Professional Documents

Culture Documents

Fabrication Protocol For 10mm

Fabrication Protocol For 10mm

Uploaded by

Suryaveer 6th AOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication Protocol For 10mm

Fabrication Protocol For 10mm

Uploaded by

Suryaveer 6th ACopyright:

Available Formats

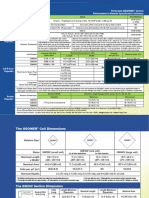

DIMENSIONAL CONTROL REPORT FOR 10mm THICK FERRULES DURING FABRICATION OF PENSTOCK OF PHATA BYUNG H.E.

PROJECT (AS PER IS : 2825-1969)

REACH : PLATE SPECIFICATION: HEAT NUMBER:-

FERRULE No. PLATE NUMBER:-

S.NO DESCRIPTION FORMULA AS PER CODE ACTUAL REMARKS (IF ANY)

Ends of penstock sections must not vary by more than 1/16

inch at any point from a plane normal to the longitudinal axis Refer ASCE Manual 79

1 Squareness of ends for butt welding 1.6mm

and passing through the center of the section at the end. clause no. 11.3.3.1 (3)

Variation in external cirumference of Circumferential tolereance = ± 0.25% of external

2 ferrule for outside diameter more than circumference where Outside Diameter = Nominal inside 20mm

600 mm. diameter + 2(actual plate thickness)

3 Variation in straightness of ferrule (For 2500mm length) 2L/1000 where L is the length of ferrule 5mm

Difference between maximum and (Internal.Diameter + 1250)/200 OR

4 minimum diameters at any cross 1% of the nominal internal diameter of the shell 19mm

section of the ferrule (whichever is less)

Irregularities in profile of a shell

5 3mm +5% of min plate thickness 3.5mm

(Cheked by 20° gauge)

Prepared edges of the plates shall be in For longitudinal joints (10% of nominal plate thickness with a

maximum of 3mm). However, for plates up to and including 1mm welds made with

alignment to meet the requirement of

10 mm thick a misalignment of 1mm is permitted. backing strips require

6 welding process and defects in

better alignmnet than

alignmnet at the surface of the plates For circumferential joints (10% of maximum nominal plate

2mm specified

shall not be more than thickness plus 1 mm with a maximum of 4mm)

up to plate thickness 12mm 1.5mm

7 Reinforcement layer of weld metal over plate thickness 12mm and including 25mm 2.5mm

over plate thickness 25mm and including 52mm 3.0mm

2 coats of zinc rich primer, which should not

contain less than 85 % zinc in dry film, to obtain Total dry film thickness

Primer thickness

dry film thickness 75 microns (40 microns per of paint including primer

8 Painting coat). shall not be less than 500

3 coats of coal tar blind epoxy resin paint to get a microns.

Coal Tar epoxy thickness

dry film thickness of 150 microns in each coat.

CHECKED BY FOR LANCO INFRA TECH LTD

You might also like

- Nitomortar TC2000 PDFDocument3 pagesNitomortar TC2000 PDFtalatzahoor100% (2)

- FEWA WOODEN POLE and OHL PDFDocument56 pagesFEWA WOODEN POLE and OHL PDFscribdgineerNo ratings yet

- DownloadDocument2 pagesDownloadPhú Vũ TrươngNo ratings yet

- Pro Form - Plywood Formwork For Exposed Concrete AreaDocument2 pagesPro Form - Plywood Formwork For Exposed Concrete AreaĐức Anh NguyễnNo ratings yet

- API Acceptance CriteriaDocument1 pageAPI Acceptance CriteriaravigurajapuNo ratings yet

- Tolerance As Per AWS D1.1Document3 pagesTolerance As Per AWS D1.1milind bedarkarNo ratings yet

- Compocel Al FR: Aluminium and Thermoplastic Honeycombs, Laminates, Sandwich PanelsDocument3 pagesCompocel Al FR: Aluminium and Thermoplastic Honeycombs, Laminates, Sandwich Panelsbenadam10No ratings yet

- Doka Birch Plywood Specs - 18 MMDocument2 pagesDoka Birch Plywood Specs - 18 MMAnupam GhoshNo ratings yet

- MARLEY Roofing - South AfricaDocument2 pagesMARLEY Roofing - South AfricaJoão Athayde e MeloNo ratings yet

- KIRK KWM Mist Eliminators2Document3 pagesKIRK KWM Mist Eliminators2TesisAyF ProyectoNo ratings yet

- Comparison Bet Stds For Rubber TubesDocument2 pagesComparison Bet Stds For Rubber TubesRam SudheerNo ratings yet

- Lamination Recipe-700mmDocument1 pageLamination Recipe-700mmSai PrasathNo ratings yet

- TS-Gabion - 10x12 - Galmac+PolimacDocument8 pagesTS-Gabion - 10x12 - Galmac+Polimacdigvijay singhNo ratings yet

- Material Tests Requirements (Avg of 6 Tiles)Document1 pageMaterial Tests Requirements (Avg of 6 Tiles)arr149No ratings yet

- Acceptance Standards RTDocument1 pageAcceptance Standards RTRaju Tiwary100% (1)

- Pionite Standard Laminate Tech Bulletin 6.2020Document4 pagesPionite Standard Laminate Tech Bulletin 6.2020rfrankivNo ratings yet

- Since 1999: Terracotta Roof FabricationDocument16 pagesSince 1999: Terracotta Roof FabricationSaran T SNo ratings yet

- Technical Guidance Note: Omnia Wideslab Permanent Formwork Guide To SpecifiersDocument1 pageTechnical Guidance Note: Omnia Wideslab Permanent Formwork Guide To SpecifiersBogdanBNo ratings yet

- Rooftiles Western Slate Datasheet 201106Document2 pagesRooftiles Western Slate Datasheet 201106Radu BriaNo ratings yet

- QC For Structural WorkDocument9 pagesQC For Structural Workwirya soeNo ratings yet

- Wood Packer Sample Inspection ReportDocument1 pageWood Packer Sample Inspection Reportmanjunath RNo ratings yet

- Catálogos de Láminas de PolicarbonatoDocument5 pagesCatálogos de Láminas de PolicarbonatoRoberth RoberthNo ratings yet

- 1200mm (Revised) W6x25 C6x13 C6x13 W6x25 4.5mm Checkered PlateDocument6 pages1200mm (Revised) W6x25 C6x13 C6x13 W6x25 4.5mm Checkered PlateMARKCHRISTMASNo ratings yet

- Silkscreen Stencil Making GuideDocument8 pagesSilkscreen Stencil Making GuideJoe GardnerNo ratings yet

- Unit 1-Laminates & VeneersDocument17 pagesUnit 1-Laminates & VeneersImtiyaz MohammadNo ratings yet

- Grateshield Gratemesh: Rate HieldDocument4 pagesGrateshield Gratemesh: Rate HieldSarwar KhanNo ratings yet

- Flexi EarthedDocument1 pageFlexi Earthedarsya_agasNo ratings yet

- Presto: Property Value Test MethodDocument2 pagesPresto: Property Value Test MethodledagoNo ratings yet

- TDS - CHALCOFOIL SoftDocument1 pageTDS - CHALCOFOIL SoftVova TripolskyNo ratings yet

- BS1088 Standard: Bonding WBP Glue LineDocument2 pagesBS1088 Standard: Bonding WBP Glue LineJing VeeNo ratings yet

- IS 13801 (1993) - Checkered Cement Concrete Tiles - 2Document1 pageIS 13801 (1993) - Checkered Cement Concrete Tiles - 2Abhinandan JasrotiaNo ratings yet

- NumunePCB-PCB Manufacturing & Assembly CapabilitiesDocument18 pagesNumunePCB-PCB Manufacturing & Assembly CapabilitiesBruh BruhNo ratings yet

- API 1104 NDT AcceptanceDocument1 pageAPI 1104 NDT AcceptanceErAnisAlamNo ratings yet

- GW Geoweb GW30v6 SummaryDocument1 pageGW Geoweb GW30v6 SummaryChowdhury PriodeepNo ratings yet

- Datos CableDocument3 pagesDatos CablePablo Briceño NavarroNo ratings yet

- British Gypsum PDS Gyproc Habito 12 5mmDocument3 pagesBritish Gypsum PDS Gyproc Habito 12 5mmretniafrinda0No ratings yet

- Presto Geocell - GeogridDocument2 pagesPresto Geocell - GeogridLIMITLESSNo ratings yet

- Helical Reinforcement BarsDocument1 pageHelical Reinforcement BarsruwanthaNo ratings yet

- API 1104 Defects Acceptance Criteria FinalDocument3 pagesAPI 1104 Defects Acceptance Criteria FinalAbdul Wajid AliNo ratings yet

- Transformer Winding PracticesDocument7 pagesTransformer Winding PracticeskshgunawardenaNo ratings yet

- Cable JointDocument2 pagesCable JointfaarigNo ratings yet

- Boism PanelDocument24 pagesBoism PanelhipreyashNo ratings yet

- PCB CapabilitiesDocument5 pagesPCB CapabilitiesDanielCervNo ratings yet

- PCB SpecificationsDocument3 pagesPCB SpecificationsVlad VrabieNo ratings yet

- Multi Rib Metal Roofing TileDocument1 pageMulti Rib Metal Roofing Tilevadivel415No ratings yet

- 09 60 00 TilingDocument13 pages09 60 00 TilingKiran D AnvekarNo ratings yet

- Toll Plaza Structure - Technical SpecificationsDocument3 pagesToll Plaza Structure - Technical SpecificationsNeeraj SinghNo ratings yet

- Elephant Gypsum Boards Specification - Moistbloc BoardDocument1 pageElephant Gypsum Boards Specification - Moistbloc BoardDilon Fernando0% (1)

- Cembrit INSTALARE Instructions PDFDocument24 pagesCembrit INSTALARE Instructions PDFpapiNo ratings yet

- Fundermax-Max-Exterior-Concealed-FastenersDocument17 pagesFundermax-Max-Exterior-Concealed-Fastenersdilian bikovNo ratings yet

- Kingspan Europanel Jumbo KS100 ERO Datasheet MEATCA enDocument5 pagesKingspan Europanel Jumbo KS100 ERO Datasheet MEATCA en1BQ19AT069 PRAJWAL B KAMATHNo ratings yet

- Tyre Flap (EPDM) Specification306 - 83 - SEP - 2016Document5 pagesTyre Flap (EPDM) Specification306 - 83 - SEP - 2016Purchase and Stores Officer Contract Cell-II100% (1)

- Dubai Mnicipality G+12 - 3Document2 pagesDubai Mnicipality G+12 - 3Ali403No ratings yet

- Sealing Gasket (ENKA)Document6 pagesSealing Gasket (ENKA)Apras TyoNo ratings yet

- Bison Panel Cement Bonded Particle BoardDocument16 pagesBison Panel Cement Bonded Particle BoardafifkadriNo ratings yet

- Tech Handbook - Bison BoardsDocument51 pagesTech Handbook - Bison BoardsRaj Mani0% (1)

- Bromide Printing and Enlarging A Practical Guide to the Making of Bromide Prints by Contact and Bromide Enlarging by Daylight and Artificial Light, With the Toning of Bromide Prints and EnlargementsFrom EverandBromide Printing and Enlarging A Practical Guide to the Making of Bromide Prints by Contact and Bromide Enlarging by Daylight and Artificial Light, With the Toning of Bromide Prints and EnlargementsNo ratings yet

- Top View Section View: CHB Perimeter Walls To Serve As A Catch BasinDocument1 pageTop View Section View: CHB Perimeter Walls To Serve As A Catch BasinJan GarciaNo ratings yet

- EWACDocument2 pagesEWACsandeepNo ratings yet

- MS008 Steel Tank MSDocument9 pagesMS008 Steel Tank MSMhando IgnasNo ratings yet

- Editable List of Industrial ReportDocument3 pagesEditable List of Industrial ReportKoya ThangalNo ratings yet

- Mild Steel Product Guide 25Document25 pagesMild Steel Product Guide 25shani5573No ratings yet

- Keedex Price Book - 2015Document12 pagesKeedex Price Book - 2015Security Lock DistributorsNo ratings yet

- In-Situ Metallography Mett-Bio PDFDocument3 pagesIn-Situ Metallography Mett-Bio PDFMettBioNo ratings yet

- Chapter 10 - Testing of Welded JointsDocument18 pagesChapter 10 - Testing of Welded JointsFauzan BenraxidNo ratings yet

- Complete Joint Penetration and Partial PDFDocument3 pagesComplete Joint Penetration and Partial PDFBudimanNo ratings yet

- A Welding Lectures 3-3Document2 pagesA Welding Lectures 3-3hayder1920No ratings yet

- MILLER MigmagDocument48 pagesMILLER MigmagMatija BušićNo ratings yet

- Welding Consumable For Piping Work (UAIL Project)Document7 pagesWelding Consumable For Piping Work (UAIL Project)Karthik100% (1)

- Böhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Document1 pageBöhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Thanh TamNo ratings yet

- ANSI/AWS D14.5-97 Specification For Welding of Presses and Press ComponentsDocument157 pagesANSI/AWS D14.5-97 Specification For Welding of Presses and Press Componentslightjp1No ratings yet

- Gas Metal Arc WeldingDocument28 pagesGas Metal Arc WeldingMuhammad Syahir Mat SharifNo ratings yet

- WSX ND24C User ManualDocument19 pagesWSX ND24C User ManualAndrejNo ratings yet

- HFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ADocument14 pagesHFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ANashaat DhyaaNo ratings yet

- Test: Test Method(s) : Corrosion:: Tests)Document4 pagesTest: Test Method(s) : Corrosion:: Tests)Sheik Mohamed AliNo ratings yet

- NCPWB February 2000Document8 pagesNCPWB February 2000Claudia MmsNo ratings yet

- ICEE097 - Full Length Paper PDFDocument4 pagesICEE097 - Full Length Paper PDFWeld TechNo ratings yet

- En 15085 Design ModuleDocument89 pagesEn 15085 Design Module0502ravi100% (1)

- Damage MechaismDocument11 pagesDamage Mechaismsoheilkhosh3311No ratings yet

- Welding Acceptance Criteria On Pipe LineDocument2 pagesWelding Acceptance Criteria On Pipe Linewahyu100% (1)

- 1 s2.0 S0143974X23002134 MainDocument6 pages1 s2.0 S0143974X23002134 MainClaudia CaicedoNo ratings yet

- 08 Surface HT Volumic VWeld InstructionsDocument10 pages08 Surface HT Volumic VWeld Instructionsjdial9664No ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationCarlos Bustamante100% (1)

- A 814 - A 814M - 03 Qtgxnc9bode0tqDocument6 pagesA 814 - A 814M - 03 Qtgxnc9bode0tqsachinguptachdNo ratings yet

- Procedure For Welder QualificationDocument28 pagesProcedure For Welder Qualificationjagannath100% (1)

- Catalogue Revolloy Welding ConsumablesDocument30 pagesCatalogue Revolloy Welding ConsumablesAdi SutardiNo ratings yet

- Welding Procedures and Welders Qualification: SOLID HDS2-9048Document41 pagesWelding Procedures and Welders Qualification: SOLID HDS2-9048Niranjan khatuaNo ratings yet