Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

3 viewsT 4

T 4

Uploaded by

Marco GomesSCI P358 T-4

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- T 7Document1 pageT 7Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 1B.2Document1 pageBolted Beam To Column Connections-Design Step 1B.2Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 2.1Document1 pageBolted Beam To Column Connections-Design Step 2.1Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 1A.3Document1 pageBolted Beam To Column Connections-Design Step 1A.3Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 1C.1Document1 pageBolted Beam To Column Connections-Design Step 1C.1Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 1A.2Document1 pageBolted Beam To Column Connections-Design Step 1A.2Marco GomesNo ratings yet

- T 8Document1 pageT 8Marco GomesNo ratings yet

- T 15Document1 pageT 15Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 1.2Document1 pageBolted Beam To Column Connections-Design Step 1.2Marco GomesNo ratings yet

- T 13Document1 pageT 13Marco GomesNo ratings yet

- T 5Document1 pageT 5Marco GomesNo ratings yet

- T 14Document1 pageT 14Marco GomesNo ratings yet

- T 3Document1 pageT 3Marco GomesNo ratings yet

- T 9Document1 pageT 9Marco GomesNo ratings yet

- T 12Document1 pageT 12Marco GomesNo ratings yet

- T 7Document1 pageT 7Marco GomesNo ratings yet

- T 6Document1 pageT 6Marco GomesNo ratings yet

- T 2Document1 pageT 2Marco GomesNo ratings yet

- T 10Document1 pageT 10Marco GomesNo ratings yet

- T 11Document1 pageT 11Marco GomesNo ratings yet

- Distribution of Forces in Weld GroupsDocument10 pagesDistribution of Forces in Weld GroupsMarco GomesNo ratings yet

- Unnamed 1Document7 pagesUnnamed 1Marco GomesNo ratings yet

- AD 288 Discontinuous Columns in Simple Construction Beam-Column ConnectionDocument3 pagesAD 288 Discontinuous Columns in Simple Construction Beam-Column ConnectionMarco GomesNo ratings yet

T 4

T 4

Uploaded by

Marco Gomes0 ratings0% found this document useful (0 votes)

3 views1 pageSCI P358 T-4

Original Title

T-4

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSCI P358 T-4

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

3 views1 pageT 4

T 4

Uploaded by

Marco GomesSCI P358 T-4

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

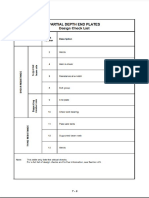

Partial depth end plates

Table G.1

Explanatory notes - PARTIAL DEPTH END PLATES

Use of Resistance Tables.

"The check numbers refer 10 ose listed in Table GS and Gescribea in Sechon 4.5 Design proceaures,

‘The resistance tables are based on the standard details given in Table G2.

4 SHEAR RESISTANCE OF THE BEAM

A,

Brw

|A+ symbol adjacent to tne beam designation indicates that the serial size is additonal to thase spectied in BS 4-1

2. SHEAR RESISTANCE OF THE CONNECTION

‘This is the critical value of the design checks for the ‘supported beam side’ of the connection, i.e. the minimum

resistance from Checks 2, 4,5 (if applicable) 8 and 9.

‘The value given in { } below each beam designation is the shear resistance of the beam, given by

For connections with Ordinary or Flowdrll bolts, connection shear resistances are given for un-notched, single:

notched and double notched beams.

For connections with Hollo-Boit, connection shear resistances sre tabulated for un-notched beams only, 38

Hollo-Bolts are generally only used with un-notched beams.

3 GRITICAL DESIGN CHECK

‘The check which gives the critical value of shear resistance. See Table G3 for ine description of tne checks.

4) NOTCH LIMIT

‘These are maximum lengths of notches for single and double notched beams that can be accommodated if the

beam is to camry the tabulated corresponding shear resistance of the connection. The notch length is

‘measured from the end of the beam. The calculated resistances allow for the thickness af the end plate.

is assumed that me beam is fully restrained against lateral torsional buckling, and the limiting notch lengths

are derived fram Check 5.

To provide @ simple check for double notched beams, i has been assumed that the remaining web» depth is

the same as the end plate length.

5 MINIMUM SUPPORT THICKNESS

‘This is the minimum thickness of supparting column or beam element thel is needed to carry the given shear

Fesistance (un-notched or single notched) of the connection. It ls dered trom Check 10 and & has

conservatively been taken as 90 mm.

For a symmetrical two sided connection, the minimum support thickness would be twice the tabulated value.

I ine applied shear torce Is less then the quoted resistance, the minimum support thickness reduces

proportionally.

6 TYING RESISTANCE

‘This ie the cribel value of the design checks for ie ‘supported beam’ side of the connection, Le. the minimum

resistance from Checks 11, 12, and 13. The ealeulations assume that no washer is present and dy is taken a3

the wigin acrass paints of the bolt head.

‘Separate checks will have to be carried out on the suppemting members (see Checks 14 and 15).

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- T 7Document1 pageT 7Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 1B.2Document1 pageBolted Beam To Column Connections-Design Step 1B.2Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 2.1Document1 pageBolted Beam To Column Connections-Design Step 2.1Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 1A.3Document1 pageBolted Beam To Column Connections-Design Step 1A.3Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 1C.1Document1 pageBolted Beam To Column Connections-Design Step 1C.1Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 1A.2Document1 pageBolted Beam To Column Connections-Design Step 1A.2Marco GomesNo ratings yet

- T 8Document1 pageT 8Marco GomesNo ratings yet

- T 15Document1 pageT 15Marco GomesNo ratings yet

- Bolted Beam To Column Connections-Design Step 1.2Document1 pageBolted Beam To Column Connections-Design Step 1.2Marco GomesNo ratings yet

- T 13Document1 pageT 13Marco GomesNo ratings yet

- T 5Document1 pageT 5Marco GomesNo ratings yet

- T 14Document1 pageT 14Marco GomesNo ratings yet

- T 3Document1 pageT 3Marco GomesNo ratings yet

- T 9Document1 pageT 9Marco GomesNo ratings yet

- T 12Document1 pageT 12Marco GomesNo ratings yet

- T 7Document1 pageT 7Marco GomesNo ratings yet

- T 6Document1 pageT 6Marco GomesNo ratings yet

- T 2Document1 pageT 2Marco GomesNo ratings yet

- T 10Document1 pageT 10Marco GomesNo ratings yet

- T 11Document1 pageT 11Marco GomesNo ratings yet

- Distribution of Forces in Weld GroupsDocument10 pagesDistribution of Forces in Weld GroupsMarco GomesNo ratings yet

- Unnamed 1Document7 pagesUnnamed 1Marco GomesNo ratings yet

- AD 288 Discontinuous Columns in Simple Construction Beam-Column ConnectionDocument3 pagesAD 288 Discontinuous Columns in Simple Construction Beam-Column ConnectionMarco GomesNo ratings yet