Professional Documents

Culture Documents

AComparatve Studyon PSDModelsfor Chromte Ores Commnutedby Dfferent Devces

AComparatve Studyon PSDModelsfor Chromte Ores Commnutedby Dfferent Devces

Uploaded by

Nursultan IliyasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AComparatve Studyon PSDModelsfor Chromte Ores Commnutedby Dfferent Devces

AComparatve Studyon PSDModelsfor Chromte Ores Commnutedby Dfferent Devces

Uploaded by

Nursultan IliyasCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/227719922

A Comparative Study on PSD Models for Chromite Ores Comminuted by

Different Devices

Article in Particle and Particle Systems Characterization · April 2009

DOI: 10.1002/ppsc.200800035

CITATIONS READS

29 751

2 authors:

A. Tasdemir Tuba Taşdemir

Eskisehir Osmangazi University Eskisehir Osmangazi University

15 PUBLICATIONS 166 CITATIONS 15 PUBLICATIONS 136 CITATIONS

SEE PROFILE SEE PROFILE

All content following this page was uploaded by Tuba Taşdemir on 03 May 2019.

The user has requested enhancement of the downloaded file.

Part. Part. Syst. Charact. 26 (2009) 69–79 69

Technical Note

A Comparative Study on PSD Models for Chromite Ores

Comminuted by Different Devices

Adem Taşdemir*, Tuba Taşdemir*

(Received: 14 August 2008; accepted: 12 March 2009)

DOI: 10.1002/ppsc.200800035

Abstract

The objective of this study was to characterize the parti- single-pass devices, i.e., jaw and cone crushing were bet-

cle size distributions (PSDs) of chromite ores comminu- ter described by the GGS model than RR model. The

ted by different devices, i.e., subjected to different RR model gave the best results for all ore sample PSDs

breakage modes and to compare the performances of generated by retention type systems, i.e., hammer crush-

the PSD functions selected. Different PSDs were ob- ing and ball mill grinding. Both distribution functions

tained for five different mineralogical samples of chro- gave higher R2 values as the size distribution became

mite ores by jaw, cone and hammer crushing and ball uniform. The results of piecewise regression were found

mill grinding. The PSDs of the products were character- very useful to improve the performance of GGS distri-

ized to find the most suitable model by Gates–Gaudin– bution in terms of correlation coefficients for samples

Schuhmann (GGS) and Rosin–Rammler (RR) func- from a hammer crusher and ball mill.

tions. It was found that the PSDs of all chromite types in

Keywords: comminution, Gates–Gaudin–Schuhmann distribution, particle size distribution,

piecewise linear regression, Rosin–Rammler distribution

1 Introduction sizes to control process efficiency and product quality.

Knowledge of the distribution of particulate material

Particles must be characterized in terms of particle size properties such as size, density, hydrophobicity, mag-

and size distribution for a variety of reasons [1], includ- netic susceptibility, etc., is important in many industrial

ing that the behavior and properties of particulate mate- applications including cement, food, pharmaceuticals,

rials are, to a large extent, dependent on particle size, cosmetics, pigment, fertilizers and mineral processing

size distribution and shape [2]. Particle size is probably [4]. It influences the combustion efficiency of pulverized

the single most important physical characteristic of pow- coal, the setting time of cements, the flow characteristics

ders. Particle size distribution (PSD) is frequently exam- of granular materials, the compacting and sintering be-

ined to obtain details on the particulate material. A fun- havior of metallurgical powders and the masking power

damental knowledge of particle size and distribution is of paint pigment [5]. Transport and chemical reactivity

essential for a wide variety of industrial processes [3]. problems are also functions of particle size and PSDs.

This is valuable in the production of particles of specific A fundamental building block in the development of

engineered solutions to mineral processing problems is

the ability to readily determine and to mathematically

* Dr. A. Taşdemir (corresponding author), Dr. T. Taşdemir, describe PSDs [6]. Most mineral processing operations

Eskişehir Osmangazi University, Department of Mining En-

gineering, Mineral Processing Division, 26480, Eskişehir rely on the measurement of size distributions, as this is a

(Turkey). key factor in improving process efficiencies. Mineral

E-mail: atasdem@ogu.edu.tr manufacturing processes often involve comminution.

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim http://www.ppsc-journal.com

70 Part. Part. Syst. Charact. 26 (2009) 69–79

Amongst other uses, knowledge of particle size is used the relative proportion of dominant breakage events,

in the development of sampling protocols which in turn and consequently alter the PSD of the ground product

feeds into quality control, whereas PSD parameters are [12].

employed in modeling and simulation of various unit No fundamental mechanism or model enables a theory

operations, especially in comminution and in physical on particle-size distribution to be built. As a result, a

enrichment separations. Models described for plant wide variety of empirical models or equations have been

equipment, such as cyclones or flotation cells, require a developed to characterize experimental PSDs of com-

knowledge of particle size as an input. The separation minuted products [13]. The two most common methods,

by size is, of course, another frequently used unit opera- which are often applied to comminution studies, are the

tion, and here too, knowledge of particle size allows de- GGS and RR models. Both methods were derived from

termination of the effectiveness of such separations [6]. attempts to represent PSD curves by means of equations

Particle size, like other variables in nature, tends to fol- which result in scales which, relative to a linear scale,

low well-defined mathematical laws in its distribution. are expanded in some regions and contracted in others

The size distribution of ground materials is typically [14]. The various equations fit specific situations and no

skewed and normal distribution for ground materials is universal equation has been accepted yet [15]. In the lit-

uncommon and occurs only for narrow size ranges [2]. erature section of a study, Buchholtz et al. [16] revealed

Numerous equations have been developed to describe that in some situations the RR law proved superior

fragment generation mathematically after comminution whereas in other cases the GGS law was more adequate.

processes [7]. Several two-parameter mathematical mod- In this study, different PSDs showing different physical

els and expressions have been published, ranging from properties were obtained for five different mineralogical

the well known normal and log-normal, to the Rosin– samples of chromite ores comminuted under the usual

Rammler (RR) and Gates–Gaudin–Schuhmann (GGS) working conditions for the different devices. The sam-

models; the most important grain-size distribution func- ples were subjected to different comminution mecha-

tions have been reviewed by Allen [2] and King [8]. nisms by jaw crusher, cone crusher, hammer crusher and

Although numerous three- and four-parameter models ball mill and thus, different particulate products of dif-

have also been proposed for greater accuracy in fering size ranges were generated. To establish the suit-

describing PSDs, their widespread application has been ability of the GGS and RR distribution functions in all

limited due to their greater mathematical complexity [5]. cases, the accuracy of the functions in determining PSDs

The results of PSD analysis may be expressed in terms were tested to determine if they could be adopted in all

of cumulative percent oversize or undersize in relation situations. Also, piecewise linear regression was applied

to the diameters of the particles, or as a distribution of to improve the performance of the GGS model for ham-

the amounts present in each of a defined number of size mer crusher and ball mill products by dividing the PSDs

classes [9]. In many applications, particle-size results are into two regions.

processed by plotting the cumulative frequency data on

a scale expressed by the related distribution model. If a

straight line is obtained, the particle-size distribution is 2 Materials and Methods

said to obey the distribution function.

The characteristics of a PSD generated by comminution 2.1 Mineralogical Characteristics of Chromite Ores

can be dependent on a variety of factors such as the ex- Used

tent of comminution mechanisms applied by the devices,

comminution conditions, initial ore characteristics, The five different mineralogical samples of chromite

whether a size classification system is applied during ores used in these experiments were taken from the run-

comminution or not, etc. Comminution conditions that of-mines, namely Bantli which was from Karaburhan,

favor one breakage mode over another may be critical Eskisehir, Turkey and Dereboyu, Kef, Lasir and Yunus-

in determining the PSDs of products. For any comminu- kuyu which were from Guleman, Elazig, Turkey. Chemi-

tion system, the prevailing conditions generally depend cal analysis of chromites by XRF is given in Table 1.

on the type of comminution device and the initial prop- Thin and polished sections from the lump samples of

erties and size of the particles being broken [10]. In chromites were made for mineralogical examination.

comminution, different fracture mechanisms exist. The unbroken grain size distributions were carried out

These do not occur alone, but are found in combination on the cube-shaped polished sections of each ore sample

with one another. Only their relative predominance by an automatic image analyzer and were found to give

varies as a function of the machine type, the operating excellent fits to lognormal distribution [17]. These mea-

conditions and the material being ground [11]. Altering surements were also used to designate the degree of cat-

the grinding environment in a single device may change aclastic deformation of the chromite ores by a number-

http://www.ppsc-journal.com © 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

Part. Part. Syst. Charact. 26 (2009) 69–79 71

Table 1: XRF analysis of chromite ores used. Both, the mineralogical examinations and quantitative

grain size measurements indicated that the chromite ore

Compound Chromite ores samples were deformed differently by cataclasis and

Wt.% Bantli Dereboyu Kef Lasir Yunuskuyu have different mineralogical properties.

MgO 30.0 18.5 20.0 20.0 28.0

Al2O3 3.1 9.9 17.0 9.7 3.3

SiO2 23.2 9.3 7.4 14.1 24.3 2.2 Comminution Studies

CaO 0.3 0.5 0.3 1.1 0.3

Fe2O3 8.6 13.9 12.7 11.6 7.0

Cr2O3 25.0 45.2 39.8 41.3 30.3 Jaw, cone, and hammer crushers as well as ball mills

LOIa 9.8 2.65 2.75 2.05 6.8 were used in this study to comminute the ore samples.

Total 100 100 100 100 100 During the experiments, the comminution devices were

operated under usual working conditions since the pur-

All samples have Na2O (%) = 0.1; P2O5 (%) = < 0.1; K2O (%) = 0.1;

pose of the study did not deal with analyzing the effect

TiO2 (%) = 0.1; MnO (%) = 0.1

a

: Loss of ignition of operational parameters on the PSDs of chromite sam-

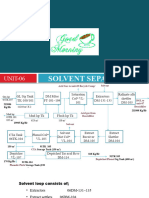

ples. The general flow sheet of comminution applied in

this work is shown in Figure 1. The amount of comminu-

based fractal approach proposed by Blenkinsop and Fer- ted samples of each ore from each device was reduced

nandes [18]. According to this evaluation, cataclastic by applying the sampling procedures and these repre-

deformation of the chromite ores studied was domi- sentative samples were used in sieve analysis. First, the

nated by extension microstructure due to fragmentation chromite samples were crushed to –15 mm by a jaw

by micro fracturing. The XRD studies were also carried crusher. The –15 +3.35 mm fraction was used for cone

out on the representative samples of chromite ores. The and hammer crusher feeds. After the first stage of crush-

results of these detailed mineralogical examinations and ing by the cone crusher, the product was sieved and the

unbroken grain size distributions have been published +3.35 mm fraction was crushed by the cone crusher

elsewhere [17]. Thus, the mineralogical properties of the again (second stage), making the output of the crusher

chromite ores used in this study are summarized briefly narrower. A –2 +1 mm feed size was used for ball mill

below: grinding. Ball mill conditions for the chromite minerals

Bantli Ore: This banded ore type consisted dominantly studied are given in Table 2. A loading of 20 % of the

of serpentinized olivines. The chromite grains were mill volume filled by the ball bed and a fractional inter-

mainly of cataclastic texture due to tectonic effects. The stitial filling of the bed voids by the dry powder of 0.47

fractured chromite crystals were filled with serpentines. at 72.4 % of the critical speed were chosen to run the

The serpentine, which was of sieve texture, contained

olivine relicts. Dereboyu Ore: This spotted ore type was

composed mainly of a pyroxene mineral. The pyroxene Ore samples

was serpentinized in the contact zone of chromite grains

and filled the fractures. The chromite grains were frac-

Jaw crusher

tured and showed cataclastic texture. Kef Ore: This mas-

+15 mm

sive type of chromite consisted mainly of unaltered oli-

Sieving

vine minerals. The alteration products were serpentine

and chlorite minerals. The chromite grains within the -15 mm

unaltered olivine kept their original shapes and were -15+3.35 mm

Sieving

-2+1 mm

less fractured than the grains within the altered olivine.

The fractured chromite crystals showed cataclastic struc- Ball mill

ture. The chromite grains were less fractured than the Cone crusher Hammer crusher

other ore types. Lasir Ore: This was a disseminated type (1st stage)

of chromite ore. The alteration products were serpentine

as chlorite and serpentinized olivine. The chromite crys- Sieving

tals were generally broken due to fragmentation effects +3.35 mm

to obtain cataclastic texture. Yunuskuyu Ore: The Leo- Cone crusher

par type of chromite ore comprised dominantly of ser- (2nd stage)

pentinized olivine minerals, which show sieve texture.

The chromite grains in the nodular were fractured and Sieve Sieve Sieve Sieve Sieve

analysis analysis analysis analysis analysis

showed cataclastic texture. The other altered minerals

observed in the ore were chlorite and talc. Fig. 1: The flow sheet followed for the experimental study.

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim http://www.ppsc-journal.com

72 Part. Part. Syst. Charact. 26 (2009) 69–79

Table 2: Ball mill characteristics and experimental conditions. suggest more fines, more large particles and fewer parti-

cles in the middle range [20]. The higher the value of a,

Mill Inner diameter, D (mm) 152

the narrower the distribution.

Length, L (mm) 165

Volume, V (cm3) 2994 If we take logs of both sides of this equation and rear-

Critical speed, Nc (rpm) 107,7a range it, then:

Operational speed 78

(72.4% of critical speed) (rpm) ln (M/100) = a ln x + ln c (constant). (2)

Balls Material Ceramic

Mean diameter (mm) 24 This is the equation of a straight line if x and M are

Specific gravity (gr/cm3) 3,5

plotted on a log-log scale. The slope of the straight line

Total mass (gr) 1272,1

Fractional ball filling, J 0.20b will be the distribution parameter, a, and the intercept

Void between balls (cm3) 235.3c of the straight line, when M equals 100 % will be the size

Material Feed size (mm) –2+1 parameter, k and it equals:

Volume of samples (cm3) 110

a

: Nc = 420 / D1/2 (rpm); (D, in cm). k exp

lnc=a: (3)

b

: J = [(mass of balls/ball density)/(mill volume)]*[1.0/0.6]

c

:[J*(mill volume)] – [volume of balls]

The RR distribution is given as [19]:

tests. The ore samples were ground until 80 % of their h i

b

R 100 exp x=x′ : (4)

undersize was minus 1 mm. This condition was achieved

in 30 min for Kef ore, while the other ores took 20 min.

Representative samples of particulate products gener-

Eq. (4) can be rewritten as follows:

ated in each device were classified by sieving. Thus, the

PSDs of different particle size ranges were obtained h i

b

after sieving the comminuted products of chromites. 100=R exp x=x′ ; (5)

Retsch test sieve series including 12700, 9525, 4750,

3350, 2360, 2000, 1000, 800, 600, 500, 400, 300, 212, 150,

106, 75, 53 and 38 lm were used for sieving. All these where x is the screen aperture size, R is the cumulative

sieves were used for sieving after the jaw crusher, while mass (in %) retained on size x, x′ is the size parameter, b

the 4750–38 lm sieves were used for sieving after the is a measure of the spread of particle sizes. Small values

first stage of cone crushing and hammer crushing. The of b indicate a scattered distribution, and large values

3350–38 lm and 1000–38 lm sieves were used for siev- imply uniform distribution [21].

ing after the second stage of cone crushing and ball The application of the function to a particular distribu-

milling, respectively. Particles greater than 1 mm were tion and the calculation of its parameters are often done

sieved by dry sieving while wet sieving was applied for via linear regression of data represented as:

particles less than 1 mm. All sieving studies were per-

ln ln (100/R) = b ln x + ln c (constant). (6)

formed by manual sieving until there was no particle

that would pass through a sieve.

This is the equation of a straight line if log (100/R) is

plotted against x on a log-log scale. The parameters of

the RR distribution, b and x′ are obtained from the

2.3 GGS and RR Mathematical Models for PSDs

slope of the straight line and the intercept at the hori-

zontal line at R = 36,79 % respectively. The x′ can be cal-

The Gates–Gaudin–Schuhmann (GGS) and Rosin–

culated as:

Rammler (RR) distributions were selected as they are

widely utilized for to determine the size distributions of

particulate materials after comminution. The GGS dis- x′ exp ln c=b: (7)

tribution is given as [19]:

RR was originally developed to describe the PSD of

M 100 x=k ;

a

(1) broken coal and has been applied to crushing, grinding

and milling operations. This general applicability to

where x is the screen size, M is the cumulative mass comminution processes can be attributed to the suitabil-

(in %) passing size x, k is the size parameter and a is the ity of the RR model to describe skewed distributions

distribution parameter. Theoretically, lower values of a [5].

http://www.ppsc-journal.com © 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

Part. Part. Syst. Charact. 26 (2009) 69–79 73

2.4 Piecewise Linear Regression age in comminution applications is dependent upon the

physical properties of the material and the quantity of

The GGS distribution function in Eq. (2) was fitted as a material being crushed. The rate of energy input is de-

two-parameter model (a and ln c) within the whole pendent upon the type of comminution device used

domain of data availability. The following equation (Eq. since the application of the comminution force changes

(8)) suggested the existence of two power laws sepa- with machine type [23].

rated by a breaking point, ln (xc). This could mean that In this research, the chromite ore samples of different

the log-transformed data would yield two straight lines mineralogical characteristics were subjected to different

separated by a cutoff, ln (xc). Thus, Eq. (8) was fitted as predominant breakage mechanisms by different commi-

a five-parameter model (a1, a2, ln c1, ln c2, and ln (xc)) nution devices. The forces acting on the particles can be

using piecewise linear regression: classified into impact forces, compressive forces and

abrasive forces in any comminution system. This classifi-

ln (M/100) = a1 ln x + ln c1 (ln x ≤ ln xc) cation is based on the direction and magnitude of the

+ a2 ln x + ln c2 (ln x > ln xc), (8) force acting on particles. In these systems, particles un-

dergo impact, compression and abrasion repeatedly

where a1 and a2 are the slopes of the first and the second [24]. The mechanisms of size reduction during crushing

domain, respectively, and ln (xc) is the cutoff of the whole and grinding are different. The chief difference being

domain [22]. Each term in parenthesis represents a logi- that in crushing operations the size reduction is more by

cal operation. This choice partitions the whole domain compression and impact and less by attrition, while in

into two sub domains. The value of ln (xc) can be consid- grinding the forces of attrition are much greater in addi-

ered as the upper limit of the first domain and the lower tion to impact forces [19]. The combination of the above

cutoff of the second domain. The latter assumes that the types of fragmentation yields a product characteristic of

upper limit of the second domain is the system size. the ground material and the grinding media, as each

type is active to a different extent with different ma-

chines and materials [15].

2.5 Data Analysis Jaw and cone crushers are the most common types of

primary compression crushers. These are essentially

The parameters from Eqs. (2), (6) and (8) were esti- considered as single-pass devices since they offer limited

mated by a Quasi-Newton non-linear method for fitting retention time for the broken ores [10]. Each applies a

each data set. In order to compare the observed data compressive force to the rock particles as they come in

with the distribution functions, some measure of the contact with the crushing surfaces. The force is applied

quality of fit between the functions and data is required. slowly (in comparison to impact machines) resulting in

In this work, the coefficient of determination (R2) was abrasion and cleavage fracture [23]. This produces frag-

used as a criterion in the selection of the appropriate fit- ments of slightly smaller size than the initial particles

ting method. If R2 is close to unity, the distribution is a and also much finer particles [8].

more appropriate fit to the experimental data. The para- Impact crushers such as hammer crushers apply a high-

meters from the distribution functions were fitted to the speed impact force to rock particles using hammers or

experimental distributions in order to determine the blow bars. The rate of energy input is much higher caus-

most suitable PSD models for comminuted chromite ing particles to shatter [23]. In grinding, the combined

samples with different mineralogical characteristics. action of repeated impact and abrasion over time causes

Linear regression analyses between predicted and ob- size reduction to takes place [19]. Hammer crushers and

served mass values using the PSD models (GGS model, ball mills can be considered retention type devices as

RR model and a piecewise approach to GGS model) the particles are subjected to repeated breakage [10].

were also carried out. All the statistical analyses were This leads to a wide range of fragment sizes being pro-

computed using the Statistica software package [22]. The duced, most being much smaller in size than the original

values of ln (xc) in Eq. (8) was estimated by the software particle. The difference between the finest and the coar-

to give the best breakpoints for the chromite ores. sest size is small when the particles are subjected to a

repeated fragmentation process [25].

3 Size Reduction Mechanisms in the Comminution

Devices Used 4 Results and Discussion

It is well known that comminution in general is an en- Depending on the initial mineralogical properties, size

ergy intensive process. The energy required for break- of the ores, retention times in the devices and dominant

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim http://www.ppsc-journal.com

74 Part. Part. Syst. Charact. 26 (2009) 69–79

breakage modes applied by the different comminution Table 3: PSD parameters of GGS and RR models for jaw crusher.

devices, different PSDs with different ranges of particle GGS predictions RR predictions

sizes were obtained. The PSDs of chromites generated Ores

a k R2 b x′ R2

by similar dominant energy-events were evaluated to-

Bantli 0.67 25045 0.980 0.75 14700 0.962

gether and the results obtained from the different miner-

Dereboyu 0.66 20130 0.990 0.75 11300 0.976

alogical samples of chromite ores are presented in the Kef 0.73 22770 0.990 0.81 13980 0.972

following. Lasir 0.71 15500 0.990 0.80 8930 0.986

Yunuskuyu 0.74 18930 0.982 0.82 11480 0.972

4.1 Characterization of PSDs of Jaw and Cone Table 4: PSD parameters of GGS and RR models for the first

Crushers stage of cone crusher.

GGS predictions RR predictions

The performance of the GGS and RR distribution mod- Ores

a k R2 b x′ R2

els for jaw and cone crusher products is shown in Fig-

ure 2. Tables 3–5 show the model parameter values ob- Bantli 0.71 18830 0.958 0.77 12525 0.927

Dereboyu 0.79 12250 0.984 0.86 8310 0.954

tained when the RR and GGS functions were applied.

Kef 0.81 13140 0.978 0.87 9280 0.958

These results suggested that initial mineralogical ore Lasir 0.82 9425 0.986 0.90 6250 0.964

characteristics can be expected to affect the PSDs after Yunuskuyu 0.78 12070 0.974 0.85 8050 0.949

0 1

GGS linearization by Eq.(2) RR linearization by Eq.(6)

Jaw crusher Jaw crusher comminution because there are different PSD

0

-1 model parameters for ore samples comminuted

-1 in the same device, as seen in Tables 3–5. Chro-

ln(ln(100/R ))

-2

ln(M /100)

-2

mite ores showed a different size distribution

-3 modulus for GGS and RR models, a and b,

Bantlı -3 Bantlı

Dereboyu Dereboyu which characterize the broadness of distribu-

-4 Kef

Kef -4

Lasir

tions. Bantli ore showed the widest size distri-

Lasir

-5

Yunuskuyu

-5

Yunuskuyu butions compared to the other ores (lower va-

3 4 5 6 7 8 9 10 3 4 5 6 7 8 9 10 lues of a and b) and the differences in a and b

ln(x) ln(x)

between the other ores was quite small. It can

0 1 be concluded that the size distribution of dif-

GGS linearization by Eq.(2) RR linearization by Eq.(6)

Cone crusher-1st stage Cone crusher-1st stage ferent mineralogical samples of chromites gen-

0

-1

erated by jaw and cone crushers indicated that

-1 PSDs depended to a large extent on the mode

ln(ln(100/R))

-2

ln(M /100)

-2 of fragmentation used, which has an important

-3 influence on the particle size distribution of the

Bantlı -3 Bantlı

Dereboyu Dereboyu resultant fragments, and to a lesser extent on

-4 Kef

Lasir

-4 Kef

Lasir

the nature of the ores crushed. Because ores

-5

Yunuskuyu

-5

Yunuskuyu comminuted by the same devices showed a

3 4 5 6 7 8 9 3 4 5 6 7 8 9 general characteristic distribution trend when

ln(x) ln(x)

the PSDs are shown on both, GGS and RR

GGS linearization by Eq.(2) 2 plots (Figure 2).

RR linearization by Eq.(6)

0 Cone crusher-2st stage

Cone crusher-2nd stage Figure 3 shows the relationship between the

1

coefficient of determination of GGS and RR

-1 0 models for single-pass devices, i.e., jaw and

ln(ln(100/R))

ln(M /100)

-1 cone crushers. In this figure, each ore samples

-2

Bantlı

is given a number and shown in the x axis.

-2 Bantlı

-3

Dereboyu Dereboyu Since the dominant size reduction mechanism

Kef

Lasir

-3 Kef

Lasir

in jaw and cone crushers is compression, the

-4

Yunuskuyu

-4

Yunuskuyu effective breakage mode is mainly cleavage

3 4 5 6 7 8 9 3 4 5 6 7 8 9 and abrasion. PSDs of minerals generated from

ln(x) ln(x)

these devices have more fines, more large par-

Fig. 2: GGS and RR plots of PSDs of chromite samples comminuted by jaw ticles and fewer particles in the middle range.

and cone crushers. The characteristic PSDs obtained for all differ-

http://www.ppsc-journal.com © 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

Part. Part. Syst. Charact. 26 (2009) 69–79 75

Table 5: PSD parameters of GGS and RR models for the second Table 6: PSD parameters of GGS and RR models for hammer

stage of cone crusher. crusher.

GGS predictions RR predictions GGS predictions RR predictions

Ores Ores

a k R2 b x′ R2 a k R2 b x′ R2

Bantli 0.72 2655 0.994 0.99 1090 0.970 Bantli 0.58 3460 0.960 0.79 1275 0.974

Dereboyu 0.80 2550 0.994 1.09 1110 0.974 Dereboyu 0.63 2890 0.956 0.87 1110 0.990

Kef 0.82 2455 0.994 1.09 1120 0.982 Kef 0.66 3015 0.960 0.90 1215 0.986

Lasir 0.85 2285 0.988 1.15 1030 0.986 Lasir 0.69 2550 0.939 0.94 1040 0.992

Yunuskuyu 0.81 2335 0.988 1.12 1000 0.980 Yunuskuyu 0.65 2625 0.922 0.89 1045 0.980

1.00

Table 7: PSD parameters of GGS and RR models for ball mill.

GGS predictions RR predictions

2

Coefficient of determination, R

Ores

a k R2 b x′ R2

Bantli 0.44 1135 0.929 0.63 375 0.970

Dereboyu 0.59 1080 0.964 0.79 480 0.990

0.95 Kef 0.49 1110 0.953 0.69 410 0.984

Lasir 0.59 1045 0.962 0.79 460 0.990

Yunuskuyu 0.56 1070 0.939 0.75 455 0.974

the different ores. This excludes the Bantli ore, which

Rosin-Rammler

Gates-Gaudin-Schuhmann gives the most scattered and a wider size distribution

0.90

0 5 10 15 with a smaller distribution modulus for both distribution

Ore No. models in the same devices. The differences in values

between the other ores, which gave a more uniform dis-

Fig. 3: The R2 values obtained from jaw and cone crusher prod-

tribution and hence higher values, are quite small.

ucts, fitted by GGS and RR models.

Although the Kef ore’s distribution modulus in the ball

mill was quite small compared with the other ores, this

ent mineralogical samples of chromite ores

which were subjected to this kind of breakage 2

GGS linearization by Eq.(2) RR linearization by Eq.(6)

mechanism were found to be represented bet- 0 Hammer crusher

Hammer crusher

1

ter by the GGS function than the RR model.

In GGS distribution, plotting on a log-log scale -1 0

ln(ln(100/R))

ln(M /100)

considerably expands the region below 50 % in -1

-2

the cumulative undersize curve, especially be-

Bantlı -2 Bantlı

low 25 %. It does, however, severely contract Dereboyu Dereboyu

-3

Kef

the region above 50 %, and especially above Kef

Lasir

-3

Lasir

75 % [14]. -4

Yunuskuyu

-4

Yunuskuyu

3 4 5 6 7 8 9 3 4 5 6 7 8 9

ln(x) ln(x)

4.2 Characterization of PSDs of Hammer 0 1

GGS linearization by Eq.(2) RR linearization by Eq.(6)

Crusher and Ball Mill Ball mill Ball mill

0

The estimated distribution parameters of GGS -1

ln(ln(100/R))

ln(M /100)

and RR methods for the hammer crusher and -1

ball mill are shown in Tables 6 and 7. In Fig-

-2 Bantlı Bantlı

ure 4, the cumulative mass fractions of the Dereboyu -2 Dereboyu

Kef Kef

hammer crusher and ball mill are plotted as a Lasir Lasir

function of particle diameter on GGS and RR -3

Yunuskuyu

-3

Yunuskuyu

3 4 5 6 7 3 4 5 6 7

distribution scales.

ln(x) ln(x)

The values of a and b depend on the mineralo-

gical properties of ore samples since different Fig. 4: GGS and RR plots of PSDs for chromite samples comminuted by

values in the same devices are obtained from hammer crusher and ball mill.

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim http://www.ppsc-journal.com

76 Part. Part. Syst. Charact. 26 (2009) 69–79

was due to the higher retention time required to achieve 1.0

Hammer crusher-Lasir Ore

a product which has d80 less than 1 mm. Here again, the 0.5

results indicated that the parameters of particle size dis- 0.0

tribution functions are largely dependent upon the type -0.5

a 2 = 0.43

of the comminution device and hence the energy events -1.0

applied rather than the type of the ore.

ln(M/100)

-1.5

The coefficients of determination of GGS and RR mod- Breakpoint = 5.57

-2.0

els for retention type devices, i.e., a hammer crusher and a 1 = 1.13

-2.5

ball mill were plotted versus individual ore sample va-

-3.0

lues and illustrated in Figure 5. The RR model can be

-3.5

suggested to describe the characteristic PSD curves of

chromite ores from hammer crushing and ball milling, -4.0

since it fitted the PSD data better than the GGS func- -4.5

3 4 5 6 7 8 9

tion for all types of chromites. ln(x)

1.00 0.2

0.0 Ball mill-Lasir Ore

-0.2

2

Coefficient of determination, R

-0.4

-0.6 a 2 = 0.37

0.95

-0.8

ln(M/100) -1.0

-1.2 Breakpoint = 5.19

a 1 = 0.87

-1.4

0.90

-1.6

-1.8

-2.0

Rosin-Rammler

Gates-Gaudin-Schuhmann -2.2

0.85

-2.4

0 2 4 6 8 10

3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

Ore No. ln(x)

Fig. 5: The R2 values obtained from hammer crusher and ball mill Fig. 6: Fit to the piecewise model to GGS distribution of Lasir ore

products fitted by GGS and RR models. for hammer crusher and ball mill product.

In comparison with the GGS model, the RR plot ex- describe the data across the entire range of measured

pands the regions below 25 % and above 75 % cumula- particle sizes, but two power-law functions can be fitted

tive undersize and it contracts in the 30–60 % region across the data points, indicating two different scaling

[14]. Thus, the double log scale expands the fine and regimes for different ranges of particle sizes. It was

coarse ends of the size range and compresses the mid noted that the transition point from the first linear re-

range. gion to the second linear region changes with the type of

chromite sample (Table 8). Thus, the identified power-

law domains separate the particle sizes into two classes

4.3 Application of Piecewise Linear Regression and values of a have been estimated by linear fitting of

The plots of hammer crusher and ball mill GGS distribu-

tion show that a single power law could not describe the Table 8: Piecewise regression model parameters for hammer

data across the entire range of measured particle sizes. crusher and ball mill.

Different power laws applied to the two domains in the

GGS distribution plots of the hammer crusher and ball Hammer crusher Ball mill

Ores 2

mill. A piecewise linear regression was applied to the a1 a2 ln(xc) R a1 a2 ln(xc) R2

GGS model of hammer crusher and ball mill by using Bantli 1.01 0.45 5.076 0.999 0.75 0.24 5.061 0.998

Eq. (8). Figure 6 displays some representative PSD of Dereboyu 0.98 0.45 5.497 0.998 0.87 0.38 5.145 0.999

the Lasir ore sample drawn on a double logarithmic Kef 1.04 0.48 5.449 0.998 0.76 0.29 5.136 0.999

scale for the hammer crusher and ball mill, respectively. Lasir 1.13 0.43 5.572 0.996 0.87 0.37 5.197 0.999

Yunuskuyu 1.18 0.39 5.420 0.997 0.89 0.29 5.180 0.999

The plots clearly show that a single power-law cannot

http://www.ppsc-journal.com © 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

Part. Part. Syst. Charact. 26 (2009) 69–79 77

the data in the two scaling regions for all studied chro- the average values of R2 for GGS and RR functions were

mite samples. found to be 0.947 and 0.985 for the hammer crusher and

0.952 and 0.983 for the ball mill, respectively (Table 9).

The RR function was best at describing the hammer

4.4 Overall Performance Evaluation of PSD Models crusher and ball mill data in terms of model predicted

values versus experimentally predicted values. In work

To assess the performance of the PSD distribution func- reported previously, the RR model was found to be a

tions with different types of chromite ore samples for good estimate of the cumulative PSD of ground products

the entire range of data for each comminution device, from stirred media mills [12]. In many grinding cases,

linear regression analyses between predicted and ob- mainly during the last stages of the process, the cumula-

served mass values using the PSD models (GGS model, tive particle size distribution was found to follow the RR

RR model and piecewise approach to GGS model) were equation [26]. For impact fragmentation, Grady and

carried out. The observed data was the percent mass Kipp suggested the RR representation to characterize

measured during sieving while the predicted data was the cumulative distribution of fragment fractions [27].

the amounts found by the models. Table 9 shows the The relationship between distribution modulus of both

results (predicted versus observed) of applying GGS, models and R2 is shown in the Figure 7. The figure sug-

RR and piecewise distribution models to the PSDs of gests that both size distribution models were sensitive to

chromite samples and compares the performance of the the spread of size distribution. The trend lines in Fig-

models. All pairs of observed and predicted values ob- ure 7 show that both distribution models fits the data

tained for each chromite samples in each comminution best at higher values of a and b (narrower size distribu-

device were included in the regression models. The tions). Increasing of range of size distribution has a re-

number of observations (n) was obtained by multiplying verse effect on the efficiency of the GGS function, than

the number of samples (5 ore samples) by the number RR model. The results implied that the RR model may

the sieve fractions (for example, for jaw crusher: 5 sam- be more suitable for evaluating PSDs which are more

ples × 18 sieve fractions = 90 observations). scattered and in wider size distributions than the GGS

The average R2 for GGS and RR models were 0.986 and model. Consistent with the literature [28], its efficiency

0.974 for jaw crushing, 0.976 and 0.95 for the first stage also increases with increasing b, i.e., the size distribution

of cone crushing and 0.992 and 0.978 for the second become more uniform.

stage of cone crushing, respectively, when the different The distribution modulus of both distribution models, a

mineralogical samples of chromite ores were comminu- and b, which describe the fineness and the size range of

ted by low-energy events and the fracture mode was the PSD, properly identify the differences between the

mainly due to cleavage. The comparisons showed that ores comminuted in each device. The distribution para-

the GGS function was best at describing the jaw and meters of both models separated the chromite ores into

cone crusher’s data, when looking at standard errors of similar groups. As can be clearly seen from Figure 8,

regression coefficients for the fitted values. there was a close relationships between these para-

When the ore samples were subjected to high-energy meters, as a increased, b also increased and suggested

events where the main breakage mode was shattering, the same results.

The highest R2 values were ob-

Table 9: Regression analysis of predicted versus observed values for GGS, RR and piecewise tained for all types of chromite

regression models. ores when a piecewise linear re-

gression was applied to the GGS

Comminution device Method Intercept Slope R2

model of hammer crusher and

Jaw crusher GGS –0.032 (0.033) 0.987 (0.012) 0.987

ball mill products. 99.8 % of the

(n = 90) RR –0.060 (0.046) 0.974 (0.017) 0.974

total variation in the observed

Cone crusher-first stage GGS –0.061 (0.049) 0.977 (0.017) 0.977

(n = 80) RR –0.122 (0.069) 0.952 (0.024) 0.952

data values were explained by

Cone crusher-second stage GGS –0.013 (0.019) 0.992 (0.011) 0.992

using piecewise linear regression.

(n = 75) RR –0.024 (0.031) 0.979 (0.017) 0.979 Harris [29] suggested dividing the

GGS –0.065 (0.039) 0.947 (0.025) 0.947 PSD into two regions, fine and

Hammer crusher RR –0.013 (0.021) 0.985 (0.014) 0.985 coarse, with each region described

(n = 80) Piecewise –0.003 (0.008) 0.998 (0.005) 0.998 by a specific distribution when a

GGS –0.041 (0.029) 0.952 (0.028) 0.952 single law cannot describe the

Ball mill RR –0.008 (0.016) 0.983 (0.017) 0.983

(n = 60) data across the entire range of

Piecewise –0.001 (0.004) 0.999 (0.004) 0.999

measured sizes. Consistent with

(Values in parentheses are standard errors of regression coefficients) this suggestion, the piecewise lin-

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim http://www.ppsc-journal.com

78 Part. Part. Syst. Charact. 26 (2009) 69–79

1.00

particle-size distribution of the resulting fragments, and

to a lesser extent on the ore characteristics.

0.99

2

Although each of the PSD models offered enough flex-

Coefficient of determination, R

0.98

ibility to properly describe PSDs for different mineralo-

0.97 gical samples of chromite ores, the GGS model should be

0.96 considered for characterizing of PSDs generated by low-

energy events, i.e., jaw and cone crushing while the RR

0.95

model was more suitable for PSDs obtained by high-en-

0.94

ergy events, i.e., hammer crushing and ball milling.

0.93 The efficiency of the both distribution models was found

Rosin-Rammler

0.92 Gates-Gaudin-Schuhmann

to increase as the size distribution got narrower. The

0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3

GGS function was more reversely affected by the spread

Distribution modulus, a, b

of the distribution than the RR function.

The results of piecewise regression indicated that GGS

Fig. 7: Relationship between the coefficient of determination and distribution plots of hammer crusher and ball mill pro-

distribution modulus of GGS and RR models. ducts showed the presence of two different scaling

domains for different ranges of particle sizes. The pre-

sented model was better than traditional distributions

0.9 (GGS and RR) in terms of R2 since higher correlation

Distribution modulus, a, by GGS model

coefficients were obtained than the other PSD models

0.8 when a piecewise linear regression approach was applied.

It can be concluded that particle size and distribution

0.7 can usually be related to a particular mode of breakage,

the mineralogical properties of the ores comminuted,

0.6

comminution time and feed size, etc., under the usual

Jaw crusher

st

working conditions of the devices. Altering the grinding

Cone crusher(1 stage)

0.5 nd

Cone crusher(2 stage)

environment may change the relative proportion of

Hammer crusher energy events and consequently alter the PSDs of the

Ball mill

0.4

ground products [12]. Therefore, whether or not the

0.6 0.7 0.8 0.9 1.0 1.1 1.2 PSDs obtained in altered conditions can be character-

Distribution modulus, b, by R-R model ized properly in all situations by the application of a sin-

gle distribution function may be examined further.

Fig. 8: Relationship between the distribution modulus of GGS ver-

sus distribution modulus of RR models.

6 Nomenclature

ear regression improved the performance of GGS distri-

bution in terms of correlation coefficient for samples a – distribution parameter of the GGS

from the hammer crusher and ball mill. function

b – spread of distribution by the RR function

GGS Gates–Gaudin–Schuhmann function

k lm size parameter of the GGS function

5 Conclusions

M % cumulative mass passing size, x

Depending on the dominant breakage modes and initial PSD particle size distribution

mineralogical characteristics and size of the ore parti- R % cumulative mass retaining size, x

cles, different PDSs for chromite ore samples were ob- RR Rosin–Rammler function

tained by different comminution devices that were oper- xc lm breakpoint of piecewise linear regression

ated in their conventional working conditions and x′ lm size parameter of RR function

characterized by using GGS and RR models.

The distribution modulus of GGS and RR functions ob- 7 References

tained for chromite ore samples offered a characteristic

range of values in the same comminution device. This [1] A. Lieberman, Particle Characterization in Technology,

results suggests that the PSDs produced by comminu- Volume I, Applications and Microanalysis, in Fine Parti-

tion therefore depends to a large extent on the mode of cle Characterization Methods in Liquid Suspensions

fragmentation used which has an important influence on (Ed.: J. K. Beddow), CRC Press, 1988, pp. 187–232.

http://www.ppsc-journal.com © 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

Part. Part. Syst. Charact. 26 (2009) 69–79 79

[2] T. Allen, Powder Sampling and Particle Size Determina- [16] V. Buchholtz, J. A. Freud, T. Pöschel, Molecular Dy-

tion. Chapman and Hall, 2003, p. 682. namics of Comminution in Ball Mills. Eur. Phys. J. B.

[3] K. N. Ramakrishnan, Fractal Nature of Particle Size Dis- 2000, 16, 169–182.

tribution. J. Mater. Sci. Lett. 2000, 19, 1077–1080. [17] A. Tasdemir, Evaluation of Grain Size Distribution of

[4] H. A. M. Ahmed, J. Rrzymala, Two-dimensional Fractal Unbroken Chromites. Miner. Eng. 2008, 21(10), 711–719.

Linearization of Distribution Curves. Physicochem. [18] T. G. Blenkinsop, T. R. C. Fernandes, Fractal Characteri-

Probl. Miner. Process. 2005, 39, 129–139. zation of Particle Size Distributions in Chromitites from

[5] K. M. Djamarani, I. M. Clark, Characterization of Parti- the Great Dyke, Zimbabwe. Pure Appl. Geophys. 2000,

cle Size Based on Fine and Coarse Fractions. Powder 157, 505–521.

Technol. 1997, 93, 101–108. [19] A. Gupta, D. S. Yan, Mineral Processing Design and

[6] H. von Blottnitz, A. Pehlken, Th. Pretz, The Description Operation: An Introduction. Elsevier, 2006, p. 693.

of Solid Wastes by Particle Mass Instead of Particle Size [20] P. Lu, I. F. Jefferson, M. S. Rosenbaum, I. J. Smalley,

Distributions. Resourc. Conservation Recycl. 2002, 34, Fractal Characteristics of Loess Formation: Evidence

193–207. from Laboratory Experiments. Eng. Geol. 2003, 69, 287–

[7] A. W. Momber, The Fragmentation of Standard Con- 293.

crete Cylinders under Compression: The Role of Sec- [21] B. Manohar, B. S. Sridhar, Size and Shape Characteriza-

ondary Fracture Debris. Eng. Fracture Mech. 2000, 67, tion of Conventionally and Cryogenically Ground Tur-

445–459. meric (Curcuma Domestica) Particles. Powder Technol.

[8] R. P. King, Modeling and Simulation of Mineral Proces- 2001, 120, 292–297.

sing Systems. Butterworth-Heinemann, 2001, p. 403. [22] StatSoft, Statistica for Windows. Computer Program

[9] A. Macias-Garcia, E. M. Cuerda-Correa, M. A. Diaz- Manual, Tulsa, OK. 1998.

Diez, Application of the Rosin-Rammler and Gates- [23] J. G. Donovan, Fracture Thoughness Based Models for

Gaudin-Schuhmann Models to the Particle Size Distri- the Prediction of Power Consumption, Product Size and

bution Analysis of Agglomerated Cork. Mater. Charact. Capacity of Jaw Crushers, PhD Thesis, Virginia Polytech-

2004, 52, 159–164. nic Institute, 2003.

[10] E. Kaya, R. Hogg, S. R. Kumar, Particle Shape Modifica- [24] P. Pitchumani, N. Gupta, G. M. H. Meesters, B. Scarlett,

tion in Comminution. Kona. 2002, 20, 188–194. Analysis of Single Particle Attrition during Impact

[11] C. Varinot, S. Hiltgun, M. Pons, J. Dodds, Identification Experiments, Part. Part. Syst. Charact. 2003, 20, 323–326.

of the Fragmentation Mechanisms in Wet-phase Fine [25] A. Raghem-Moayed, A Mechano-Statistical Model of

Grinding in a Stirred Bead Mill. Chem. Eng. Sci. 1997, Fragmentation, MSc Thesis, University of Toronto, 1993.

52(20), 3605–3612. [26] G. Delagrammatikas, S. Tsimas, Grinding Process Simu-

[12] Y. Wang, E. Forssberg, Product Size Distribution in Stir- lation Based on Rosin-Rammler Equation. Chem. Eng.

red Media Mills. Miner. Eng. 2000, 13 (4), 459–465. Comm. 2004, 191, 1362–1378.

[13] P. Gonzalez-Tello, F. Camacho, J. M. Vicaria, P. A. Gon- [27] D. E. Grady, M. E. Kipp, Fracture Mechanics of Rock, in

zalez, A Modified Nukiyama-Tanasawa Distribution Dynamic Rock Fragmentation (Ed.: B. K. Atkinson),

Function and a Rosin-Rammler Model for the Particle- London Academic Press, 1987, p. 429–475.

Size-Distribution Analysis. Powder Technol. 2008, 186, [28] J. Yue, B. Klein, Particle Breakage Kinetics in Horizon-

278–281. tal Stirred Mills. Miner. Eng. 2005, 18, 325–331.

[14] B. A. Wills, T. Napier-Munn, Mineral Processing Tech- [29] C. C. Harris, The Application of Size Distribution Equa-

nology, An Introduction to the Practical Aspects of Ore tions to Multi-Event Comminution Process. Transactions

Treatment and Mineral Recovery. Elsevier, 2006, p. 444. of AIME. 1968, 241, 343–358.

[15] P. Somasundaran, Offprints from Ceramic Processing

Before Firing, in Theories of Grinding (Eds.: G. Jr. Ono-

da, L. Hench), John Wiley & Sons, 1978, pp. 105–123.

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim http://www.ppsc-journal.com

View publication stats

You might also like

- T SC 2549972 ks3 Electricity and Magnetism Foundation Revision Mat - Ver - 9Document4 pagesT SC 2549972 ks3 Electricity and Magnetism Foundation Revision Mat - Ver - 9Margarida SeromenhoNo ratings yet

- From Energetics To Ecosystems The Dynamics and Structure of Ecological Systems (Mariano Koen-Alonso (Auth.), Neil Rooney Etc.) (Document277 pagesFrom Energetics To Ecosystems The Dynamics and Structure of Ecological Systems (Mariano Koen-Alonso (Auth.), Neil Rooney Etc.) (Lizeil May D. GunitaNo ratings yet

- EOLO Mini 24-28 Export - Manual Tehnic - Ed 07-07 Centrala TermicaDocument48 pagesEOLO Mini 24-28 Export - Manual Tehnic - Ed 07-07 Centrala Termicadaniellioana100% (1)

- Garcia 2004 Application of The Rosin-Rammler and Gates-Gaudin-Schuhmann Models To The Particle Size Distribution Analysis of Agglomerated CorkDocument6 pagesGarcia 2004 Application of The Rosin-Rammler and Gates-Gaudin-Schuhmann Models To The Particle Size Distribution Analysis of Agglomerated CorknurulNo ratings yet

- Agglomerated Cork, Particle Size Distribution Analysis PDFDocument6 pagesAgglomerated Cork, Particle Size Distribution Analysis PDFDiego GuerreroNo ratings yet

- Scalability of Angle of Repose Tests For The Calibration of DEM ParametersDocument12 pagesScalability of Angle of Repose Tests For The Calibration of DEM ParametersKoyreNo ratings yet

- Articulo DefDocument7 pagesArticulo DefropmachadoNo ratings yet

- KundinRezende 18-01-2013Document36 pagesKundinRezende 18-01-2013PRITISH - ShubhamNo ratings yet

- Graduation ProjectredaDocument36 pagesGraduation ProjectredaRuchit JainNo ratings yet

- 15 J 5973Document20 pages15 J 5973Adil AminNo ratings yet

- The Effect of Aggregate Packing On The Performance of SCC Using Dune SandDocument14 pagesThe Effect of Aggregate Packing On The Performance of SCC Using Dune SandKhaled BOUALINo ratings yet

- Modified Kuz-Ram Fragmentation Model and Its Use at The Sungun Copper MineDocument8 pagesModified Kuz-Ram Fragmentation Model and Its Use at The Sungun Copper MineElías Bravo CortésNo ratings yet

- TBM DEM ModelingDocument10 pagesTBM DEM ModelingczoobsNo ratings yet

- Advanced Powder Technology: Varun Gupta, Xin Sun, Wei Xu, Hamid Sarv, Hamid FarzanDocument13 pagesAdvanced Powder Technology: Varun Gupta, Xin Sun, Wei Xu, Hamid Sarv, Hamid FarzanneusonNo ratings yet

- Spe 200949 MseismicDocument10 pagesSpe 200949 MseismicAziz Mennan (Adanali01)No ratings yet

- 1 s2.0 S0921883117304715 MainDocument11 pages1 s2.0 S0921883117304715 MainLinus HalsNo ratings yet

- Measurement of Particle Size Distribution in Portland Cement Powder: Analysis of ASTM Round Robin StudiesDocument12 pagesMeasurement of Particle Size Distribution in Portland Cement Powder: Analysis of ASTM Round Robin Studiesmahreza189No ratings yet

- 3DSPmoldproperties JOM GuhaDocument16 pages3DSPmoldproperties JOM GuhaTalha Nibras AliNo ratings yet

- Finite Element Simulation of Selective Laser Melting Process Considering Optical Penetration Depth of Laser in Powder BedDocument9 pagesFinite Element Simulation of Selective Laser Melting Process Considering Optical Penetration Depth of Laser in Powder Bedsahilnagula0504No ratings yet

- Shape and Size of Microfine Aggregates: X-Ray Microcomputed Tomography vs. Laser DiffractionDocument11 pagesShape and Size of Microfine Aggregates: X-Ray Microcomputed Tomography vs. Laser DiffractionSiddhesh Kamat MhamaiNo ratings yet

- Modeling and Optimization of Multi Gravity Separator To Produce Celestite ConcentrateDocument7 pagesModeling and Optimization of Multi Gravity Separator To Produce Celestite ConcentrateManishankar PandaNo ratings yet

- ModifiedKuz RamDocument8 pagesModifiedKuz RamElie Binja MasumbukoNo ratings yet

- Comparison Between CSM and NTH Hard Rock TBM PerfoDocument12 pagesComparison Between CSM and NTH Hard Rock TBM PerfoLuca BrandiNo ratings yet

- Numerical Simulations of Sand-Screen Performance in Standalone ApplicationsDocument13 pagesNumerical Simulations of Sand-Screen Performance in Standalone ApplicationsMoharaNo ratings yet

- Ijmet: ©iaemeDocument8 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- Simulation and Optimization of Gyratory Crusher Performance Based On The Discrete Element MethodDocument30 pagesSimulation and Optimization of Gyratory Crusher Performance Based On The Discrete Element Methodthe requiem LastNo ratings yet

- ESCC2015 Proceedings Final V1.0 Investigationofhighspeedconecrushing Johansson QuistDocument8 pagesESCC2015 Proceedings Final V1.0 Investigationofhighspeedconecrushing Johansson QuistVicente RodriguezNo ratings yet

- Sand Erosion Model Prediction, Selection and Comparison ForDocument10 pagesSand Erosion Model Prediction, Selection and Comparison Fork.zaripova.hNo ratings yet

- Measuring and Analyzing Particle Size in A Geomorphic ContextDocument30 pagesMeasuring and Analyzing Particle Size in A Geomorphic Contextbenjamin kwasi boatengNo ratings yet

- DEM Prediction of Particle Flows in Grinding Processes: P. W. Cleary, M. D. Sinnott and R. D. MorrisonDocument35 pagesDEM Prediction of Particle Flows in Grinding Processes: P. W. Cleary, M. D. Sinnott and R. D. MorrisonLuciano Cruz JancoNo ratings yet

- Modeling and Optimization of Extrusion Process Parameters For The Development of Nylon6-Al-Al O Alternative FDM FilamentDocument14 pagesModeling and Optimization of Extrusion Process Parameters For The Development of Nylon6-Al-Al O Alternative FDM FilamentManiNo ratings yet

- 1 s2.0 S0272884222019708 MainDocument12 pages1 s2.0 S0272884222019708 Main363331272No ratings yet

- Powder Technology: Raj Kumar, Srikanth R. Gopireddy, Arun K. Jana, Chetan M. PatelDocument17 pagesPowder Technology: Raj Kumar, Srikanth R. Gopireddy, Arun K. Jana, Chetan M. PatelCynosure SkyNo ratings yet

- Powder Technology: Yun-Wang Li, La-La Zhao, Er-Yi Hu, Kang-Kang Yang, Jing-Feng He, Hai-Shen Jiang, Qin-Fu HouDocument13 pagesPowder Technology: Yun-Wang Li, La-La Zhao, Er-Yi Hu, Kang-Kang Yang, Jing-Feng He, Hai-Shen Jiang, Qin-Fu HouMaisam JdeedNo ratings yet

- JMP MoldingCompositionOptimizationDocument8 pagesJMP MoldingCompositionOptimizationTalha Nibras AliNo ratings yet

- ArabianDocument19 pagesArabianAref AlipourNo ratings yet

- Tabla GP GWDocument13 pagesTabla GP GWJulio César Vásquez ToralNo ratings yet

- JMP-Molding Composition OptimizationDocument8 pagesJMP-Molding Composition OptimizationSudhir KumarNo ratings yet

- Effect of Molding Parameters On Chemically Bonded Sand Mold PropertiesDocument8 pagesEffect of Molding Parameters On Chemically Bonded Sand Mold PropertiesDiditOctianoNo ratings yet

- Economic ModelDocument20 pagesEconomic Modeldr_hsn57No ratings yet

- Particle Size Distribution by LASER Diffraction SPDocument11 pagesParticle Size Distribution by LASER Diffraction SPhamedNo ratings yet

- Gas-Liquid Separators Sizing ParameterGas-Liquid Separators Sizing ParameterDocument11 pagesGas-Liquid Separators Sizing ParameterGas-Liquid Separators Sizing ParameterFlavia RuizNo ratings yet

- Study On Alumina Ball Size Distribution in White Cement GrindingDocument6 pagesStudy On Alumina Ball Size Distribution in White Cement GrindingHamed MostafaNo ratings yet

- Minerals: Optimization of Solids Concentration in Iron Ore Ball Milling Through Modeling and SimulationDocument17 pagesMinerals: Optimization of Solids Concentration in Iron Ore Ball Milling Through Modeling and SimulationRyan CunninghamNo ratings yet

- MaterialsDocument7 pagesMaterialsLune NoireNo ratings yet

- Applsci 12 03720 v2Document11 pagesApplsci 12 03720 v2NAO RobotNo ratings yet

- Honeycomb LegalDocument14 pagesHoneycomb LegalMatheus NeivockNo ratings yet

- Materials and Design: Anoop Kumar Sood, R.K. Ohdar, S.S. MahapatraDocument9 pagesMaterials and Design: Anoop Kumar Sood, R.K. Ohdar, S.S. MahapatraRui MatiasNo ratings yet

- Research Results Digest: National Cooperative Highway Research ProgramDocument24 pagesResearch Results Digest: National Cooperative Highway Research ProgramddffffNo ratings yet

- Influence of Magnesium and Stirrer Model in Production of Al-Fly Ash Composites - A Taguchi ApproachDocument9 pagesInfluence of Magnesium and Stirrer Model in Production of Al-Fly Ash Composites - A Taguchi ApproachRockey KumarNo ratings yet

- Sand ProductionDocument12 pagesSand ProductionAli Mahmoud AyalNo ratings yet

- v1 CoveredDocument32 pagesv1 CoveredoraideNo ratings yet

- Research ArticleDocument11 pagesResearch ArticleKevin FeigeNo ratings yet

- Scale Up of HSM GranulatorsDocument15 pagesScale Up of HSM Granulatorshicham1963No ratings yet

- Azizi2020 Article ModelingAndPredictionOfWearRatDocument10 pagesAzizi2020 Article ModelingAndPredictionOfWearRatvici95821No ratings yet

- NMCOE4054ijarseDocument5 pagesNMCOE4054ijarseUsman AhmadNo ratings yet

- Machines 10 00750Document15 pagesMachines 10 00750Khawaja TaimoorNo ratings yet

- Science Direct JournalDocument5 pagesScience Direct JournalsivaNo ratings yet

- Discrete Element Simulations of Granular Pile FormationDocument26 pagesDiscrete Element Simulations of Granular Pile FormationHosseinNo ratings yet

- 3D Printed Parts With Honeycomb Internal Pattern by Fused Deposition Modelling Experimental Characterization and Production OptimizationDocument14 pages3D Printed Parts With Honeycomb Internal Pattern by Fused Deposition Modelling Experimental Characterization and Production OptimizationWissam HajarNo ratings yet

- Samanli Et Al-2010-Particle Particle Systems CharacterizationDocument10 pagesSamanli Et Al-2010-Particle Particle Systems CharacterizationJD FCNo ratings yet

- Sensitivity Analysis and Optimisation of HVOF Process Inputs To Reduce Porosity and Maximise Hardness of WC-10Co-4Cr CoatingsDocument23 pagesSensitivity Analysis and Optimisation of HVOF Process Inputs To Reduce Porosity and Maximise Hardness of WC-10Co-4Cr Coatingssuresh_501No ratings yet

- Fragmentation in Production RoDocument13 pagesFragmentation in Production RoNursultan IliyasNo ratings yet

- Impact of Rock Blasting On Mining EngineeringDocument11 pagesImpact of Rock Blasting On Mining EngineeringNursultan Iliyas100% (1)

- Maximizing SAG Mill Circuit Throughput at Porgera - 20Document9 pagesMaximizing SAG Mill Circuit Throughput at Porgera - 20Nursultan IliyasNo ratings yet

- Minerals Engineering: Erik Hulthén, C. Magnus EvertssonDocument8 pagesMinerals Engineering: Erik Hulthén, C. Magnus EvertssonNursultan IliyasNo ratings yet

- Control Oriented Modeling of Flow and Size Distribution in Cone CrushersDocument10 pagesControl Oriented Modeling of Flow and Size Distribution in Cone CrushersNursultan IliyasNo ratings yet

- 3 +safitri+et AlDocument25 pages3 +safitri+et AlTITIS WAHYUNINo ratings yet

- FMM - Unit I QBDocument43 pagesFMM - Unit I QBThiruvasagamoorthy KaNo ratings yet

- Light: 1.1 Light Travels in Straight LinesDocument11 pagesLight: 1.1 Light Travels in Straight Linesching_jyoNo ratings yet

- Java Coding Style by Achut ReddyDocument26 pagesJava Coding Style by Achut ReddyAdarsh100% (4)

- Physics 11 Kinematics - Vector Analysis Treasure HuntDocument6 pagesPhysics 11 Kinematics - Vector Analysis Treasure Huntascd_msvuNo ratings yet

- AXSS-II Access Control Configuration Guide: Enterprise Buildings IntegratorDocument128 pagesAXSS-II Access Control Configuration Guide: Enterprise Buildings IntegratorJaime AvellaNo ratings yet

- Using eQube-BITcRA To Make Sense of PLM DataDocument15 pagesUsing eQube-BITcRA To Make Sense of PLM Datayacey52153No ratings yet

- Kaylee Analco - Calorimetry GizmosDocument7 pagesKaylee Analco - Calorimetry GizmosKaylee Analco100% (1)

- Solvent Separation UNIT-06 - GOODDocument17 pagesSolvent Separation UNIT-06 - GOODAamir HasanNo ratings yet

- FORMULA S SHEET Math IIIDocument2 pagesFORMULA S SHEET Math IIIDani RuizNo ratings yet

- SPSS Wulan RahmaniaDocument12 pagesSPSS Wulan RahmaniaUlanNo ratings yet

- J.W. Hodgeson, A.L. Cohen - Method 551, (1990) D.J. Munch (USEPA, Office of Water) and D.P. Hautman (International Consultants, Inc.) - Method 551.1, (1995)Document61 pagesJ.W. Hodgeson, A.L. Cohen - Method 551, (1990) D.J. Munch (USEPA, Office of Water) and D.P. Hautman (International Consultants, Inc.) - Method 551.1, (1995)Ítalo LimaNo ratings yet

- Goldengate Installtion 12cDocument6 pagesGoldengate Installtion 12chariprasathdbaNo ratings yet

- C4 Digital TransmissionDocument42 pagesC4 Digital Transmissionaditya_polepeddiNo ratings yet

- Dynamic Relation Between Exchange Rate and Stock Prices - A Case For India Golaka C. Nath and G. P. SamantaDocument8 pagesDynamic Relation Between Exchange Rate and Stock Prices - A Case For India Golaka C. Nath and G. P. SamantaTen WangNo ratings yet

- Ihueze MgbemenaSDIDocument16 pagesIhueze MgbemenaSDImosanidNo ratings yet

- Dummy Design Rule-D0.5Document27 pagesDummy Design Rule-D0.5Dinesh ChaitanyaNo ratings yet

- Chapter 17 - FatigueDocument26 pagesChapter 17 - FatigueSumit BabbarNo ratings yet

- Air DryersDocument4 pagesAir Dryersmanpreetsodhi08No ratings yet

- Math 3401Document3 pagesMath 3401EDU CIPANANo ratings yet

- 3V FM Transmitter CircuitDocument6 pages3V FM Transmitter CircuitMahmood AhmedNo ratings yet

- Icp SVDDocument37 pagesIcp SVDNguyễn Đăng KhoaNo ratings yet

- Word TutorialDocument12 pagesWord TutorialMuahamad MusaNo ratings yet

- T SB 0051 09Document3 pagesT SB 0051 09goombaNo ratings yet

- Define Load PatternDocument4 pagesDefine Load PatternsovannchhoemNo ratings yet

- MGT LearningDocument18 pagesMGT Learningmoraiskp321No ratings yet

- An Evaluation of Soft Soil Models Based On Trial EmbankmentsDocument6 pagesAn Evaluation of Soft Soil Models Based On Trial EmbankmentsJose Luis Nava HernandezNo ratings yet