Professional Documents

Culture Documents

Nissan Almera n16 2001 Electronic Repair Manual 162

Nissan Almera n16 2001 Electronic Repair Manual 162

Uploaded by

netifig352Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nissan Almera n16 2001 Electronic Repair Manual 162

Nissan Almera n16 2001 Electronic Repair Manual 162

Uploaded by

netifig352Copyright:

Available Formats

DRIVE BELTS YD

Inspection

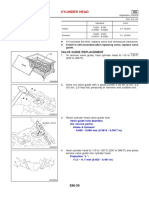

Inspection NJEM0088

+ Before inspecting the engine, make sure the engine has

cooled down; wait approximately 30 minutes after the engine

has been stopped.

+ Visually inspect all belts for wear, damage, or cracks on con-

tacting surfaces and edge areas.

+ When measuring deflection, apply 98 N (10 kg, 22 lb) at the .

marked point.

+ When checking belt deflection immediately after

installation, first adjust it to the specified value. Then,

JEM249G after turning the crankshaft two turns or more, re-adjust to

the specified value to avoid variation in deflection

between pulleys.

+ Tighten idler pulley lock nut by hand and measure deflec-

tion without looseness.

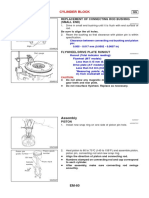

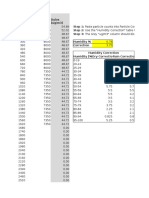

Belt Deflection:

Belt deflection with 98 N (10 kg, 22 lb) force

Belt specifica- applied* mm (in)

Applied belt

tion Limit for re-

New Adjusted

tightening

Air conditioner

HA type low 4-5 6-7

compressor 8.5 (0.335)

edge belt (0.16 - 0.20) (0.24 - 0.28)

belt

Alternator & HA type low- 9.0 - 10.5 11.0 - 12.5

water pump edge wide (0.354 - (0.433 - 16.5 (0.650)

belt angle belt 0.413) 0.492)

*: When engine is cold.

Adjustment NJEM0089

+ Adjust belts with the parts shown below.

Applied belt Belt tightening method for adjustment

Air conditioner compressor belt Adjusting bolt on idler pulley

Alternator water pump belt Adjusting bolt on alternator

CAUTION:

+ When a new belt is installed as a replacement, adjust it to

the value specified under “New” accommodations

because of insufficient adaptability with pulley grooves.

EM-84

You might also like

- Nissan Almera n16 2001 Electronic Repair Manual 111Document1 pageNissan Almera n16 2001 Electronic Repair Manual 111netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 194Document1 pageNissan Almera n16 2001 Electronic Repair Manual 194netifig352No ratings yet

- Engine PDFDocument327 pagesEngine PDFspeedkar9No ratings yet

- Installation Manual: Model T455B/C Engine BrakesDocument10 pagesInstallation Manual: Model T455B/C Engine BrakesemmanuelNo ratings yet

- DC16 Cylinder SequenceDocument1 pageDC16 Cylinder Sequencejengandxb100% (1)

- Vernacular Architecture-Agraharam-Ajila ShinyDocument22 pagesVernacular Architecture-Agraharam-Ajila Shinyajila100% (1)

- 2856 Valve ClearanceDocument1 page2856 Valve ClearanceLuis SolNo ratings yet

- 3MZ-FE Engine Belt Tension SpecificationsDocument1 page3MZ-FE Engine Belt Tension SpecificationsdilanNo ratings yet

- Super Multiple Junction (SMJ) : CautionDocument8 pagesSuper Multiple Junction (SMJ) : CautionTESA MOTORSNo ratings yet

- Nissan BD30 Valve Adjustment Procedure, Valve Lash Clearance Specifications, Nissan BD30 Engine Parts ContactDocument1 pageNissan BD30 Valve Adjustment Procedure, Valve Lash Clearance Specifications, Nissan BD30 Engine Parts ContactLuis BastardesNo ratings yet

- MantenimientoDocument1 pageMantenimientoever ojedaNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 163Document1 pageNissan Almera n16 2001 Electronic Repair Manual 163netifig352No ratings yet

- Pajero 6G72 3.5LDocument26 pagesPajero 6G72 3.5LMuruganNo ratings yet

- 4D5 SeriesDocument45 pages4D5 Seriesco.videojornalismoNo ratings yet

- Ica1602 PDFDocument52 pagesIca1602 PDFanush_swaminathanNo ratings yet

- J E0 A J E0 A LPG: Sub-SectionDocument4 pagesJ E0 A J E0 A LPG: Sub-SectionMihaela SuteuNo ratings yet

- Group 11e Engine Mechanical - PDFDocument52 pagesGroup 11e Engine Mechanical - PDFm.fadhlyaugustami fadhlyNo ratings yet

- SSV 2019 Brakes Maverick Shop Supp 219100971-030Document7 pagesSSV 2019 Brakes Maverick Shop Supp 219100971-030Coke Ker JetspeedNo ratings yet

- 4M41Document10 pages4M41Guadalupe GuerreroNo ratings yet

- Magtrol Load ISP521Document11 pagesMagtrol Load ISP521irfanNo ratings yet

- Yamaha Mio Engine Idling SpeedDocument1 pageYamaha Mio Engine Idling Speedmotley crewzNo ratings yet

- ATV 2015 OUTLANDER L (Continuously Variable Transmission (CVT) - 450) - Shop Manual - 04cE60AAE - SM51Y015S01 - enDocument22 pagesATV 2015 OUTLANDER L (Continuously Variable Transmission (CVT) - 450) - Shop Manual - 04cE60AAE - SM51Y015S01 - enfe100% (1)

- Piaggio MP3 400 I.E Service Station Manual-10Document20 pagesPiaggio MP3 400 I.E Service Station Manual-10H. KeithNo ratings yet

- Super Multiple Junction (SMJ) : CautionDocument6 pagesSuper Multiple Junction (SMJ) : CautionDarioNo ratings yet

- CBEALAN Full Es Metric LetterDocument2 pagesCBEALAN Full Es Metric Letternicole tapiaNo ratings yet

- Magtrol: AHB Series Compressed-Air-Cooled Hysteresis BrakesDocument12 pagesMagtrol: AHB Series Compressed-Air-Cooled Hysteresis Brakessezgin bayramNo ratings yet

- Values and Settings Timing Belt TensionDocument1 pageValues and Settings Timing Belt TensionsimpluokNo ratings yet

- Super Multiple Junction (SMJ) : CautionDocument8 pagesSuper Multiple Junction (SMJ) : CautionFranciscoNo ratings yet

- 11A Engine 4G9Document57 pages11A Engine 4G9Rodolphe AzarNo ratings yet

- Angular Gripper-Cam Driven Series-HeadingDocument2 pagesAngular Gripper-Cam Driven Series-HeadingBe HappyNo ratings yet

- Pressure Switches: VacuumDocument5 pagesPressure Switches: VacuumTomas VargasNo ratings yet

- TRZ Eqz Eqzk2021r3Document4 pagesTRZ Eqz Eqzk2021r3Victor avendañoNo ratings yet

- 4TNV88 BGGE Bro PDFDocument1 page4TNV88 BGGE Bro PDFSamsung KalimantanNo ratings yet

- PU126TI E1F MotorDocument2 pagesPU126TI E1F MotorANGEL UQUILLASNo ratings yet

- AjcoolDocument3 pagesAjcoolIonut GrozaNo ratings yet

- Adjustable Dead Band Pressure Switches CAT281Document15 pagesAdjustable Dead Band Pressure Switches CAT281Senthil KumarNo ratings yet

- 13b Renesis Engine DetailsDocument326 pages13b Renesis Engine DetailsGustavo RivasNo ratings yet

- Hyundai Santa FE (2005-2007) Workshop Manual - Clutch SystemDocument12 pagesHyundai Santa FE (2005-2007) Workshop Manual - Clutch SystemJenny Mora LeonNo ratings yet

- 4m4 EngineDocument60 pages4m4 EngineEdmar PalacioNo ratings yet

- FJ20 Engine ETDocument12 pagesFJ20 Engine ETAkun Bisnis KuNo ratings yet

- SEA 2019 Jet Pump SPARK Shop Supp. 219100959-021Document16 pagesSEA 2019 Jet Pump SPARK Shop Supp. 219100959-021Coke Ker JetspeedNo ratings yet

- BD355Document4 pagesBD355ruby100% (1)

- Values and Settings Accessories Belt TensionDocument1 pageValues and Settings Accessories Belt TensionsimpluokNo ratings yet

- InstDocument1 pageInstmisterminitcastleNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 116Document1 pageNissan Almera n16 2001 Electronic Repair Manual 116netifig352No ratings yet

- ATV-S07-SS06A-Air Controlled Suspension (ACS) (XMR) - Shop Manual - OUT-REN-SUPP - Version 5AA - ENDocument23 pagesATV-S07-SS06A-Air Controlled Suspension (ACS) (XMR) - Shop Manual - OUT-REN-SUPP - Version 5AA - ENJakub TubekNo ratings yet

- Shaft AlignmentDocument44 pagesShaft Alignmentrodolfosti100% (1)

- DozerDocument4 pagesDozerbipin kumarNo ratings yet

- Belt Tension PDFDocument23 pagesBelt Tension PDFAAALVARNo ratings yet

- Worldwide Parts Source LLC Source For Hard To Find Engine Gasket Sets Engine Rering Kits Engine Overhaul Kits With Pistons Phone: 269 673 2313Document125 pagesWorldwide Parts Source LLC Source For Hard To Find Engine Gasket Sets Engine Rering Kits Engine Overhaul Kits With Pistons Phone: 269 673 2313Ed MenēndezNo ratings yet

- E5111EDocument3 pagesE5111EtinhleNo ratings yet

- Catalogue Yanmar 4TNV84T GGEDocument4 pagesCatalogue Yanmar 4TNV84T GGEAhmad Fahmi IrfandaNo ratings yet

- Clamping and Braking Elementsclamping and Braking Elements RBPSDocument2 pagesClamping and Braking Elementsclamping and Braking Elements RBPSDong HungNo ratings yet

- Timing Manual Galant ST v6!24!1998 2005 PDFDocument8 pagesTiming Manual Galant ST v6!24!1998 2005 PDFArya RamadhanNo ratings yet

- Engine Tune-UpDocument43 pagesEngine Tune-UpЮра ПетренкоNo ratings yet

- Adjustment: - Electronic Modulated Air SuspensionDocument2 pagesAdjustment: - Electronic Modulated Air SuspensionThar KyiNo ratings yet

- Tavor Sar & Tavor X95: Operator Manual RevisionDocument8 pagesTavor Sar & Tavor X95: Operator Manual RevisionN'fast NgNo ratings yet

- SKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Document12 pagesSKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Erne Lange OlsenNo ratings yet

- Manual de Reparacion Motor Jac 4da1 Parte 3Document100 pagesManual de Reparacion Motor Jac 4da1 Parte 3Briset Emagsc100% (2)

- 009 - 000 - 000-2GD-FTV Engine Mechanical PDFDocument273 pages009 - 000 - 000-2GD-FTV Engine Mechanical PDFJosé Ignacio Quijada RojasNo ratings yet

- Engine Removal and InstallationDocument8 pagesEngine Removal and InstallationEj GonzalezNo ratings yet

- Engine MechanicalDocument17 pagesEngine MechanicalAdrian Marian GafincuNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 139Document1 pageNissan Almera n16 2001 Electronic Repair Manual 139netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 140Document1 pageNissan Almera n16 2001 Electronic Repair Manual 140netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 137Document1 pageNissan Almera n16 2001 Electronic Repair Manual 137netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 117Document1 pageNissan Almera n16 2001 Electronic Repair Manual 117netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 108Document1 pageNissan Almera n16 2001 Electronic Repair Manual 108netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 138Document1 pageNissan Almera n16 2001 Electronic Repair Manual 138netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 107Document1 pageNissan Almera n16 2001 Electronic Repair Manual 107netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 141Document1 pageNissan Almera n16 2001 Electronic Repair Manual 141netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 116Document1 pageNissan Almera n16 2001 Electronic Repair Manual 116netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 114Document1 pageNissan Almera n16 2001 Electronic Repair Manual 114netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 110Document1 pageNissan Almera n16 2001 Electronic Repair Manual 110netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 109Document1 pageNissan Almera n16 2001 Electronic Repair Manual 109netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 177Document1 pageNissan Almera n16 2001 Electronic Repair Manual 177netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 197Document1 pageNissan Almera n16 2001 Electronic Repair Manual 197netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 118Document1 pageNissan Almera n16 2001 Electronic Repair Manual 118netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 176Document1 pageNissan Almera n16 2001 Electronic Repair Manual 176netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 195Document1 pageNissan Almera n16 2001 Electronic Repair Manual 195netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 115Document1 pageNissan Almera n16 2001 Electronic Repair Manual 115netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 178Document1 pageNissan Almera n16 2001 Electronic Repair Manual 178netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 166Document1 pageNissan Almera n16 2001 Electronic Repair Manual 166netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 170Document1 pageNissan Almera n16 2001 Electronic Repair Manual 170netifig352No ratings yet

- Timing Chain: JEM147GDocument1 pageTiming Chain: JEM147Gnetifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 163Document1 pageNissan Almera n16 2001 Electronic Repair Manual 163netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 182Document1 pageNissan Almera n16 2001 Electronic Repair Manual 182netifig352No ratings yet

- Removal and Installation: Intake ManifoldDocument1 pageRemoval and Installation: Intake Manifoldnetifig352No ratings yet

- Installation: Drive BeltsDocument1 pageInstallation: Drive Beltsnetifig352No ratings yet

- Changing Air Cleaner FilterDocument1 pageChanging Air Cleaner Filternetifig352No ratings yet

- Oil PanDocument1 pageOil Pannetifig352No ratings yet

- Molecules of Life: 1.1 A) Explain The Structure of Water MoleculeDocument37 pagesMolecules of Life: 1.1 A) Explain The Structure of Water Moleculekhanny96No ratings yet

- Design ProjectDocument24 pagesDesign ProjectUtsavSaxena100% (1)

- Crack Width Calculation For ColumnDocument3 pagesCrack Width Calculation For ColumnMohammad KasimNo ratings yet

- Fabrication of Four Side Pneauamtic Lifting JackDocument3 pagesFabrication of Four Side Pneauamtic Lifting Jackieee4mybusinessonlyNo ratings yet

- Red Mark IndexDocument22 pagesRed Mark Indexaravindhana1a1No ratings yet

- Ot Online Quiz Ce181Document8 pagesOt Online Quiz Ce181Chrispin BarnigoNo ratings yet

- DRILLING OdtDocument4 pagesDRILLING Odtperiya salehNo ratings yet

- Tanker FamiliarisationDocument7 pagesTanker FamiliarisationPasha PavelsNo ratings yet

- PRD 3750 ConfigDocument136 pagesPRD 3750 ConfigGenus SumNo ratings yet

- Coursera SAQC4FU6AB6T PDFDocument1 pageCoursera SAQC4FU6AB6T PDFbabaguglianaNo ratings yet

- DSPF Paper Feed SectionDocument3 pagesDSPF Paper Feed SectionAbraham Wzziel Aguilar HernandezNo ratings yet

- Dylos Conversion Education - Cehs.health - Umt.eduDocument117 pagesDylos Conversion Education - Cehs.health - Umt.eduMCNo ratings yet

- Alfa 147 - Brake Pad and Disc Change Guide (Front)Document15 pagesAlfa 147 - Brake Pad and Disc Change Guide (Front)arnold7894100% (3)

- Mackie PPM1012 12 Channel Powered Mixer ManualDocument36 pagesMackie PPM1012 12 Channel Powered Mixer Manualaaronspeed620No ratings yet

- Intro To VulcanDocument242 pagesIntro To VulcanNik Agarwal67% (3)

- ABB Price Book 516Document1 pageABB Price Book 516EliasNo ratings yet

- Project ReportDocument24 pagesProject ReportAdarsh RajNo ratings yet

- GIS For Facilities ManagementDocument54 pagesGIS For Facilities ManagementEsri100% (1)

- Shipping Part3Document32 pagesShipping Part3mohdsuhail2k3055No ratings yet

- A DSB Tender Clarifications 2Document1 pageA DSB Tender Clarifications 2anupamkhannaNo ratings yet

- Cooling and Lubrication of I.C. EngineDocument18 pagesCooling and Lubrication of I.C. EnginePrakhar ParetaNo ratings yet

- WSC IomDocument36 pagesWSC IomArief100% (2)

- Instruction Manual: Slim Burner InsertDocument14 pagesInstruction Manual: Slim Burner Insertflorin_iordan285No ratings yet

- IP 60-75 Cosmic Motor Starter - New PDFDocument16 pagesIP 60-75 Cosmic Motor Starter - New PDFAshok Kumar JenaNo ratings yet

- Wafer-Level Chip Scale Package (WLCSP)Document30 pagesWafer-Level Chip Scale Package (WLCSP)Anonymous G1iPoNOKNo ratings yet

- Latex Side by Side ImagesDocument3 pagesLatex Side by Side ImagesSalman ShahNo ratings yet

- Brochure Swimming PoolDocument12 pagesBrochure Swimming PoolzaidosamaNo ratings yet

- 9868 - Procedures For Air Navigation Services Training Second Edition 2016Document214 pages9868 - Procedures For Air Navigation Services Training Second Edition 2016Vincent Grondin100% (2)

- Avedos Risk2value System Requirements v5 3Document6 pagesAvedos Risk2value System Requirements v5 3new2trackNo ratings yet