Professional Documents

Culture Documents

Ijcer V4i3p101

Ijcer V4i3p101

Uploaded by

Pavan KOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijcer V4i3p101

Ijcer V4i3p101

Uploaded by

Pavan KCopyright:

Available Formats

SSRG International Journal of Chemical Engineering Research ( SSRG – IJCER ) – Volume 4 Issue2 May to Aug 2017

Optimum Biocide Concentration Required to

Preserve the Highest Amount of Sucrose

During Mud Filtration

Jemimah Jehopio#1, George William Nyakairu*2

1

Student, Department of Chemistry, Makerere University, Uganda

2

Associate Professor, Department of Chemistry, Makerere University, Uganda

Abstract: often interrupts normal processing operations and also

This study focused on the determination of interferes with the polarimetric analysis of sucrose

optimum biocide concentration required to minimize because, having a positive rotation, it is interpreted as

sugar loss during mud filtration as a way of keeping sucrose, resulting in false high estimates of the sugar

sugar loss to the lowest possible level. To this point, content in the cane juice.

the study investigated cane juice purity at varying Usually, raw cane sugar is produced from

biocide concentrations and determined the minimum sugarcane (Saccharum officinarum). The major unit

biocide concentration to inhibit microbial activities operations involved in raw cane sugar processing are

during sugar processing so that, at juice purification washing, size reduction, milling (where juice is

stage, the highest amount of sucrose is preserved extracted from harvested cane stalks), juice

during mud filtration. Accordingly, the study found purification, vacuum evaporation and crystallization;

the optimum biocide concentration required to as is graphically presented in the Figure 1 which

preserve the highest amount of sucrose during mud follows.

filtration to be 5.0 ppm. Consequently, the study

recommends the use of biocide for inhibition of

Washing

microbial activities during sugar processing so that, CANE PREPARATION

at juice purification stage, the highest amount of

sucrose is preserved during mud filtration. Further,

the study recommends 5.0 ppm as the optimum

biocide concentration to be used so that the highest MILLING Bagasse

amount of sucrose during mud filtration is preserved, Juice, 10-15%

especially when using the biocide known as (Lime + Heat)

dermacide-BD-2084. PURIFICATION

PREPARATION

Filter mud

Keywords: biocide concentration; sugar loss;

microbial activity; juice purification; mud filtration; EVAPORATION

sucrose.

Syrup, 65-67%

I. INTRODUCTION Raw sugar

CRYSTALIZATION

Molasses

The loss of sucrose at all stages from sugar

cane in the field to crystal sugar in the bag is a serious

economic problem to the sugar industry, making it Figure 1: Generalized Flow Diagram of Unit

necessary for the industry to cut the losses to the Steps in Raw Cane Sugar Processing, Adapted

from [1]

lowest possible level. This post-harvest deterioration

in cane is principally the consequence of the action of

In this study, the unit of interest was cane

the bacteria Leuconostoc mesenerioides,

juice preparation (refer to the Figure 1 above), given

Lactobacillus which lead to inversion of sucrose and a

that cane juice contains sucrose and other nutrients in

large production of dextran, acids and ethanol

the right concentration for promoting microbial

affecting juice purification and kinetics of sucrose

growth [2] and it was microbial activities that this

crystallization. In high enough concentration, dextran

study sought to inhibit.The first stage of purifying

causes gummy solutions and difficulties in

cane juice is called clarification or defection.

processing, along with sucrose loss. The presence of

Clarification employs lime and heat intended to

high concentrations of gums in sugarcane and

remove maximum amount of impurities from the

subsequent processing streams adversely affect

juice. It (clarification) affects juice filterability,

sugarcane processing, yields and the quality of the

evaporator scale composition, sucrose crystallization,

sugar produced. Not only does the formation of

and the quality of raw sugar produced [3].

dextran result in expensive sucrose losses, but also

the high-viscosity associated with this polysaccharide

ISSN: 2394 – 5370 www.internationaljournalssrg.org Page 10

SSRG International Journal of Chemical Engineering Research ( SSRG – IJCER ) – Volume 4 Issue2 May to Aug 2017

Lime serves the dual purpose of raising the The main objective of the study was to

pH and stabilizing the juice against hydrolysis of the determine the optimum biocide concentration

sucrose in the acid juice and forming a precipitate to required to minimize sugar loss during mud filtration,

remove impurities. The heat helps to disinfect the as a wayof cutting sugar loss to the lowest possible

juice of harmful bacteria and improves coagulation level during processing. Specifically, the study sought

and precipitation of the impurities. In simple lime to investigate cane juice purity at varying biocide

defection, lime is added to the juice to raise the pH concentrations and to determine the optimum biocide

from 5.5–5.7 to 6.7–7.5 and to react with inorganic concentration required to preserve the highest amount

phosphate present in the cane juice to form a calcium of sucrose during mud filtration.

phosphate floc which entraps insoluble impurities

from the cane juice as it settles [2]. The lime is added III. LITERATURE REVIEW

either in the form of milk of lime, lime-juice mixtures In the early 1960‟s, Chen [7] encountered

or lime saccharate. Lime addition may be batch-wise some white gelatinous substance removed from juice

or continuous: to cold juice (35–40 oC), intermediate heaters in a factory in Peru. It was identified as

juice (72–76 oC) or hot juice (100 oC). dextran. The name „dextran‟ was introduced by

Polyacrylamide flocculants are added to aid in the Scheibler in 1874, when he discovered that the

coagulation of the precipitate [3]. In cold liming, milk mysterious thickening of cane and beet sugar juices

of lime is added to the cold juice, and the limed juice was caused by a carbohydrate of empirical formula

is then pumped through heaters in which the juice is (C6H10O6) with a positive optical rotation [8]. Shortly

heated to (90–115 oC). Studies have shown the thereafter it was suggested that Leuconostoc

advantage of hot or intermediate liming over cold mesenerioideswas responsible for the slime

liming, resulting in less sucrose loss through production in sugar factories [9]. Today we know that

inversion, less dextran formation, and better control dextran (and other gums) can be produced from

of pH and turbidity[4], [5]. sucrose by several bacterial species and that the

The combination of lime and heat forms a structure of each type of gum depends on the

flocculent precipitate with various components in the microbial strain that produces it [10]-[15]. In sugar

juice, consisting mostly of insoluble lime salts, production, dextrans are undesirable compounds

coagulated protein, entrapped colloidal and suspended produced by contaminant microorganisms from

matter. The precipitate is removed by sedimentation sucrose [16]. The physical and chemical properties of

or settling in continuous closed-tray clarifiers. The sugarcane juice make it an excellent substrate for

juice leaving the clarifier is a clear brown liquid. The proliferation of a variety of microorganisms which

flocculent precipitates that settle on the clarifier trays ultimately cause sucrose degradation and the

are called “muds,” [2]. Muds contain about five production of microbial metabolites such as acids

percent solid matter. In sugar manufacturing factory, (lactic and acetic acid), alcohols (mannitol and

entrained sugar is recovered from the mud by means ethanol) and polysaccharides (levan and dextran) in

of rotary vacuum filters equipped with a perforated the sugarcane juice [17]. The identification of dextran

metallic screen cloth. The turbid filtrate is returned to was the starting point of a long series of tests carried

the clarification system and the press cake or filter out in the following years confirming that physical

mud is usually sent to the fields as fertilizer. Good cleaning can only achieve 50- 60 percent of mill

clarification depends upon the formation of a stable sanitation and that dextran formation could not be

flocculent precipitate that settles rapidly [6]. avoided without the addition of biocide. Similar tests

also conducted by Tilbury [18] showed that biocide

II. THE PROBLEM AND STUDY addition had a significant benefit in sugar factories

OBJECTIVES which could reduce the rate of sugar loss by saving of

Several strategies involving the use of up to 60 percent sucrose.

chemicals, particularly biocides, have been invoked to

minimize bacterial inversion and these have been A. Cane Juice Purification

successful in preventing sugar losses. At very low The first stage of purifying cane juice is

dose, biocides cannot inhibit activities of called clarification or defection. Clarification employs

microorganisms; at optimum concentration, biocides lime and heat intended to remove maximum amount

do substantially inhibit microbial activities. However, of impurities from juice [4],[5]. It, clarification,

literature is generally silent on the minimum affects juice filterability, evaporator scale

inhibitory biocide concentration required so that the composition, sucrose crystallization and the quality of

highest amount of sucrose is preserved during mud raw sugar produced [3]. According to [2], the cane

filtration. Therefore, problem remained to find the juice obtained from milling (or diffusion) is acidic

optimum concentration of biocide required to (pH around 5.5–5.7), turbid and dark brown in colour.

preserve the highest amount of sucrose during mud By weight, it contains 12–18 percent sucrose (the

filtration. more mature the cane is, the higher the concentration

of sucrose) in addition to soluble and insoluble

impurities such as soil, protein, waxes,

ISSN: 2394 – 5370 www.internationaljournalssrg.org Page 11

SSRG International Journal of Chemical Engineering Research ( SSRG – IJCER ) – Volume 4 Issue2 May to Aug 2017

polysaccharides, starch, fine bagasse (bagacillo), boiling juice for clarification and in fact some grow at

organic and phenolic acids, soluble salts and clarifier and continue to grow during subsequent

pigments. Cane juice also contains 0.5-3 percent processes. Moreover, microbes produce various

reducing sugars (glucose and fructose in metabolites that interfere in the process and affect

approximately equal quantities). sugar recovery and sugar quality adversely. To make

The post-harvest deterioration in cane is sucrose recovery even more difficult, microbes

principally the consequence of the action of the protect themselves by growing as biofilms or spores

bacteria Leuconostoc, Lactobacillus saccharomyces, resistant to penetration by antimicrobials such as

Rodotorula genera, which lead to inversion of sucrose biocides [22].

and a large production of dextran, acids and ethanol The loss of sucrose at all stages from sugar

affecting kinetics of sucrose crystallization [19], [20]. cane in the field to crystal sugar in the bag, is a

In sugar processing, not only does the formation of serious economic problem to the sugar industry,

dextran results in expensive sucrose losses, but also increasing costs and making it necessary for industry

the high-viscosity associated with this polysaccharide to cut the loses to the lowest possible level [24], [25].

often interrupts normal processing operations [21] According to [22], sugar losses are of four types,

and also interferes with the polarimetric analysis of namely: (i) chemical, due to changes in pH and

sucrose because, having a positive rotation, it is temperature – this can be reduced only by strict

interpreted as sucrose, resulting in false high control on parameter (e.g. pH and temperature); (ii)

estimates of the sugar content in the cane juice [2]. microbial, due to direct consumption of sugars for

Biocides or bactericides or microbial growth; (iii) enzymatic – microbial and invertase

inhibitors are organic compounds designed to kill present in sugarcane cells and (iv) indirect losses due

bacteria. These compounds are important for control to microbial metabolites.Microbial degradation of

in sugarcane processing, as the juice contains sucrose sugars occurs as follows [22]: (i) sucrose is first

and other nutrients in the right concentration for converted to glucose and fructose, which are then

promoting microbial growth [2]. In the sugar degraded or utilized by microbes to produce various

industry, there are several proprietary biocides metabolites; (ii) glucose is utilized to form dextran,

available that are intentionally added to control acids, alcohol, gas and other polysaccharides; (iii)

Leuconostoc bacteria. Two classes of biocides fructose is converted to glucose and also used to form

important to the sugar industry are the carbamates and complex polysaccharides and (iv) no rules apply for

the quaternary ammonium compounds [22]. The the conversion and all reactions can occur irrespective

biocides in most common use around the world are of pH and temperature.

dithiocarbamates, glutaraldehyde, and ammonium Two major actions of contaminating

bisulfite[23]. Although they differ in composition, microorganisms are (i) the removal of sucrose from

they are all intended to kill or retard the growth of the the sugar production process, directly resulting in

Leuconostoc microorganism and prevent it from reduced sucrose availability for sugar production and,

decomposing sucrose into dextran [7]. It is therefore (ii) producing gums from the sucrose, resulting in a

evident that the application of biocide serves a two- multitude of problems in sugarcane processing [26].

fold purpose: (i) to reduce sucrose loss and (ii) to The main microorganisms of concern are those which

avoid or reduce the formation of dextran or gummy are heat-resistant (thermophilic) such as Leuconostoc

substances in cane juice. mesenerioides. Heat-resistant organisms can enter the

process system with outside ingredients. Heat

B. Biocide Concentration Required for Sucrose resistant molds, including Byssochlamys,

Preservation Paecilomyces, Eupenicillium, Talaromyces and

According to [24], the chemical, physical, Eurotium have been found in juices even after heat

sensory and nutritional attributes of sugarcane juice treatment [27]. The minimum level of thermophilic

are affected by several factors that can be physical bacteria found in cane entering the factory is between

(light, heat), chemical (O2), biochemical (enzymes) 600 and 800 per 10 grams. It seems that this level

and/or biological (microorganisms, insects). These remains more or less constant during extraction and

properties of sugarcane juice make it an excellent clarification. Declining cane quality, frequent

substrate for the proliferation of a variety of breakdowns or process conditions increase the

microorganisms which ultimately cause sucrose number of thermophiles and the use of a biocide then

degradation and the production of microbial becomes necessary to inhibit their activities [28]. For

metabolites such as acids (lactic and acetic acid), example, the biocide di-methyl dithiocarbamate kills

alcohols (mannitol and ethanol) and polysaccharides 90 percent of microbes in 45 minutes. However, to be

(levan and dextran) in the sugarcane juice [17]; effective in saving sucrose loss, a biocide must have

depending on environmental conditions: varying the capacity to kill 90 percent of microbes within 10

qualitatively from place to place and season to minutes [22]. Microbial degradation of sugars at high

season. Primary juice (PJ) contains about 106 to 109 temperatures involves the following [22]: (i) microbes

colony forming units (cfu) of microorganisms per ml. capable of growing at higher temperature also gain

Many of these metabolites are not eliminated by entry via cane; they remain dormant at normal

ISSN: 2394 – 5370 www.internationaljournalssrg.org Page 12

SSRG International Journal of Chemical Engineering Research ( SSRG – IJCER ) – Volume 4 Issue2 May to Aug 2017

temperature; (ii) these thermophiles grow in clarifier from primary juice (PJ) to mixed juice (MJ) or

and during subsequent processes; (iii) major end analysis of dextran or analysis of alcohol or microbial

product of their (thermophilic microbes) metabolism count or rise in reducing sugars from PJ to MJ or rise

(80%) is lactic acid and (iv) thermal degradation of in reducing sugars (RS) as well as acidity from PJ to

invert also produces acid. MJ to clear juice till final molasses [22].

The major microbiological losses in sugar

processing are caused by the common soil bacterium

Leuconostoc mesenerioides, which uses sucrose as a IV. METHODOLOGY

food source, producing a long-chain polysaccharide This study focused on finding the optimum

known as dextran as a waste product. Dextran is the concentration of biocide required to preserve the

name given to a large class of extra-cellular bacterial highest amount of sucrose during mud filtration. The

polysaccharides composed almost exclusively of methods and materials that were moved to achieve the

glucose units linked predominantly by 1:6 bonds, but objectives of the study are presented as follow.

also containing 1:4, 1:3 and some 1:2 glucosyl

linkages [16, 20]. In high enough concentration, A. Apparatus and Materials

dextran causes gummy solutions and difficulties in The study monitored brix, polarization (pol)

processing, along with sucrose loss. It is widely and purity change of the samples as biocide

reported that the presence of high concentrations of concentrations were varied from 0.0 to 7.0 ppm. To

gums in sugarcane and subsequent processing streams this end, samples were taken during the July to

adversely affects sugarcane processing and yields and August 2016 sugar cane crop at the SCOUL. The

quality of the produced sugar [29], [30]; Gums are following noteworthy apparatus and materials were

“carbohydrates of high molecular weight which are put to use, namely: sampling cup and buckets; cold

precipitated from aqueous solutions by acidified water for dilution; hot water as a water bath; beakers;

ethanol,”[29]. Not only does the formation of dextran measuring cylinders; filter paper; filter funnels;

results in expensive sucrose losses, but also the high- polarimeter for measuring pol value; refractometer for

viscosity associated with this polysaccharide often measuring brix and biocide, in particular Dermacide-

interrupts normal processing operations [21]. It also BD-2084 (chemicals for controlling microorganisms

interferes with the polarimetric analysis of sucrose in cane-sugar and beet-sugar mills) as detailed in the

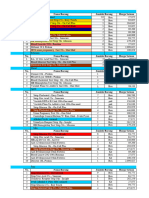

because, having a positive rotation, it is interpreted as Table I which follows.

sucrose; resulting in false high estimates of the sugar

content in the cane juice [2]. Dextrans in the sugar Table I. Biocide (Dermacide-Bd-2084) Composition

industry are predominantly linear, but [31] have

Active ingredients Parts per

shown that branching can be significant, particularly

million

with the low molecular weight dextrans where five to

Disodium 2.5

eight percent branching is possible.

cyanodithioimidocarbonate

Measures adopted to combat the effects of

dextran have included high-pressure washing with hot Ethylenediamine 1.0

water and the use of biocides. Physical cleaning only Potassium 3.5

achieves 50-60 percent of mill sanitation [7] and N-methyldithiocarbamate

dextran formation could not be avoided without the (Source: US Drug and Food Administration.

use of biocide. While proper control on microbial (2016). CFR - Code of Federal Regulations Title 21.

activity is essential so as to minimize impurity Volume 3. CITE: 21CFR173.320) [18], [36]).

development, at very low dose biocides cannot kill

microorganisms[4], [22]. B. Methods

Though in raw sugar manufacturing, The methods applied in order to achieve the

biocides such as carbamates, quaternary compounds, objectives of the study involved treatment of muddy

halogenated phenols and antibiotics are required to be sugar cane juice samples with varying biocide

added to sugar cane juice, not only are biocides concentrations, determination of brix, pol and purity.

costly, in large doses biocides have by-side effects on

humans [32], [33]. Residual biocide has been reported 1) Treatment of Muddy Sugar Cane Juice with

as forming a white surface deposit after drying [34]. Biocide Concentration

Indeed, excess biocide was suggested as the cause of The procedure followed in the treatment of

this residue formation [35]. Hence, only minimum muddy sugar cane juice with varying biocide

inhibitory concentration (MIC) of biocides should be concentration was the following.

required to recover sucrose from cane juice so as to

avoid harm to human beings and the environment. i) Samples were taken from the clarifier mud tray just

Indeed, [37] studied and found optimization of as the muddy juice exited to the mud recirculation

concentration to be plausible. Evaluation of sucrose tank.

loss during sugar processing from cane juice is ii) The samples were then immediately transferred to

normally achieved through the following: purity drop the laboratory for analysis.

ISSN: 2394 – 5370 www.internationaljournalssrg.org Page 13

SSRG International Journal of Chemical Engineering Research ( SSRG – IJCER ) – Volume 4 Issue2 May to Aug 2017

iii) In the laboratory, the samples were placed in a C. Limitations of the Study

water bath of 100.0 oC to maintain temperature. Limitations to the findings of this study

iv) A portion of the sample (100.0 cm3) was placed would likely arise from the maturity of the sugar cane

into a measuring cylinder and biocide added. The plant from which juice was extracted and the season

biocide concentrations were varied from 0.0 to 7.0 of cane harvesting, since the amount of sucrose

ppm. depends on the maturity of the sugar cane. The more

v) The mud sample and biocide were allowed to react mature the sugar cane, the higher the sucrose content

for a length of five (5) minutes, while still in the [17] – certainly not for over mature sugar cane.

water bath.

vi) After five minutes, the sample was filtered and pol, V. RESULTS

brix and purity of the resultant filtrate, for the The main objective of this study was to

various concentrations determined. determine the optimum biocide concentration

required to minimize sugar loss during mud filtration,

2) Determination of Brix so that sugar loss is cut to the lowest level possible.

Brix was measured using an index Specifically, the study set out to investigate sucrose

instrument temperature controlled refractometer after purity against biocide concentration and to determine

the filtration of samples with kieselguhr through filter the minimum biocide concentration required to inhibit

paper according to the standard method described as microbial activities so that the highest amount of

follows: (i) the prism surface and the presser were sucrose is preserved during mud filtration. The Table

cleaned with a clean tissue soaked in distilled water II which follows presents brix, pol and purity at

and (ii) the muddy juice sample was introduced onto varying biocide concentration.

the prism surface using a dropper and the read key

engaged. The Brix observation was then directly read Table Ii. Brix, Pol% And Purity Against Biocide

off. Concentration

Biocide Brix Pol% Sugar

Concentra- [1g of (Sucrose)

3) Pol Determination

tion [ppm] sucrose in % Purity

First, basic lead acetate was added to the

100g of

samples, then filtered through filter paper according

solution]

to the standard method described as follows.

0.0 10.65 8.29 77.84

1.0 9.76 7.74 79.30

i) A muddy juice sample (200 ml) was transferred

into a beaker. 2.0 8.77 7.06 80.50

ii) Lead sub acetate (2g) was added to the sample 3.0 10.81 8.73 80.76

and mixed well to coagulate the impurities and 4.0 11.24 9.10 80.96

the sample filtered. 5.0 10.10 8.25 81.68

iii) The pol tube was cleaned thoroughly with 6.0 11.12 9.06 81.50

distilled water to remove all traces of previous 7.0 8.34 6.79 81.40

sample and then rinsed with the sample to be Source: Author.

read.

iv) The filtrate of the clarified sample was poured From the Table II at biocide concentration of

into the pol tube which was then placed in the 5.0 ppm, the highest amount of sucrose (82.59%) was

polarimeter to determine pol value. recovered during mud filtration. The apparent slight

v) The pol reading was taken when the readings drop in sucrose purity beyond biocide concentration

stabilised. 5.0 ppm appears to be a result of impurities, basing on

vi) Pol% was obtained from Schmitz‟s table by the suggestion by [34], [35] that residual biocide

multiplying the pol reading with the pol factor forms a white surface deposit which are most likely

corresponding to brix, as follows, impurities and not sucrose. The slight apparent drop

may also be explained basing on the observation

Pol% = pol reading x Brix factor ... (3.1). attributed to [22], that sugar loss is not only as a result

of microorganisms‟ direct consumption of sugars for

4) Purity Determination growth, but also result of changes in pH and

The purity of sugar product is the cane sugar temperature, microbial and invertase present in

present in percentage terms of the solid matter. Since sugarcane cells and indirect losses due to microbial

the sugar may be expressed as pol, and the solid as metabolites.

brix, the apparent purity that is generally known as Plotting purity against biocide concentration

purity was derived as follows. and reading off the graph, for clarity, confirms that

the optimum biocide concentration required to

Pol % preserve the highest amount of sucrose during mud

Purity = x 100%. . .(3.2). filtration is 5.0 ppm, as presented in the Figure 2

Brix

which follows.

ISSN: 2394 – 5370 www.internationaljournalssrg.org Page 14

SSRG International Journal of Chemical Engineering Research ( SSRG – IJCER ) – Volume 4 Issue2 May to Aug 2017

level apparently as a result of impurities, basing on

the suggestion by [34], [35] that residual biocide

Sucrose Purity Against Biocide forms a white surface deposit. It may also be noted

Concentration that microbes protect themselves by growing as

82.00 biofilms or spores resistant to penetration

81.00 antimicrobials such as biocides [22], so biocides are

seen to be effective only up to a certain concentration

Sucrose Purity [%]

80.00

before microorganisms react to form biofilms and

79.00 spores.

78.00 This study has demonstrated that optimum

77.00 biocide concentration added to cane juice preserves

sucrose during mud filtration in agreement with [7],

76.00

[22]. According to this study, the optimum

75.00 concentration of biocide required to preserve the

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 highest amount of sucrose during mud filtration is 5.0

ppm.

Biocide Concentration [ppm]

B. Conclusion

Figure 2: Biocide Concentration Against Pol This study focused on the determination of

Percentage the optimum biocide concentration required to

minimize sugar loss during mud filtration, so that

From the Figure 2, subsequent to biocide sugar loss is cut to the lowest possible level. To this

concentration 5.0 ppm, purity does not increase point, the study investigated the brix, pol and purity

anymore. Therefore, 5.00 ppm is the optimum biocide of the resultant cane juice filtrate at varying biocide

concentration required to preserve the highest amount concentrations and determined the minimum biocide

of sucrose during mud filtration. concentration required to inhibit dextran formation

during sugar processing such that the highest amount

of sucrose is preserved during mud filtration. The

optimum biocide concentration required to preserve

VI. DISCUSSION, CONCLUSION AND the highest amount of sucrose during mud filtration

RECOMMENDATIONS was found to be 5.0 ppm.

A. Discussion C. Recommendations

The study found that the optimal biocide Following the findings presented here, this

concentration during sugar processing so that the study recommends the following: (i) since biocides

highest amount of sucrose is preserved during mud are effective in inhibiting microbial activities, they

filtration was 5.0 ppm; thus demonstrating that may be used for inhibition of dextran formation

biocides are successful in limiting sugar losses, in during cane juice purification so that the highest

tandem with [22]. To attain this optimal amount of sucrose may be preserved during mud

concentration, the biocide concentration had to be filtration and (ii) the optimum biocide (Dermacide-

increased gradually in consonance with the study by BD-2084) concentration to be used so that the highest

[33] who, using a similar procedure, attained amount of sucrose is preserved during mud filtration

minimum inhibitory concentration (MIC) to verify the is 5.0 ppm.

effect of chlorine dioxide, a well-known biocide, for

bacterial decontamination of water and equipment. REFERENCES

With regards to sugar processing, from Table II [1] M. E.Clarke,“Cane sugar process and byproduct

recovery of sucrose (as reflected in the purity rise) streams,”Paper presented at Iowa biotechnology consortium,

increases with increase of concentration of biocide San Diego, March 1991.

[2] A. J. Kent, Ed.,“Handbook of Industrial Chemistry and

applied. Beyond biocide concentration 5.0 ppm,

Biotechnology,” Volume 1 and 2, 12th Edition,Springer,

sucrose purity does not increase anymore. This then is ISBN 978-1-4614-4258-5 ISBN 978-1-4614-4259-2

the optimum biocide concentration required to (eBook). DOI 10.1007/978-1-4614-4259-2 Springer New

preserve the highest amount of sucrose during mud York Heidelberg Dordrecht London, Library of Congress

Control Number: 2012952590, 2012.

filtration.

[3] W. O. S.Doherty, J. Greenwood, D. Pilaski, P. G. Wright,

That at the beginning biocide concentration “The effect of liming conditions in juice clarification,” Proc

more-or-less linearly increase with sucrose purity, Aust Soc Sugar Cane Technol 24:443–451,2002.

given that biocides inhibit activities of [4] G. Eggleston, A. Monge, A., Pepperman, “Preheating and

incubation of cane juice prior to liming: a comparison of

microorganisms is indicative that at low dose biocides

intermediate and cold lime clarification,” J Agric Food

do not sufficiently inhibit activities of Chem 50:484–490,2002.

microorganisms as noted by [4, 22]. Upon preserving [5] G. Eggleston, A. Monge, B. Ogier, “Further insights on the

the highest amount (82.59%) of sucrose during mud factory performance of cold, intermediate and hot lime

clarification systems,” Proceedings of the sugar processing

filtration, there was a slight drop in sucrose purity

ISSN: 2394 – 5370 www.internationaljournalssrg.org Page 15

SSRG International Journal of Chemical Engineering Research ( SSRG – IJCER ) – Volume 4 Issue2 May to Aug 2017

research conference, vol 348–365, New Orleans, Louisiana, https://www.internationalsugarjournal.com/paper/2014/page

USA,(2002b). /7 on 14th April 2017.

[6] R. J. Steindl, “The clarification of cane juice. Int Sugar J [22] V. M. Kulkarni, “importance of controlling microbes during

101:213–215,1999. sugar production from cane and its effect on sugar yield and

[7] J. C. P.Chen,and J. S. Rauh, “Technical and Economic losses,” 6th International Sugar Conference, November 10 –

Justification for the use of Sugar Process Chemicals,”49th 13, Aswan, Egypt, 2012.

Annual Sugar Technologists Conf. (pp. 48-57), [23] M. Fowers, and L. E. Lloyd, “Biocide synergy: reducing

Hawaiian,1990. costs and losses through physical and chemical

[8] C. Scheibler, “Investigation on the nature of the gelatinous interactions,” Presented at the 30th general meeting of the

excretion (so-called frog‟s spawn) which is observed in American Society of Sugar Beet Technologists, Orlando,

production of beet-sugar juices,”Z Dtsch Zucker-Ind 24: FL, Feb., 1999.

309-335,1874. [24] M. Kunitake, C. Ditchfield, C. Silva, and R. Petrus, “Effect

[9] P. Van Tieghem, “Sur la gomme de sucrerie (On sugar-mill of Pasteurization Temperature on Stability of an Acidified

gum),”Ann Sci Natur Bot 7: 180-203,1878. Sugarcane Juice Beverage” Ciênc. Agrotec, Lavras, v.38,

[10] S. Kralj, G. H. van Geel-Schutten, M. M. G. Dondorff, S. n.6, p.554-561, nov./dez., 2014.

Kirsanovs, M. J. van der Maarel, and L. Dijkhuizen, [25] M. M.Bukhari, S. El Khaseh, A. Osman, and S. E. F.

“Glucan synthesis in the genus Lactobacillus: isolation and Hegazi, “Investigations of the influence of dextran on sugar

characterisation of six glucansucrases genes, enzymes and cane quality and sugar cane processing in Kenana sugar

glucan products from six different strains,”Microbiology factory,” Journal of Chemical and Pharmaceutical Research,

150(11): 3681-3690,2004. 2015, 7(4):381-392.

[11] M. S.Bounaix, H. Robert, V. Gabriel, S. Morel, M. Remaud- [26] S. Nel, “Microbial Diversity Profiling In Sugarcane

Siméon, B. Gabriel, and C. Fontagné-Faucher, Processing: What, Why And How?” Proc S Afr Sug

“Characterisation of dextran producing Weissella strains Technol Ass (2014) 87: 246 – 254.

isolated from sourdoughs and evidence of constitutive [27] M., S., B.de Cássia, C. Muller, H. C. do Amparo, and G. M.,

dextransucrase expression,”FEMS Microbiol Lett 311(1): de Aragão, “Survey of molds, yeast and Alicyclobacillus

18-26, 2010. spp. from a concentrated apple juice productive process,”

[12] A. Lakshmi-Bhavani, andJ. Nisha, J. “Dextran – The Braz J Microbiol, 2014 May 19;45 (1):49-58, eCollection,

polysaccharide with versatile uses‟”Int J Pharma Bio Sci 2014.

1(4): 569-573, 2010. [28] P. Antier, “Microbiological Control in Acane Sugar Mill:

[13] S. Palomba, S. Cavella, E. Torrieri, A. Piccolo, P. Mazzei, Implications on Sugar Quality and on Losses,”Proc S Afr

G. Blaiotta, V. Ventorino, and O. Pepe, “ Polyphasic Sug Technol Ass, 1996, pp. 185-188.

screening, homopolysaccharide composition and [29] J. A.Cuddihy Jr, M. E. Porro, and J. S. Raiih, “The presence

viscoelastic behaviour of wheat sourdough from a of total polysaccharides in sugar production and methods for

Leuconostoc lactis and Lactobacillus curvatus reducing their negative effects,”J Am Soc Sug Cane

exopolysaccharides producing starter culture,”Appl Environ Technol 21: 73-91, 2001

Microbiol 78(8): 2732-2747, 2012. [30] A. B. Ravnö, and B. S. Purchase, “Dealing with dextran in

[14] E. M.Paulo, M. P.Vasconcelos, I. S.Oliveira, H. M. J.Affe, the South African sugar industry,"Proc S Afr Sug Technol

R. Nascimento, I. S. de Melo,M. E. A.Roque., and S. A. de Ass 79: 28-47, 2005.

Assis, “An alternative method for screening lactic acid [31] L. A.Edye, M. A.Clarke, E. J. Roberts, and R. S. Blanco,

bacteria for the production of exopolysaccharides with rapid “Dextran analysis by N.M.R,” Publication of Technical

confirmation,”Ciênc Tecnol Aliment 32(4): 710-714,2012. Papers and Proceedings of the Sixty-Third Annual Meeting

[15] M. H. P. B.Vettori, K. C. Blanco, M. Cortezi, M, C. J. B. de of Sugar Technologists, Vancouver, Canada, S. I. T,55-64,

Lima, and J. Contiero, “Dextran: Effect of process 1995.

parameters on production, purification and molecular weight [32] , F. A.Guardiola, A. Cuesta, J. Meseguer, and A. E. M.

and recent applications,”Diálogos Ciência 31: 171-186, A.Maria,“Risks of Using Antifouling Biocides in

2012. Aquaculture,” International Journal of Molecular Sciences;

[16] E. R. Jimenez, “Biotecnologia Aplicada, 22(1), 20-27, 2005. 2012, 13, 1541-1560; doi:10.3390/ijms13021541, ISSN

[17] G. Cerutti de Guglielmone, O. Diez, G. Cárdenas, and G. 1422-0067 www.mdpi.com/journal/ijms.

Oliver, “Sucrose utilisation and dextran production by [33] S. P.Meneghin, F. C.Fabricia Cristina-Reis, P. Garcia de

Leuconostoc mesenteroides isolated from the sugar Almeida, andS. R. Ceccato-Antonini, “Chlorine dioxide

industry,”Sug J 62(10): 36-41, 2000. against bacteria and yeasts from the alcoholic

[18] R. H.Tilbury, B. S.Hollingsworth, S. D. Graham, andP. Fermentation,” Brazilian Journal of Microbiology (2008)

Pottage,“Mill sanitation: A fresh approach to biocide 39:337-343, ISSN 1517-8382337, 2008.

evaluation,” Proceeding of International Society of Sugar [34] R. Payton, “The freeze drying of organic materials,”

Cane Technologists, 16th Congress. pp. 2749-2767, 1977. unpublished report, Institute of Archaeology, 1980.

[19] P. Singh, N. Arya, P. Tiwari, A. Suman, R. K. Rai, A. K. [35] A. M. Rosenquist, “The Stabilizing of wood found in the

Shrivastava, and S. Solomon, “Use of Glutaraldehyde and Viking ship Oseberg – Part IV,”Studies in Conservation. 4

Benzalkonium Chloride for Minimizing Post-Harvest (1959), 62-72, 1959.

Physio-Chemical and Microbial Changes Responsible for [36] US Drug and Food Administration, 2016, CFR - Code of

Sucrose Losses in Sugar Cane,” J. Agric. Food Chem,2008, Federal Regulations Title 21, Volume 3. CITE:

56, 7176–7183. 21CFR173.320. Sec. 173.320 Chemicals for controlling

[20] P. G. Morel, S. du Boil and S. Wienese,“Enzymic reduction microorganisms in cane-sugar and beet-sugar mills, 2016.

of dextran in process - laboratory evaluation of [37] S. J. Kulkarni, and J. P., Kaware, “Groundnut Shell

dextranasesproc s afrsugtechnol” ASS, 76, 2002. Adsorbent in Packed Bed for Cadmium Removal- Modeling

[21] Z. G.Zhao, X. He, S. Yu, and H. Atsuya, “Optimizing for Breakthrough Curve,” SSRG International Journal of

conditions for dextranase application of sugarcane mixed Chemical Engineering Research, ISSN: 2394 – 5370, –

juice using response surface methodology,“International volume 2 Issue1 May to June 2014.

Sugar Journal,” 2014, Retrieved from:

ISSN: 2394 – 5370 www.internationaljournalssrg.org Page 16

You might also like

- Lehninger Principles of Biochemistry Test Bank CH 4Document13 pagesLehninger Principles of Biochemistry Test Bank CH 4Jubeena SadiqueNo ratings yet

- Clarke 1988Document14 pagesClarke 1988aruna prasadNo ratings yet

- Doherty2011 - Improved Sugar Cane Juice CL by Understanding CalciumOxide-Phosphate-Sucrose SysDocument8 pagesDoherty2011 - Improved Sugar Cane Juice CL by Understanding CalciumOxide-Phosphate-Sucrose SysMolly0630No ratings yet

- Optimal EgyptianfactorsaffectingnonsugareliminationDocument23 pagesOptimal EgyptianfactorsaffectingnonsugareliminationMohammed HassanNo ratings yet

- Okra Project AcuoDocument7 pagesOkra Project Acuopacoto livingstoneNo ratings yet

- CPT Final PBLDocument5 pagesCPT Final PBLsyedhafza4No ratings yet

- The Influence of Oxidizing and Non-Oxidizing BiociDocument14 pagesThe Influence of Oxidizing and Non-Oxidizing BiociGIANFRANCO JESUS PUICAN POPUCHENo ratings yet

- Chapter - 2 Sugar Manufacturing ProcessDocument13 pagesChapter - 2 Sugar Manufacturing Processalan kharelNo ratings yet

- Chapter 1 Sugare Production ProcessDocument51 pagesChapter 1 Sugare Production ProcessAddis WelelawNo ratings yet

- Production of Vinegar From PineappleDocument11 pagesProduction of Vinegar From PineappleYahaya Danjuma BabaNo ratings yet

- Pengolahan Limbah Buangan Industri Tahu Dengan Menggunakan Bioreaktor Biakan Melekat Secara Anaerob-AerobDocument12 pagesPengolahan Limbah Buangan Industri Tahu Dengan Menggunakan Bioreaktor Biakan Melekat Secara Anaerob-AerobRizky AnjanaNo ratings yet

- The Effect of Liming Conditions in Juice ClarificationDocument12 pagesThe Effect of Liming Conditions in Juice Clarificationmohammed amerNo ratings yet

- Review Article: The Role of Microbes in Coffee Fermentation and Their Impact On Coffee QualityDocument7 pagesReview Article: The Role of Microbes in Coffee Fermentation and Their Impact On Coffee QualityKIMCHI TAEGUKNo ratings yet

- Appl. Environ. Microbiol. 2008 Dumbrepatil 333 5Document3 pagesAppl. Environ. Microbiol. 2008 Dumbrepatil 333 5DHENADANo ratings yet

- IJRTI2303037Document8 pagesIJRTI2303037vivekNo ratings yet

- 7 PBDocument7 pages7 PBat6315763No ratings yet

- DAIRY INDUSTRY, Sugar Industry, Paper and Pulp, Textile Mill WasteDocument79 pagesDAIRY INDUSTRY, Sugar Industry, Paper and Pulp, Textile Mill WasteHemantha RajuNo ratings yet

- LionnetDocument537 pagesLionnetYadav Shweta100% (3)

- Ijpab 2017 5 2 379 386Document8 pagesIjpab 2017 5 2 379 386Harsha Vardhan ReddyNo ratings yet

- Chem Project XII (1) ARYAN KAUSHIKDocument16 pagesChem Project XII (1) ARYAN KAUSHIKAryan PanwarNo ratings yet

- Physicochemical, Morphological, Functional, and Pasting Properties of Potato Starch As A Function of Extraction MethodsDocument16 pagesPhysicochemical, Morphological, Functional, and Pasting Properties of Potato Starch As A Function of Extraction MethodsanandaNo ratings yet

- Journal of Food Science - 2021 - Rani - Quality Attributes For Barley Malt The Backbone of BeerDocument19 pagesJournal of Food Science - 2021 - Rani - Quality Attributes For Barley Malt The Backbone of Beeralbalo15No ratings yet

- Ramos 2009Document4 pagesRamos 2009Julieth Orduña OrtegaNo ratings yet

- Isca RJCS 2017 048Document11 pagesIsca RJCS 2017 048Hanumi Oktiyani RusdiNo ratings yet

- Environmental Factsheet: Succinic Acid: Product InformationDocument4 pagesEnvironmental Factsheet: Succinic Acid: Product Informationchintya kewotNo ratings yet

- The Dextranase Along Sugar-Making IndustryDocument8 pagesThe Dextranase Along Sugar-Making IndustryaxgxpNo ratings yet

- Cas Sales 2011Document9 pagesCas Sales 2011Camila NevesNo ratings yet

- Introduction To The Sugar Industry WastewaterDocument2 pagesIntroduction To The Sugar Industry WastewaterNemo Cyzar LiisNo ratings yet

- Biological Losses in Milling TandemDocument6 pagesBiological Losses in Milling TandemMaydolNo ratings yet

- US20100062503A1Document6 pagesUS20100062503A1Rismalita Wardani 1707122911No ratings yet

- Citric Acid Production by Solid State Fermentation Using Sugarcane BagasseDocument8 pagesCitric Acid Production by Solid State Fermentation Using Sugarcane BagasseHritik LalNo ratings yet

- Synthesisand Mass Balanceof Citric Acidfrom Sugarcane Molasses Using Bakers Yeastand Submerged Batch Fermentation TechniqueDocument5 pagesSynthesisand Mass Balanceof Citric Acidfrom Sugarcane Molasses Using Bakers Yeastand Submerged Batch Fermentation Technique19L1031099 LÊ THỊ THỦYNo ratings yet

- Module 14: SanitationDocument22 pagesModule 14: Sanitationsena100% (1)

- Yadav Et Al., 2017Document5 pagesYadav Et Al., 2017Ajeng MayzaNo ratings yet

- Barna Baston DarabaDocument6 pagesBarna Baston DarabaOpal Priya WeningNo ratings yet

- Research Paper Sugar MillDocument6 pagesResearch Paper Sugar MillVaishnavi SrivastavaNo ratings yet

- Membrane Separation Beer IndustryDocument16 pagesMembrane Separation Beer IndustryMarina ButuceaNo ratings yet

- Sugar IndustryDocument27 pagesSugar IndustryChali HaineNo ratings yet

- Oonkhanond 2017Document37 pagesOonkhanond 2017Gebby FebriliaNo ratings yet

- Lecture Notes Osmotic DehydrationDocument11 pagesLecture Notes Osmotic DehydrationJasvir Mann100% (1)

- Characterization of Orange Peel Waste and Valorization To Obtain Reducing SugarsDocument21 pagesCharacterization of Orange Peel Waste and Valorization To Obtain Reducing Sugarsyvet garciaNo ratings yet

- Ethanol-Water Fractionation of Sugar Cane Bagasse Catalyzed With AcidsDocument10 pagesEthanol-Water Fractionation of Sugar Cane Bagasse Catalyzed With AcidsAlphonse SambranoNo ratings yet

- 1956 Marches Liming of Cane JuicesDocument19 pages1956 Marches Liming of Cane JuicesGustavo CardonaNo ratings yet

- 222222Document20 pages222222Hoàng TấnNo ratings yet

- Raw Cane Sugar Production: Robles, Mariecor Elsie BDocument5 pagesRaw Cane Sugar Production: Robles, Mariecor Elsie BElsie RoblesNo ratings yet

- Vinegar From PineappleDocument12 pagesVinegar From PineappleMarites ParaguaNo ratings yet

- ClarificationDocument10 pagesClarificationuglysnrNo ratings yet

- Residual Yoghurt Whey For Lactic Acid ProductionDocument8 pagesResidual Yoghurt Whey For Lactic Acid ProductionJuan Daniel GuaquetaNo ratings yet

- Biology Class 12 Microbes in Human WelfareDocument30 pagesBiology Class 12 Microbes in Human Welfaresouravsinghrathore.2006No ratings yet

- Culture Development of Baker-S Yeast in Spent Fermentation Broth For Production of Single Cell Protein (Abstract)Document1 pageCulture Development of Baker-S Yeast in Spent Fermentation Broth For Production of Single Cell Protein (Abstract)Komathi BalasupramaniamNo ratings yet

- Food Bioscience: Arifin Dwi Saputro, Davy Van de Walle, Koen DewettinckDocument8 pagesFood Bioscience: Arifin Dwi Saputro, Davy Van de Walle, Koen Dewettincklaycang malangNo ratings yet

- Production and Total Quality ManagementDocument12 pagesProduction and Total Quality ManagementPrachi PatilNo ratings yet

- Recovery Processes of Organic Acids From Fermentation Broths inDocument8 pagesRecovery Processes of Organic Acids From Fermentation Broths inRocio ChongNo ratings yet

- Sensors 22 06247 v2Document11 pagesSensors 22 06247 v2nimmi kumariNo ratings yet

- The Sugar IndustryDocument22 pagesThe Sugar IndustryAbraham wisdomNo ratings yet

- Tebu Thai2012Document8 pagesTebu Thai2012111280No ratings yet

- Impact of Malolactic Fermentation With LactobacillDocument19 pagesImpact of Malolactic Fermentation With LactobacillLaurie DevilersNo ratings yet

- Journal FYP 6Document7 pagesJournal FYP 6Mira FazziraNo ratings yet

- Sugar RefiningDocument64 pagesSugar RefiningVenus Abigail Gutierrez100% (1)

- Patent PA153178P - A PROCESS FOR EXTRACTING MUCILAGE FROM OPUNTIA FICUS-INDICA, ALOE BARBADENSIS AND AGAVE AMERICANADocument50 pagesPatent PA153178P - A PROCESS FOR EXTRACTING MUCILAGE FROM OPUNTIA FICUS-INDICA, ALOE BARBADENSIS AND AGAVE AMERICANAAlba Du ToitNo ratings yet

- Ijms 18 01395Document17 pagesIjms 18 01395Pavan KNo ratings yet

- Ijfans Vol1 Issue1 Article14Document12 pagesIjfans Vol1 Issue1 Article14Pavan KNo ratings yet

- GMN 018Document9 pagesGMN 018Pavan KNo ratings yet

- Goetz 2004Document13 pagesGoetz 2004Pavan KNo ratings yet

- C15 Notes CH6 Solutions Acids and BasesDocument10 pagesC15 Notes CH6 Solutions Acids and BasesArnie100% (1)

- Using Chitosan To Extend Shelf Life Research Proposal Mantillas X-Faraday (Final)Document7 pagesUsing Chitosan To Extend Shelf Life Research Proposal Mantillas X-Faraday (Final)Tristan Jay AranasNo ratings yet

- BELANJA BHP Medis SinarindoDocument183 pagesBELANJA BHP Medis SinarindowerryNo ratings yet

- EAD 350454-00-1104 Penetration SealsDocument52 pagesEAD 350454-00-1104 Penetration SealsLuke PeachNo ratings yet

- Control of Nitrosamine Impurities in Human Drugs PDFDocument24 pagesControl of Nitrosamine Impurities in Human Drugs PDFSrinivasNo ratings yet

- Overview On Basic Chemistry of UV-curing TechnologyDocument32 pagesOverview On Basic Chemistry of UV-curing TechnologyEugene PaiNo ratings yet

- SHORT NOTES RA SirDocument19 pagesSHORT NOTES RA Sirmdmanzaralam6278No ratings yet

- Reactions of Benzene and Its DerivativeDocument46 pagesReactions of Benzene and Its Derivativequyenda08hhaNo ratings yet

- BIOL BCHM 111 BiomoleculesDocument49 pagesBIOL BCHM 111 BiomoleculeshavenNo ratings yet

- Gomes Basso BeansDocument9 pagesGomes Basso Beansjuan diegoNo ratings yet

- Brady Art PPT Ch02Document55 pagesBrady Art PPT Ch02ok paijoNo ratings yet

- Unit 1 Molecules, Diet, Transport and HealthDocument61 pagesUnit 1 Molecules, Diet, Transport and HealthGem VanabrikshaNo ratings yet

- Primer DesignDocument37 pagesPrimer DesignRyu- MikaNo ratings yet

- Thermal Cracking of Fischer-Tropsch WaxesDocument6 pagesThermal Cracking of Fischer-Tropsch WaxesSyed Mustafa Hussain Zaidi100% (1)

- About The Dyes: Dyes For Cellulose FibersDocument4 pagesAbout The Dyes: Dyes For Cellulose FibersmanqabatNo ratings yet

- Biomolecules SheetDocument21 pagesBiomolecules SheetMahendra Shah100% (1)

- Chem273 Take Home LabDocument12 pagesChem273 Take Home LabMentari Permata HatiNo ratings yet

- 2010 JanDocument160 pages2010 JanaliceNo ratings yet

- pc2 MCQDocument27 pagespc2 MCQYashwant ChauhanNo ratings yet

- Topic 6.1Document22 pagesTopic 6.1Nehir TorunoğluNo ratings yet

- Karnafuli Paper Mills ProcessDocument59 pagesKarnafuli Paper Mills Processsvo svo67% (3)

- Instrutech®: Rohs Compliance StatementDocument3 pagesInstrutech®: Rohs Compliance StatementsolNo ratings yet

- SR Elite (Set - 2), SR Aiims S60 & Neet MPL Neet Module Test - 3 Paper (01-04-2024)Document26 pagesSR Elite (Set - 2), SR Aiims S60 & Neet MPL Neet Module Test - 3 Paper (01-04-2024)prabha bandaruNo ratings yet

- 17.salt Aluminium Sulphate 3Document3 pages17.salt Aluminium Sulphate 3Sarthika GaulkarNo ratings yet

- Rapid Approach To Biobased Telechelics Through Two One-Pot Thiol-Ene Click ReactionsDocument8 pagesRapid Approach To Biobased Telechelics Through Two One-Pot Thiol-Ene Click ReactionsbelkhamasNo ratings yet

- Common Polyatomic IonsDocument1 pageCommon Polyatomic Ionsmudasser_rafiq3271No ratings yet

- Astm D-5577Document5 pagesAstm D-5577williamcondoriNo ratings yet

- A.env.0107 Covered Ponds Final ReportDocument108 pagesA.env.0107 Covered Ponds Final ReportKedir omerNo ratings yet

- Greases and Grease Thickener Systems: Dr. George S. Dodos, Chemical Engineer, ELDON'S S.ADocument2 pagesGreases and Grease Thickener Systems: Dr. George S. Dodos, Chemical Engineer, ELDON'S S.AHesham MahdyNo ratings yet