Professional Documents

Culture Documents

IJCRT1812056

IJCRT1812056

Uploaded by

Francis FaustineCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJCRT1812056

IJCRT1812056

Uploaded by

Francis FaustineCopyright:

Available Formats

www.ijcrt.

org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882

Detection of Crack in Railway Track by Crack

Detection System

1

Prof. V. S. Shah, 2Pranjali Neware, 3Bharti Gode, 4 Vikky Bhatkar, 5Ashish Tajne

1

Assistant Professor, 2,3,4,5 B.E Students

1

Dept. of Electrical & Electronics Engineering,

1

PRMCEAM, Badnera-Amravati, M.S, India

Abstract: Now a-days Transportation is very important for passenger as well as for goods from one place to another. Economic level

depends on capacity and the level of transport. This paper presents an implementation of an efficient and cost effective solution for

railway application. In this paper it consists of GSM module, GPS module and Ultra sonic sensor. In this paper motor driver is used to

control the motor. The GPS and GSM module help us to send crack detection to nearest railway station. Now-a-days we use high cost

LVDT having less accuracy to measure the crack. But also we use less ultrasonic sensor for above process. The importance of this

paper is that, it is applicable in the detection during both day and night.

Index Terms - GPS Module, GSM Module, Ultrasonic Sensor, Aurdino-mega, MINI ARM 7KIT, L298 Motor Driver.

I. INTRODUCTION

In recently developments in railway systems, high-speed trains are being extensively used and rail-transportation is being

increased. Reasons for this increase are high speed, economical, cost effectiveness, environment friendly, safety and modern

characteristics of railway system. In railway tracks, anytime the tracks are damaged due to weather conditions, floods, earthquake,

cyclones etc. The existing track surveying systems have some limitations. It takes more time and it is less accurate. In this paper by

placing the robot in each stations and checking at uneven intervals will help to reduce train accidents. In proposed system consists

of ultrasonic sensor which finds the cracks on the tracks. This section mainly consists of GPS module which is used to find the

exact position of the cracks and GSM modules for transmitting the information to railway authority. It also consist two motors

which is controlled by the motor driver L298. We used Arduino a vast majority of the work is done in the field of crack detection

uses the infrared sensing technique. It was initially thought to be the best solution to the problem of crack detection. They introduce

surveying systems in this project is operational on both ballast and slab tracks. This System can be operated in tunnels without any

interruption. This is a very cheap, simple scheme with sufficient ruggedness suitable to the Indian scenario to track geometry

survey by using sensor, which proves to be cost effective as compared to the existing methods.

II. PREVIOUS WORK

1] Akhil N, The author has presented an efficient and cost effective solution suitable for railway application. This paper consists of

GPS module, GSM module, an Ultrasonic sensor, a microcontroller LPC2148 and motor driver L293D. This system is applicable

in detection during both day and night. The proposed system immediately notices cracks in tracks and inform the railway authority

and hence reduce railway accidents. It concludes that this system is more accurate and can be operated in tunnels without any

interruption. In future, more sensors can be adopted for faster work. CCTV system with IP based camera for monitoring can be

used.

2] Er. Nisthul G, The author has suggested that have a project for addressing an issue of crack detection on railway track by

developing a automatic detection system using Infrared (IR) crack sensing module and a communication module based on GSM

technology. It concludes that it will help in preventing train accidents to a large extent. With the help of crack detection is possible

even in places like deep coal mines, mountain region and dense thick forest regions. In future, solar panel can also be used for

conservation of power.

3] M. Kalaimathi, In this paper they are working on Innovative Railway Track Surveying with Sensors and Controlled by Wireless

Communication system, in which they used MEMS,GPS,GSM,ARM7TDMI-S microcontroller, RF transmitter, LCD Display

,LVDT. The system is design in this paper is cheap in cost and used in both ballast and slab tracks, and because of LVDT sensor it

is very accurate and take less time to inform to station and railway which on that track and also it operate in tunnel without

interruption.

4] M. Benisha, This paper is base on Crack Detection & Fire Safety Monitoring System for Railway Inspection. In this paper, the

robotic module is place in the train and ZigBee Network is in it which is used to inform the train. Ultra sonic sensors are used to

monitor the track status & detect the exact location of crack on track. MEMs sensor is used to detect the obstacle on track and also

Fire alarm are used alert the passenger, driver, and fire service station.LCD help to display crack position to the train operator. It

concludes that the system is beneficial because it detect the crack without human intervention. This system has some advantages

like less cost, low power consumption, less analysis time.

IJCRT1812056 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 451

www.ijcrt.org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882

5] Mr. Prashanth Addagatla, In this paper, the proposed system automatically detects cracks on railway track without any human

intervention. This paper has given the use of microcontroller LPC2148, LED & LDR, GSM & GPRS, DC motor. In this method

cracks can be detected by using IR transmitter and receiver. Advantages of this system are less cost, less analysis time and low

power consumption. Hence it concludes that this system is not suitable for small crack detection.

6] B. Siva Rama Krishna: The paper proposes design of robust railway crack detection scheme (RRCDS). It consists of IR sensor,

Bluetooth and Arduino. The manual inspection of railway track took more time and human fatigue. The proposed system

introduces Bluetooth based technology to prevent the train accident. The author has implemented the IR sensor based railway crack

detection system using Bluetooth technology and IP based camera for monitoring the visual video capture from the track. The

proposed broken rail detection system automatically detects the faulty railway track without any human interference.

7] N. Karthick, The Author has presented a system suitable for railway transportation to identify the crack in railway track and to

prevent the accident. They have used Magnetic particle inspection (MPI), Non destructive testing (NDT), Ultraviolet (UV), Anti

collision device (ACD).In this system, sensors are placed in train engine so that when crack is detected on the track, train starts to

slow and stop at respective point automatically and exact place of the crack is given to control room. Secondly, the next cause of

accident is prevented from two trains opposite in same track by using same sensors fitted in the engine if the sensor senses same

signal from opposite train then it automatically applies brake and stop train at certain distance. It concludes that, both face to face

collision and crack on track are detected 4-5km before by the continuous monitoring of ultrasonic metal detecting sensor. System

can be used in village areas by which man power is reduced and time is saved.

8] Prof. P. Navraja, This paper consists of GPS Module, GSM modem, IR sensor, PIR sensor for application of communication

purpose, crack detection and finding of human being present in the railway track. The GPS module and GSM modem help us to

find and sending railway geometric parameter of crack detection to the nearest railway station. For measurement of track distance

Ultrasonic sensor with high accuracy and less cost is used. System is applicable for both day and night time detection purpose. It

concludes that it does not give false output and crack can be detected without error.

9] Reenu George, The author suggest existing system has been modified by using smart phone which helps in detecting the exact

location of the fault. This system consists of IR transmitter and receiver, crack detection, GPS, GSM, PIC microcontroller. The

method utilizes IR transmitter and receiver for the detection purpose and have many advantages compared to the traditional

technique. The advantage includes less cost, low power consumption and less analysis time. The method can be implemented in

large scale in the long run to facilitate better safety standards and provide effective infrastructure for achieving better results in the

future.

10] Aliza Rza Rizvi, In this research paper, a computer vision based method is presented. A system has been suggested which can

periodically take images of the railway tracks and compared with the existing database of non-faulty track images on a continuous

basis. If a fault arises in the track section, the system will automatically detect the fault and necessary actions can be taken, to avoid

miss happening. This system includes railway track, cracks, manual inspection, Image processing, computer vision. The method

replaces manual inspection by automatic inspection. Thus efficiency is ensured.

11] Mohit Dodval, The author has presented the paper to inspect the railway track by using real time photo image processing

through wireless module. The methods were designed for various software setups, specifically MATLAB and C ++ using the Intel

open CV library. To find the fault in railway track several techniques are used vibration sensor ultrasonic sensor detection of track

using infrared.

12] Kunduru Umamaheswari, In this paper author considering the major problem that lead to railway accident. Which include

obstacles entry on the track and crack on the track. To overcome this author have proposed a testing train which uses ultrasonic

sensor with range of 100 Cms and delay 30 cm and according to distance between the obstacle slow down speed of vehicle and

finally stop. The paper uses Aurdino micro-controller, light emitting diode (LED), Liquid crystal display (LCD), Global system for

mobile (GSM), Global positioning System (GPS). In this paper, authors have proposed a proto type of testing for detecting obstacle

and crack. The aurdino used for this system is Atmega 328 with flash memory and SPRM for storing data for future purposed. It

concludes that the prototype of testing vehicle can efficiently detect crack and obstacle on railway track.

13] Rakesh V. Pise, The work proposes a cost effective solution to the problem of railway track crack detection utilizing IR

transmitter and receiver which track the location of faulty track which then mended immediately so that many lives will be saved.

If these deficiencies are not controlled at early stages they might lead to a number of derailments resulting in heavy loss of life and

property has train derailment can be avoided and chance of loss of human life and economy can be minimize.

14] Parag Nikhar, This paper proposes a cost effective solution to the problem of crack detection of rail track utilizing IR sensors.

In this paper is implementation of LPC2148 microcontroller along with GSM module and GPS receiver. Whenever the crack is

detected a buzzer will be activated to alert the surroundings and message will be automatically sent to the controlling station of

railway authority. It consists of Transport, Efficient, Detection, Derailment, GSM, and Liquid Crystal Display (LCD) , GPS. It

concludes that the GSM based crack detection system automatically detects the faulty rail track without any human interface. The

main advantages of this system are less cost, low power consumption, on time data operation and minimum analysis time. The

simple idea can be implemented in large scale in order to have long run to facilitate better safety and provide effective testing

infrastructure for achieving better results in the future.

15] Ebi Benny, This paper, consists of an introduction to railway track inspection and its various applications. Sensor is used to

detect the various cracks and object. In this project sensor used is optical sensor for detection of crack in the track. 89C25 control

IJCRT1812056 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 452

www.ijcrt.org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882

unit is used to analyze the fault. The FM receiver unit is fixed at the nearest railway station and transmitted signal is received by

receiver unit and gives information to the responsible authority. This paper also consists of Relay for Buzzer operation and

different voltages 12V, 7Ah lead acid battery. The IR sensor is used to detect the crack in the track and send signal up to 9 Volt to

the frequency modulator. It has an advantageous than problem to GSM communication.

16] Diksha Nagdevte, This paper introduces the detection of cracks in rail road’s using ultrasonic and PIR sensor. This system

mainly consists of PIR sensor, Ultrasonic transmitter and receiver, GPS module and GSM modem, IR sensor. There is several

crack detection technique but this system is less costing and gives more accurate result. By using this system manual checking is

avoided hence requires less power. This idea can be implemented in large scale for safety and helps in reduction of derailments.

17] Anand S. Muley, This paper presents an implementation of an efficient and cost effective solution suitable for large scale

application by using the op-based crack detection in railway track using GSM system. This system is also helpful for another

application where cracking problem take place. The sensitivity of this system is high hence no any problem comes in detection of

crack. Due to simple idea, installation is quite easy. This document provides an overview of the key measurement required for

testing GSM trans-receivers. By using the op-amp, cost of this system is reduces.

III. PROPOSED CONTROL DESIGN

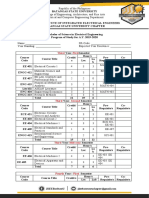

Fig. 1 Block Diagram of Proposed Control Design

Fig.1 Block Diagram mainly consists of an Ultrasonic Sensor, GSM Module, GPS Module, Motor driver and Arduino Mega. DC

motor is used to run the robotic section with the help of motor driver L298. In this, block diagram Ultrasonic sensor is used to detect

the crack. It sends the sound signal to track and receives the echo signal. A motor driver can control two motors at a time. And also

Ultrasonic sensor is used to detect the crack. The GPS module will collect the longitude and latitude position of the crack and send to

the authority by GSM module. These parts are placed inside robotic vehicle that travel through the track. Two motors are used to

drive the vehicle and a motor driver is used to drive the motor.

IJCRT1812056 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 453

www.ijcrt.org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882

IV. PROGRAM FLOW CHART

Fig. 2 Flow Chart

Fig. 2 shows the flow chart of implementation of Arduino to detect the fault. We have to initialize the GPS module, GSM module and

input - output port of the Arduino. Then start the motor using motor driver L298. At that time the Arduino sends a trigger pulse

continuously to the ultrasonic sensor and turn on the timer. And the transmitter of the ultrasonic sensor send sound signal to the track

and Receiver of the ultrasonic sensor receives the echo signal. Then Arduino will turn on the timer. Due to this we get the time and

velocity of the sound. Accordingly, we can calculate the distance between the sensors and track continuously and check it with

reference value (7cm). If the distance is 7cm, then it will continuously track the distance. It is the continue process (checking

distance). Otherwise (distance greater than 7 cm), motor will be stop. GPS module will collect the position of the crack and send to

the authority by GSM module.

V. EXPERIMENTAL SETUP & RESULTS

Fig. 3 Robotic Section

It Contains GPS module, GSM module, Motor Driver, 2 DC motors, LCD display, Vehicle Kit and an arm board.

IJCRT1812056 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 454

www.ijcrt.org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882

When crack is found, the robotic section sends that location of the crack to the authority. Above given is the message received from

the robotic section. The crack is founded at 20.878765N, 77.757671E position.

VI. CONCLUSION

The Railway crack detection system is introduce in this paper, for this surveying system experiment had done on a surface having

crack by running our designed robot section having ultrasonic sensor to sense the crack. It is more accurate than the existing works

more over the GPS module gives the exact position of the crack.

In this, the system is presented to detect the cracks in tracks effectively. With the ultrasonic sensor the cracks in the railway track is

detected and by using wireless modules the information is passed to the authority. Continuously check the crack by robotic section.

The location can be found out by using GPS module in the system. The introduced surveying system is operational on both ballast and

slab tracks. These systems can be operated in tunnels without any kind of interruption. We use the cctv systems with IP based camera

for monitoring the visuals videos captured from the track. Here DC supply is given to the system from ac supply through adaptors. A

rechargeable battery can replace the adaptors and making the system much more user friendly.

VII. ACKNOWLEDGMENT

Despite all our efforts, it would have been impossible to complete our paper successfully without the kind support and help of many

individuals and organizations. We would like to extend our sincere thanks to all of them.

REFERENCES

1. Akhil N. “Railway Crack Detection System” International Research Journal of Engineering and Technology (IRJET) Vol-3,

Issue-5 May2016.

2. Er. Nisthul “Automatic Railway Track Crack Detection System” Imperical Journal of Interdisciplinary Research (IJIR) Vol-

3, Issue-4, 2017.

3. M. Kalaimathi “Innovative Railway Track Surveying with Sensors and Controlled by Wireless Communication” A. R.

Engineering College, Vilupuram, Tamil Nadu, India.Vol-2,Issue-3,2013.

4. M. Benisha “Crack Detector & Fire Monitering System for Railway Inspection” The International Journal Of Science

&Technologe Vol-4, Issue-5, May 2016

5. Mr. Prashant addagatla “A Modern Method for Detecting Cracks in Railway Tracks by the Efficient Utilization of LDR and

LED System” International Journal of Engineering Science Invention. ISSN (Online): 2319-6734, ISSN (Print): 2319-6726.

6. B. Siva Rama Krishna “Railway Track Fault Detection System by Using IR Sensors and Bluetooth Technology” Assian

Journal of Applied Science and Technology (AJAST) Vol-1, Issue-6, July 2017.

7. N.Karthick “Implementation of Railway Track Crack Detection and Protection” International Journal Of Engineering and

Computer Science Vol-6, Issue-5, May 2017.

8. Prof. P. Navaraja “Crack Detection System For Railway Track By Using Ultrasonic and PIR Sensor” IJAICT Vol-1, Issue-1,

May2014

9. Reenu George “Automatic Broken Track Detection Using IR Transmitter and Receiver” International Journal of Advanced

Research in Electrical, Electronics and Instrumentation Engineering. Vol-4, Issue, April 2015.

IJCRT1812056 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 455

www.ijcrt.org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882

10. Aliza Raza Rizvi “Crack Detection in Railway Track Using Image Processing” International Journal of Advance Research,

Ideas and Innovations in Technology Vol-3, Issue-4, 2017.

11. Mohit Dodval “Railway Track Crack Detection Using Vibration Analysis ” International Journal For Technology Research

In Engineering, Vol-4, Issue 07, March-2017

12. Kunduru Umamaheswari “An Arduino Based Method For Detecting Cracks And Obstacle in Railway Track” International

Journal Of Electronics, Electrical And Computational System, Vol-6, Issue 4, April-2017

13. Rakesh Pise “Review Of Railway Track Crack Detection Using IR Transmitter and receiver ” International Research Journal

of Engineering and Technology (IRJET) Vol-4,Issue-1,Jan 2017

14. Parag Nikhar “IR Sensor Based Crack detection of Railway Track Using GSM &GPS System” International Journal for

Research in Applied Science &Engineering Technology (IJRASET),Vol-5,Issue-1,January 2014

15. Ebi Benny “Design Of Automatic Railway Track Crack Detecting Vehicle ” International Journal On Research Innovation In

Engineering Science And Technology, Vol-2, Issue-5, May-2017

16. Diksha Nagdevete “Detection of Cracks In Rail Road Using Ultrasonic and PIR Sensor” International Research Journal of

Engineering and Technology (IRJET) Vol-4, Issue-1, Jan 2017.

17. Mr. Anand S. Muley “Railway Track Crack Detection Based on GSM Technique” International Research Journal Of

Engineering and Technology (IRJET) Vol-4, Issue-1Jan- 2017.

18. Prof. P.Navaraja Assistant Professor, Electronic and Communication Engineering, Mahendra Institute of Technology,

Namakkal, Tamilnadu, India. "Crack Detection System for Railway Track by Using Ultrasonic and PIR Sensor" ISSN 2348

9928 IJAICT Volume -1, Issue-1, May 2014.

19. Athira Ajith, Aswathy K S, Binoy Kumar H, Dantis Davis, Lakshmi S Pai, Janahanlal P Stephen "Innovative Railway Track

Surveying With Sensors and Controlled By Wireless Communication" IJREAT International Journal of Research in

Engineering and Advanced Technology, Volume 2, Issue 2, Apr-May, 2014.

20. V.Radha, Sreedevi, V.Sandhya " An Innovative Railway Track Surveying System for Accident Reduction" ISSN 2319-8885

Vol.03,Issue.44 December 2014, Pages:8907-8910.

21. K.N.Sreekumar , G.Sankar , M.Kumaresan " Robust Railway Crack Detection Scheme Using ARM IRTRDS Algorithm"

.Journal of NanoScience and NanoTechnology | Vol 2 | Issue 5 | Spring Edition | ISSN 2279 0381

IJCRT1812056 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 456

You might also like

- 818507-M ELITE Service and Parts ManualDocument374 pages818507-M ELITE Service and Parts Manualotrupon melli100% (1)

- Welding Principles and Applications 7th Edition Jeffus Test BankDocument8 pagesWelding Principles and Applications 7th Edition Jeffus Test BankGlennGarciacaweq100% (12)

- IJRPR5085Document4 pagesIJRPR5085srinivasNo ratings yet

- Automatic Detection System For Railway TrackDocument6 pagesAutomatic Detection System For Railway TrackIJRASETPublicationsNo ratings yet

- Railway Track Crack Detection Using GPS and GSMDocument4 pagesRailway Track Crack Detection Using GPS and GSMInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Implosion of Railway Sleepers and Propounded AntidoteDocument6 pagesImplosion of Railway Sleepers and Propounded AntidoteAdvanced Research PublicationsNo ratings yet

- IoT Based Robotic Car For Railway Track Crack Detection SystemDocument7 pagesIoT Based Robotic Car For Railway Track Crack Detection SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Matchava Rajalakshmi RaviDocument6 pagesMatchava Rajalakshmi Raviravishankar yadavNo ratings yet

- Ijaerv14n2spl 04Document4 pagesIjaerv14n2spl 04srinivasNo ratings yet

- C O D R T: Rack and Bject Etection On The Ailway RackDocument4 pagesC O D R T: Rack and Bject Etection On The Ailway Rack004ICEDhanooj SNo ratings yet

- Fin Irjmets1683721244Document8 pagesFin Irjmets1683721244Pavan NKHNo ratings yet

- Railway Track Structural Heath Monitoring SystemDocument46 pagesRailway Track Structural Heath Monitoring Systempunith100% (1)

- Paper 1763Document5 pagesPaper 1763srinivasNo ratings yet

- B10. Iot Railway Fault DetectionDocument88 pagesB10. Iot Railway Fault DetectionECEK85A0409No ratings yet

- Crack Detection in Railway Tracks Using Image ProcessingDocument10 pagesCrack Detection in Railway Tracks Using Image ProcessingIJRASETPublicationsNo ratings yet

- Railway Track Security System Report PDFDocument26 pagesRailway Track Security System Report PDFeshu50% (2)

- Yash Bhowate .Document15 pagesYash Bhowate .Yash BhowateNo ratings yet

- Railway Track Security System ReportDocument26 pagesRailway Track Security System ReportAshishNegi100% (28)

- T.E. Mini Project Report: Submitted byDocument34 pagesT.E. Mini Project Report: Submitted byVAISHNAVI PATILNo ratings yet

- A Literature Survey On "Density Based Traffic Signal System Using Loadcells and Ir Sensors"Document3 pagesA Literature Survey On "Density Based Traffic Signal System Using Loadcells and Ir Sensors"hiraNo ratings yet

- Smart System of Potholes DetectionDocument6 pagesSmart System of Potholes DetectionIJRASETPublicationsNo ratings yet

- Railway Security System Based On Wireless Sensor Networks: State of The ArtDocument4 pagesRailway Security System Based On Wireless Sensor Networks: State of The ArtSunny LeoneNo ratings yet

- Detection of Humps and Potholes On Roads and Notifying The Same To The DriversDocument4 pagesDetection of Humps and Potholes On Roads and Notifying The Same To The Driversdhanu suriyaNo ratings yet

- Object Detection and Collision Avoidance With Train Using GSMDocument4 pagesObject Detection and Collision Avoidance With Train Using GSMBereket LemmaNo ratings yet

- An Intelligent Design To Detect Broken Track For Indian RailwayDocument4 pagesAn Intelligent Design To Detect Broken Track For Indian RailwayijaertNo ratings yet

- Bachelor of Technology: " Railway Crack Track Detection"Document18 pagesBachelor of Technology: " Railway Crack Track Detection"Huxtle RahulNo ratings yet

- Obstacle Detection System For Railways: Karthick S, Aishwarya Patil, Ullas S U K. SaravanakumarDocument3 pagesObstacle Detection System For Railways: Karthick S, Aishwarya Patil, Ullas S U K. Saravanakumarkarthick sNo ratings yet

- Smart Ambulance by IotDocument5 pagesSmart Ambulance by Iotlee kok onnNo ratings yet

- Automatic Railway System Using Wireless Sensor NetworkDocument5 pagesAutomatic Railway System Using Wireless Sensor NetworkMar CelNo ratings yet

- BPI - Template - 2024 (2) (1111)Document16 pagesBPI - Template - 2024 (2) (1111)nitumoni0202No ratings yet

- Adaptive Real Time Traffic Prediction Using Deep Neural NetworksDocument13 pagesAdaptive Real Time Traffic Prediction Using Deep Neural NetworksIAES IJAINo ratings yet

- Design and Fabrication of Automatic Railway Track Crack Detection SystemDocument6 pagesDesign and Fabrication of Automatic Railway Track Crack Detection SystemGRD Journals100% (1)

- Automatic Detection of Potholes and Humps On Road: Parag Kadale, Shivam Barde, Anand PawarDocument3 pagesAutomatic Detection of Potholes and Humps On Road: Parag Kadale, Shivam Barde, Anand PawarDeepak DasNo ratings yet

- Automatic Broken Track Detection Using LED-LDR Assembly: Avinash - Vanimireddy, D.Aruna KumariDocument4 pagesAutomatic Broken Track Detection Using LED-LDR Assembly: Avinash - Vanimireddy, D.Aruna Kumariswapnil kaleNo ratings yet

- Advanced Driver Assistance SystemDocument5 pagesAdvanced Driver Assistance SystemIJRASETPublicationsNo ratings yet

- On - Automotive Rail Track Crack Detection SystemDocument17 pagesOn - Automotive Rail Track Crack Detection SystemHuxtle RahulNo ratings yet

- Android Pothole Detection System Using Deep LearningDocument3 pagesAndroid Pothole Detection System Using Deep LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- JournalNX - Smart Public TransportDocument3 pagesJournalNX - Smart Public TransportJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Microcontroller Based Embedded System For Railway Gate Monitoring and ControllingDocument11 pagesMicrocontroller Based Embedded System For Railway Gate Monitoring and ControllingDBugsNo ratings yet

- Automatic Tunnel Lighting System For Road Traffic With Auto Exhaust FanDocument17 pagesAutomatic Tunnel Lighting System For Road Traffic With Auto Exhaust FanIJRASETPublicationsNo ratings yet

- Robust Railway Crack Detection Scheme (RRCDS) Using LED-LDR AssemblyDocument6 pagesRobust Railway Crack Detection Scheme (RRCDS) Using LED-LDR AssemblyMohanaprakash EceNo ratings yet

- Pothole DetectionDocument5 pagesPothole DetectionLocal techNo ratings yet

- Street Lights That Glows On Detecting Vehicle Movement - 104407Document17 pagesStreet Lights That Glows On Detecting Vehicle Movement - 104407Hitesh PimpalshendeNo ratings yet

- Automated Pothole Filling MachineDocument5 pagesAutomated Pothole Filling MachineIJRASETPublicationsNo ratings yet

- Rfid BunDocument7 pagesRfid BunSimona NicoletaNo ratings yet

- Railway Track Security System IJERTV4IS031135Document3 pagesRailway Track Security System IJERTV4IS031135Prasoon KumarNo ratings yet

- Automatic Railway SystemDocument5 pagesAutomatic Railway SystemTomu RomsonNo ratings yet

- Automotive Crack Detection For Railway Track Using Ultrasonic SensorzDocument5 pagesAutomotive Crack Detection For Railway Track Using Ultrasonic SensorzVivek SinghNo ratings yet

- Automatic Railway Gate ControlDocument6 pagesAutomatic Railway Gate ControlRithesh VRNo ratings yet

- JETIR2205016Document7 pagesJETIR2205016abhiraj2258.inNo ratings yet

- INTELLIGENCE AMBULANCE - TRAFFIC MANAGEMENT SYSTEM A Review PractiseDocument4 pagesINTELLIGENCE AMBULANCE - TRAFFIC MANAGEMENT SYSTEM A Review Practiselee kok onnNo ratings yet

- Detection and Notification of Potholes and Humps On Roads: IjarcceDocument4 pagesDetection and Notification of Potholes and Humps On Roads: IjarcceDeepak DasNo ratings yet

- Density Based Smart Traffic Control System Using Canny Edge DetectionDocument10 pagesDensity Based Smart Traffic Control System Using Canny Edge DetectionIJRASETPublicationsNo ratings yet

- A Review On Iot Based Energy Monitoring and Controlling SystemDocument4 pagesA Review On Iot Based Energy Monitoring and Controlling SystemIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- Continuous Monitoring of Train ParametersDocument61 pagesContinuous Monitoring of Train ParametersPraveen MathiasNo ratings yet

- Real-Time Traffic Management SystemDocument8 pagesReal-Time Traffic Management SystemIJRASETPublicationsNo ratings yet

- Potholes and Humps Detection For Vehicle SafetyDocument4 pagesPotholes and Humps Detection For Vehicle SafetyEditor IJTSRDNo ratings yet

- Unmanned Level Crossing Controller and Rail Track Broken Detection System Using IR Sensors and Internet of Things TechnologyDocument5 pagesUnmanned Level Crossing Controller and Rail Track Broken Detection System Using IR Sensors and Internet of Things TechnologyjohnsonNo ratings yet

- Smart Control of Traffic Using Artificial Intelligence: CE4098D Major Project - Part IDocument28 pagesSmart Control of Traffic Using Artificial Intelligence: CE4098D Major Project - Part IBhaskhar ReddyNo ratings yet

- Smart Security System For Indian Rail Wagons UsingDocument7 pagesSmart Security System For Indian Rail Wagons UsingKeshav BhumarajuNo ratings yet

- Automatic Railway Gate Control System Using PLCDocument6 pagesAutomatic Railway Gate Control System Using PLCIJRASETPublicationsNo ratings yet

- Microwave and Millimeter Wave Circuits and Systems: Emerging Design, Technologies and ApplicationsFrom EverandMicrowave and Millimeter Wave Circuits and Systems: Emerging Design, Technologies and ApplicationsNo ratings yet

- Rodrick Saimon 190640722194 Project (June) OgDocument61 pagesRodrick Saimon 190640722194 Project (June) OgFrancis FaustineNo ratings yet

- UntitledDocument1 pageUntitledFrancis FaustineNo ratings yet

- Raiyway TrackDocument1 pageRaiyway TrackFrancis FaustineNo ratings yet

- Irjet Automatic Railway Track Crack DeteDocument9 pagesIrjet Automatic Railway Track Crack DeteFrancis FaustineNo ratings yet

- Ijireeice 2021 9611Document5 pagesIjireeice 2021 9611Francis FaustineNo ratings yet

- HT 030 R20en112Document1 pageHT 030 R20en112Anirudh GaragNo ratings yet

- Piezoelectric Transducer: Submitted To Submitted by Ketan Tarkas Priyesh SirDocument7 pagesPiezoelectric Transducer: Submitted To Submitted by Ketan Tarkas Priyesh SirKetan TarkasNo ratings yet

- 994 0078 D20 D200 Install Operations Guide V200 R16Document191 pages994 0078 D20 D200 Install Operations Guide V200 R16Gabriel Romero cortésNo ratings yet

- Course Title Course No(s) DE ZC415/MEL ZC415 Credit UnitsDocument15 pagesCourse Title Course No(s) DE ZC415/MEL ZC415 Credit UnitsUmesh BhadaleNo ratings yet

- L2: Sensors & TransducersDocument77 pagesL2: Sensors & TransducersMaheshNo ratings yet

- Ingaas Pin Photodiodes: Wide Spectral Response Range (0.5 To 1.7 Μm)Document5 pagesIngaas Pin Photodiodes: Wide Spectral Response Range (0.5 To 1.7 Μm)Mustafa PashaNo ratings yet

- Third First: JiieebatstateuDocument3 pagesThird First: JiieebatstateuWyndellRioNo ratings yet

- PIC16C7X: 8-Bit CMOS Microcontrollers With A/D ConverterDocument34 pagesPIC16C7X: 8-Bit CMOS Microcontrollers With A/D ConvertersureshNo ratings yet

- BOD Incubator-User ManualDocument4 pagesBOD Incubator-User ManualTech LabNo ratings yet

- Wire Code Identification: Color Code Color Color Code Color Tracer Wire Color Code ChartDocument8 pagesWire Code Identification: Color Code Color Color Code Color Tracer Wire Color Code ChartLuis Antonio Velazquez OlguinNo ratings yet

- CZ Sincro DG83Document14 pagesCZ Sincro DG83JoNo ratings yet

- EeeDocument84 pagesEeedavidmanohar232No ratings yet

- CBLM-Mensuration and CalculationDocument83 pagesCBLM-Mensuration and CalculationMat Domdom Sansano33% (3)

- Sequential CircuitsDocument32 pagesSequential CircuitsRockRahilNo ratings yet

- dmc-g85 en Adv Om PDFDocument338 pagesdmc-g85 en Adv Om PDFOmsNo ratings yet

- Wittur Midi SupraDocument34 pagesWittur Midi SupraLudwin MezaNo ratings yet

- Manual Multimetro REDDocument4 pagesManual Multimetro REDRoberto justinoNo ratings yet

- A Steady-State Model of The Photovoltaic System in Emtp: H. I. Cho, S. M. Yeo, C. H. Kim, V. TerzijaDocument6 pagesA Steady-State Model of The Photovoltaic System in Emtp: H. I. Cho, S. M. Yeo, C. H. Kim, V. TerzijagilbertomjcNo ratings yet

- Cardinal 205 Operation ManualDocument56 pagesCardinal 205 Operation ManualMatjaz LNo ratings yet

- Tracked Dozer Mining Unit For High Throughput in Mineral Sands and Alluvial OresDocument1 pageTracked Dozer Mining Unit For High Throughput in Mineral Sands and Alluvial OresVinceS2No ratings yet

- Lab 9 Areeba Sana 220610Document13 pagesLab 9 Areeba Sana 220610Bismah AsifNo ratings yet

- Single Phase SeriDocument18 pagesSingle Phase SeriFaris RiyadiNo ratings yet

- DRP001-PUC-ELE-MS-000-0628 Rev 1Document20 pagesDRP001-PUC-ELE-MS-000-0628 Rev 1Ali RazaNo ratings yet

- Re: Cb. Sms Viking - Departure Report at PROBOLINGGO // SMS - Viking Departure Detail 28 Nov'2018Document8 pagesRe: Cb. Sms Viking - Departure Report at PROBOLINGGO // SMS - Viking Departure Detail 28 Nov'2018Moch SugenkNo ratings yet

- SW 85 AspDocument65 pagesSW 85 AspEsau HernandezNo ratings yet

- Pixracer r14Document5 pagesPixracer r14ashleyNo ratings yet

- Spring DIY - Diy Spring Reverb DriverDocument49 pagesSpring DIY - Diy Spring Reverb DrivermrgreengenesNo ratings yet

- MP-6 Sonixs 800x600 2020 Rev ADocument184 pagesMP-6 Sonixs 800x600 2020 Rev Agoretty cantonNo ratings yet