaw804No ratings yet

- Model JP1 EFI Kit For JEEP 258 CID 4.2 6 CylinderDocument14 pagesModel JP1 EFI Kit For JEEP 258 CID 4.2 6 CylinderMildo BurgosNo ratings yet

- Iso 4427-3-2019Document40 pagesIso 4427-3-2019Abdurrafi SholahuddinNo ratings yet