Professional Documents

Culture Documents

Projek Penswastaan Lebuhraya Bertingkat Sungai Besi - Ulu Kelang (Suke)

Projek Penswastaan Lebuhraya Bertingkat Sungai Besi - Ulu Kelang (Suke)

Uploaded by

fendi azizOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Projek Penswastaan Lebuhraya Bertingkat Sungai Besi - Ulu Kelang (Suke)

Projek Penswastaan Lebuhraya Bertingkat Sungai Besi - Ulu Kelang (Suke)

Uploaded by

fendi azizCopyright:

Available Formats

SYARIKAT MUHIBAH PERNIAGAAN & PEMBINAAN SDN. BHD.

PROJEK PENSWASTAAN LEBUHRAYA

BERTINGKAT SUNGAI BESI – ULU KELANG (SUKE)

METHOD STATEMENT

PRECAST PARAPET

CONSTRUCTION AND COMPLETION OF MAINLINE

AND OTHER ASSOCIATED WORKS

PACKAGE: CA3

(CH. 4200 TO CH. 7800)

Document No. :

**

Revision :

00

Date Issued :

23 July 2018

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 1 of 18

**

REVISION HISTORY

REVISION ISSUE

DETAILS OF REVISION

NO. DATE

00 23/07/2018 First submission

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 2 of

18

**

PRECAST PARAPET Revision: 00

TABLE OF CONTENTS

1.0 General Introduction...................................................................................................5

1.2 Purpose...........................................................................................................................5

1.2 Location of Precast Yard................................................................................................5

2.0 Abbreviations and Definitions.....................................................................................5

2.1 Abbreviations.................................................................................................................5

2.2 Definitions......................................................................................................................6

3.0 References.........................................................................................................................6

3.1 Project Documents.........................................................................................................6

3.2 Standards........................................................................................................................6

4.0 Resources..........................................................................................................................6

4.1 Plant and Machineries....................................................................................................6

4.2 Manpower.......................................................................................................................7

4.3 Material..........................................................................................................................7

5.0 Precast Parapet Work Procedure...................................................................................7

5.1 Steel Parapet Mould (Formwork)...............................................................................7-8

5.2 Reinforcement Work......................................................................................................8

5.3 Placing Concrete............................................................................................................8

5.4 Compacting Concrete.....................................................................................................9

5.5 Precaution for concreting during heavy rain..................................................................9

5.6 Erections / Dismantle of Steel Formwork......................................................................9

5.7 Curing Work.............................................................................................................9-10

5.8 Lifting, Handling and Stacking of Precast Members...................................................10

5.9 Construction Sequences for Parapet Works.................................................................10

6.0 Safety and Health Requirement...................................................................................11

6.1 Job Safety Analysis......................................................................................................11

6.2 Information to Personnel..............................................................................................11

6.3 Emergency Arrangements.......................................................................................11-12

6.4 Permit Requirement......................................................................................................12

7.0 Environmental Issue......................................................................................................13

7.1 Environmental Aspects, Impacts & Control Measures................................................13

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 3 of 18

**

PRECAST PARAPET Revision: 00

7.1 Air Quality and Noise..................................................................................................13

7.2 Waste Management......................................................................................................13

7.3 Temporary Drainage System........................................................................................13

7.4 Housekeeping...............................................................................................................13

8.0 Quality Assurance and Quality Control

8.1 Contractual Requirements

8.2 Inspection and Testing

8.3 Follow up and Evaluation

Appendix A : Shop Drawing Precast Parapet Steel Mould (Formwork)

Appendix B : Construction Drawing for Parapet Work

Appendix C : Concrete Curing Compound

Appendix D : Construction Sequences for Parapet Works

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 4 of 18

**

PRECAST PARAPET Revision: 00

1.0 General Introduction

This method statement serves as guidelines and explaining the procedures for all the

necessary works to be carried out for precast parapet for the Construction and Completion of

Proposed Sungai Besi – Ulu Kelang Elevated Expressway (SUKE).

1.1 Purpose

This method statement is issued to describe the procedure to be carry out for parapet

construction works to ensure that the work is planned and performed in accordance with technical

specification and drawings.

1.2 Location of Precast Yard

Figure 1: Location of Precast Yard

2.0 Abbreviations and Definitions

2.1 Abbreviations

Abbreviation Definition

PLSUSB Projek Lintasan Sungai Besi – Ulu Kelang Sdn. Bhd.

Employer Turnpike Synergy Sdn. Bhd.

SUKE Sungai Besi – Ulu Kelang Elevated Expressway

SC Supervising Consultant

SMPP Syarikat Muhibbah Perniagaan & Pembinaan Sdn. Bhd.

Table 2.1: Table of Abbreviations

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 5 of 18

**

PRECAST PARAPET Revision: 00

2.2 Definitions

Terms Definition

Project Sungai Besi – Ulu Kelang Elevated Expressway

Work Package Contractor Syarikat Muhibah Perniagaan & Pembinaan Sdn. Bhd.

Sub-contractor China Communications Construction Company (M) Sdn Bhd

Table 2.1: Table of Definitions

3.0 References

3.1 Project Documents

Document Number Document Title

SUKE-SMPP-CA3-QMS-PQP-000001 Project Quality Plan

SUKE-SMPP-CA3-QMS-PSP-000001 Safety & Health Plan

SUKE-SMPP-CA3-QMS-EMP-000001 Environmental Management Plan

SUKE-SMPP-CA3-ITP-CIVS-00000** Inspection & Test Plan

Table 3.1: List of References ~ Contractual Documents

3.2 Standards

Document Number Document Title

Section 9 Concrete Works (JKR/SPJ/2008)

Section 15 Parapet (JKR/SPJ/2013)

Table 3.2: List of References - Standard

4.0 Resources

4.1 Plant and Machineries

No Type Quantity Remark/ Purpose

1 Gantry crane-10t 2 To do lifting works

2 Mixing plant-1.5m3 2 To batch Concrete.

3 Bar Bending Machine 1 To bend steel bar.

4 Bar Cutting Machine 1 To cut the steel reinforcement as per drawing.

5 Concrete Mixer Truck 2 Transportation and casting of concrete

6 Concrete Pump 1 To pump concrete into the mould.

7 Concrete Vibrator 2 To mix concrete, Concrete compaction

8 Genset 3 To generate/supply electricity

Table 4.1: List of Plant and Machineries

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 6 of 18

**

PRECAST PARAPET Revision: 00

4.2 Manpower

No Description Quantity Remark/ Purpose

1 Construction Manager 1 To decide and delegate works

2 Site Engineer 2 Supervision during the whole process

3 Testing Supervisor 1 To monitor of the cube making

4 Safety Supervisor 1 To enforce the safety precaution on site.

5 Environmental officer 1 To enforce DOE requirement on site.

6 QA/QC Engineer 1 To monitor the quality of the precast parapet.

7 Bar bender 8 Cutting, bending and fixing of rebar

8 Form worker 4 To prepare and erection of formwork

9 Concreter 4 To execute the concrete works.

11 Crane Operator 2 To operate the crane.

12 Repairman 1 Mechanical and electrical repair

13 General worker 3 To execute work assigned.

Total 29

Table 4.2: List of Manpower

4.3 Material

No Description Remark/ Purpose

1 M.S. Galvanized post To be fixed in the parapet structure.

2 Cement mortar 10mm in thick.

Dia.20mm m.s. galvanized bolt completed with nuts and

3 U-shape bolt

washes.

3 uPVC duct 82mm (Dia) (Embedded at the cast in-situ part of parapet).

16mm (Dia) x 250mm(L),Grade 4.6 complete with nuts

4 Bolt

(check IFC drawing (klu ada) sbb biasa pkai gred 8.8)

5 Concrete(G40/20) To be used to concrete parapet.

7 Rebars To be used in the structure.

8 Axel 905D To be used as a curing compound.

Table 4.3: List of Materials

Material lain dh submit utk approval x..klu x submit utk approval dlu

5.0 Precast Parapet Work Procedure

5.1 Steel Parapet Mould (Formwork)

a) Fabrication of steel formwork will be to the dimensions, shapes and sizes required to obtain

the accurate alignment, location and plumb of the finished structure.

b) Mould shall be placed on flat ground and shall be properly secure to avoid movement

during concrete. Mould shall be levelled and tight properly. Spirit level/plumb shall be used

to check the verticality and straightness of the mould.

c) The steel formwork should able to support the concrete during pouring works.

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 7 of 18

**

PRECAST PARAPET Revision: 00

d) The shop drawing for the details measurement or dimension of the steel formwork may

refer to the attachment in Appendix A

e) The inspection of steel formwork will be conducted during pre-concreting work to ensure

assemble of steel formwork is according to the submitted shop drawing.

f) The surface of the steel formwork should be clean from any debris or leftover concrete

before proceed with concreting work.

5.2 Reinforcement Work

a) Rebar cutting, bending and tying will be based on the contracts / shop drawings. Sketches

may be developed at site as identified by Site Engineer for better understanding of the rebar

installation sequence as per attached in the construction drawing at Appendix B.

b) Delivery notes, mill certificates, steel origin, supplier, manufacturer and other details of all

delivered steel consignments will be checked on site. The records will be available for

consultant reference or any future use.

c) Install rebar accurately in position and secure against displacement that might be caused

during concrete pouring.

d) Ensure all embedded items are fixed accurately at required locations and secure tightly

against any possible displacement. Any modification done during the installation and the

embedded items shall be indicated in the checklist as required.

e) Reinforcement sample test shall be carried out at the frequency as specified in the technical

specification.

5.3 Placing Concrete

a) Concrete placement can only commence upon approval of the Request for Inspection (RFI)

request by the Client / consultant. Request for inspection shall be submitted only upon

approval of QC Engineer and at least 24 hours before the casting schedule.

b) Ensure that all required inspections are performed.

c) Ensure that all embedded items required are installed and secured at their correct location

and levels.

d) Prior to placing of G40/20 concrete and concrete will be transported from the central

mixing plant and placed as rapidly as possible by using the concrete mixer truck.

e) Segregation and loss of ingredients shall be prevented.

f) The concrete vibrator will be use to ensure the concrete distribute evenly in the steel

formwork

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 8 of 18

**

PRECAST PARAPET Revision: 00

g) Temperature of concrete mix at the time of placing shall be monitored randomly and shall

not exceed 36° C referring to specification clause 9.5.6 placement temperature clause (b).

5.4 Compacting Concrete

a) All reinforcement concrete, where possible, be fully compacted by means of power driven

immersion type vibrators (poker vibrator).

b) Vibrators shall be placed vertically in the concrete, held in position until air bubbles cease

to come to the surface, and then slowly withdrawn, so that concrete can flow into the space

previously occupied by poker.

c) All exposed surfaces of concrete in contact with fresh in-situ concrete shall be roughed to

the exposed aggregates before receiving new concrete

5.5 Precaution for concreting during heavy rain

a) Concreting shall not be started if there is heavy rain prior to arrivals of concrete. The

concreting operation only to start after rain subside.

b) However, if heavy rain falls during the concreting operation, the following additional steps

have to be implemented:

The top surface of parapet shall be covered with proper canvas.

A polythene cover shall be placed over the mixer truck top hopper to prevent any rain

water going into the mixer drum which may affect the mix consistency.

c) Make rough concrete surface using wire brush following setting to broom finish surface for

construction joints.

5.6 Erection / Dismantle of Steel Formworks

a) The periods of time for formwork should be remove is as per technical specification under

the section 9 for concreting with the sub-clause 9.8.4 which is removal of forms.

b) Formwork will be remove without such shock or vibration which might cause damaged to

the formwork or the precast parapet structure.

c) Upon the removing of formwork, no further loads should imposed to the precast parapet

until at least the curing periods complete or until such later time in as in the opinion of

consultant which the precast parapet attained sufficient strength to safety withstand loads.

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 9 of 18

**

PRECAST PARAPET Revision: 00

5.7 Curing Work

a) For open surface, a curing compound (Refer to Appendix C) shall be applied equally by

hand pump or brush immediately upon removal of formwork to reduce incidence of plastic

cracking, shrinkage and dusting

b) Roughened surface shall be covered with damp absorbent material (gunny sack) or other

approved concrete retarder before proceeding the next level .

5.8 Lifting, Handling and Stacking of Precast Members

a) At all times, especially during transportation, members shall be secured in an upright

position.

b) To mention the minimum grade of concrete for lifting, minimum grade for stacking i.e

10kN for lifting, 40kN for stacking.

c) Members shall be handled, lifted and supported carefully at the positions and in the manner

intended to them. Always lift them vertically at the lifting hooks/points provided as

approved by SC.

d) Temporary supports for members shall be of timber. These bearers shall support the

members over their full width at the specified lifting points only. The ground or space

between the bearers supporting the members shall be carefully cleared and levelled so as to

prevent the member from being accidentally supported other than on the bearers. The

bearers themselves shall be supported on firm foundation, and every precaution shall be

made to prevent subsidence from occurring as per specification.

e) The members shall be transported on motorway by trailers, and are safeguarded against

tilting by means of suitable precaution.

5.9 Construction Sequences for Parapet Works

Please refer to the Appendix D for details of construction sequence on parapet works.

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 10 of 18

**

PRECAST PARAPET Revision: 00

6.0 Safety and Health Requirement

6.1 Job Safety Analysis

Job Safety & Health Analysis shall be carried on the project site. Traffic management shall

be approved and implemented at work areas. Safety awareness signs shall be established at location

of works. The hazards in a particular activity and the control measures implemented shall be

briefed to the workers during safety induction, tool box talk and JSA briefing.

6.2 Information to Personnel

a) All workers employed in the project site must have CIDB green card.

b) All new workers and staff to attend the Safety Training or Safety Induction Course Before

commencing works site and attendances shall be recorded in an induction list.

c) All site personnel shall wear proper Personnel Protective Equipment (PPE) such as safety

helmets, safety vest, safety boots, etc.

d) Activities may require additional PPE on top of the above such as Mask if necessary.

e) Monthly safety meetings shall be held with all the contractors related to the works.

f) All workers to attend the weekly toolbox meetings conducted by the safety officer held at

site and attendances shall be recorded.

6.3 Emergency Arrangements

a) The actual potential emergency situation may arise during the work are:

Fire

Electric Hazard,

Accident due to Equipment Failure

Major traffic accident when mobilization & demobilization of

equipment/machineries

Lifting failure

Escape of Combustible or Toxic Material

b) An Emergency Response and Communication Team shall be formed at the site.

c) The organization chart, list of emergency contact person and relevant authorities with their

contact numbers shall be showed in the Notice Board.

d) In the event of emergency, the site management staffs must evaluate the situation and

commence the necessary procedures as follow :

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 11 of 18

**

PRECAST PARAPET Revision: 00

Raise the alarm.

Stop works.

Remain composed.

Make sure notifications of emergency or evacuation are in place for

all workers surrounding the vicinity.

Make sure all workers are assembled at designated assembly point.

Make sure first aid kits are prepared at assembly point.

All workers are told not to leave the assembly point until clear sign

is issued.

Headcount shall be conducted.

First aiders shall attend to the injured workers.

Prepare assessment reports for the losses.

6.4 Permit Requirement

No. Descriptions Person In Charge Remarks

1 Work Permit Safety Officer, Construction Notify SC

Manager

2 Lifting Works Permit Safety Officer, Construction Attain permit and

Manager display

3 Outside Normal Working Authorities (TBA) Notify SC

Hours Works’ Permit

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 12 of 18

**

PRECAST PARAPET Revision: 00

7.0 Environmental Issue

7.1 Environmental Aspects, Impacts & Control Measures

The significant environmental impacts associated with the precast parapet works have been

identified of the related method of statements.

7.1 Air Quality and Noise

All construction machineries shall be in well maintain and in good working condition to

reduce emission of soot, smoke and noise. The following measures shall be implemented if the

above mentioned (soot, smoke and noise) is deteriorating:

Increase maintenance frequency

Replace to better equipment if necessary

Switched-off equipment if not in used

Supply workers on-site with proper PPE (i.e. ear plugs and mask)

Temporary noise barrier will be installed to control the noise and vibration

if necessary

7.2 Waste Management

Scheduled waste from maintenance works of machineries, vehicles and tools will be placed

in designated areas. Proper oil tray or drum shall be placed to prevent the oil spillage all over the

place. Subsequent waste shall be collected and transfer to area as assigned. The schedule waste

storage area shall be placed in designated area with proper bund. Construction waste will be sent to

(location TBA). Schedule waste will be disposed at approved schedule waste dumpsite.

7.3 Temporary Drainage System

Drainage design should be adequate to ensure that no flooding occurs. Where necessary,

the actual drainage layout will be reviewed depending on the site terrain and condition. All runoff

from undisturbed areas should not be allowed to mix with runoff from the disturbed area.

7.4 Housekeeping

Housekeeping is an essential part of safety for the daily routine. Housekeeping would

include the following items:

Maintain access/egress to all working area.

Store and stack all construction materials in safe and orderly manner.

No littering around the site.

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 13 of 18

**

PRECAST PARAPET Revision: 00

8.0 Quality Assurance & Quality Control

8.1 Contractual Requirements

Shall be implemented in accordance with submitted comprehensive Project Quality Plan

Ref. No. SUKE-SMPP-CA3-QMS-PQP-000001.

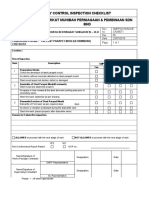

8.2 Inspection & Testing

Refer to Inspection and Test Plan as per attached for Quality Control Inspection Checklist

SUKE-SMPP-CA3-ITP-GEO-000006.

8.3 Follow Up & Evaluation

RFIs and respective Permit to Work shall be submitted prior execution of any construction

activities. In additional to this requirement weekly walk-about will be conducted to measurement,

analysis and propose for improvement as construction activities are on-going.

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 14 of 18

**

PRECAST PARAPET Revision: 00

Appendix A

Shop Drawing for Precast Parapet Steel

Mould(Formwork)

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 15 of 18

**

PRECAST PARAPET Revision: 00

Appendix B

Construction Drawing for Parapet

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 16 of 18

**

PRECAST PARAPET Revision: 00

Appendix C

Concrete Curing Compound

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 17 of 18

**

PRECAST PARAPET Revision: 00

Appendix D

Construction Sequences for Parapet Work

Stage 1

Ensure the dimension & usage of parapet

confirmed as per construction drawing

Stage 2

Inspect the cleanliness, dimension &

embedded item as per construction

drawing

Not okay

Stage 3 Inspection by consultant (SSP) and SMPP

Assemble the steel formwork

Okay

Stage 4

Sample to be taken for cube compressive

Placement of fresh concrete and concrete

strength test

vibration works

Stage 5

Dismantle of steel formwork

Stage 6

Apply curing compound on parapet

Stage 7

Transport to the provide yard storage

Stage 8

Stacking properly at storage yard before

transport to the usage location

SYARIKAT MUHIBAH PERNIAGAAN DAN PEMBINAAN SDN BHD Page 18 of 18

**

You might also like

- Method Statement For Project Signages Rev 0 AfcDocument16 pagesMethod Statement For Project Signages Rev 0 AfcEchik Kici0% (1)

- Method of Statement For Cold JointDocument17 pagesMethod of Statement For Cold Jointfendi azizNo ratings yet

- Method of Statement For Cold JointDocument17 pagesMethod of Statement For Cold Jointfendi azizNo ratings yet

- A Practical Guide to Concrete Pavement Technology for Developing CountriesFrom EverandA Practical Guide to Concrete Pavement Technology for Developing CountriesNo ratings yet

- Method Statement For Road and Paving WorkDocument32 pagesMethod Statement For Road and Paving WorkĐặng Quang Huy100% (8)

- Feasibility Report of MHTLDocument168 pagesFeasibility Report of MHTLalim shaikhNo ratings yet

- Foundation Method Statement: Uganda Electricity Transmission Corporation Limited. UETCLDocument20 pagesFoundation Method Statement: Uganda Electricity Transmission Corporation Limited. UETCLAnonymous CPEha1db7UNo ratings yet

- Method Statement TemplateDocument33 pagesMethod Statement TemplateBhushan Kumar100% (1)

- Sagana Kutus 132kv Transmission Line and SubstationDocument324 pagesSagana Kutus 132kv Transmission Line and Substationshivvaram-1100% (1)

- SSP Nfra BDT1 Jind MST 00032Document42 pagesSSP Nfra BDT1 Jind MST 00032Zulhazmi ZulkafliNo ratings yet

- Method Statement of Soft Ground TreatmentDocument21 pagesMethod Statement of Soft Ground TreatmentMiDdin818No ratings yet

- Package A1 - Geotechnical Review Report (Word File)Document29 pagesPackage A1 - Geotechnical Review Report (Word File)WanNo ratings yet

- MRT Works General SpecificationDocument226 pagesMRT Works General SpecificationPetar PospišNo ratings yet

- 2020-06-25 Method Statement of RCBC Construction CH402+737Document33 pages2020-06-25 Method Statement of RCBC Construction CH402+737施智捷100% (2)

- Ms-021 - Laying of GRP Pipelines For SEWERGAE Pressure Works - DMDocument19 pagesMs-021 - Laying of GRP Pipelines For SEWERGAE Pressure Works - DMruwaaquaNo ratings yet

- Construction Report of The New MPA Hotel, Lahore (Building Construction and Technology Course)Document17 pagesConstruction Report of The New MPA Hotel, Lahore (Building Construction and Technology Course)toobaiftikhar383No ratings yet

- Method StatementDocument43 pagesMethod StatementAbdul LatheefNo ratings yet

- 22031-C-Rep-Tec-2-001 Shatale Water Works Upgrade Updated DDR 2Document99 pages22031-C-Rep-Tec-2-001 Shatale Water Works Upgrade Updated DDR 2Clement TakavarashaNo ratings yet

- APPENDIX-5-DRC-000-16540-0001 - 00-HSE PlanDocument57 pagesAPPENDIX-5-DRC-000-16540-0001 - 00-HSE PlanSaleem AkhtarNo ratings yet

- Package A4 - Geotechnical Review ReportDocument28 pagesPackage A4 - Geotechnical Review ReportWanNo ratings yet

- Draft Report RLA Pipeline PDFDocument47 pagesDraft Report RLA Pipeline PDFTengku Nizarul AslamiNo ratings yet

- GH Sinopec Ms SC Pkg17 r0Document75 pagesGH Sinopec Ms SC Pkg17 r0AmeerHamzaWarraichNo ratings yet

- MS-0007 Hardscape WorksDocument37 pagesMS-0007 Hardscape WorksAbdul LatheefNo ratings yet

- 2973 - Method Statement For Cable LayingDocument13 pages2973 - Method Statement For Cable LayingMuhammad SajjadNo ratings yet

- 2 Bid Document Vol IIDocument394 pages2 Bid Document Vol IIDhabalia AshvinNo ratings yet

- Pa-m02-Tendering Management - Mohamad Wazid CCM LatestDocument31 pagesPa-m02-Tendering Management - Mohamad Wazid CCM Latestmohamad wazidNo ratings yet

- MS-0001 Mobilization of Portacabin.Document31 pagesMS-0001 Mobilization of Portacabin.Abdul LatheefNo ratings yet

- RFQ For Pressure TransmitterDocument21 pagesRFQ For Pressure Transmittersugeng wahyudiNo ratings yet

- Closing-Out Report: Project Consultancy ServicesDocument175 pagesClosing-Out Report: Project Consultancy ServicesHusam AhmedNo ratings yet

- 5688 Pre Final Design Report Tunnel Rev01-A PDFDocument108 pages5688 Pre Final Design Report Tunnel Rev01-A PDFDevinder Sokhi100% (1)

- 26071-100-583-GST-00004 - 000 - EDG First EnergizationDocument104 pages26071-100-583-GST-00004 - 000 - EDG First Energizationwidionosucipto29No ratings yet

- Scope of Work-GTC-016-2018Document41 pagesScope of Work-GTC-016-2018haroonNo ratings yet

- Shree Sayan Vibhag Sahakari Khand Udhyog Mandli LTD Srt65 Eia1Document300 pagesShree Sayan Vibhag Sahakari Khand Udhyog Mandli LTD Srt65 Eia1Sv KhanNo ratings yet

- DRC 000 16540 0055 00 Project Quality PlanDocument41 pagesDRC 000 16540 0055 00 Project Quality PlanSaleem AkhtarNo ratings yet

- GTRUTFDocument16 pagesGTRUTFAbdul SabirNo ratings yet

- 1.method Statement - Roadwork ZPBDocument25 pages1.method Statement - Roadwork ZPBfatinNo ratings yet

- AFCONS - DESIGN - Design Basis Report - Anglais - 2020-12-30Document22 pagesAFCONS - DESIGN - Design Basis Report - Anglais - 2020-12-30Adrian FrantescuNo ratings yet

- MS-0006 Storm Water NetworksDocument35 pagesMS-0006 Storm Water NetworksAbdul LatheefNo ratings yet

- EDDR of Batching Plant Sialkot Pdf1Document33 pagesEDDR of Batching Plant Sialkot Pdf1aqeelNo ratings yet

- Geometric Design Report PK49.9 - PK74.9 en Revised 20th July 2021Document91 pagesGeometric Design Report PK49.9 - PK74.9 en Revised 20th July 2021Adrian FrantescuNo ratings yet

- 100 530 GST 000012 001Document32 pages100 530 GST 000012 001widionosucipto29No ratings yet

- 009-2021 - R1 - Techno-Commercial Proposal-MAKDocument28 pages009-2021 - R1 - Techno-Commercial Proposal-MAKpavanNo ratings yet

- A61 003 A 022 A00 Operation ManualDocument132 pagesA61 003 A 022 A00 Operation ManualRahil TasawarNo ratings yet

- Irfan's Final IrDocument28 pagesIrfan's Final Iraaqib2021bciv003No ratings yet

- 26071-100-GPP-GCX-00162 - Method Statement of Bore Piling Work in Interconnecting Piperacks (Unit PR-321-21 (R84) and Unit PR-321-03 (R12) )Document38 pages26071-100-GPP-GCX-00162 - Method Statement of Bore Piling Work in Interconnecting Piperacks (Unit PR-321-21 (R84) and Unit PR-321-03 (R12) )Amy Amaliah HSENo ratings yet

- Revised Pavement Design - Beawar Pali Section PDFDocument119 pagesRevised Pavement Design - Beawar Pali Section PDFSanket ShahNo ratings yet

- SK-12 09.02.2021 Word FormatDocument97 pagesSK-12 09.02.2021 Word FormatPrabhnoor KaurNo ratings yet

- State Dearptment of Housing & Urban Development PDFDocument81 pagesState Dearptment of Housing & Urban Development PDFly0039No ratings yet

- R03-C02C02-AAP-MTS-CI-0004 RevDocument20 pagesR03-C02C02-AAP-MTS-CI-0004 Revlike saddamNo ratings yet

- 9686-6130-MS-000-0002 - B2 - MS Tank Construction. - ApprovedDocument23 pages9686-6130-MS-000-0002 - B2 - MS Tank Construction. - ApprovedANIL PLAMOOTTIL100% (1)

- MCP 2020.12.02 Wipl Ieng - 356Document41 pagesMCP 2020.12.02 Wipl Ieng - 356Purshottam SharmaNo ratings yet

- Annex A2 Mogden CDRDocument49 pagesAnnex A2 Mogden CDRkwaikwai1089No ratings yet

- HSE-R1126-003-Rev.03 Construction Environment Management PlanDocument28 pagesHSE-R1126-003-Rev.03 Construction Environment Management PlansunthuNo ratings yet

- 02-DG-Section 2 Geotechnical Investigation Guideline - Version 3.0Document90 pages02-DG-Section 2 Geotechnical Investigation Guideline - Version 3.0Jamshed AlamNo ratings yet

- Hydroelectric Poner: Plant Pr02EctDocument3 pagesHydroelectric Poner: Plant Pr02EctNahemiah Marie AbianNo ratings yet

- MS-0002 Dismantling, Demolition and Site ClearanceDocument25 pagesMS-0002 Dismantling, Demolition and Site ClearanceAbdul LatheefNo ratings yet

- Modified DPR Part 1Document336 pagesModified DPR Part 1Bhuvan BajajNo ratings yet

- Ebs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanDocument80 pagesEbs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanAsaad AdnanNo ratings yet

- P4B02 Gut CV Bas PP4 00 00 Des 0007 B01Document57 pagesP4B02 Gut CV Bas PP4 00 00 Des 0007 B01nipun jainNo ratings yet

- Road Map to Scale Up Solar Irrigation Pumps in Bangladesh (2023–2031)From EverandRoad Map to Scale Up Solar Irrigation Pumps in Bangladesh (2023–2031)No ratings yet

- Precast Parapet Works Rev 00Document2 pagesPrecast Parapet Works Rev 00fendi azizNo ratings yet

- Quality Control Inspection Checklist Syarikat Muhibah Perniagaan & Pembinaan SDN BHDDocument1 pageQuality Control Inspection Checklist Syarikat Muhibah Perniagaan & Pembinaan SDN BHDfendi azizNo ratings yet

- Hazard Identification Risk Assement and Risk Control: Precast Parapet WorksDocument2 pagesHazard Identification Risk Assement and Risk Control: Precast Parapet Worksfendi azizNo ratings yet

- COVERDocument9 pagesCOVERfendi azizNo ratings yet

- ITP Repair Works (COLD JOINT) (Rev 00)Document3 pagesITP Repair Works (COLD JOINT) (Rev 00)fendi azizNo ratings yet

- Repair Works For Civil Structure (Cold Joint) Rev 00Document1 pageRepair Works For Civil Structure (Cold Joint) Rev 00fendi azizNo ratings yet

- JSA Repair Works (COLD JOINT) (Rev 00)Document2 pagesJSA Repair Works (COLD JOINT) (Rev 00)fendi azizNo ratings yet