Professional Documents

Culture Documents

Soil Compaction: Alberoni University, Fall 2020 Pavement Analysis and Design

Soil Compaction: Alberoni University, Fall 2020 Pavement Analysis and Design

Uploaded by

Abadullah Mujadidi0 ratings0% found this document useful (0 votes)

9 views25 pagesThis document discusses soil compaction. It explains that soil is commonly used as a construction material due to its availability, durability and low cost. Compaction involves mechanically densifying soil to reduce voids, while consolidation reduces voids over a longer period through drainage. Proper compaction increases soil strength and reduces permeability, compressibility, and shrink-swell potential. The moisture-density relationship and factors like soil type and compaction effort determine optimal compaction. Standard and modified proctor tests evaluate compaction in a lab, while various rollers are used for field compaction.

Original Description:

Original Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses soil compaction. It explains that soil is commonly used as a construction material due to its availability, durability and low cost. Compaction involves mechanically densifying soil to reduce voids, while consolidation reduces voids over a longer period through drainage. Proper compaction increases soil strength and reduces permeability, compressibility, and shrink-swell potential. The moisture-density relationship and factors like soil type and compaction effort determine optimal compaction. Standard and modified proctor tests evaluate compaction in a lab, while various rollers are used for field compaction.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

9 views25 pagesSoil Compaction: Alberoni University, Fall 2020 Pavement Analysis and Design

Soil Compaction: Alberoni University, Fall 2020 Pavement Analysis and Design

Uploaded by

Abadullah MujadidiThis document discusses soil compaction. It explains that soil is commonly used as a construction material due to its availability, durability and low cost. Compaction involves mechanically densifying soil to reduce voids, while consolidation reduces voids over a longer period through drainage. Proper compaction increases soil strength and reduces permeability, compressibility, and shrink-swell potential. The moisture-density relationship and factors like soil type and compaction effort determine optimal compaction. Standard and modified proctor tests evaluate compaction in a lab, while various rollers are used for field compaction.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 25

Soil Compaction

Alberoni University, Fall 2020 Pavement Analysis and Design 1

Soil Compaction

• Soil is used as a basic material for construction of:

• Retaining walls,

• Highways, Embankments, Ramps

• Airports,

• Dams, Dikes, etc.

• The advantages of using soil are:

• Is generally available everywhere

• Is durable - it will last for a long time

• Has a comparatively low cost

Alberoni University, Fall 2020 Pavement Analysis and Design 2

Compaction vs. Consolidation

• Compaction:

• When loose soils are applied to a construction site, compressive

mechanical energy is applied to the soil using special equipment to

densify the soil (or reduce the void ratio). Typically applies to soils that are

being used or re-used to a site.

• Consolidation

• When a static loads are applied to saturated soils, and over a period of

time the increased stresses are transferred to the soil skeleton, leading to

a reduction in void ratio.

• Depending on the permeability of the soil and the magnitude of the

drainage distance, this can be a very time-consuming process.

• Typically applies to existing, undisturbed soil deposits that has

appreciable amount of clay.

Alberoni University, Fall 2020 Pavement Analysis and Design 3

Compaction vs. Consolidation

• Compaction means the removal of air-filled porosity while

Consolidation means the removal of water-filled porosity

Alberoni University, Fall 2020 Pavement Analysis and Design 4

Compaction Benefits

1. Increased Shear Strength

2. Reduced Permeability

• This inhibits soils’ ability to absorb water, and therefore reduces

the tendency to expand/shrink and potentially liquefy

3. Reduced Compressibility

4. Control Swelling & Shrinking

5. Reduce Liquefaction Potential

Alberoni University, Fall 2020 Pavement Analysis and Design 5

Principles of Compaction

• Compaction of soils is achieved by reducing the volume of

voids. It is assumed that the compaction process does not

decrease the volume of the solids or soil grains·

uncompacted compacted uncompacted compacted

Alberoni University, Fall 2020 Pavement Analysis and Design 6

Principles of Compaction

• Moisture Density Relationship:

Alberoni University, Fall 2020 Pavement Analysis and Design 7

Compaction—General Principles

• Approximate optimum moisture content

Alberoni University, Fall 2020 Pavement Analysis and Design 8

Factors Affecting Compaction

1. Effect of soil type:

Compaction

Group Symbol

Characteristics

GW

GP

GM

GC Good

SW

SP

SM

SC

Good to Fair

CL

ML Good to Poor

OL, MH, CH, OH, PT Fair to Poor

Alberoni University, Fall 2020 Pavement Analysis and Design 9

Factors Affecting Compaction

1. Effect of soil type:

Group Symbol Value as Embankment Material

GW

Very Stable

SW

CL Stable

GP

GM

Reasonably Stable

GC

SC

SP

Reasonably Stable when Dense

SM

ML Poor, gets better with high density

OL, MH, CH, OH, PT Poor, Unstable

Alberoni University, Fall 2020 Pavement Analysis and Design 10

Factors Affecting Compaction

1. Effect of soil type:

Group Symbol Value as Subgrade Material

GW Excellent

GP

Excellent to Good

GM

GC

Good

SW

SP

SM Good to Fair

SC

ML

Fair to Poor

CL

OL, MH, CH, OH, PT Poor to Not Suitable

Alberoni University, Fall 2020 Pavement Analysis and Design 11

Factors Affecting Compaction

2. Effect of compaction effort:

Alberoni University, Fall 2020 Pavement Analysis and Design 12

Factors Affecting Compaction

2. Effect of compaction effort:

• If the compaction effort per unit volume of soil is changed, the

moisture–unit weight curve also changes.

• Three layers for all cases, number of hammer blows 20 to 50.

• As the compaction effort is increased, the maximum dry unit

weight is also increased and the moisture content is decreased.

Alberoni University, Fall 2020 Pavement Analysis and Design 13

Factors Affecting Compaction

2. Effect of compaction effort:

Alberoni University, Fall 2020 Pavement Analysis and Design 14

Laboratory Compaction Test

Methods

• Standard Proctor Test

Alberoni University, Fall 2020 Pavement Analysis and Design 15

Laboratory Compaction Test

Methods

• Standard Proctor Test

• 2.5 Kg rod

• 12 in. drop

• Modified Proctor Test

• 4.5 Kg rod

• 18 in. drop

Alberoni University, Fall 2020 Pavement Analysis and Design 16

Field Compaction

• Most of the compaction in the field is done with rollers. The

four most common types of rollers are:

• Smooth-wheel rollers (or smooth-drum rollers)

• Pneumatic rubber-tired rollers

• Sheep foot rollers

• Vibratory rollers

Alberoni University, Fall 2020 Pavement Analysis and Design 17

Field Compaction

• Smooth-wheel rollers (or smooth-drum rollers)

• Provide 100% coverage under the wheels

• Ground contact pressures as high as 310 to 380 kN/m2

• Not suitable for producing high unit weights of compaction when

used on thicker layers.

Alberoni University, Fall 2020 Pavement Analysis and Design 18

Field Compaction

• Pneumatic rubber-tired rollers

• Heavily loaded with several rows of tires.

• Tires are closely spaced—four to six in a row.

• The contact pressure under the tires can range from 600 to 700

kN/m2 and they produce about 70 to 80% coverage.

• Can be used for sandy and clayey soil compaction.

Alberoni University, Fall 2020 Pavement Analysis and Design 19

Field Compaction

• Sheep foot rollers

• drums with a large number of projections

• most effective in compacting clayey soils.

• The contact pressure under the projections can range from 1400

to 7000 kN/m2

Alberoni University, Fall 2020 Pavement Analysis and Design 20

Field Compaction

• Vibratory rollers

• Vibratory rollers are extremely efcient in compacting granular

soils.

• Vibrators can be attached to smooth-wheel, pneumatic rubber-

tired, or sheep foot rollers to provide vibratory effects to the soil.

Alberoni University, Fall 2020 Pavement Analysis and Design 21

Factors Affecting Field Compaction

• Soil type and moisture content

• Thickness of lift, the intensity

of pressure applied by the

compacting equipment,

• The area over which the

pressure is applied

Alberoni University, Fall 2020 Pavement Analysis and Design 22

Factors Affecting Field Compaction

• (a) Variation of dry unit weight with number of roller passes;

thickness of lift 5 2.44 m (8 ft); (b) estimation of compaction lift

thickness for minimum required relative density of 75% with

five roller passes

Alberoni University, Fall 2020 Pavement Analysis and Design 23

Specifications for Field Compaction

• In most specifications for earthwork, the contractor is

instructed to achieve a compacted field dry unit weight of 90

to 95% of the maximum dry unit weight determined in the

laboratory by either the standard or modified Proctor test.

• Relative Compaction:

Alberoni University, Fall 2020 Pavement Analysis and Design 24

Question?

Alberoni University, Fall 2020 Pavement Analysis and Design 25

You might also like

- Xarios 500-600 Operacion ServicioDocument61 pagesXarios 500-600 Operacion ServicioJavier Jose Gamboa Escalona100% (5)

- Executive Teaser South Tuban KSODocument4 pagesExecutive Teaser South Tuban KSObambang mulyadi100% (2)

- Chart InstallationDocument138 pagesChart InstallationPaul Lucian VentelNo ratings yet

- Soil Stabilization: TopicsDocument25 pagesSoil Stabilization: Topicsحسن كاظم ريسان B-4No ratings yet

- Robertson P.K. - 2013 - Cone Pentration Testing Interpretation of Soil Parameters Fine-Grained SoilsDocument23 pagesRobertson P.K. - 2013 - Cone Pentration Testing Interpretation of Soil Parameters Fine-Grained SoilsCristian Villa SiordiaNo ratings yet

- Presentation On GIBR-20May2020Document49 pagesPresentation On GIBR-20May2020Jasmine ENo ratings yet

- Summary of Drilling, Stresses, Pressures, and Borehole StabilityDocument11 pagesSummary of Drilling, Stresses, Pressures, and Borehole StabilityRoberta S.No ratings yet

- Raines-Site-Investigations-And-Geotechncial-Risk TUNNELDocument63 pagesRaines-Site-Investigations-And-Geotechncial-Risk TUNNELrakoNo ratings yet

- Advanced Geotechnical Engineering - CE 631A - Index Properties of SoilDocument12 pagesAdvanced Geotechnical Engineering - CE 631A - Index Properties of SoilBabul PratapNo ratings yet

- Discontinuity Characterization - QueensMineDesignWikiDocument4 pagesDiscontinuity Characterization - QueensMineDesignWikiImranNo ratings yet

- Effect of Fly AshDocument7 pagesEffect of Fly AshHenryNo ratings yet

- Modulus of Subgrade Reaction PDFDocument10 pagesModulus of Subgrade Reaction PDFMisgun Samuel100% (1)

- Stone Column DesignDocument11 pagesStone Column DesignKha nguyenNo ratings yet

- Determining The Geological Strength Index (GSI) Using Different MethodsDocument7 pagesDetermining The Geological Strength Index (GSI) Using Different MethodsJuan Pablo Alvarado RiquelmeNo ratings yet

- Unit 2Document25 pagesUnit 2Akshata MusaleNo ratings yet

- Unit 2Document25 pagesUnit 2akshata.musaleNo ratings yet

- Accepted Manuscript: 10.1016/j.enggeo.2018.06.010Document29 pagesAccepted Manuscript: 10.1016/j.enggeo.2018.06.010Reza OsgouiNo ratings yet

- Unit 2Document22 pagesUnit 2Akshata MusaleNo ratings yet

- 10 1016@j Conbuildmat 2020 121874Document15 pages10 1016@j Conbuildmat 2020 121874klismanfloresdNo ratings yet

- Cement Bond EvaluationDocument7 pagesCement Bond EvaluationFaizal WALIYNo ratings yet

- Ome Important Issues in Eng Rock Mass Class-Goel 2017Document13 pagesOme Important Issues in Eng Rock Mass Class-Goel 2017racoon11No ratings yet

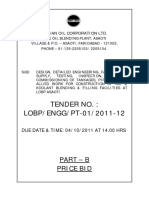

- LOBPENGGPT01201112 File2of3Document55 pagesLOBPENGGPT01201112 File2of3Vikas TanejaNo ratings yet

- Tan 2020 IOP Conf. Ser. Mater. Sci. Eng. 943 012005Document10 pagesTan 2020 IOP Conf. Ser. Mater. Sci. Eng. 943 012005GregorioNo ratings yet

- Greggdrilling Webinars RPHPG ZgzC5gDocument22 pagesGreggdrilling Webinars RPHPG ZgzC5gOscar GonzalezNo ratings yet

- Karin Olson Hoal Colorado School of Mines, Golden USA and KOH Consulting LLC, Golden USADocument21 pagesKarin Olson Hoal Colorado School of Mines, Golden USA and KOH Consulting LLC, Golden USAHugo PomaNo ratings yet

- Handout RDM-001 Subsurface Revised FinalDocument13 pagesHandout RDM-001 Subsurface Revised FinalDidi MelkybudiantoroNo ratings yet

- Top-Up T3 GI 04 - 13 - Note - Field TestingDocument11 pagesTop-Up T3 GI 04 - 13 - Note - Field Testing廿田一No ratings yet

- Drilling Engineering Overview: Project ManagementDocument24 pagesDrilling Engineering Overview: Project ManagementIgorCencičNo ratings yet

- A01 Fundamentals - of - Reservoir - Drilling - Completion - AtsDocument63 pagesA01 Fundamentals - of - Reservoir - Drilling - Completion - AtsrenangeminoNo ratings yet

- 1 - Introduction To Formation Evaluation3333333333333 PDFDocument28 pages1 - Introduction To Formation Evaluation3333333333333 PDFmuhaimen mahedeyNo ratings yet

- 28 35 1598 Dungca May 2022 93Document8 pages28 35 1598 Dungca May 2022 93John SinnerNo ratings yet

- Compaction PilesDocument11 pagesCompaction PilesJuhili SawantNo ratings yet

- Vdocument - in - Cement Bond Log Interpretation Reliabilityjpt 2007Document5 pagesVdocument - in - Cement Bond Log Interpretation Reliabilityjpt 2007حيدر خالد خلفNo ratings yet

- Stone Column-Stabilized Soft-Soil Performance InfluencedDocument18 pagesStone Column-Stabilized Soft-Soil Performance InfluencedrkNo ratings yet

- DLS212-02_Importance_of_Geology_20231013Document30 pagesDLS212-02_Importance_of_Geology_20231013iliavaNo ratings yet

- 8DayetalT TFeb2015JournalDocument9 pages8DayetalT TFeb2015JournalsokhnaNo ratings yet

- NZGS Liquefaction and Lateral Spread Poster V4Document1 pageNZGS Liquefaction and Lateral Spread Poster V4Bikesh ShresthaNo ratings yet

- E NordlundDocument47 pagesE Nordlundsukhoi200900No ratings yet

- Geotechnical Report27.07.23..Document37 pagesGeotechnical Report27.07.23..neilagxicarNo ratings yet

- Hotel & Resorts: Report On Geological InvestigationDocument54 pagesHotel & Resorts: Report On Geological InvestigationLim TiNo ratings yet

- 6.1 Rock Stabilisation MethodsDocument28 pages6.1 Rock Stabilisation Methodsxdhrts54 yNo ratings yet

- Formation EvaluationDocument27 pagesFormation EvaluationHerry SuhartomoNo ratings yet

- Annex V Response To Comment On The Draft GIRDocument2 pagesAnnex V Response To Comment On The Draft GIRSolomon MehariNo ratings yet

- 07 NAC Inclining Test (160213)Document9 pages07 NAC Inclining Test (160213)Gilles MathieuNo ratings yet

- SPE "Back To Basics" Bond Log Theory and Interpretation: April 16, 2013 Ian Cameron, P.Eng. FormerlyDocument34 pagesSPE "Back To Basics" Bond Log Theory and Interpretation: April 16, 2013 Ian Cameron, P.Eng. FormerlyZohaib HassanNo ratings yet

- Jurnal Agregat PipihDocument9 pagesJurnal Agregat PipihSIPIL100% (1)

- Soil Stabilizer: Case Study, Japan: Shoho TsutsumiDocument18 pagesSoil Stabilizer: Case Study, Japan: Shoho TsutsumiHidayat ErwinNo ratings yet

- Topic 7 Dr. KamruzzamanDocument31 pagesTopic 7 Dr. KamruzzamanCEG BangladeshNo ratings yet

- Rahul and SandeepDocument23 pagesRahul and SandeeptejeswarNo ratings yet

- Material Balance: Samarth D. PatwardhanDocument30 pagesMaterial Balance: Samarth D. PatwardhanAman DeshmukhNo ratings yet

- CGS - The Influence of Tailings Dam Failures On PracticeDocument41 pagesCGS - The Influence of Tailings Dam Failures On PracticeAdnan KaderNo ratings yet

- KARAKTERISASI RESERVOIR 2D - TrisaktiDocument215 pagesKARAKTERISASI RESERVOIR 2D - Trisaktirabby jeggoatzeNo ratings yet

- Introduction To Petroleum Engineering: Course OutlinesDocument200 pagesIntroduction To Petroleum Engineering: Course OutlinesAlamen GandelaNo ratings yet

- Slope Design & Construction PracticeDocument153 pagesSlope Design & Construction PracticeKAI CHUAN CHUNo ratings yet

- PethographyDocument41 pagesPethographyHeirwireNo ratings yet

- Ship Stability PDFDocument17 pagesShip Stability PDFMd. Shahjada TarafderNo ratings yet

- Presentation - Roles Geologist 210130Document57 pagesPresentation - Roles Geologist 210130gabrielNo ratings yet

- 0.formation Evaluation-IntroductionDocument11 pages0.formation Evaluation-IntroductionAshish ChaudharyNo ratings yet

- Large Simple Shear Testing of Soft Bangkok Clay Stabilized With Soil - Cement-Columns and Its ApplicationDocument12 pagesLarge Simple Shear Testing of Soft Bangkok Clay Stabilized With Soil - Cement-Columns and Its ApplicationRichard CallohuariNo ratings yet

- Cementing Zonal IsolationDocument1 pageCementing Zonal IsolationWilsson GalindoNo ratings yet

- GL 4052 Geologi Well Logging Inroduction - Mud Logging Sem 1 2021 - 2022 Send at 15092021Document17 pagesGL 4052 Geologi Well Logging Inroduction - Mud Logging Sem 1 2021 - 2022 Send at 15092021Muhammad SatriyoNo ratings yet

- Design Optimization of The Lines of The Bulbous BowDocument12 pagesDesign Optimization of The Lines of The Bulbous BowFernando Raúl LADINONo ratings yet

- 40.00 EnForcer HF Full Line Brochure Page by page-LowResDocument6 pages40.00 EnForcer HF Full Line Brochure Page by page-LowResLuis Alberto Rivas GarciaNo ratings yet

- Renesas Flexible Software Package (FSP) v410 User ManualDocument4,346 pagesRenesas Flexible Software Package (FSP) v410 User Manualmar_barudjNo ratings yet

- Cambridge International AS & A Level: Mathematics 9709/53Document12 pagesCambridge International AS & A Level: Mathematics 9709/53Aiotha SatryaNo ratings yet

- Effective Delivery of Synchronous and Asynchronous Teaching Reflection SynchronousDocument2 pagesEffective Delivery of Synchronous and Asynchronous Teaching Reflection SynchronousE Noicale GadibeNo ratings yet

- Introduction To Human Computer Interaction PQ1-PQ2Document12 pagesIntroduction To Human Computer Interaction PQ1-PQ2CedNo ratings yet

- KWU Electro Hydraulic Governing Final1Document41 pagesKWU Electro Hydraulic Governing Final1Rahul Dev Goswami100% (3)

- Insulation Monitoring Relay DCDocument4 pagesInsulation Monitoring Relay DCNICUSORNo ratings yet

- الهجمات السيبرانية على القطاع البنكي التهديدات والحلول - فادي الأسوديDocument16 pagesالهجمات السيبرانية على القطاع البنكي التهديدات والحلول - فادي الأسوديikuytrfNo ratings yet

- Lineas de Presion y Retorno de Los JostickDocument3 pagesLineas de Presion y Retorno de Los JostickhidraulicosNo ratings yet

- Resume Sudhananda Biswas - Net DevDocument2 pagesResume Sudhananda Biswas - Net DevMdsharif JahanNo ratings yet

- Sri Krishna Arts and Science Computer Technology: Course Coordinator Dr. V. S. Anita Sofia Prof. & HeadDocument78 pagesSri Krishna Arts and Science Computer Technology: Course Coordinator Dr. V. S. Anita Sofia Prof. & HeadAnita Sofia VNo ratings yet

- CS 229, Summer 2019 Problem Set #1 SolutionsDocument22 pagesCS 229, Summer 2019 Problem Set #1 SolutionsSasanka Sekhar SahuNo ratings yet

- Megapulse Senior 265: Continuous & Pulsed Shortwave TherapyDocument1 pageMegapulse Senior 265: Continuous & Pulsed Shortwave Therapyأياام زمانNo ratings yet

- Concepts (PPT) - Data PreprocessingDocument19 pagesConcepts (PPT) - Data Preprocessingmtemp7489No ratings yet

- A Nlp-Based Solution To Prevent From Privacy Leaks in Social Network PostsDocument6 pagesA Nlp-Based Solution To Prevent From Privacy Leaks in Social Network PostsfareesaNo ratings yet

- Atc Q-Bridge Thermal ConductorDocument4 pagesAtc Q-Bridge Thermal ConductorwjsynNo ratings yet

- Internet Marketing Integrating Online and Offline Strategies 3rd Edition Roberts Solutions ManualDocument14 pagesInternet Marketing Integrating Online and Offline Strategies 3rd Edition Roberts Solutions ManualRichardGrantsdtmz100% (15)

- PARTIIOUTPUTDEVICEDocument333 pagesPARTIIOUTPUTDEVICEFiras BEN HMIDANo ratings yet

- Iwt PracticalDocument18 pagesIwt Practical[04] - Abrar ShahNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument3 pagesData Sheet: Three Phase Induction Motor - Squirrel CageErick Nilzon Montañez CalachuaNo ratings yet

- Gate 3-Execution: Machinery, Methods, and Management SkillsDocument36 pagesGate 3-Execution: Machinery, Methods, and Management Skillsjosh salagan100% (1)

- Estimate-Bus Queue ShelterDocument3 pagesEstimate-Bus Queue ShelterAmit KumarNo ratings yet

- B.M. Rakibul HasanDocument2 pagesB.M. Rakibul HasanGEAR Travel LtdNo ratings yet

- Lesson Plan in Teaching Speaking-Etos, MyraDocument4 pagesLesson Plan in Teaching Speaking-Etos, MyraMyra EtosNo ratings yet

- Introduction of InheritDocument2 pagesIntroduction of InheritNugroho BagusNo ratings yet

- Philips Projection Catalogue 2021-22Document15 pagesPhilips Projection Catalogue 2021-22James StanleyNo ratings yet

- HIGHEST 47.5 Individual Project Report ASM501 (AMIR ISKANDAR)Document14 pagesHIGHEST 47.5 Individual Project Report ASM501 (AMIR ISKANDAR)Zahratul FauziyyahNo ratings yet