Professional Documents

Culture Documents

9965NC1

9965NC1

Uploaded by

Linh LyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9965NC1

9965NC1

Uploaded by

Linh LyCopyright:

Available Formats

Environmental

Operating -55 °C (-67 °F) to 200 °C (392

Temperature: °F), sensing end

Storage -55 °C (-67 °F) to 110 °C (230

Temperature: °F), entire unit is limited by tag

and shrink tubing

200125 Thermocouple Installation Humidity: Up to 100% relative humidity,

Guide condensing

Vibration: Up to 50 m/s² pk (5.1g pk)

continuous, 500 m/s² pk (51g pk)

short duration

Shock: Will survive a 1-metre drop to a

concrete floor.

Physical

Case Material: 304 Stainless Steel

Insulation/Sheathing: Teflon®, Neoflon® PFA Duplex

Insulation, 304 SS overbraid

Cable Size: 20 AWG Solid

Mechanical: 23 kgf (50 lb) static pull parallel

12 kgf (25 lb) static pull

perpendicular

Specifications

Operation outside of the specified limits can result in false

or inaccurate readings.

Electrical

Calibration: Type K

Accuracy: ±1.1°C (±2 °F), per ANSI MC96.1

Special Limits

Resistance: 1.92 Ω per Double Metre @ 20 °C

(0.585 Ω per Double Foot @ 68 °F) CRIMPED REGION

Isolation: 600 Vrms, less than 1mA current

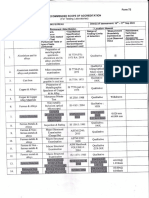

50.8 [2.00]

Polarity (USA, Positive = Yellow 5/16-24 UNF 29.7 [1.17]

ANSI MC96.1): Negative = Red POSITION OF SENSING ELEMENT 2.55 [0.10]

Dimensions are mm[in] 6.48 [0.26]

Figure 1: Thermocouple Case Dimensions

200125 Thermocouple Installation Guide 1 of 2

P/N 149965-01, Revision NC

Field Installation

The 200125 Trendmaster® Thermocouple can be installed in

various configurations. The installation techniques and

practices used can impact performance. To maximize sensor

performance note the following:

1. Install the thermocouple shown in figure 1 with the

tip 1 in contact with the surface to be measured. If

a mounting adapter is used such as that shown in

figure 2, adjust adapter and threaded case to establish

3

contact with the surface to be measured at point 1 .

50.8 [2.00] REF

2

2. Tighten the thermocouple jam nut 2 from 11.3 to

12.7 [0.50] 2.54 [0.10]

16.9 N*m (100 to 150 in-lb). The jam nut prevents

the thermocouple from coming loose whether

CUT AWAY

1

installed as shown in figure 1 or as shown using the

adapter in figure 2.

53.34 [2.10] Note: Do not apply more than 5.6 N*m (50 in-lb) torque

15.24 [0.60] to the crimped region 3 on the thermocouple shown in

figure 1. Damage to the thermocouple may result.

9.52 [0.38]

10.41 [0.41] 19.05 [0.75] Note: Use an appropriate thread-locking compound on

the jam nut and thermocouple threads.

Dimensions are mm[in]

Figure 2: Thermocouple and Optional Right Angle Warning

Mounting Adapter

Route thermocouple cable away from high voltage

lines. Contact with exposed wires can cause

injury or death.

3. Route the thermocouple cable away from excessive

heat, sharp edges, and high voltages. Maintain a

bend radius of 25.4 mm (1 in) or greater.

4. Tie the thermocouple cable at a point no more than

153 mm (6 inches) from the threaded steel sensor

case. Secure remaining cable at regular intervals.

Proper securing of the cable will minimize cable

fatigue failure caused by excessive cable motion. See

figure 3.

Electrical Connection

The 200125 Trendmaster® Thermocouple connects to type k

interfaces. Standard ANSI color coding (USA, ANSI MC96-

BENTLY

NEVADA

R

1-82) is used on the thermocouple wire.

• Outer Jacket – Brown

HOUSTON, TX

ACCELEROMETER

PART NO. 200150

DATE CODE

• Positive – Yellow

• Negative – Red

Refer to the appropriate interface instructions for further

Figure 3: Vibration Transducer and Thermocouple details.

© 2001 Bently Nevada Corporation

Trendmaster® is a registered mark of Bently Nevada

Teflon® is a registered mark of DuPont Corporation

Neoflon® is a registered mark of Daikin Industries, LTD.

200125 Thermocouple Installation Guide 2 of 2

P/N 149965-01, Revision NC

You might also like

- 0337NC1Document6 pages0337NC1Linh Ly100% (1)

- Prince New Price List 2021-22Document1 pagePrince New Price List 2021-22Shivam Kumar67% (9)

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- Boundary Wall Design Staad File PDFDocument6 pagesBoundary Wall Design Staad File PDFParwan Exceltech0% (1)

- OrnamentsDocument62 pagesOrnamentsopanak100% (4)

- Gs01c20b04-00e (18) Ej130Document8 pagesGs01c20b04-00e (18) Ej130Nguyen ThuongNo ratings yet

- Trendmaster® 2000 Thermocouple - Install Guide PDFDocument4 pagesTrendmaster® 2000 Thermocouple - Install Guide PDFchicaokNo ratings yet

- TDS - Terluran GP-22 PDFDocument3 pagesTDS - Terluran GP-22 PDFebercueNo ratings yet

- Nylacast Moly Cast Nylon 6, MoS2 FilledDocument3 pagesNylacast Moly Cast Nylon 6, MoS2 Filledprasad.jppmNo ratings yet

- Re4H1Le: Type of CableDocument4 pagesRe4H1Le: Type of CableMena KamelNo ratings yet

- Gs01c20d01-00e (19) Ej310Document8 pagesGs01c20d01-00e (19) Ej310Nguyen ThuongNo ratings yet

- Re4H1Le: Type of CableDocument4 pagesRe4H1Le: Type of CableMena KamelNo ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- 2p en dpd1t - dpd2tDocument2 pages2p en dpd1t - dpd2tghNo ratings yet

- CCT 3000 Technical SheetDocument14 pagesCCT 3000 Technical SheetcecepQQNo ratings yet

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoNo ratings yet

- GPT - Honeywell Pressure SensorDocument10 pagesGPT - Honeywell Pressure SensorKaran Bir SinghNo ratings yet

- Pa 6 GF 30 (En)Document1 pagePa 6 GF 30 (En)Alessandro WeissNo ratings yet

- Luran 368R: Technical DatasheetDocument3 pagesLuran 368R: Technical DatasheetVictor PuertoNo ratings yet

- User Manual: FKS-0-10.p65 16/09/99, 16.51 1Document34 pagesUser Manual: FKS-0-10.p65 16/09/99, 16.51 1Jose luisNo ratings yet

- T Top81Document2 pagesT Top81Malek Ellouz (Jay)No ratings yet

- Lexan™ Exell™ D - Sheet DatasheetDocument3 pagesLexan™ Exell™ D - Sheet DatasheetAmritraj CharlesNo ratings yet

- Honeywell Sensing Heavy Duty Pressure px3 Series D 1228635Document11 pagesHoneywell Sensing Heavy Duty Pressure px3 Series D 1228635neetuyadav22No ratings yet

- Gs01c22b01-00e (32) Eja110Document9 pagesGs01c22b01-00e (32) Eja110Nguyen ThuongNo ratings yet

- Technical Specification For 18 (30) KV Cold-Shrinkable Cable AccessoriesDocument9 pagesTechnical Specification For 18 (30) KV Cold-Shrinkable Cable AccessoriesDkalestNo ratings yet

- 240715Document2 pages240715Hector Jose Murillo CordobaNo ratings yet

- TDS PC - LEXAN+141R - enDocument2 pagesTDS PC - LEXAN+141R - enSơn Nguyễn ĐắcNo ratings yet

- CM 230 - TDS 230Document3 pagesCM 230 - TDS 230dadangNo ratings yet

- Pe-Uhmw Technical Data SheetDocument1 pagePe-Uhmw Technical Data SheetPrashant MalikNo ratings yet

- Balluff Abs Enc.Document2 pagesBalluff Abs Enc.ersenNo ratings yet

- Resin-Impregnated Paper (RIP) Condenser Transformer BushingDocument6 pagesResin-Impregnated Paper (RIP) Condenser Transformer BushingDHANASEKARAN NNo ratings yet

- SYLGARD™ 184 Silicone Elastomer: Features & Benefits ApplicationsDocument4 pagesSYLGARD™ 184 Silicone Elastomer: Features & Benefits ApplicationsZhan FangNo ratings yet

- EJX430A General SpecDocument11 pagesEJX430A General SpecvyasathNo ratings yet

- High Current Relay 200Document3 pagesHigh Current Relay 200ShiaTVfanNo ratings yet

- Prysmian - TECSUN XPVXDocument5 pagesPrysmian - TECSUN XPVXsydneyaus2005No ratings yet

- 29UM69GDocument24 pages29UM69GClaudio Teruo TanakaNo ratings yet

- PHE426 CapacitorDocument7 pagesPHE426 Capacitormsicoie1851No ratings yet

- Grupos Electrogenos Nafta Kipor Kge12e Kge12e3Document19 pagesGrupos Electrogenos Nafta Kipor Kge12e Kge12e3Jhonald LanzNo ratings yet

- AC2056R 35 Data SheetDocument9 pagesAC2056R 35 Data SheetIslem LiliyaneNo ratings yet

- TechCalc-Project ComponentDocument3 pagesTechCalc-Project ComponentB rgNo ratings yet

- MP806FCT-CO: Fan Coil Unit On/Off ThermostatDocument1 pageMP806FCT-CO: Fan Coil Unit On/Off ThermostatChhomNo ratings yet

- NFXI-BEAM Lineare PDFDocument6 pagesNFXI-BEAM Lineare PDFDanielNo ratings yet

- Solar PV1 F Cable Technical Data SheetDocument1 pageSolar PV1 F Cable Technical Data SheetKelvin ChngNo ratings yet

- Saturn Geo: Earth-/ Ground-TesterDocument2 pagesSaturn Geo: Earth-/ Ground-TesterTecno ArteNo ratings yet

- Common Mode Chokes Pwc0603St Series: PWC 0603 S T 900 SDocument8 pagesCommon Mode Chokes Pwc0603St Series: PWC 0603 S T 900 SscribdpinoNo ratings yet

- Ecuacion de TermistorDocument20 pagesEcuacion de TermistorPeter GonzalezNo ratings yet

- LG Hecto Service ManualDocument98 pagesLG Hecto Service ManualKSnakeWNo ratings yet

- KTZ54X41SANXX Specification G02Document14 pagesKTZ54X41SANXX Specification G02Alfonso Lopez toroNo ratings yet

- Pet-Cal-Std-033 Bruel & Kjar 4294Document2 pagesPet-Cal-Std-033 Bruel & Kjar 4294CALIBRATION TRACKINGNo ratings yet

- Industrial Icp® Accelerometer: 603C91 Performance English SI Optional VersionsDocument1 pageIndustrial Icp® Accelerometer: 603C91 Performance English SI Optional VersionsKaradiasNo ratings yet

- Gs01c20c01-00e (18) Ej210&220Document10 pagesGs01c20c01-00e (18) Ej210&220Nguyen ThuongNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- Catalogo Bosch InglesDocument2 pagesCatalogo Bosch InglesDouglas FernandoNo ratings yet

- Tecsun (PV) Pv1 F Cable For Photovoltaics: EnergyDocument5 pagesTecsun (PV) Pv1 F Cable For Photovoltaics: Energyrommy_boy330No ratings yet

- Vishay Foil Resistors: FeaturesDocument7 pagesVishay Foil Resistors: FeaturesMahemehr MehrNo ratings yet

- Bayblend T85 XF ISO enDocument3 pagesBayblend T85 XF ISO enryanNo ratings yet

- Datasheet L4E78-PSDocument3 pagesDatasheet L4E78-PSHollmandavid VasquezNo ratings yet

- Solyndra Product Data Sheet 2008-10-06Document2 pagesSolyndra Product Data Sheet 2008-10-06studentenvoormorgenNo ratings yet

- KTA Caracteristicas TecnicasDocument4 pagesKTA Caracteristicas TecnicasGeraldo VinciusNo ratings yet

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Document3 pagesBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoNo ratings yet

- 32BL95UWDocument40 pages32BL95UWJosifNo ratings yet

- T Work9000Document2 pagesT Work9000Maike SongNo ratings yet

- UTP Cat 5E Belden F CatDocument3 pagesUTP Cat 5E Belden F CatDumi NeluNo ratings yet

- Trendmaster Dynamic Scanning Module: ManualDocument63 pagesTrendmaster Dynamic Scanning Module: ManualLinh LyNo ratings yet

- High Temperature Accelerometer System: Operation ManualDocument26 pagesHigh Temperature Accelerometer System: Operation ManualLinh LyNo ratings yet

- Low Pressure Cable Seal Model Number 43501: ManualDocument6 pagesLow Pressure Cable Seal Model Number 43501: ManualLinh LyNo ratings yet

- 3300 16 MM High Temperature Proximity System: ManualDocument48 pages3300 16 MM High Temperature Proximity System: ManualLinh LyNo ratings yet

- 3300/15 Dual Vibration Monitor: Operation ManualDocument25 pages3300/15 Dual Vibration Monitor: Operation ManualLinh LyNo ratings yet

- High Temperature Accelerometer System: User GuideDocument36 pagesHigh Temperature Accelerometer System: User GuideLinh LyNo ratings yet

- How To Use The 3300 XL Shaft Micrometer Kit SetupDocument2 pagesHow To Use The 3300 XL Shaft Micrometer Kit SetupLinh LyNo ratings yet

- 3300/55 Dual Velocity Monitor: Operation ManualDocument22 pages3300/55 Dual Velocity Monitor: Operation ManualLinh LyNo ratings yet

- 1970NC1Document46 pages1970NC1Linh LyNo ratings yet

- Procedure: Step-by-Step InstructionsDocument1 pageProcedure: Step-by-Step InstructionsLinh LyNo ratings yet

- Fisher 667Document12 pagesFisher 667Linh LyNo ratings yet

- Pressure Gauge: Product NameDocument11 pagesPressure Gauge: Product NameLinh LyNo ratings yet

- 3300 SYSTEM Troubleshooting: PART NO. 80173-01 Revision D, November 1993Document11 pages3300 SYSTEM Troubleshooting: PART NO. 80173-01 Revision D, November 1993Linh LyNo ratings yet

- 3300 System: PART NO. 80171-01 Revision D, MARCH 1994Document10 pages3300 System: PART NO. 80171-01 Revision D, MARCH 1994Linh LyNo ratings yet

- 589-LN-210322-0006881 Rev A - CollatedPackage - 2021 - Mar - 22 - 11 - 49 - 32 - 20210322114932Document1 page589-LN-210322-0006881 Rev A - CollatedPackage - 2021 - Mar - 22 - 11 - 49 - 32 - 20210322114932Linh LyNo ratings yet

- E1JSE6 2012 v4n4 335Document18 pagesE1JSE6 2012 v4n4 335Linh LyNo ratings yet

- Vna201a N15aDocument31 pagesVna201a N15aLinh LyNo ratings yet

- A Spherical Pressure Vessel Has An Inside Diameter...Document2 pagesA Spherical Pressure Vessel Has An Inside Diameter...RjNo ratings yet

- Irc 111 2009 Dense Graded BituminousDocument33 pagesIrc 111 2009 Dense Graded BituminousSelvi M100% (1)

- Class y Messebo OpcDocument7 pagesClass y Messebo OpcTewodros TadesseNo ratings yet

- Uems Kaia Heights Brochure p5Nk6rhxDocument5 pagesUems Kaia Heights Brochure p5Nk6rhxNor Azman JusofNo ratings yet

- RENR65060001 Hid 773Document21 pagesRENR65060001 Hid 773mauricio suarezNo ratings yet

- Steel-Beam Design in Accordance To BS-5950: PreliminariesDocument16 pagesSteel-Beam Design in Accordance To BS-5950: PreliminariesRecardoNo ratings yet

- Ly Coming Service Pubs IndexDocument65 pagesLy Coming Service Pubs IndexBobby ChippingNo ratings yet

- S&T Stainless Catalogue May 2016 01Document76 pagesS&T Stainless Catalogue May 2016 01AnthonyNo ratings yet

- Lindner KatalogDocument64 pagesLindner KatalogAnonymous hISvHbfiB1No ratings yet

- Covers Series CPT in PVCDocument3 pagesCovers Series CPT in PVCDwi SetyaoneNo ratings yet

- Iso 14001 - PanduitDocument3 pagesIso 14001 - PanduitMELITON ELIAS AVILA LLACUANo ratings yet

- 20-0035 Pricelist 2020 ROI - LRP PDFDocument166 pages20-0035 Pricelist 2020 ROI - LRP PDFJigar JainNo ratings yet

- PRV - CsaDocument19 pagesPRV - CsazaidNo ratings yet

- Calculation of Back Pressure of Silencer: Tempf 9 X C Lbs HR KG Second Acfm Exhaust Temp - +460 X Lbs HRDocument1 pageCalculation of Back Pressure of Silencer: Tempf 9 X C Lbs HR KG Second Acfm Exhaust Temp - +460 X Lbs HRDeifEricNo ratings yet

- Tema Locuinte Colective enDocument7 pagesTema Locuinte Colective enSebasNo ratings yet

- 1 - ATF EJOT DELTA - PT - Thread-Former For PlasticsDocument8 pages1 - ATF EJOT DELTA - PT - Thread-Former For PlasticsCamiLeaNo ratings yet

- Fire StopDocument48 pagesFire StopRoberto CuevasNo ratings yet

- TR 051 2016 12 Job Site Tests Plastic Anchors and ScrewsDocument5 pagesTR 051 2016 12 Job Site Tests Plastic Anchors and ScrewscoolkaisyNo ratings yet

- Starvalve BrochureDocument12 pagesStarvalve BrochureSharanGullNo ratings yet

- Mechanical Services HVAC Design MES v2017.05Document14 pagesMechanical Services HVAC Design MES v2017.05Elie BaradhyNo ratings yet

- Comparative Study of TRUSS Bridges Under Static ConditionsDocument6 pagesComparative Study of TRUSS Bridges Under Static ConditionsIJRASETPublicationsNo ratings yet

- What Is XRFDocument1 pageWhat Is XRFصصNo ratings yet

- Sydney Water Supplement WSA 07 2021Document76 pagesSydney Water Supplement WSA 07 2021joeNo ratings yet

- Pile Foundation Notes DesignDocument24 pagesPile Foundation Notes DesignSnow YoshimaNo ratings yet

- Module 3 - Mud Plastering, Mud ConstructionDocument23 pagesModule 3 - Mud Plastering, Mud ConstructionmUSINo ratings yet

- LA Ravi Sir NC 2Document10 pagesLA Ravi Sir NC 2mangalamtestingbureaNo ratings yet

- ITB - QA - QC of 8S and 14S Flowlines ConstructionDocument17 pagesITB - QA - QC of 8S and 14S Flowlines ConstructionChukwuma Emmanuel OnwufujuNo ratings yet