Professional Documents

Culture Documents

Error Message

Error Message

Uploaded by

AGH BIOMEDOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Error Message

Error Message

Uploaded by

AGH BIOMEDCopyright:

Available Formats

SECTION 6 ERROR MESSAGE 6.2.28 Settings Error ......................................................

17

6.2.29 Stored Error .........................................................17

Alphabetical error messages list is on the next page. 6.2.30 QC Data Error......................................................17

6.2.31 No Printer Paper..................................................18

6.1 ERROR CODE and report PRIORITY ..................................1 6.2.32 Printer Error.........................................................19

6.2.33 Print Buffer Full....................................................20

6.2 ERROR MESSAGES ...........................................................2 6.2.34 HC Buffer Full ......................................................20

6.2.1 Vacuum Error.........................................................2 6.2.35 LAN Buffer Full ....................................................20

6.2.2a Waste C. Error 1....................................................4 6.2.36 HC Off-Line .........................................................21

6.2.2b Discard Waste 1 ....................................................4 6.2.37 HC ACK Timeout .................................................21

6.2.38 HC NAK Retry .....................................................22

6.2.3a Replace Diluent 1 ..................................................4

6.2.39 LAN no Response ...............................................22

6.2.3b Replace Lyse 1 ......................................................4

6.2.40 PPMC Cont. Error................................................23

6.2.4 MC Drain Error.......................................................6 6.2.41 WBC Noise Error .................................................23

6.2.5 Piercer MT Error (UD)............................................7 6.2.42 RBC Noise Error..................................................23

6.2.6 Piercer MT Error (FB) ............................................7 6.2.43 PLT Noise Error ...................................................23

6.2.7 Syringe MT Error (Diluent) .....................................7 6.2.44 Tube holder Err....................................................24

6.2.8 Syringe MT Error (Sample Aspiration)....................7 6.2.45 R-Cover Open .....................................................25

6.2.9 PinchV1 MT Error ..................................................8 6.2.46 Setting Seq. Error ................................................26

6.2.10 Piercer MC Error (UD) .........................................10

6.2.46 Drain Reag. Error 9 .............................................26

6.2.11 Piercer MC Error (FB) ..........................................10

6.2.12 Syringe MC Error (Diluent)...................................10

6.2.13 Syringe MC Error (Reagent Aspiration)................10

6.2.14 PinchV1 MC Error ................................................10

6.2.15 PinchV2 MC Error ................................................10

6.2.16 Aperture Clog ...................................................... 11

6.2.17 Temp. Error (H) Room Temp. (H) 9......................12

6.2.18 Temp. Error (L) Room Temp. (L) 9.......................12

6.2.19 Blank Error...........................................................13

6.2.20 WBC Smp’g Error ................................................14 1 303B046, 9 303J056

6.2.21 RBC Smp’g Error .................................................14

6.2.22 PLT Smp’g Error ..................................................14

6.2.23 HGB Error............................................................15

6.2.24 QC (L-J) Error......................................................16

6.2.25 QC (X) Error ........................................................16

6.2.26 RAM Error............................................................16

6.2.27 ROM Error ...........................................................16

pocH-100i S/M (i) December 13, 2007

<A> <Q>

Aperture Clog ..................................................................... 11 QC Data Error ....................................................................17

QC (L-J) Error ....................................................................16

<B> QC (X) Error.......................................................................16

Blank Error .........................................................................13

<R>

<D> R-Cover Open....................................................................25

Discard Waste 1 ..................................................................4 RAM Error ..........................................................................16

Drain Reag. Error 9............................................................26 RBC Noise Error ................................................................23

RBC Smp’g Error ...............................................................14

<H>

Replace Diluent 1 ................................................................4

HC ACK Timeout ................................................................21

Replace Lyse 1 ....................................................................4

HC Buffer Full.....................................................................20

HC NAK Retry ....................................................................22 ROM Error .........................................................................16

HC Off-Line ........................................................................21 Room Temp. (H) 9 .............................................................12

HGB Error ..........................................................................15 Room Temp. (L) 9 ..............................................................12

<L> <S>

LAN Buffer Full...................................................................20 Settings Error .....................................................................17

LAN no Response ..............................................................22 Setting Seq. Error ..............................................................26

Stored Error .......................................................................17

<M> Syringe MC Error (Diluent) .................................................10

MC Drain Error .....................................................................6 Syringe MC Error (Reagent Aspiration) ..............................10

Syringe MT Error (Diluent) ...................................................7

<N>

Syringe MT Error (Sample Aspiration) ..................................7

No Printer Paper ................................................................18

<T>

<P>

Tube holder Err. .................................................................24

Piercer MC Error (FB) ........................................................10

Piercer MC Error (UD)........................................................10 <V>

Piercer MT Error (FB)...........................................................7 Vacuum Error .......................................................................2

Piercer MT Error (UD) ..........................................................7

PinchV1 MC Error ..............................................................10 <W>

PinchV1 MT Error.................................................................8 Waste C. Error 1 ..................................................................4

PinchV2 MC Error ..............................................................10 WBC Noise Error ...............................................................23

PLT Noise Error..................................................................23 WBC Smp’g Error ..............................................................14

PLT Smp’g Error.................................................................14

PPMC Cont. Error ..............................................................23

1 303B046, 9 303J056

Printer Error .......................................................................19

Print Buffer Full ..................................................................20

pocH-100i S/M (ii) December 13, 2007

SECTION 6 ERROR MESSAGE

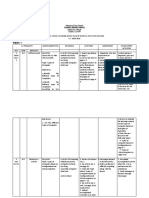

6.1 ERROR CODE AND REPORT PRIORITY

The following indicates message on the screen and the priority for each

error.

Priority Error Message Error Code Priority Error Message Error Code

1 RAM Error 431010 27 PinchV1 MT Error 216000

2 ROM Error 431020 28 Vacuum Error 112100

3 Settings Error 431030 29 MC Drain Error 143010

4 Stored Error 463000 30 R-Cover Open 421510

5 QC Data Error 432010 31 Tube holder Err. 421210

6 Print Buffer Full 448030 32 Waste C. Error 1 141000

7 HC Buffer Full 441120 33 Discard Waste 1 141190

8 LAN Buffer Full 486030 34 Replace Diluent 1 131000

9 Printer Error 448010 35 Replace Lyse 1 133220

10 No Printer Paper 448020 36 WBC Noise Error 412010

11 HC Off-line 441020 37 RBC Noise Error 412020

12 HC ACK Timeout 441030 38 PLT Noise Error 412030

13 HC NAK Retry 442020

39 Blank Error 411010

14 LAN no Response 486000

15 PPMC Cont. Error 451600 40 Aperture Clog 331010

16 Piercer MC Error (U/D) 452240 41 HGB Error 415000

17 Piercer MC Error (F/R) 452250 42 WBC Smp’g Error 413010

18 Syringe MC Error (Diluent) 452260 43 RBC Smp’g Error 413020

19 Syringe MC Error (Sample) 452270 44 PLT Smp’g Error 413030

20 Pinch V1 MC Error 452280 45 QC(X) Error 461150

21 Pinch V2 MC Error 452290 46 QC(L-J) Error 461160

22 Setting Seq. Err 429090 47 122511

Room Temp. Error (H) 9

23 Piercer MT Error (U/D) 269020

48 Room Temp. Error (L) 9 122516

24 Piercer MT Error (F/R) 269030

25 Syringe MT Error (Diluent) 215110 49 Drain Reag. Err. 9 429090

26 Syringe MT Error (Sample) 214010

1 303B046, 9 303J056

pocH-100i S/M 6-1 December 13, 2007

6.2 ERROR MESSAGES < Pneumatic Error >

6.2.1 Vacuum Error

This section explains about the described items for each error message.

(1) Error Code

(1) Error Code

Error Code Sub-code 1 Sub-code 2

The error code for each error and 2 kinds of sub-codes “Sub-code 1” 112100 Pressure value when the Time after pressing the

and “Sub-code 2”, which indicate the information of an error. Error Occurred. Start SW till the error is

Error Code will be displayed with 6 digits maximum. Sub-code 1 “0.021 Mpa” will be displayed displayed.

and 2 will be displayed with 4 digits maximum. as “210”.

If the sub-code becomes less than maximum 4 digits, zero

suppression will be taken and left aligned as below. (2) Status

Example: “123000.1200.0000” will be displayed as “123.12.0”.

All mechanical system stops immediately.

(2) Status

The system status when the error occurred. (3) Monitoring Method

(3) Monitoring Method Check Timing: WB Mode:

Total 13 times since opening the pinch valve after

The check timing, judgment module and monitoring method. starting analysis till rinsing sequence before next

sample analysis. (0.1 second before draining/filling

(4) pocH-100i’s Action chambers or opening pinch valve)

The pocH-100i’s action when the error occurred. PD Mode:

Total 12 times in the same time frame as WB

(5) Action to be Taken Mode.

Your probable action to clear the error. Judgment Method: System monitors the A/D converted value from

vacuum sensor. When it reads less than the

“VACUUM1 L” value set in the Hardware Limit,

reports the error. (Default: 0.0180 MPa)

pocH-100i S/M 6-2 December 13, 2007

(4) pocH-100i’s Action

1) System displays the error dialog when the error is detected.

2) All mechanical system stops immediately.

3) If the error occurred before counting sequence completed, all results

are masked with asterisks (*). 1

If the error occurred after counting sequence completed, the

analysis results are all reported.

(5) Action to be Taken

1) Press [Execute] on the Help screen to start up the recovery

sequnece and error is removed.

When the recovery sequence is completed normally, Auto Rinse and

background check will run automatically. (The background check

may extend maximum 3 cycles.) After completing the background

check, Main screen appears.

NOTE: When the system is in Service Mode, this Auto Rinse and

background check are not performed.

2) Press [Cancel] key on the Help screen to display the previous

screen.

Figure 6-2-1: Vacuum Sensor (PCB No. 3057T1)

pocH-100i S/M 6-3 December 13, 2007

< Chamber Related Error > (4) pocH-100i’s Action

6.2.2a Waste C. Error 1

6.2.2b Discard Waste 1 1) Displays the error dialog when the error is detected.

(1) Error Code 2) If the error occurred before counting sequence completed, all results

are masked with asterisks (*). 1

Error Code Sub-code 1 Sub-code 2 If the error occurred after counting sequence completed, the

Waste C. Error: 141000 0 Time after pressing the Start analysis results are all reported.

Discard Waste: 141190 SW till the error is displayed.

(2) Status (5) Action to be Taken

Next analysis is disable. 1) Press [Execute] on the Help screen to start up the recovery

sequnece and error is removed.

(3) Monitoring Method When the recovery sequence is completed normally, run the Auto

Rinse and background check. 1 (The background check may extend

Check Timing: Waste Chamber is monitored during WBC counting. maximum 3 cycles.) After completing the background check, Main

Waste Container is monitored at start/end of screen appears.

analysis and during WBC counting.

Judgment Method Waste C. Error: 2) Press [Cancel] key on the Help screen to display the previous

Error is reported when Float SW in Waste Chamber screen.

(SNS5) turns OFF (filled).

Discard Waste:

Error is reported when Float SW in Waste

Container (SNS8) turns OFF (filled). 6.2.3a Replace Diluent 1

6.2.3b Replace Lyse 1

(1) Error Code

Error Code Sub-code 1 Sub-code 2

Replace Diluent: 131000 Error condition. Time after pressing the

Replace Lyse: 133220 See (4) below. Start SW till the error is

displayed.

1 303B046

Figure 6-2-2: Waste Chamber (Left Interior)

pocH-100i S/M 6-4 December 13, 2007

(2) Status (4) pocH-100i’s Action

Next analysis is disable. 1) Displays the error dialog when the error is detected.

Sub-Code 1 indicates the sensor which detected the error as below:

(3) Monitoring Method 1: Diluent air bubble sensor

2: Diluent Chamber float SW

Check Timing: Diluent: During WBC/RBC counting. 4: Lyse air bubble sensor

Lyse: While the syringe is charging the lyse. 10: Diluent expired

When starting a test, the reagent expiry date and 20: Diluent test number counter is “0” 1

test number is checked. 40: Lyse expired

80: Lyse test number counter is “0” 1

Judgment Method Replace Diluent:

Error is reported when Diluent line air bubble sensor NOTE:

(SNS 3) is ON (detected air), and/or when Diluent When two or more sensors detect the error, the numbers are added.

Chamber float SW (SNS 7) is ON (empty) Ex.) When both bubble sensors detect the error status,

Replace Lyse: 1+4 = “5” is indicated.

Error is reported when Lyse line air bubble sensor

(SNS 4) is ON (detected air). 2) All mechanical system stops immediately.

3) If the error occurred before counting sequence completed, all results

are masked with asterisks (*). 1

If the error occurred after counting sequence completed, the

analysis results are all reported.

4) Change the lyse reagent bottle indicator to an empty bottle. 1

(5) Action to be Taken

Figure 6-2-3-1: Air Bubble Sensors (Left Interior) 1) Press [Execute] on the Help screen to start up the reagent

replacement sequnece and error is removed.

If reagent replacement sequence is not completed properly, the

error will be detected again and returns to the previous screen of the

Help display screen.

2) Press [Cancel] key on the Help screen to display the previous

screen.

1 303B046

Figure 6-2-3-2: Diluent Chamber (Right Interior)

pocH-100i S/M 6-5 December 13, 2007

6.2.4 MC Drain Error

(1) Error Code

Error Code Sub-code 1 Sub-code 2

143010 Pressure value when the Time after pressing the

Error Occurred. Start SW till the error is

“0.021 Mpa” will be displayed.

displayed as “210”.

(2) Status

Next analysis is disable.

(3) Monitoring Method

Check Timing: Just after discharging diluent from the Mixing

Chamber after rinsing chamber.

Judgment Method: System monitors the A/D converted value from

vacuum sensor. When it reads less higher than the

“VACUUM2 L” value set in the Hardware Limit,

reports the error. (Default: 0.0320 MPa) 1

Detector

Mixing Chamber Figure 6-2-4-2: Vacuum Sensor (PCB No. 3057T1)

Figure 6-2-4-1: Mixing Chamber Location

1 303B046

pocH-100i S/M 6-6 December 13, 2007

(4) pocH-100i’s Action < Motor Related Errors >

6.2.5 Piercer MT Error (UD)

1) System displays the error dialog when the error is detected. 6.2.6 Piercer MT Error (FB)

6.2.7 Syringe MT Error (Diluent)

2) If the error occurred before counting sequence completed, all results 6.2.8 Syringe MT Error (Sample Aspiration)

are masked with asterisks (*). 1

If the error occurred after counting sequence completed, the Refer to Section 2.4 for the location of each motor. Jump to Section 2.4

analysis results are all reported.

(1) Error Code

(5) Action to be Taken Error Code Sub-code 1 Sub-code 2

Piercer MT Error Error Time after pressing the

1) Press [Execute] on the Help screen to start up the recovery (UD): 269020 condition. Start SW till the error is

sequnece and error is removed. (FB): 269030 See (4) below. displayed.

When the sequence is completed, the error is removed and Main Syringe MT Error

Screen appears. (Diluent): 215110

(Sample): 214010

2) Press [Cancel] key on the Help screen to display the previous

screen. (2) Status

All mechanical system stops immediately.

(3) Monitoring Method

Check Timing: Piercer U/D: When moving up to the upper limit.

Piercer F/B: When moving to the front limit.

Diluent Syringe: When moving to the lower limit.

Sample Syringe: When moving to the upper limit.

Judgment Method: Error is reported when the sensor is OFF, or does

not operated by the specified pulse.

(4) pocH-100i’s Action

1) All mechanical system stops immediately.

pocH-100i S/M 6-7 December 13, 2007

2) Displays the error dialog when the error is detected. 6.2.9 PinchV1 MT Error

Sub-Code 1 indicates the motor status which the error is detected. :

1: Does not stop at the limit position at specified timing. (1) Error Code

2: Stops at the limit position at unexpected timing.

4: Does not stop within the specified time. Error Code Sub-code 1 Sub-code 2

8: Overrun. 216000 Pressure value when Time after pressing the Start

NOTE: When two or more phenomena are observed, the numbers the Error Occurred. SW till the error is displayed.

are added. “0.018 Mpa” will be

Ex.) When the motor overrun and does not stop at the limit when displayed as “180”.

specified, 1+8 = “9” is indicated.

(2) Status

3) If the error occurred before counting sequence completed, all results

are masked with asterisks (*). 1 All mechanical system stops immediately.

If the error occurred after counting sequence completed, the

analysis results are all reported. (3) Monitoring Method

Check Timing: During start-up, error recovery, and auto rinse

(5) Action to be Taken sequences.

Judgment Method: System monitors the A/D converted value from

1) For FSRs only:

vacuum sensor. When it exceeds the “VACUUM1

The error is recovered by Motor Test program. Press [Cancel]on the

L” value set in the Hardware Limit, reports the error.

Help screen to exit Help. Select [Service]-[Test Operation]-

(Default: 0.0180 MPa)

[SV/MT Test] from Main Menu, and press the corresponding motor

button. Pinch Valve 1

[MT1]: Diluent Syringe [MT2]: Piercer U/D

[MT3]: Sample Syringe [MT4]: Piercer F/RD

Refer to Section 5.5.1 for the Motor Test program.

Jump to Section 5.5.1

2) For customers:

Press [Execute] on the Help screen to move the power OFF

preparation process. It becomes ready to be powered OFF safely.

The system will be recovered when re-started.

3) Press [Cancel] key on the Help screen to display the previous

screen.

Pinch Valve 2

Figure 6-2-9-1: Pinch Valve Location

pocH-100i S/M 6-8 December 13, 2007

(4) pocH-100i’s Action

1) System displays the error dialog when the error is detected.

2) All mechanical system stops immediately.

3) If the error occurred before counting sequence completed, all results

are masked with asterisks (*). 1

If the error occurred after counting sequence completed, the

analysis results are all reported.

(5) Action to be Taken

1) For FSRs only:

The error is recovered by Motor Test program. Press [Cancel]on the

Help screen to exit Help. Select [Service]-[Test Operation]-

[SV/MT Test] from Main Menu, and press the corresponding motor

button.

[MT5]: Pinch Valve operation only.

[MT6]: Pinch Valve operation while applying vacuum.

Either test will clear the error.

Refer to Section 5.5.1 for the Motor Test program.

Jump to Section 5.5.1

2) For customers:

Press [Execute] on the Help screen to move the power OFF

preparation process. It becomes ready to be powered OFF safely.

The system will be recovered when re-started.

3) Press [Cancel] key on the Help screen to display the previous

screen.

Figure 6-2-9-2: Vacuum Sensor (PCB No. 3057T1)

pocH-100i S/M 6-9 December 13, 2007

6.2.10 Piercer MC Error (UD) (4) pocH-100i’s Action

6.2.11 Piercer MC Error (FB)

6.2.12 Syringe MC Error (Diluent) 1) Displays the error dialog when the error is detected.

6.2.13 Syringe MC Error (Reagent Aspiration)

6.2.14 PinchV1 MC Error 2) All mechanical system stops immediately.

6.2.15 PinchV2 MC Error

3) If the error occurred before counting sequence completed, all results

(1) Error Code are masked with asterisks (*). 1

If the error occurred after counting sequence completed, the

Error Code Sub-code 1 Sub-code 2 analysis results are all reported.

Piercer MC Error (UD): 452240

Piercer MC Error (FB): 452250 0 0

Syringe MC Error (Diluent): 452260 (5) Action to be Taken

Syringe MC Error (Sample): 452270

PinchV1 MC Error: 452280 1) Press [Execute] on the Help screen to move the power OFF

PinchV2 MC Error: 452290 preparation process. It becomes ready to be powered OFF safely.

The system will be recovered when re-started.

(2) Status

2) Press [Cancel] key on the Help screen to display the previous

All mechanical system stops immediately. System restart is required. screen.

(3) Monitoring Method

Check Timing: When driving the motor.

Judgment Method: The error is reported if communication error is

detected between the PCB No.3057T1 (driver) and

PPMC controller on PCB No. 6374 (CPU).

pocH-100i S/M 6-10 December 13, 2007

< Detector Related Error > (4) pocH-100i’s Action

6.2.16 Aperture Clog

1) Displays the error dialog when the error is detected.

(1) Error Code

2) If the error occurred before counting sequence completed, all results

Error Code Sub-code 1 Sub-code 2 are masked with asterisks (*). 1

331010 (Se/Sh)x1000 A/D converted value of RBC Clog If the error occurred after counting sequence completed, the

Refer to (3) below. Detection Voltage (Max. value) analysis results are all reported.

(2) Status

(5) Action to be Taken

The analysis is available.

1) Any analysis sequence or clog removal sequence can clear the

error.

(3) Monitoring Method Press [Execute] on the Help screen to start the “Clean Transducer”

sequence. Execusion of “Clog Removal” from “Mainte.”, WB/PD

Check Timing: During RBC counting or WBC analysis. 2 mode analysis, background check, etc. is also effective.

Judgment Method: During RBC/PLT counting, the A/D converted value 2) Press [Cancel] key on the Help screen to display the previous

of RBC clog detection voltage is monitored every screen.

0.5 seconds. Error is reported if it becomes larger

than the “Clog-R” of Hardware Limits setting.

At WBC clog level check, the following calculation is

satisfied.

Se/Sh > CLOG_LTM_W

Se: Mean of sampling data before gate off.

Sh: Mean of flat part sampling data.

CLOG_LTM_W: A Hardware Limits setting

(Default value: 30.0%)

NOTE: The error is judged only when WBC total

count is 1000 or more, and Sh is 1 or

more.

Reference: RBC clog is monitored by the sequence program,

and WBC clog by system program using different

methods. 2 200315

pocH-100i S/M 6-11 December 13, 2007

< Temperature Errors > (4) pocH-100i’s Action

6.2.17 Temp. Error (H) Room Temp. (H) 9

6.2.18 Temp. Error (L) Room Temp. (L) 9 1) Displays the error dialog when the error is detected.

(1) Error Code 2) If the error occurred, all results are masked with asterisks (*). 1

9

Error Code Sub-code 1 Sub-code 2

Room Temp. Error (H): 122511 Temperature 0 (5) Action to be Taken

Room Temp. Error (L): 122516 35.1°C : 351

1) Press [Back] key on the Help screen to display the previous screen.

(2) Status The temperature and the acceptable range, when the error occurred,

will be displayed on the Help screen.

The analysis is available.

2) The error will be recovered when starting either of the WB mode

(3) Monitoring Method analysis, the PD mode analysis or the background check sequence.

Check Timing: During WBC counting.

Judgment Method: The system compares the A/D converted value

from thermistor and Hardware Setting values as;

“Temp. Error (H)” when higher than “TEMP H”

(default: 40°C), and

“Temp. Error (L)” when lower than “TEMP L”

(default: 14 10°C). 9

1 303B046, 9 303J056

Figure 6-2-17:Thermistor (in Detector Block)

pocH-100i S/M 6-12 December 13, 2007

< Analysis Related Errors > (5) Action to be Taken

6.2.19 Blank Error

1) Press [Execute] on the Help screen to start the “Auto Rinse”

(1) Error Code program. Or select [Mainte.]-[Auto Rinse] program.

When the auto rinse sequence is completed without problem,

Error Code Sub-code 1 Sub-code 2 background check automatically starts. (Extended to max. 3 times of

411010 0 0 background check.)

During the background check, the error is removed when all the

(2) Status results are within the above limits, and Main menu appears.

The analysis is available. 2) Press [Cancel] key on the Help screen to display the previous

screen.

(3) Monitoring Method

Check Timing: After the background check analysis is completed.

Judgment Method: When the results exceed the following, the error is

reported.

3

WBC: 0.3 [X10 /µL]

6

RBC: 0.02 [X10 /µL]

HGB: 0.1 [g/dL]

3

PLT: 10 [X10 /µL]

(4) pocH-100i’s Action

1) Displays the error dialog when the error is detected.

pocH-100i S/M 6-13 December 13, 2007

6.2.20 WBC Smp’g Error (4) pocH-100i’s Action

6.2.21 RBC Smp’g Error

6.2.22 PLT Smp’g Error 1) Displays the error dialog when the error is detected.

(1) Error Code 2) The related parameter results are masked with asterisks (*). 1

Error Code Sub-code 1 Sub-code 2

WBC Smp’g Error: 413010 0 0 (5) Action to be Taken

RBC Smp’g Error: 413030

PTL Smp’g Error: 413030 1) Any analysis sequence or clog removal sequence can clear the

error.

(2) Status Press [Execute] on the Help screen to start the “Clean Transducer”

sequence. Execusion of “Clog Removal” from “Mainte.”, WB/PD

Analysis becomes available when the sequence is completed. mode analysis, background check, etc. is also effective.

(3) Monitoring Method 2) Press [Cancel] key on the Help screen to display the previous

screen.

Check Timing: After the data analysis of the sample or background

check analysis is completed.

Judgment Method: The maximum/minimum sampling data and the total

count satisfy the following formula, error is reported.

WBC Sampling Error 9

Maximum Value - Minimum Value - 50 x 100 > 2.3 3.0 [%]

Total Sampling Value

*: 7th through 19th sampling data are used.

RBC Sampling Error

Maximum Value-Minimum Value – 200 x 100 > 3.0 [%] 9 303J056

Total Sampling Value

nd

*: 2 through 19th sampling data are used.

PLT Sampling Error

Maximum Value - Minimum Value – 100 x 100 > 3.0 [%]

Total Sampling Value

nd

*: 2 through 19th sampling data are used.

pocH-100i S/M 6-14 December 13, 2007

6.2.23 HGB Error (5) Action to be Taken

(1) Error Code 1) Any background check sequence can clear the error.

Press [Execute] on the Help screen to start the “Clean Transducer”

Error Code Sub-code 1 Sub-code 2 sequence. Execusion of “Auto Rinse” from “Mainte.”, WB/PD mode

415000 Converted value (blank) Converted value (sample) analysis, etc. is also effective.

(2) Status 2) Press [Cancel] key on the Help screen to display the previous

screen.

The analysis is available.

(3) Monitoring Method

Check Timing: After the data analysis is completed.

Judgment Method: Error is reported if either of the following is satisfied.

Blank < 50

Blank > 10000

Sample - Blank < -50

Sample - Blank > 3600

NOTE: The Hgb converted values are also checked

on [Maint.]-[Status Display] screen.

(4) pocH-100i’s Action

1) Displays the error dialog when the error is detected.

2) The system becomes Ready after the sequence is completed

however “* (an unreliable mark)” will be added to the related data.

pocH-100i S/M 6-15 December 13, 2007

6.2.24 QC (L-J) Error < Memory Related Errors >

6.2.25 QC (X) Error 6.2.26 RAM Error

6.2.27 ROM Error

(1) Error Code

(1) Error Code

Error Code Sub-code 1 Sub-code 2

QC (L-J) Error: 461160 0 0 Error Code Sub-code 1 Sub-code 2

QC (X) Error: 461150 RAM Error: 431010 0 0

ROM Error: 431020

(2) Status

(2) Status

The analysis is available.

The application will not start. System restart is required.

(3) Monitoring Method (3) Monitoring Method

Check Timing: While executing QC analysis. Check Timing: At power ON.

Judgment Method: Error is detected when any of the QC analysis result Judgment Method: RAM Error - Data read from the work memory is not

exceeds the QC Limit. identical with the written data in the work memory.

ROM Error - Incorrect checksum.

(4) pocH-100i’s Action (4) pocH-100i’s Action

1) Displays the error dialog when the error is detected. RAM Error: The system stops with the continuous beep. Nothing is

displayed on the LCD.

2) The operation will be continued and completed normally. ROM Error: The system stops with 16 times of intermittent short beep if

the error occurred in BIOS area. If the error occurred in

Logo area, the system stops with the continuing short

(5) Action to be Taken beeps.

1) Press [Back] key on the Help screen to exit the Help. Run QC again. (5) Action to be Taken

Error is recovered when the QC analysis result falls within the limits.

1) Turn the power OFF/ON.

pocH-100i S/M 6-16 December 13, 2007

6.2.28 Settings Error (5) Action to be Taken

6.2.29 Stored Error

6.2.30 QC Data Error 1) Press [Recov.] key on the Help screen to execute the recovery.

Stored Error and QC Error – The system deletes the records of

(1) Error Code which the checksum disagreed.

Settings Error – The system mirrors the correct files of redundant.

Error Code Sub-code 1 Sub-code 2 After the compliance of the file system, the system urges to restart.

Settings Error: 431030 0 0 If the recovery is disable, the file of which the error is detected will

Stored Error: 463000 be initialized.

QC Data Error: 432010

2) Press [Init.] key on the Help screen to display the confirmation

(2) Status screen.

Press [Execute] key on the confirmation screen to initialize whole

The application will not start. System restart is required. file system of BBURAM, stored files, QC files, setting values. After

restructuring of the system and compliance of the file system, the

system urges to restart.

(3) Monitoring Method Press [Cancel] key on the confirmation screen to display the restart

request screen.

Check Timing: During system check at power ON.

Judgment Method: Settings - The system checks both checksum

values of the redundant files.

Stored Data and QC - The system checks the

number of the maximum record and a number of

the stored record, and the checksum of each

record.

(4) pocH-100i’s Action

1) Displays the Help screen when the error is detected.

pocH-100i S/M 6-17 December 13, 2007

< Built-in Printer Related Errors > (4) pocH-100i’s Action

6.2.31 No Printer Paper

1) Displays the error dialog when the error is detected.

(1) Error Code

2) Completes the current analysis, then interrupts the next sample

Error Code Sub-code 1 Sub-code 2 analysis.

448020 0 0

(2) Status (5) Action to be Taken

Next analysis is disable. 1) Set the printer paper and press [Retry] key on the Help screen to

recover the error. Re-print the data from the beginning of each

sample.

(3) Monitoring Method

2) Press [Cancel] key on the Help screen to stop the current printing or

Check Timing: During print out performance. to cancel the output of the data in the buffer.

Judgment Method: Error is reported when the paper sensor of the Error is removed and the previous screen appears.

built-in printer detects no paper.

Figure 6-2-31: Paper Sensor

pocH-100i S/M 6-18 December 13, 2007

6.2.32 Printer Error (4) pocH-100i’s Action

(1) Error Code 1) Displays the error dialog when the error is detected.

Error Code Sub-code 1 Sub-code 2 2) Completes the current analysis, then interrupts the next sample

448010 0 0 analysis.

(2) Status

(5) Action to be Taken

Next analysis is disable.

Analysis becomes available when the error is recovered. 1) Press [Retry] key on the Help screen to recover the error. Re-print

the data from the beginning of each sample.

(3) Monitoring Method

2) Press [Cancel] key on the Help screen to stop the current printing or

Check Timing: During printout. to cancel the output of the data in the buffer.

Judgment Method: Error is reported when the built-in printer tries to Error is removed and the previous screen appears.

start printing while the cover is half-open, or the

printer cover half-opens during printing.

NOTE: When the printing starts with the cover

full-open, “No Printer Paper” error occurs.

Figure 6-2-32: Printer Cover Sensor

pocH-100i S/M 6-19 December 13, 2007

6.2.33 Print Buffer Full < Host Related Errors >

6.2.34 HC Buffer Full

(1) Error Code 6.2.35 LAN Buffer Full

Error Code Sub-code 1 Sub-code 2 (1) Error Code

448030 0 0

Error Code Sub-code 1 Sub-code 2

(2) Status HC Buffer Full: 441120 0 0

LAN Buffer Full: 486030

Next analysis is disable.

Analysis becomes available when the error is recovered. (2) Status

(3) Monitoring Method Next analysis is disable.

Analysis becomes available when the error is recovered.

Check Timing: When printout is assigned.

Judgment Method: Error is reported when output buffer overflows. (3) Monitoring Method

Check Timing: When data transmission is assigned.

(4) pocH-100i’s Action Judgment Method: Error is reported when output buffer overflows.

1) Displays the error dialog when the error is detected. (4) pocH-100i’s Action

2) Completes the current analysis, then interrupts the next sample

1) Displays the error dialog when the error is detected.

analysis.

2) Completes the current analysis, then interrupts the next sample

3) The data in the buffer is discarded.

analysis.

3) The data in the buffer is discarded.

(5) Action to be Taken

(5) Action to be Taken

1) Press [Back] key on the Help screen to recover the error. The data

output which is currently being processed will be continued. 1) Press [Back] key on the Help screen to recover the error. The data

output which is currently being processed will be continued.

pocH-100i S/M 6-20 December 13, 2007

6.2.36 HC Off-Line 6.2.37 HC ACK Timeout

(1) Error Code (1) Error Code

Error Code Sub-code 1 Sub-code 2 Error Code Sub-code 1 Sub-code 2

441020 0 0 441030 0 0

(2) Status (2) Status

Next analysis is disable. Next analysis is disable.

Analysis becomes available when the error is recovered. Analysis becomes available when the error is recovered.

(3) Monitoring Method (3) Monitoring Method

Check Timing: During data transmission between the host Check Timing: During data transmission between the host

computer. computer.

Judgment Method: Error is reported in the following cases: Judgment Method: Error is reported in the following cases:

- Frame error, parity error, or overrun error is - CTS does not become active within 5 seconds

detected while receiving the data from the Host. after sending the data to the Host.

- DSR is not active. - ACK or NAK is not sent from the Host within 15

- A code except ACK or NAK is sent from Host seconds after sending the data to the Host.

after sending the data to the Host.

(4) pocH-100i’s Action

(4) pocH-100i’s Action

1) Displays the error dialog when the error is detected.

1) Displays the error dialog when the error is detected. 2) Completes the current analysis, then interrupts the next sample

2) Completes the current analysis, then interrupts the next sample analysis.

analysis.

(5) Action to be Taken

(5) Action to be Taken

1) Press [Retry] key on the Help screen to clear the error and retry the

1) Press [Retry] key on the Help screen to clear the error and retry the

data transmission.

data transmission.

2) Press [Cancel] key on the Help screen to clear the error. All HC

2) Press [Cancel] key on the Help screen to clear the error. All HC

output data in buffer will be deleted.

output data in buffer will be deleted.

pocH-100i S/M 6-21 December 13, 2007

6.2.38 HC NAK Retry 6.2.39 LAN no Response

(1) Error Code (1) Error Code

Error Code Sub-code 1 Sub-code 2 Error Code Sub-code 1 Sub-code 2

442020 0 0 486000 0 0

(2) Status (2) Status

Next analysis is disable. Next analysis is disable.

Analysis becomes available when the error is recovered. Analysis becomes available when the error is recovered.

(3) Monitoring Method (3) Monitoring Method

Check Timing: During data transmission between the host Check Timing: During data transmission between the host

computer. computer when the LAN connection is selected by

Judgment Method: Error is reported if any code except ACK is sent Host Setting menu.

forth time after sending data to the Host. Judgment Method: Error is reported if TCP/IP connection cannot be

established.

(4) pocH-100i’s Action

(4) pocH-100i’s Action

1) Displays the error dialog when the error is detected.

1) Displays the error dialog when the error is detected.

2) Completes the current analysis, then interrupts the next sample

analysis. 2) Completes the current analysis, then interrupts the next sample

analysis.

(5) Action to be Taken

(5) Action to be Taken

1) Press [Retry] key on the Help screen to clear the error and retry the

data transmission. 1) Press [Retry] key on the Help screen to clear the error and retry the

data transmission.

2) Press [Cancel] key on the Help screen to clear the error. All HC

output data in buffer will be deleted. 2) Press [Cancel] key on the Help screen to clear the error. All HC

output data in buffer will be deleted.

pocH-100i S/M 6-22 December 13, 2007

< Other Errors > 6.2.41 WBC Noise Error

6.2.40 PPMC Cont. Error 6.2.42 RBC Noise Error

6.2.43 PLT Noise Error

(1) Error Code

(1) Error Code

Error Code Sub-code 1 Sub-code 2

451600 0 0 Error Code Sub-code 1 Sub-code 2

WBC Noise Error: 412010 Total Count Over/

(2) Status RBC Noise Error: 412020 Histogram Memory Over: 1 0

PLT Noise Error: 412030 Memory Clear Error: 2

All mechanical system stops immediately. System restart is required.

(2) Status

The analysis is available.

(3) Monitoring Method

(3) Monitoring Method

Check Timing: At power ON.

Judgment Method: The PPMC controller initialization is failed. Check Timing: After the data analysis of the sample or background

check analysis.

Judgment Method: The error is reported in the following cases:

(4) pocH-100i’s Action - Clear of histogram memory or total counter

(logger circuit) is failed.

1) Displays the error dialog when the error is detected. - Any channel of histogram memory (logger circuit)

overflows. (exceeds 65535)

2) All mechanical system stops immediately. - Any channel of total counter (logger circuit)

overflows. (exceeds 16770000)

(5) Action to be Taken (4) pocH-100i’s Action

1) Press [Execute] on the Help screen to move the power OFF 1) Displays the error dialog when the error is detected.

preparation process. It becomes ready to be powered OFF safely. 2) Current sequence is continued and ended normal.

The system will be recovered when re-started. 3) The related parameter results are masked with asterisks (*). 1

2) Press [Cancel] key on the Help screen to display the previous (5) Action to be Taken

screen.

1) Press [Back] key on the Help screen to display the previous screen.

2) The error will be recovered when the next analysis is started.

pocH-100i S/M 6-23 December 13, 2007

6.2.44 Tube holder Err. (4) pocH-100i’s Action

(1) Error Code 1) Displays the error dialog when the error is detected.

Error Code Sub-code 1 Sub-code 2 2) All mechanical system stops immediately.

421210 0 0

3) If the error occurred before counting sequence completed, all results

(2) Status are masked with asterisks (*). 1

If the error occurred after counting sequence completed, the

All mechanical system stops immediately. analysis results are all reported.

Next analysis is disable.

(3) Monitoring Method (5) Action to be Taken

Check Timing: While the piercer is moving up/down at sample 1) Press [Execute] on the Help screen to start up the recovery

aspiration position. “Aspirating…” is displayed on sequnece and error is removed.

the LCD. When the recovery sequence is completed normally, Auto Rinse and

Judgment Method: Error is reported when cover sensor (SNS 1) turns background check will run automatically. (The background check

OFF (open). may extend maximum 3 cycles.) After completing the background

check, Main screen appears.

2) Press [Cancel] key on the Help screen to display the previous

screen.

NOTE: When [Start] key is pressed with the cover open, an alarm

dialog is displayed but no error is reported.

Figure 6-2-44: Tube Holder Cover Sensor

pocH-100i S/M 6-24 December 13, 2007

6.2.45 R-Cover Open (4) pocH-100i’s Action

(1) Error Code 1) Displays the error dialog when the error is detected.

Error Code Sub-code 1 Sub-code 2 2) All mechanical system stops immediately, then drains the

421510 0 0 transduder.

(2) Status 3) All results are masked with asterisks (*). 1

All mechanical system stops immediately.

Next analysis is disable. (5) Action to be Taken

(3) Monitoring Method 1) Close the Right Side Cover.

Press [Execute] on the Help screen to start up the recovery

Check Timing: Every 100 ms except in the following program. sequnece and error is removed.

- Gain Adjustment When the recovery sequence is completed normally, Auto Rinse and

- Piercer Adjust background check will run automatically. (The background check

- SV/MT Test may extend maximum 3 cycles.) After completing the background

check, Main screen appears.

Judgment Method: Error is reported when the right side cover sensor

(SNS 6) is ON (open). 2) Press [Cancel] key on the Help screen to display the previous

screen.

Figure 6-2-45: Right Side Cover Sensor

pocH-100i S/M 6-25 December 13, 2007

6.2.46 Setting Seq. Error 6.2.46 Drain Reag. Error 9

(1) Error Code (1) Error Code

Error Code Sub-code 1 Sub-code 2 Error Code Sub-code 1 Sub-code 2

429090 0 0 429091 0 0

(2) Status (2) Status

System restart is required. The analysis is available.

(3) Monitoring Method (3) Monitoring Method

Check Timing: After completing the Setting Sequence. Check Timing: When starting up the Drain Reagent sequence.

Judgment Method: Any error requiring immediate mechanical stop, Judgment Method: While attempting to aspirate reagents, air bubble

such as motor error or vacuum error, occurred while sensors detected no air (SNS 3 and/or SNS4 is

the Setting Sequence is running. OFF).

(4) pocH-100i’s Action (4) pocH-100i’s Action

1) Displays the error dialog when the error is detected. 1) Displays the error dialog when the error is detected.

(5) Action to be Taken (5) Action to be Taken

1) Press [Execute] on the Help screen to move the power OFF 1) Check if no reagent containers are connected to the reagent inlet

preparation process. It becomes ready to be powered OFF safely. nipples.

The system will be recovered when re-started. Press [Execute] on the Help screen to execute reagent draining

sequence again. After completing the sequence normally, power

2) Press [Cancel] key on the Help screen to display the previous OFF the instrument, as instructed on the LCD.

screen.

2) Press [Cancel] key on the Help screen to display the previous

screen.

9 303J056

pocH-100i S/M 6-26 December 13, 2007

You might also like

- Xstore Suite-1702 - Implementation GuideDocument357 pagesXstore Suite-1702 - Implementation Guidebtm1981100% (3)

- XN-1000 2000 E 06 TroubleshootingDocument219 pagesXN-1000 2000 E 06 TroubleshootingAndrey TitenkoNo ratings yet

- XT Series E 06 Error Messages PDFDocument324 pagesXT Series E 06 Error Messages PDFjyoti ranjanNo ratings yet

- Manual Ram-400339-Af PDFDocument48 pagesManual Ram-400339-Af PDFRebeca Zarazúa Díaz0% (1)

- Open EMR Database Structure.Document1 pageOpen EMR Database Structure.Michael GeorgeNo ratings yet

- Project Management Chapter 8 Exercise Answer KeyDocument14 pagesProject Management Chapter 8 Exercise Answer Keymkashif041No ratings yet

- 8BK88 O&M ManualDocument36 pages8BK88 O&M Manualt_syamprasadNo ratings yet

- Book VTRDocument106 pagesBook VTRsauhovietNo ratings yet

- Powerboat Handling Illustrated: How to Make Your Boat Do Exactly What You Want It to DoFrom EverandPowerboat Handling Illustrated: How to Make Your Boat Do Exactly What You Want It to DoRating: 4.5 out of 5 stars4.5/5 (6)

- XN-L E Chap06 Error MessagesDocument136 pagesXN-L E Chap06 Error Messagessuraj adhikariNo ratings yet

- Error MessagesDocument53 pagesError Messagesall you need كل ما تحتاجNo ratings yet

- 728 InstalDocument56 pages728 InstalValentin VirbanNo ratings yet

- KX SM 06 Error PDFDocument65 pagesKX SM 06 Error PDFNavin kumarNo ratings yet

- XP Series E 06 Error MessagesDocument33 pagesXP Series E 06 Error MessagesJavi MedinaNo ratings yet

- HVCB Timing ApplicationDocument52 pagesHVCB Timing Applicationbhuban mohanNo ratings yet

- 728ult Ei00Document56 pages728ult Ei00Roberto QuindNo ratings yet

- Chapter 6 Error Messages: April 27, 2012 XP Series S/MDocument34 pagesChapter 6 Error Messages: April 27, 2012 XP Series S/MspirisNo ratings yet

- 1 Mbit (128Kb x8, Uniform Block) Single Supply Flash Memory: Feature SummaryDocument36 pages1 Mbit (128Kb x8, Uniform Block) Single Supply Flash Memory: Feature Summarymohammed el azhariNo ratings yet

- XS Series E 06 Error MessagesDocument72 pagesXS Series E 06 Error Messagesjocund55No ratings yet

- Rexa Troubleshoot ManualDocument338 pagesRexa Troubleshoot Manual1904sofia100% (2)

- 16mb Burst cr1 0 p23z PDFDocument59 pages16mb Burst cr1 0 p23z PDFcarmen123485No ratings yet

- Wa0011.Document60 pagesWa0011.alexandre.gozaloariasNo ratings yet

- Error MessagesDocument53 pagesError MessagesHuseyn aliyevNo ratings yet

- Caddy Tig 1500i-2200i - 0740 800 186 - Serv - ManDocument50 pagesCaddy Tig 1500i-2200i - 0740 800 186 - Serv - ManJunior ÁudioTech100% (1)

- Radio HefDocument76 pagesRadio HefmijahauanNo ratings yet

- SV19CD19Document66 pagesSV19CD19ed shittieNo ratings yet

- 24c64 DatasheetDocument26 pages24c64 DatasheetNom AkNo ratings yet

- M29F400BB70N6EDocument42 pagesM29F400BB70N6EGiapy Phuc TranNo ratings yet

- Sepam Gen 1Document35 pagesSepam Gen 1MehmetAtayNo ratings yet

- Tech Compact DR PlusDocument72 pagesTech Compact DR PlusrafikNo ratings yet

- Nand 01 GW 3 B 2 N 6Document64 pagesNand 01 GW 3 B 2 N 6marquitos550bNo ratings yet

- Section 6 Error Message: To CoverDocument44 pagesSection 6 Error Message: To CoverNGUYEN MEDICALNo ratings yet

- ST M48T86 Real Time Clock IC DatasheetDocument29 pagesST M48T86 Real Time Clock IC DatasheetIvan PetrofNo ratings yet

- Infineon-Z8F54978222_TLE7250V-ApplicationNotes-v01_20-ENDocument26 pagesInfineon-Z8F54978222_TLE7250V-ApplicationNotes-v01_20-ENalexmihai_scribdNo ratings yet

- Sepam Protocol 2Document33 pagesSepam Protocol 2MehmetAtayNo ratings yet

- M29F080DDocument37 pagesM29F080DHELVER GIOVANNI RODRIGUEZ VEGANo ratings yet

- Arena ProtocolDocument87 pagesArena Protocolclaudiu33No ratings yet

- 24 C 16 WDocument34 pages24 C 16 WmaldomattNo ratings yet

- Burner Control Unit BCU 440: Technical Information GBDocument37 pagesBurner Control Unit BCU 440: Technical Information GBjose luizNo ratings yet

- BC-348-J, - N, - QDocument76 pagesBC-348-J, - N, - QhydisNo ratings yet

- WR Workbench Ocd Command Ref 2.6Document148 pagesWR Workbench Ocd Command Ref 2.6sweden043No ratings yet

- M28W640FCBDocument55 pagesM28W640FCBmichaelliu123456No ratings yet

- Parts List KUKADocument26 pagesParts List KUKAmalikwaqasahmad41No ratings yet

- Elcometer 345 ManualDocument37 pagesElcometer 345 ManualLeigh Villalva Raymundo60% (5)

- ESAB Origo Mig 4002cw, 4002c, 5002cw, 5002c, 6502cw, 6502c Instruction ManualDocument64 pagesESAB Origo Mig 4002cw, 4002c, 5002cw, 5002c, 6502cw, 6502c Instruction ManualToader MarcuNo ratings yet

- File 11 060f737db116526.88891431Document35 pagesFile 11 060f737db116526.88891431Patrick ByronNo ratings yet

- AN2586 Application Note: STM32F10xxx Hardware Development: Getting StartedDocument28 pagesAN2586 Application Note: STM32F10xxx Hardware Development: Getting StartedRouaissi RidhaNo ratings yet

- MiindexDocument10 pagesMiindexmarboudNo ratings yet

- User Manual Ems 3p 4m enDocument22 pagesUser Manual Ems 3p 4m enCiprian CiurdeaNo ratings yet

- LT 1866Document38 pagesLT 1866cherraj ahmedNo ratings yet

- M 58 WRXXXKTBDocument111 pagesM 58 WRXXXKTBvijayasimhasNo ratings yet

- Design For Testing HandbookDocument31 pagesDesign For Testing HandbookRalf Conrado ScodelerNo ratings yet

- M95M01 125Document37 pagesM95M01 125edilberp30No ratings yet

- CA-1500 SM #6 Error MessagesDocument56 pagesCA-1500 SM #6 Error Messagesjakab.m.atilaNo ratings yet

- VNQ660SP DatasheetDocument26 pagesVNQ660SP Datasheetroberto caiadoNo ratings yet

- XE SM 06 ErrorDocument64 pagesXE SM 06 ErrorАлексейNo ratings yet

- User Manual NSA1120 140415Document101 pagesUser Manual NSA1120 140415Small HopesNo ratings yet

- M29F800DT M29F800DB: 8 Mbit (1Mb x8 or 512Kb x16, Boot Block) 5V Supply Flash MemoryDocument40 pagesM29F800DT M29F800DB: 8 Mbit (1Mb x8 or 512Kb x16, Boot Block) 5V Supply Flash MemoryAn as akrasNo ratings yet

- 29F200Document67 pages29F200antonio bonfimNo ratings yet

- E-935 Mfs Alarm DictionaryDocument146 pagesE-935 Mfs Alarm DictionarySimranbir SinghNo ratings yet

- Circuit Description Board4 0 DocV1 3Document38 pagesCircuit Description Board4 0 DocV1 3CONG TRAN NGOCNo ratings yet

- Intermittent Convex Integration for the 3D Euler Equations: (AMS-217)From EverandIntermittent Convex Integration for the 3D Euler Equations: (AMS-217)No ratings yet

- MechDocument6 pagesMechAGH BIOMEDNo ratings yet

- SchematicsDocument8 pagesSchematicsAGH BIOMEDNo ratings yet

- Past Update RecordDocument3 pagesPast Update RecordAGH BIOMEDNo ratings yet

- Professional Medical ProductsDocument6 pagesProfessional Medical ProductsAGH BIOMEDNo ratings yet

- User Manual: o - Two E700Document60 pagesUser Manual: o - Two E700AGH BIOMEDNo ratings yet

- DS-K1T331 Series Face Recognition Terminal: User ManualDocument154 pagesDS-K1T331 Series Face Recognition Terminal: User ManualJuan Carlos BastardoNo ratings yet

- Word Associate Module 5 Tasks L1 To L5Document29 pagesWord Associate Module 5 Tasks L1 To L5Габриела МихайловаNo ratings yet

- Microelectronic PillsDocument33 pagesMicroelectronic PillsAnu MavelyNo ratings yet

- Wireline Xy enDocument4 pagesWireline Xy enJuanNo ratings yet

- PCM 5864Document141 pagesPCM 5864delearntubeNo ratings yet

- KDocument3 pagesKsantosh_san20No ratings yet

- Computer Organization HamacherDocument171 pagesComputer Organization Hamachernelson acevedo100% (1)

- ARC3 1.1 Jun12 StudentWorkbookDocument255 pagesARC3 1.1 Jun12 StudentWorkbookQuimicos ColombiaNo ratings yet

- 4R1 FN08 XFC01Document2,684 pages4R1 FN08 XFC01jorge ajata valerianoNo ratings yet

- Thesis Rev 3Document47 pagesThesis Rev 3usama khalidNo ratings yet

- AD9951 AppnoteDocument6 pagesAD9951 Appnoteshabaz_yousaf2734No ratings yet

- HTML Interview QuestionsDocument15 pagesHTML Interview QuestionsSteve StewardNo ratings yet

- CC DorksDocument6 pagesCC DorksSmith RelsNo ratings yet

- F5 Customer Demo: BIG-IP AFM - Use Global RulesDocument9 pagesF5 Customer Demo: BIG-IP AFM - Use Global RulesAries Raf OndisNo ratings yet

- Engine TelegraphDocument4 pagesEngine TelegraphBrillyanNo ratings yet

- String in JavaDocument29 pagesString in JavaChaudhari Pranali BharatNo ratings yet

- SAMPLE Weekly Learning Block Plan ICT CSS G10Document4 pagesSAMPLE Weekly Learning Block Plan ICT CSS G10Jhobhel Christopher GalivoNo ratings yet

- Gelan AbdurehmanDocument6 pagesGelan AbdurehmanGelan AbdurehmanNo ratings yet

- The Kimore Dataset: Kinematic Assessment of Movement and Clinical Scores For Remote Monitoring of Physical RehabilitationDocument14 pagesThe Kimore Dataset: Kinematic Assessment of Movement and Clinical Scores For Remote Monitoring of Physical RehabilitationEbubeNo ratings yet

- Full Chapter Data Mashup With Microsoft Excel Using Power Query and M Finding Transforming and Loading Data From External Sources Adam Aspin PDFDocument54 pagesFull Chapter Data Mashup With Microsoft Excel Using Power Query and M Finding Transforming and Loading Data From External Sources Adam Aspin PDFjohnnie.randall809100% (5)

- Maths Grade 9 Assignment Gauteng Term 1 2022 QP and MemoDocument11 pagesMaths Grade 9 Assignment Gauteng Term 1 2022 QP and MemosayamengaweNo ratings yet

- Student Performance AnalysisDocument6 pagesStudent Performance AnalysisMohamed BoussakssouNo ratings yet

- Auditing in CIS Environment - Auditing IT Governance ControlsDocument69 pagesAuditing in CIS Environment - Auditing IT Governance ControlsLuisitoNo ratings yet

- ASU ToolboxDocument8 pagesASU ToolboxYanira ParraNo ratings yet

- Linear AlgebraDocument296 pagesLinear Algebrarberio100% (1)

- CS Practicals Xii 2022 23Document26 pagesCS Practicals Xii 2022 23ajinkyarsingh2006No ratings yet

- Scribus An IntroductionDocument148 pagesScribus An Introductionlarosa.ilarioNo ratings yet