Professional Documents

Culture Documents

Chemical Compatibility Chart From Ism

Chemical Compatibility Chart From Ism

Uploaded by

kumar.arunk6784Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Compatibility Chart From Ism

Chemical Compatibility Chart From Ism

Uploaded by

kumar.arunk6784Copyright:

Available Formats

ver 27-Oct-2022

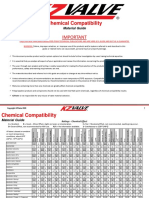

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Acetaldehyde A A D A C B A A D C C D A A B A C C C C NA A C A A D D A A D D

Acetamide B A A A B A D D A D NA A A A NA A A A D B NA A D A A D C B NA D B

Acetate Solvents A A NA A D A A C C D A C A A NA A A A C D D A NA B A D A C A D D

Acetic Acid D B D D C B D C C D B C A A A A A A B C A D B B A D C C A D B

Acetic Acid, 20% B A C C C B D C B D B A A A A A A A B A A D A A A D A B A D B

Acetic Acid, 80% D B D D D B D C C D B C A A A A A D C C A D B A A C C B A D B

Acetic Acid, Glacial C A D D D B D C C D B B B A A A A D C D A B B A A D A B A D D

Acetic Anhydride B A C D D A D C D D B D B A C A C D C A D A D B A D B C A D D

Acetone A A D A D A A A D A A D A A B A D B C C D A D A A D D D A D D

Acetylene A A NA A A A B C B A D C A NA A A B D B B NA A D A A A A B NA A A

Acrylonitrile A A D NA B B A A D A A A D B NA NA A A B C NA A D A A B A D NA NA D

Alcohols: Amyl A A A A C B A A B B A A A A A A A B1 B A C A B B A A A D B D A

Alcohols: Benzyl B B D A D B B A D B B A B A NA A B D D C D B D A A D A NA A D A

Alcohols: Butyl A A D A C B A A A NA B A A B B A B B1 A A A B B A A C A B B B A

Alcohols: Ethyl A A B A C B A A C B A B A A D A A B A A A A B1 A A C A B A C A

Alcohols: Isobutyl A A B A C B B A B C NA NA A A NA A A A A A A A A A A A A A B A A

Alcohols: Isopropyl B B D A A B B A B A B C A A A A A A1 A B A D A1 A1 A A A A B A A

Alcohols: Methyl A A D A C A A A A A B A A A B A A A A A A B B A1 A A A A B A C

Alcohols: Propyl (1-Propanol) A A B A B A A A A A A A A A NA A B A1 A A A D A A A A A1 A A A A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Aluminum Fluoride D D A C C B D D A D D A A B NA NA A A1 B A A A NA A A A A B A A A

Aluminum Hydroxide A C B A A B B C A A D A A B NA A A A1 D A A A B A A A A NA B A A

Aluminum Nitrate A A A1 B B D D NA A NA D A A NA NA A A A1 A A NA A A A1 A B A B A B A

Aluminum Sulfate, 10% B B1 A B B B B B A D A A A B B A A A1 A A A A1 A A A A A A A A A

Alums NA A A1 C B A D NA A D C A A B D A A A A B NA A NA A A NA NA A A NA A

Amines A A NA D D B B D D D NA D B B A A B C B B D D D B1 A D NA B B D D

Ammonia, 10% (Ammonium Hydroxide) A A B C A A D D A A D A A A C A A C D A A A D A1 A B A A C B D

Ammonia Nitrate A A A1 C A C A D C A D B A B B NA A A NA C A D NA A A B A1 NA NA B D

Ammonia, anhydrous A A1 D D A A D D B A D A A B D A A B D A B A D A A A A C C A D

Ammonia, liquid B A1 D D A A D D C A D A A B NA A A C D A NA B D A1 A A A NA C A D

Ammonium Acetate B A NA C A A D D B A NA A A NA D NA A A NA A NA A A A A A A NA NA A A

Ammonium Bifluoride D B A D NA B D D B D B A A B NA NA A A1 NA D A NA NA A A A A NA NA A A

Ammonium Carbonate B B A D D B D D B B D A A B NA NA B B1 A A A A C A A A A C A A A

Ammonium Chloride, 10% C B1 A B B B D D B D D A A D A A A A1 A B A B A1 A A A A C B A A

Ammonium Hydroxide (Aqueous Ammonia) A A B D A B D D D D D A A B C A A A D A A A D A1 A B A A C B D

Ammonium Nitrate, 10% A A A1 A1 A B D D A B D A A B B A A A C B A A R A A A A C A A A

Ammonium Persulfate A B A D D D D D A D D A B B NA A A A1 A A A D A A A A A D A A A

Ammonium Phosphate, Dibasic B C A1 B1 A B B D A D D A A B NA A NA A1 A A A C A1 A A A A A A A A

Ammonium Phosphate, Monobasic B C A1 B A B A D A D D A A B B NA NA A A A A B A A A A NA A A A A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Ammonium Phosphate, Tribasic B B A1 B A B NA C A D D A A B NA NA NA C A A A B NA A A A NA A A A A

Ammonium Sulfate B B A B B A D D A D D A A B B A A A A A A A A1 A A A A A A A A

Ammonium Thiosulfate A A NA B NA A D D A D D NA A A A NA B A A A NA NA NA A A A B A A NA A

Amyl Acetate A A D B C A A A D C A D A A C A NA C D D D B D B A D A D A D D

Amyl Chloride A A D A A A C A D A A C D A NA A B D D D D C D D A D A D C C B

Antifreeze A A B D A A B A A A NA A A A NA NA NA NA A C A D NA D A A NA C NA B A

Aqua Regia (80% HCl, 20% HNO3) D D D D D D D D D D D C C C NA A D B D D D D D B A C A1 D A D B

Arsenic Acid A A A D A D D B A D A A A B NA NA B B B A A C A A A A A A B B A

Asphalt B A NA B1 NA A B A B A A A D NA B A NA A D D NA A D B A A A D NA NA A

Barium Carbonate B B A A A D B B A A A A A B NA A A B NA NA A A A A A A A NA A NA A

Barium Sulfate B B A B1 A B B C A B B B A A D A B B1 A A A A D B A B A A B NA A

Barium Sulfide B B1 A A C D D D A D D A A NA NA NA A B1 A A A A NA B A A A A A NA A

Beer A A A A A A B A A D B A A A A A A A1 A A A A A1 A A A A A B C A

Benzaldehyde B B B A C B A A D A B D A A B A B A D D B A D D A D A1 D A D D

Benzene B B D A D B A A D A B D D B C B D C D D D A D D A C A1 D A C A

Benzene Sulfonic Acid B B NA C NA D B NA D D NA D D B B NA A A A A A D D D A A A D B B A

Benzoic Acid B B D B A B D B D D NA A D B D A A A D B B D B B A A A B A A A

Benzyl Chloride C B D A D D D D D D D A D C D NA NA NA D D D A1 NA C A NA A D NA NA A

Borax (Sodium Borate) A A A1 B A B A B B A B A A B A A A A1 A A A A A A1 A A A B B NA A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Boric Acid, 10% B A A1 A A D B B A D B A A A A A A A1 A D A B A A A A A A A A A

Bromine Gas D D D D D D D D D NA D D D A D A D D D D A D C D A C A D D B A

Butadiene A A NA A B A A C D NA C A C C D A D D D B D C D C A C A D NA NA B

Butane Gas A A1 B A A A A C A NA C C D A A A B C D A D A1 D A A C A D A C A

Butanol (Butyl Alcohol) A A D A D B A A A NA B A A B B A B B1 A A A B B A A C A B B B A

Butyl Amine A A NA C D A NA B C NA NA NA B B D D NA C D D D A1 D B A D A B B D D

Butyl Ether B A NA D D A NA NA B NA NA D D B NA A NA NA D D D A1 NA D A A A D NA A D

Butyric Acid, 20% B B1 D A C B A D D D C D B A B A D D D D D C D B A B A D A D B

Calcium Carbonate (Chalk) CaCO3 A B NA A A D D A A NA A A A B NA NA B B A A A A C1 A A A A A B NA A

Calcium Chloride, 10% C B B D B D B A A C B A A A A A A B A A A A A A A C A A A NA A

Calcium Hydroxide (Lye), 10% B B A1 D A C D D A A D A A A B A A A1 A A A A1 D A1 A B A1 A A B A

Calcium Hypochlorite C B NA D B D D D C D D B B B C B A A D D A D D A A B A B A A A

Calcium Nitrate C B1 A D A B B B A B B A A B NA A B A A A A A A1 A1 A A A1 B B A A

Calcium Oxide (Unslaked Lime) CaO A A D A A C NA D A NA NA A A A A NA A B B A A B D A A B A A A C B

Calcium Sulfate, 10% B B C D A C B A A A A A A B NA A A B B B A D A1 A A B A NA A NA A

Carbolic Acid (Phenol) B B D D D A D B D D D B B A D B A D D D D D D B A D A D A B A

Carbon Dioxide, dry A A B A A B B A A D A A B A A A B A B B A A NA A1 A A A B A NA B

Carbon Dioxide, wet A A B A A A A A A D A A B A A A B A B B A A A A A A A B A NA B

Carbon Monoxide Gas A A A1 A A A A A A A A A A B A A B A1 D B A A A A A A B A NA NA A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Carbonated Water (Carbonic Acid) A A A A A A D A A D B A B A D A A A C A A A A B A A A A B A A

Carbonic Acid (Carbonated Water) A A A B A B D B D D B A B A D A A A C D A A A B A A A A B A A

Chlorine Gas, dry 10% A B D D A C D B B D A D A A D D B D D C B D A D A D A D D A A

Chlorine Dioxide, 8% aqueous solution D C B NA C D D D D D D A D A D NA C C D D NA D NA C A A A B A C B

Chlorine Water (5-10 ppm) C C D D A D D B D NA D A C A D A C B C D C C NA D A A B D A NA A

Chloroacetic Acid B A NA D C D D C D D D D B A D A A D D D NA D D C A B A D A A D

Chlorobenzene (mono) A B D D D A B C D B B D D A D A D C D D D D D C B D A D B A A

Chlorobromomethane B B NA B NA D NA NA D D B NA B NA D NA NA A D D C C NA A A D NA D NA NA A

Chloroform A A D A D B B B D B A D D A D B D C D D D A D C A D A D A B A

Chlorosulfonic Acid D B1 NA D D C B D D D D D D A D A D D D D D D C D A D D D A C D

Chromic Acid, 5% B A B D C C D B D D D A A B D A A D B D A D B D A A A C A B A

Chromic Acid, 10% B B B D C D D D D D D A C A D A A D D D A D B D A A A C B C B

Chromic Acid, 30% B B B D D D D D D D D A B D D A A D D D D D C D A A A C A B A

Chromic Acid, 50% C B D D D D D D D D D D B B D A A D D D D D D D A D A C A B A

Citric Acid, aqueous 10% B A1 D B A C D D A D D B A A A A A D A A A A A A A B A A A NA A

Citrus Oil or Terpene (d-Limonene) A A C B NA C A D A D D A B A NA A C C D D A A C A A C A D A A A

Clorox® Bleach A A B D C A D NA D D D A B A C D NA NA D B A A A D A A A NA NA B A

Coffee A A NA A A A D A A NA A A A A NA NA A NA A A A A C A A NA NA A A NA A

Copper Chloride D D A A A NA D D A NA D A A NA A A B NA C A A D NA A A A A A D A A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Copper Sulfate, 5% B B A1 D A D D B A D B A A A A A A A1 C A A D A A A A A A A NA A

Cresols A A D D D A C A D C A D D B D A D C D D D D D D A D A1 D B D A

Cyclohexane A A D A C A A B B B B D D B A A D B D D D A B D A D A D A D A

Cyclohexanone A A1 D A D A B B D B B D B A D A B D D D D A D D A D D D NA D D

Detergents A A B A A B A B A NA A A A B B A A D B B A A A A A A A A A A A

Diacetone Alcohol B B NA A D A A B D A A D A A C B A A D D A A D A A D D D A B D

Dichlorobenzene NA B D B D B NA B D NA NA D D A D NA D D D D NA D D C A D A D NA NA C

Dichloroethane B B D A D B B D D NA A D NA A NA A C C D D A A D D A D A NA B D C

Diesel Fuel A A NA A B A A A A A A A D B B A D C D B D A A1 A A A A D B NA A

Diethyl Ether B B1 D A D B B A D NA A D D B C C D NA D D NA A D A A D A D A NA D

Diethylamine A A D B B B A A C B A D B A NA A D D A A NA A D A D D D B A C A

Dimethylformamide (N,N-

A B D C D B C B C B A D B A B A A A C D D A D A A D D C A D D

Dimethylformamide)

Dyes A A NA C D B A NA D NA A NA A NA D NA NA NA C C A A D NA A B NA NA NA C A

Ethane A A NA A NA A NA NA A A A A D A NA NA NA NA D B NA D NA D A A A D NA A A

Ethanol (Ethyl Alcohol) A A B A D B A A C B A B A A D A A B A A A A C A A C A B A C A

Ethanolamine A A NA D C B NA B B B D NA B B NA D NA NA B B A A NA D A D C B B NA D

Ether A A D A D B B A D C A D C B NA B D D D D D A D D A D B D A C C

Ethyl Acetate B B D A D A B A D A A D B A B A A A C D A A1 D A A D D B A D D

Ethyl Benzoate A A D A D A NA NA D A A D A A C NA B C1 D D A D D B A D D D NA D A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Ethyl Chloride A A D A D B A A A C B D A B C B C C B C D A D D A D A D A D A

Ethyl Ether B B D A D B B A D C A D D B NA A D D D D D A NA D A D A1 D A NA D

Ethylene Glycol B B A B A A B A A A A A A B A A A A1 A A A A B A A A A A A B A

Ethylene Oxide Gas (EtO), dry 3% B B D D A D D C D D D C C A A A B A D D A A C D A D A D NA NA D

Fatty Acids B A A A A A C A B C D A D A B A A D C C A A B A A A A C B B A

Ferric Chloride, 10% D D A D A D D D A D D A A B C A D A A B A A A1 A A A A B A B A

Ferric Nitrate B B A D A D D C A D D A A B D A B A1 A A A A A A A A A C A NA A

Ferric Sulfate B A A D B D D C A D D A A A A A A A1 A A A A A A A A A B A B A

Ferrous Sulfate B B A D A B B B A D B A A B A A B A1 B A A D A A A A A NA A B B

Fluosilicic Acid, 20% C B D B B D NA B A B B A A B NA A B B1 A B B D NA A A A A D D A A

Fluosilicic Acid, 100% D D D A C D NA B B D D NA A B NA B C B A B B D NA A A B A D D D A

Formaldehyde, 40% A A A A1 B B A A B B B A A B C A A D B B A A A A A A A NA B NA A

Formaldehyde, 100% C A B A D A NA B C C A A A A D A A B C C A D A1 C A A A B A B D

Formic Acid (Methanoic Acid), 10% B A D A1 B A D C C D C A A A B A A D C A A D A A A A A B C B C

Fruit Juices A A B D A A D NA A D A A A A B A A A D A B A A B A A A NA A B A

Fuel Oils A A D A B C B A A A A NA D A B A C B D B B A B A B A B D A A A

Furfural (Ant Oil) C5H4O2 A B D A D A A B D B A D D B B D A D D D D B D D A D B1 D A D D

Gallic Acid, 5% A B NA NA A D C B B D D C B B D A A A A B A A A A B B A D B A A

Gasoline (high aromatic) A A D B D D NA A A A NA C D A A A B A D A B A A A B A A D B A A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Gasoline, leaded, ref. A A D A D A A A A A B D D A A A B NA D B B A A B A B A D A C A

Gasoline, unleaded A A1 D A D A A A A A B C D A NA A B NA D B D A1 A1 C A C A D A C A

Glucose A A B A A A A NA A A A A A A A NA A A1 A A A A A A A A A A A A A

Glue, PVA (Polyvinyl Acetate) A A1 NA A D A NA A A A B A A A A NA A A A A NA A NA NA A C A A A C B

Glycerin A A C A A A B A A A A A A A A A A A A A A A A1 A A A A A A A A

Glycolic Acid A A B A C NA NA NA A NA NA A A A NA B B A D A NA NA NA A A B B A A A A

Grease NA A NA D A NA A A A A A NA D A A NA NA NA D D NA NA A NA A A A D NA A A

Heptane A A D A C A A A A A A A D A B A B B D B B A B C1 A C A D A B A

Hexane A A D A C A A A A A A B D A A A C D D B B B D B A B A D A D A

Honey A A NA A A A NA A A A NA NA A A NA NA NA B A A NA A A A A A A A NA A A

Hydraulic Oil (Petro) A A NA B D A A A A A A NA D A D NA A C D A NA A NA D A A A B NA A A

Hydraulic Oil (Synthetic) A A NA B D A A A D A A NA A A A NA A A D A NA A NA D A A A B NA A A

Hydrazine (Diamine) H2NNH2 A A NA B C NA D NA B D A D A NA C NA D NA C B NA NA D C A NA A B NA NA A

Hydrobromic Acid, 20% D D NA C D D D NA D D D A A A NA A D B A D B D NA A NA B A D A B A

Hydrobromic Acid, 100% D D B D D D D NA D D D A A C NA A D B A D B D NA C A A A D A B A

Hydrochloric Acid, 20% D D A C C D D D D D D A A A B A A A1 A C A D B B1 A A A D D A A

Hydrochloric Acid, 37% D D A C C D D D B D D A C B C A A B A B A D D C A B A B D A A

Hydrochloric Acid, 100% D D A C D D D D D D D A D A D A D NA D D A D D B A D A D D A A

Hydrochloric Acid, dry gas D D NA NA NA D D A NA NA D A NA A NA A D A NA NA A A NA B A A A NA C NA NA

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Hydrofluoric Acid, 20% D D C D C D D B D D B C D B D B A A B B C C D A1 A B A D D C A

Hydrofluoric Acid, 50% D D C D C D D B D D B C D B D B A A B D D D D A A B A D D C B

Hydrofluoric Acid, 75% D D C D D D D B D D B C C B D B B C D D D D D C A C A D D C B

Hydrofluoric Acid, 100% B B D D D D D B D D B C D B D A D NA D D D D D C A C A D D D B

Hydrogen Gas A A A1 NA NA A A A A A A A A A A B A A1 B A A A1 A1 A A A A C A A A

Hydrogen Peroxide, 10% B B A D C A D B D C D A A A D A A A B D A C A A A A A A A B A

Hydrogen Peroxide, 30% B B NA D C A D B D B D A B A D B A C1 C D A D A1 B A A A B B B A

Hydrogen Peroxide, 50% B A1 NA D D A D B D NA D A B A D A A C1 C D NA D A1 B A A A B A B A

Hydrogen Peroxide, 100% B A1 A D D A D B D B D A D A D B A C1 C D A D A B A A A B B B A

Hydrogen Sulfide, aqueous C A B C A B D A D D D A B A A A A A C A A C A A A B A C B A D

Hydrogen Sulfide, dry C A NA A A B D B D D D A B A A B A A C A NA C NA A A A A C A D D

Ketones A A A D D B NA A D A A NA D A D B D C A D D A1 D C A D C NA A D D

Lacquer Thinners A A A D D A A A D C A NA D A D NA D A D D D A B D A D NA D C D D

Lacquers A A A D NA A D A D C A A D A D A D A D D D A D D A D D D A A D

Lactic Acid B B D B A B D B A D B A A B D A A A A A A B B B A B B A A A A

Latex A A1 B B NA A A A A A NA NA A A NA NA NA NA NA B NA A NA A1 A NA A A NA A A

Ligroin A1 A1 NA B NA D NA NA A A NA NA D NA NA NA NA A D B NA D A A1 A NA A D NA A A

Lime (CaO) A A A1 B A A NA NA A A NA NA D NA C A A A NA A NA A D D A B A NA A A A

Linoleic Acid B A A B NA A D C B D D A D A NA NA B A D D NA NA NA B A A A1 B NA A B

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Lithium Hydroxide C C NA NA NA D D B C B NA NA A B NA NA D NA A D NA NA D A A NA NA NA NA NA A

Lubricants A A1 NA A A A A A A A A NA D A A NA B D D D C A A A A B A D A B A

Lye (KOH, Potassium Hydroxide) B A A A B D D D B B B A A B D B B A B B A C D A A B A C D B B

Lye (NaOH, Sodium Hydroxide) B B C C A D D D A D B A B C C B B D A B A A D A A A D A B B B

Magnesium Bisulfate A A NA NA NA D NA A B NA NA NA NA NA NA NA A NA B B NA A A A1 A A NA NA NA A NA

Magnesium Chloride, 10% D D B B A D D B A D A A A A C A A A A A A A A1 A1 A B A A A A A

Magnesium Hydroxide, 10% B A B A A C D B A A B A A A C A B A1 A A A B A A A A A A A C A

Malic Acid (Apple Acid) C4H6O5 A A1 NA A NA B B B A D D A D B NA NA NA B1 B D NA A D A A A A B A A A

Mercury A A B A A D D A A A D A A A B A A A A A A A D B A A A NA A D A

Methane Gas A A A A A A A A A NA A NA D A B NA A NA D B NA A A A A B A D NA NA A

Methanol (Methyl Alcohol) A A D A C A A A A A B A A A B A A A A A A B B A1 A A A A B A C

Methyl Acetate A B D B D A NA A D A B NA B A C A C B D B NA A D D A D B D NA A D

Methyl Acetone (mixture) A A NA D NA A A A D A NA NA A A NA NA NA NA A D NA A NA D A D D NA NA A D

Methyl Alcohol, 10% A A D A C A A A A A A A A A B A A A A A A B B A1 A A A A B A C

Methyl Butyl Ketone A A NA D D A NA D D NA NA NA A NA NA NA NA NA D D NA D D D A A D D NA NA D

Methyl Cellosolve B B A D A B A A A C B D B NA NA NA NA NA D B NA C D B A D A D NA C D

Methyl Chloride A A D B D D A B D D NA D D B D A NA C D D D B D D A D A D A D A

Methyl Ethyl Ketone (MEK, Butanone) A A D C D B A A D A A D A A B A D B D D D A D B1 A D D D A D D

Methyl Ethyl Ketone Peroxide (MEKP) NA A D D NA D D D D D D D D NA NA NA NA NA D D NA NA NA NA A NA NA B NA NA D

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Methyl Isobutyl Ketone B B D D D B NA A D C B D B A B A D C D D D B1 D A A D D D A NA D

Methyl Isopropyl Ketone A A NA A D A NA A D C A NA C A D NA D D D D D A D NA A D A C NA NA D

Methylamine A A D D D A D A B A NA NA A B NA A NA A B A NA NA D A1 A D C NA NA D D

Methylene Chloride B B D B D C A B D B B D C B D A D D B D D C D B A D B D B D B

Milk A A B A A A D A A D D A A A B A B A A A A A A B A A A1 A A B A

Mineral Spirits A A D A B A A A A B NA A D B NA A D B D C A A C B A A NA D B B A

Monochloroacetic Acid A A NA D D D B B D D D NA C A D B D NA NA A NA D D NA A NA B NA A NA C

Monoethanol Amine A A NA D NA B NA A D A D NA B NA D NA NA C B D A A NA B A D C B B NA D

Morpholine NA A C NA D A NA B D B NA NA D A NA NA B NA A D D A1 D B1 A NA B NA NA NA NA

Motor Oil A A1 C B B A A A A NA A A D NA B A A C D B A A1 A A A B B NA A A NA

Mustard A A B C NA B NA A B D NA A A A B NA A A B A A A A A A B A NA A B D

Naphtha A A D A D A A A A B A A D B B A D A D D D A B B B A A D B C A

Natural Gas A A B B A A A A A A A NA D NA B NA A A C A NA NA D A A A NA A NA A A

Nitric Acid, 5-10% A A B D A A D A D D D A A A C A A B D B A D A A A A A C A D A

Nitric Acid, 20% A A B D A D D A D D D A A A D A B C D D B D B A1 A A A D A D A

Nitric Acid, 50% A A C D C D D A D D D B D A D A D B D D B D B B A B A D A D A

Nitric Acid (Concentrated) A A D D D D D A D D D D D B D A D C D D B D C D A B A D A D A

Nitrobenzene B B D C D B C A D C B D B D D A D C D D D B D B A D A D A D B

Nitromethane A A D A D A NA NA D NA A NA B A C A D A B D D B D B1 A B A1 D NA B D

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Nitrous Acid B B D NA C D D B D D C A A D NA B D NA C D NA NA NA A A A B NA NA A B

Nitrous Oxide B B NA NA D B B D A B B NA A B NA NA NA C A A NA C D D A A D NA NA A B

Oils: Citric A A D A NA A B NA D D NA NA B A NA NA B A NA D A A A A A B A NA A D A

Oils: Cod Liver A A A B A A D NA A D NA A A A NA A A NA D B NA NA A A A A A B NA NA A

Oils: Corn A A B A A A B NA D A B NA C A A A A A D A A A NA A1 A B A A NA B B

Oils: Cottonseed A A A A A A A NA A A A A D A A A A A D C A B NA A A B A A A B A

Oils: Diesel Fuel (20, 30, 40, 50) A A NA D B A A A A A A NA D B A A D A D B D A A A A B A D B A A

Oils: Fuel (1, 2, 3, 5A, 5B, 6) A A D D B C B A B A A NA D A A A C B D D A A B B A A B C B A B

Oils: Hydraulic Oil (Petro) A A NA B NA A A A A A A NA D A A NA A C D A NA A NA D A A A B NA A A

Oils: Hydraulic Oil (Synthetic) A A NA B NA A A A D A A NA A A A NA A A D A NA A NA D A A A B NA A A

Oils: Mineral A A A A A A A A A NA B A D A A A A B D B A A B A A B A C A B A

Oils: Silicone A A A A B A A A A A A A A A A NA A A D D A A A A A A A C NA A A

Oils: Soybean A A A A NA A NA A A A NA A C A B A A A D C NA A NA A A A A A A B A

Oils: Turbine A A NA A NA A NA A B A A A A NA NA NA NA C D D NA A NA B A A A D A A A

Oleic Acid A A D A C A D B B NA A A B A A B C C1 D C A A A B A C A D B C B

Oxalic Acid, cold 10% B A A B A A D B D C B A A B D D A A1 B D A B1 NA A1 A B B B A B A

Ozone Gas B A B C A B B B D C A A A A C A C1 C D C NA D A B A B A A A B A

Palmitic Acid B A A A D B D A A NA B A B B A NA A NA B D NA A A B A B A1 D NA B A

Paraffin A A A A A A A A B NA B A D B NA A B B B B A A A A A B A NA A B B

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Pentane (Amyl Hydride) C5H12 C C A B NA B A C A NA A NA D A B NA NA D D B NA A A D A A A D NA A A

Peracetic Acid (Peroxyacetic Acid) B A B D D C D D C D D D B A NA NA A D D D NA D A A A C A C NA D A

Perchloric Acid C C NA C C D NA B D NA D A B B D B D B D A NA D D C A C A D D D A

Peroxyacetic Acid (Peracetic Acid) B A B D D C D D C D D D B A NA NA A D D D NA D A A A C A C NA D A

Petroleum A A B B NA D NA A A NA B A D NA B NA D C D B D A C B A NA A D A NA A

Phenol, 10% B B D B D A NA B D D B A B B D B D B A D D D B B A C A D B C A

Phenol (Carbolic Acid) B B D D D A D B D D D B B A D B D D D D D D D B A D A D A B A

Phosphoric Acid, >40% D D C D C C D B D D D A B A D A A B B B A B A A1 A B B D C D A

Phosphoric Acid, crude D B C D D C D B D D D NA B A NA A B B D D A B A B A B A D C D A

Phosphoric Acid, S40% D C B D D C D B D D D A B A NA A A A B B A B A A A B B C C D A

Phosphorus A A NA B D B NA A NA NA B B NA A NA NA D B NA NA NA NA D A A A A NA NA B NA

Photographic Developer A A B D B NA NA A A D D A B B D NA A A A A A NA A A A A NA B A NA A

Photographic Solutions D NA NA D B NA NA A B NA D A A B B A A A B B A A A A A A B A A A B

Potassium Bicarbonate B B A C A D NA B A A B A A B NA A B A A A A A NA A A A B A A A A

Potassium Bromide B B A A A C NA B A D B A A B NA A B A A A A A A A A A A A A B A

Potassium Chloride, up to 30% B A A A A D D B A A B A A A B A A A A A A A A A A A A A A A A

Potassium Dichromate B B B A B B D B A A B A A B C A B A B A A B A A A A A A A C A

Potassium Ferrocyanide B B A1 B C B NA B D C B B A B NA A B A1 A A A B D A1 A A A1 NA A B A

Potassium Hydroxide (Caustic Potash) B A A A B D D D B B B A A B D B A A B B A C D A A A A C D B B

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Potassium Iodide A A B NA A B NA A A A A A A A NA NA B B B A NA A A A1 A A A1 NA A B A

Potassium Nitrate, 10% B B B A A B B B A A A A A B B NA B A A A A B A A A A A A A A A

Potassium Nitrite B B B A NA B B B A A A A A B B NA NA A A A A B A A A A A A A A A

Potassium Permanganate B B B A B B C A C A A A A A D NA A A A A A D A1 A A A A NA A B A

Propane (liquefied) A A A A NA A A A A A A A D A A A D C D C A A C A A A A D NA NA A

Propylene (C3H6, Propene, Methyl

B A B A B A NA NA D A A NA D A NA NA NA NA D D NA NA A A A B A D NA B A

Ethylene)

Propylene Glycol B B B B B B B A A A A C A B NA NA A B1 A C NA A B A1 A C A A A NA A

Pyridine (C₅H₅N) A A A B D B B B D A B D B B C A D B D D B C D A1 A D D D B D D

Resorcinol (C6H6O2) NA NA A NA C NA NA NA NA NA NA NA B NA D NA A B1 NA D NA D B A1 A C NA NA NA C A

Rosins A A NA B NA B C B A D B C A A NA A B B NA A NA A NA A1 A C NA A NA NA A

Salicylic Acid B B1 A D B B C A B A A NA A A NA A A B1 A D NA A A A A B A NA A B A

Salt Brine (NaCl saturated) B A A1 A A B A B A D B A A A A NA A A A A A A A A A A A A A NA A

Sea Water C C A1 A A B D A A D B A A A D A A A1 A B A A1 A1 A A A A A A NA A

Shellac (Bleached) A A NA A NA A B A A A A NA A NA NA NA NA A A B NA A NA A A NA NA NA NA NA A

Shellac (Orange) A A NA A NA A B A A A A NA A NA NA NA NA A D D NA A NA A A NA NA NA NA NA A

Silicone A A D A NA A A A A A A A A A A A A NA C A A A A1 A A A A C NA NA A

Silver Bromide D D NA C A D NA D NA D NA NA NA B NA A NA A NA NA A NA NA NA A NA NA NA NA NA NA

Silver Nitrate B B B A A D D B B C D A A A D A A A A A A A A1 A A A A A A B A

Soap Solutions A A A A A C B B A A A A A A A NA B D B B A A A A A A A A A B A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Sodium Acetate B B B B B B B B B B A A A A NA A A A A B A B A A A B A D A NA D

Sodium Benzoate NA NA A NA A A NA A B NA NA A A A NA NA B A1 A A NA B A1 A1 A B A1 NA A B A

Sodium Bicarbonate (Baking Soda) A A A A A D D A A C B A A B B A A A1 A A A A A1 A A A A A A B A

Sodium Bisulfate, 10% D C A B A D D A1 B D B A1 A B C A1 B A1 A A A A A A A A1 A A A B A

Sodium Bisulfite B B A C A D D B A D B A1 A B B NA B A1 A A A C A A A A1 A A A B A

Sodium Bromide C C B A A D NA A NA C D A1 A B NA A A A1 A A A1 B A A A B1 A1 NA A B1 A

Sodium Carbonate A A B A B D B A1 A B A A1 A A B A A B1 A A A B A1 A A A1 A A A B A

Sodium Chlorate A B A A A C B B B B B A A B NA NA B B1 A A A D A A A A A C A B A

Sodium Chloride B B A A A C D B A D B A1 A A A A A A1 A A A A A1 A A A1 A A A B A

Sodium Hydroxide, 80% C B A D A D D C D D D A B A D A C D A B A C D A A A A A D A D

Sodium Hypochlorite, <20% C C B D A D D C B D D A B A A A A A C C A D C A A A A B C C A

Sodium Hypochlorite, 100% D D D D NA D D C D D D C B B D A C B1 C C A D D B A B A B C NA A

Sodium Hydrosulfite (Sodium Dithionite) NA NA NA NA A A NA NA C NA NA C B A NA NA NA NA C B NA A NA NA A C NA C NA A B

Sodium Nitrate B B A1 A A B B B A B D A A B B A B A1 B B A A D A A A A D A B A

Sodium Perborate B B A B A C D B B C B A A B B A A A B B A B A A A A NA B NA NA A

Sodium Peroxide A A A1 D C C D A B C B A A B B A B A B B NA A A B A B A D NA NA A

Sodium Polyphosphate B B NA B NA D D B A D A A A A NA A B A C B A A NA A A A A D A NA A

Sodium Silicate (Water Glass) A B A1 C A A D B A B B A A B A A A A1 A A A A A A A A A A A B A

Sodium Sulfate (Salt Cake, Thenardite) B B A1 B A A B B A B B A A B A A A A1 B A A A A1 A A A A A A NA A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Sodium Sulfide B D A1 B A D D B A C D A A B A A B A B A A A D A A A A A A B A

Sodium Sulfite B A A1 A A C D B A A D A A B A A B B B A A D A A1 A A A A A A A

Sodium Thiosulfate (hypo) A B A1 C B A D A B C D A A A NA A A A B A A B D A1 A A A A A NA A

Starch A A A1 A A A A B A C NA A A NA B A A B A A A A A A A A A NA NA NA A

Stearic Acid B A A1 A A B D B B C D B B B C NA A B C B A A1 A A1 A B A B A B A

Stoddard's Solvent A A B A A A A A A A A C D A A A NA C1 D C D A A1 C A C A D A C A

Styrene (Vinylbenzene) C6H5CHCH2 A A NA A D A A A D A B D D D D NA NA NA D D A A D NA A D A D NA NA B

Sulfite Liquors B B NA D NA D D B A C D B A B NA NA A A1 B B NA B NA A A B A B NA NA A

Sulfur Dioxide D A D B D B D B D NA B A A C C A D B NA B A C B A A A A B A C A

Sulfur Dioxide Gas, dry D A A B B B D B D A A A A B C A A A C D A B A A A A A B A C A

Sulfur Dioxide Gas, wet A C A B D A D C D B D A C B X NA D A C D D D A C A A A B NA A A

Sulfur Trioxide, dry D A NA D NA A A B D A B A C B X NA A C C D D A NA D A A C B D B A

Sulfuric Acid, <10% D B B D A D D B A C D A A B A A A A A B A C A A1 A A A C D B A

Sulfuric Acid, 10-75% D D B D D D D B B D D A B B X A A A C B A D B A A A A D D NA A

Sulfuric Acid, 75-100% C D A D D D D B C D D C B B C A B B D D A D D C A D A D D D A

Sulfuric Acid, cold concentrated C B D D D B D B D D D D C A B A B C D D A D NA A1 A D A D D D B

Sulfurous Acid, 10% B B NA C A B D B B D D A B B C A B B1 B C A D D A A A A D A B A

Tannic Acid, 10% B A A B A C B B A C A A A B A A A B1 A A A C C A A A B B A B A

Tetrachloroethane B A D A D C C NA D A A C D A NA A D NA D D D C D C A C A D A NA A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Toluene (Toluol) A A D C D A A A D A A D D A B B D C D D D A D C A D A D A D C

Tributyl Phosphate (TBP) A A D B NA A A B D A B D B A C NA B B D D NA B C B A D A D A NA D

Trichloroacetic Acid D C NA NA C D NA NA C D D NA B B D A C A C D NA C D A A B B D D C C

Trichloroethylene B B D D D D NA B D C A D D A C A D D D D D C D C A D B D A NA A

Triethylamine A A NA D A NA NA C C A A A A NA NA A NA NA B A B A D D A B A1 NA NA A D

Trisodium Phosphate B B B A B D A A A NA B A A A A NA A A A A A A A A A A A A NA A A

Turpentine (C0H16) A A D A1 B A D A A NA B A D B B A B D D D D B D D A D A D B B A

Urea B B B A A B NA B B NA D A A B B NA A A NA B A A D A A D A B A B A

Varnish A A NA A NA A A B B C B D D A NA A B A D D D A D A A D A D NA D A

Vegetable Juice A A B A NA D A A A D A NA A NA NA NA NA NA NA NA A A A NA A NA NA B NA A A

Vinegar A A A B A D D A B D B A A A C A A A B B A A A1 A A B B A A A A

Water, Deionized A A1 A1 NA A A A NA A D B A A A NA A A NA A A A A NA A1 A A A1 NA A A A

Water, Distilled A A B B A A A A A D B A A A NA A A A1 A A A A A1 A A A A C A B A

Water, Fresh A A A A1 A B B A A D B A A A A A A A1 A A A A A1 A A B A B A B A

Water, Salt B B A1 A A B D A A D B A A A A A A A1 A A A A1 A1 A A B A B A B A

Weed Killers A A NA A NA D NA NA B NA NA NA NA NA B NA NA NA NA C NA A NA C NA NA NA A NA NA A

Whiskey and Wines A A C A A C B A A D B A A NA B A B C A C A A A A A A A A A C A

Xylene (Xylol, Dimethylbenzene) B B D A D A A A D B A D D A B A D B D D B A1 D B A D A D A D B

Zinc Chloride, 10% B B A C B D D B A D C A A B A A A A A A A A A A A B A B A A A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

ver 27-Oct-2022

Chemical Compatibility Chart

Ratings -- Chemical Effect C = Fair -- Moderate Effect, not recommended swelling may occur. *Explanation of Footnote

A = Excellent. D = Severe Effect, not recommended for ANY use. 1. Satisfactory to 120°F (48° C)

B = Good -- Minor Effect, slight corrosion or discoloration. NA = Information Not Available.

All data are based on ambient or room temperature conditions, about 64° F (18° C) to 73° F (23° C).

Polycarbonate (PC)

Polypropylene (PP)

304 Stainless Steel

316 Stainless Steel

Kel-F® (PCTFE)

Buna N (Nitrile)

Natural Rubber

PVDF (Kynar®)

Acrylic (PMMA)

Silicone (VMQ)

Neoprene (CR)

Hastelloy® - C

Hytrel® (TPE)

Viton® (FKM)

Noryl® (PPO)

Acetal, POM

ABS Plastic

Nylon (PA)

Aluminum

Cast Iron

Titanium

Copper

Bronze

Tygon

EPDM

CPVC

Brass

HDPE

LDPE

PTFE

PVC

Zinc Sulfate, 10% B A A C B D B B A D B A A A D A A A1 B A A A A1 A A A A A A A A

Key to General Chemical Resistance – All data is based on ambient or room temperature conditions, about 64°F (18°C) to 73°F (23°C)

A = Excellent C = Fair - Moderate Effect, not recommended

B= Good - Minor Effect, slight corrosion or discoloration D = Severe Effect, not recommended for ANY use

It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products.

Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or product damage.

4091 S. Eliot St., Englewood, CO 80110-4396

Industrial Specialties Mfg. and IS Med Specialties

Phone 303-781-8486 I Fax 303-761-7939

End your search, simplify your supply chain industrialspec.com I ismedspec.com

ISO 9001:2015 Certified Companies © Copyright 2022 Industrial Specialties Mfg.

You might also like

- Chart - August 2011: Pressure VesselDocument1 pageChart - August 2011: Pressure Vesselabo151067% (3)

- Mogas Data Sheet Purge System Designs (En)Document7 pagesMogas Data Sheet Purge System Designs (En)kumar.arunk6784100% (1)

- Sales Pursuit ProbabilityDocument1 pageSales Pursuit Probabilitykumar.arunk6784No ratings yet

- Case Study On Diff SettlementDocument22 pagesCase Study On Diff Settlementsravyasai13100% (1)

- Exp 5 Lit ReviewDocument3 pagesExp 5 Lit ReviewDhanesh KumarNo ratings yet

- Chemical Compatibility Chart From IsmDocument11 pagesChemical Compatibility Chart From IsmMajid KhanNo ratings yet

- Chemical Compatibility Chart From IsmDocument14 pagesChemical Compatibility Chart From IsmRozaq Alfan WNo ratings yet

- Valve Material Selection Guide 2020Document14 pagesValve Material Selection Guide 2020Jan Andre EriksenNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument2 pagesDarlington: Silicon NPN Triple Diffused Planar TransistorGilberto DiazNo ratings yet

- 3 P 132 9301 1a3a N 01 - Rev01Document1 page3 P 132 9301 1a3a N 01 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- 3 P 132 9401 1a3a N 03 - Rev01Document1 page3 P 132 9401 1a3a N 03 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2642)Document1 pageDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2642)Migue Rodriguez RamirezNo ratings yet

- 3 P 132 9501 1a3a N 02 - Rev01Document1 page3 P 132 9501 1a3a N 02 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- Data-Sheet HiBrite PDFDocument3 pagesData-Sheet HiBrite PDFRaj H PatelNo ratings yet

- Pages From ESR00400-43-L-P-43R10-731 - 0ADocument1 pagePages From ESR00400-43-L-P-43R10-731 - 0AAnonymous hNpF6INo ratings yet

- 2sd2560 Ds enDocument1 page2sd2560 Ds enMarius IggyNo ratings yet

- 3 P 132 9301 1a3a N 04 - Rev01Document1 page3 P 132 9301 1a3a N 04 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Singapore Expansion Project: BillofmaterialsketchlistDocument4 pagesSingapore Expansion Project: BillofmaterialsketchlistLocus Jhun MichaelNo ratings yet

- Singapore Expansion Project: BillofmaterialsketchlistDocument3 pagesSingapore Expansion Project: BillofmaterialsketchlistLocus Jhun MichaelNo ratings yet

- Ag Ug: 330 TH Ru GR Av El at El - +2 370 0Document1 pageAg Ug: 330 TH Ru GR Av El at El - +2 370 0John SmitNo ratings yet

- PUG Marisel - PD MARISELDocument1 pagePUG Marisel - PD MARISELCojocaru Pojar OanaNo ratings yet

- 2sd2438 Ds enDocument1 page2sd2438 Ds enGuille SoriaNo ratings yet

- Phase-I: Job No. 26148Document1 pagePhase-I: Job No. 26148Rodrigo Andres CeledonNo ratings yet

- Ne1-10-Em-Eai-Drw-Scc (M) - 02552-01 10QFB21BR003Document1 pageNe1-10-Em-Eai-Drw-Scc (M) - 02552-01 10QFB21BR003NITHIN MATHEWNo ratings yet

- SCU-2290-PP-XIS-320134 - 3 FirmadoDocument6 pagesSCU-2290-PP-XIS-320134 - 3 FirmadoCristopher MosqueiraNo ratings yet

- Temperature Solar Selective Coating Development For Power Tower ReceiversDocument1 pageTemperature Solar Selective Coating Development For Power Tower ReceiversВиктор ИсакNo ratings yet

- 10lba50br001 SHT1 Rev0Document1 page10lba50br001 SHT1 Rev0ruralashishNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument2 pagesDarlington: Silicon NPN Triple Diffused Planar Transistorroberto carlos martinez narvaezNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument1 pageDarlington: Silicon NPN Triple Diffused Planar TransistorLucas JúniorNo ratings yet

- World LNG Market 2016-2020Document2 pagesWorld LNG Market 2016-2020U.K.No ratings yet

- Contrato Vertical Contrato Teck: Job No. 25800Document1 pageContrato Vertical Contrato Teck: Job No. 25800Gabriel PulidoNo ratings yet

- NWMPDataforthemonthofJanuary2022 2Document4 pagesNWMPDataforthemonthofJanuary2022 2kabirshamlani04No ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- 172 I1909e 000 46 DW 0109Document2 pages172 I1909e 000 46 DW 0109Jose Carlos Moraga LópezNo ratings yet

- EASTWICK SITE 68 THE GATES APPROVED SUBMISSION DRAWINGS 30 04 20 Site Plan and Loft 1Document1 pageEASTWICK SITE 68 THE GATES APPROVED SUBMISSION DRAWINGS 30 04 20 Site Plan and Loft 1kimNo ratings yet

- V-41112 Pi PDFDocument1 pageV-41112 Pi PDFVivek VNo ratings yet

- Crt-Npc-Dmm-Hva-Dwg-Sd-Gn-33501 - Equipment Capacity Schedule 1-6Document1 pageCrt-Npc-Dmm-Hva-Dwg-Sd-Gn-33501 - Equipment Capacity Schedule 1-6Shah MuzzamilNo ratings yet

- P20c30tu02chp Aecg Civstrdwg 30303 01 (B)Document1 pageP20c30tu02chp Aecg Civstrdwg 30303 01 (B)subhash kumarNo ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- Stionofrtrn: Katosan KalolDocument1 pageStionofrtrn: Katosan KalolRajender Reddy ParneNo ratings yet

- 4WDDocument1 page4WDSerg GarkushaNo ratings yet

- 172 I1909e 000 46 DW 0106Document1 page172 I1909e 000 46 DW 0106Jose Carlos Moraga LópezNo ratings yet

- Onkyo tx-nr414x PDFDocument19 pagesOnkyo tx-nr414x PDFDAN ALEXANDRUNo ratings yet

- Light Pole On MSE Walls Details-TexasDocument2 pagesLight Pole On MSE Walls Details-TexaswalidNo ratings yet

- Shematic Ems Siemens Pars (Single Box)Document1 pageShematic Ems Siemens Pars (Single Box)bladekeenNo ratings yet

- ECS-1NZ de 2 Conectores PDFDocument1 pageECS-1NZ de 2 Conectores PDFHarold Rodriguez CastilloNo ratings yet

- P6022mab WD 179 11193 01 - S1Document1 pageP6022mab WD 179 11193 01 - S1John SmitNo ratings yet

- Ecs 1urDocument1 pageEcs 1urengazyNo ratings yet

- Telford Test HouseDocument1 pageTelford Test HouseUmesh MishraNo ratings yet

- Major1107202x12.2pscslab V4 Approve P11Document1 pageMajor1107202x12.2pscslab V4 Approve P11rushi123No ratings yet

- Darlington: Silicon PNP Epitaxial Planar TransistorDocument1 pageDarlington: Silicon PNP Epitaxial Planar Transistorroberto carlos martinez narvaezNo ratings yet

- 10MAX31BR001Document1 page10MAX31BR001bisondaniel3No ratings yet

- Bill of Material: Dangote Oil Refining Company Ltd. Engineers India Limited New DelhiDocument4 pagesBill of Material: Dangote Oil Refining Company Ltd. Engineers India Limited New Delhishambu nath.vNo ratings yet

- KCD A210 BACH8SchematicDiagrams ENGDocument12 pagesKCD A210 BACH8SchematicDiagrams ENGChip KitNo ratings yet

- Modif Precast Pile Cap PC.18A, PC18.B, PC.18C, PC.19ADocument8 pagesModif Precast Pile Cap PC.18A, PC18.B, PC.18C, PC.19AMarco ValerianNo ratings yet

- MV-02 Site PlanDocument1 pageMV-02 Site PlanriyazNo ratings yet

- Heat LoadDocument41 pagesHeat LoadpanyamnrNo ratings yet

- Pragati Maidan Layout MapDocument1 pagePragati Maidan Layout Mapviv0% (1)

- Darlington: Silicon PNP Epitaxial Planar TransistorDocument1 pageDarlington: Silicon PNP Epitaxial Planar Transistormarcelo giussaniNo ratings yet

- Game Gear Schematic 2-ASICDocument1 pageGame Gear Schematic 2-ASICmarioplateadoNo ratings yet

- Chapter 14Document42 pagesChapter 14NayLinNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- HEAVY OIL Related Galperti G-Lok Ref List 5 29 17Document1 pageHEAVY OIL Related Galperti G-Lok Ref List 5 29 17kumar.arunk6784No ratings yet

- G LokDocument41 pagesG Lokkumar.arunk6784No ratings yet

- GP Series - Valve Coupling DimensionsDocument1 pageGP Series - Valve Coupling Dimensionskumar.arunk6784No ratings yet

- CLG Isodewaxing and Isofinishing Tech SheetDocument2 pagesCLG Isodewaxing and Isofinishing Tech Sheetkumar.arunk6784No ratings yet

- World Class Manufacturer of Check Valves: Spring-Assisted, Non-Slam, Axial Flow, Silent Check ValvesDocument6 pagesWorld Class Manufacturer of Check Valves: Spring-Assisted, Non-Slam, Axial Flow, Silent Check Valveskumar.arunk6784No ratings yet

- CLG ISODEWAXING Paper - IDW - NPRA - PaperDocument11 pagesCLG ISODEWAXING Paper - IDW - NPRA - Paperkumar.arunk6784No ratings yet

- Effective Solutions: Oil & Gas IndustryDocument60 pagesEffective Solutions: Oil & Gas Industrykumar.arunk6784No ratings yet

- Techlok General BrochureDocument6 pagesTechlok General Brochurekumar.arunk6784No ratings yet

- VOLK Valves CatalogDocument46 pagesVOLK Valves Catalogkumar.arunk6784100% (1)

- Jan2014 TD Technical Specs - Gadarwara STPPDocument77 pagesJan2014 TD Technical Specs - Gadarwara STPPkumar.arunk6784No ratings yet

- HPCL Mumbai - RUF Consideration - 31 - Aug - 2018Document2 pagesHPCL Mumbai - RUF Consideration - 31 - Aug - 2018kumar.arunk6784No ratings yet

- Seawater Pump SeriesDocument13 pagesSeawater Pump SeriesRiski SuhardinataNo ratings yet

- Spiral BoruDocument2 pagesSpiral Borumohamed bakryNo ratings yet

- NABAKEM Welding SuppliesDocument6 pagesNABAKEM Welding Suppliessutrisno00No ratings yet

- Cold Storage Design CalcsDocument3 pagesCold Storage Design CalcsRichard John PurdonNo ratings yet

- Module # 1 of # 273 Basic Overview of HVACR SectorDocument53 pagesModule # 1 of # 273 Basic Overview of HVACR Sectorsumair uddinNo ratings yet

- Grease SLL 00Document1 pageGrease SLL 00nghiaNo ratings yet

- Additives and Active Agents For The Concrete Admixture IndustryDocument52 pagesAdditives and Active Agents For The Concrete Admixture IndustryDileepa DissanayakeNo ratings yet

- Technische Manual CSRN XHE2 FFA 12.2 44.4Document52 pagesTechnische Manual CSRN XHE2 FFA 12.2 44.4SolarNo ratings yet

- ANSI-ESD S11.4-2012 Static Control BagsDocument16 pagesANSI-ESD S11.4-2012 Static Control BagsDavino MartinezNo ratings yet

- LT2A - 15 - Krisna Surya Pamungkas - SolderDocument2 pagesLT2A - 15 - Krisna Surya Pamungkas - SolderMuhammad Hanif HidayatNo ratings yet

- Prestress Losses IRC 112-2011Document2 pagesPrestress Losses IRC 112-2011naveen srinivasNo ratings yet

- Braun Espresso Master Professional E400 3060 SMDocument11 pagesBraun Espresso Master Professional E400 3060 SMnemfogomNo ratings yet

- ConversionDocument118 pagesConversionAlpian SaputraNo ratings yet

- Conquest CXAX Air-to-Water Heat PumpDocument6 pagesConquest CXAX Air-to-Water Heat PumpAlexandre LopesNo ratings yet

- 4 Volume-IIDocument31 pages4 Volume-IIChirag SharmaNo ratings yet

- List Material Dead Stock PKSDocument12 pagesList Material Dead Stock PKSbintang_arifNo ratings yet

- Selectrode: Non-Machinable Cast IronDocument2 pagesSelectrode: Non-Machinable Cast IronAlvaro Fernando Reyes CastañedaNo ratings yet

- Technical Bulletin Surface Treatment - EnCRES DUBUIT - 06Document2 pagesTechnical Bulletin Surface Treatment - EnCRES DUBUIT - 06marimadiNo ratings yet

- Pintu Dan JendelaDocument39 pagesPintu Dan JendelaDebbie MaharaniNo ratings yet

- H2O2 Materials of Construction For The Storage of H2O2Document2 pagesH2O2 Materials of Construction For The Storage of H2O2Umar khanNo ratings yet

- Base Module For Experiments in Fluid MechanicsDocument3 pagesBase Module For Experiments in Fluid MechanicsshmomenyNo ratings yet

- Electrical Power Cable Engineering - HTMLDocument4 pagesElectrical Power Cable Engineering - HTMLceragonNo ratings yet

- Fluid Mechanics QtnsDocument3 pagesFluid Mechanics QtnsAnonymous NV1AeWXEo100% (1)

- Chen 801-T3Document28 pagesChen 801-T3hussainiNo ratings yet