Professional Documents

Culture Documents

Oil Pan

Oil Pan

Uploaded by

netifig3520 ratings0% found this document useful (0 votes)

27 views1 pageThe document provides installation instructions for an oil pan. It lists the steps to install the upper oil pan using the correct bolts and tightening torque. It instructs to wait 30 minutes before refilling the engine oil. It then lists additional steps to install related components like the transaxle bolts, oil pan cover, and front exhaust tube. Finally, it describes preparing the surfaces and applying liquid gasket to install the lower oil pan.

Original Description:

Original Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides installation instructions for an oil pan. It lists the steps to install the upper oil pan using the correct bolts and tightening torque. It instructs to wait 30 minutes before refilling the engine oil. It then lists additional steps to install related components like the transaxle bolts, oil pan cover, and front exhaust tube. Finally, it describes preparing the surfaces and applying liquid gasket to install the lower oil pan.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

27 views1 pageOil Pan

Oil Pan

Uploaded by

netifig352The document provides installation instructions for an oil pan. It lists the steps to install the upper oil pan using the correct bolts and tightening torque. It instructs to wait 30 minutes before refilling the engine oil. It then lists additional steps to install related components like the transaxle bolts, oil pan cover, and front exhaust tube. Finally, it describes preparing the surfaces and applying liquid gasket to install the lower oil pan.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

OIL PAN YD

Installation (Cont’d)

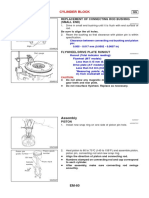

d. Install upper oil pan.

+ Tighten bolts in numerical order.

+ Bolt dimensions vary depending on the installation location.

Refer to the following and use appropriate bolts.

M6 x 30 mm: Bolt No. 15, 16

M8 x 25 mm: Bolt No. 3, 4, 9, 10

M8 x 60 mm: Bolt No. 1, 2, 5, 6, 7, 8, 11, 12, 13, 14

+ The shank length under the bolt neck above is the length of the

threaded part (pilot portion not included).

+ Wait at least 30 minutes before refilling engine oil.

JEM116G

2. Install the four engine-to-transaxle bolts. For tightening torque,

refer to MT-24, “Installation”.

3. Install oil pan cover.

4. Install air compressor bracket.

: 57 - 65 N·m (5.8 - 6.7 kg-m, 42 - 48 ft-lb)

5. Install drive belts.

6. Install center member.

7. Install front and rear engine mounting insulator nuts and bolts.

8. Install crankshaft position sensor (TDC sensor).

+ Tighten bolt while positioning and setting the side surface of

the crankshaft position sensor (TDC sensor) sleeve against

the arc of the upper oil pan.

9. Install front exhaust tube and its support.

10. Install oil strainer.

JEM119G

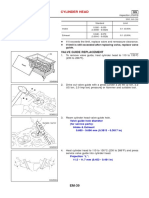

11. Install lower oil pan.

a. Use a scraper to remove old liquid gasket from mating sur-

faces.

+ Also remove old liquid gasket from mating surface of

upper oil pan.

SEM493G

b. Apply a continuous bead of liquid gasket to mating surface of

lower oil pan.

+ Use Genuine Liquid Gasket or equivalent.

SEM159F

EM-91

You might also like

- DD15 Detroit DieselDocument10 pagesDD15 Detroit Dieselstarsky100% (4)

- Nissan Almera n16 2001 Electronic Repair Manual 111Document1 pageNissan Almera n16 2001 Electronic Repair Manual 111netifig352No ratings yet

- Cylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsDocument17 pagesCylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsFran SanchezNo ratings yet

- 2002 Nissan Altima 2.5 Timing Chain MarksDocument16 pages2002 Nissan Altima 2.5 Timing Chain MarksInternal88100% (1)

- Nissan Almera n16 2001 Electronic Repair Manual 194Document1 pageNissan Almera n16 2001 Electronic Repair Manual 194netifig352No ratings yet

- SECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyDocument35 pagesSECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyHassan Vela VenegasNo ratings yet

- Cylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsDocument8 pagesCylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsFran SanchezNo ratings yet

- Cummins Ism, QSMDocument11 pagesCummins Ism, QSMibnu67% (6)

- Poseidon Pegasus Seals Deluxe (Forw) Installation and Maintenance Manual...Document10 pagesPoseidon Pegasus Seals Deluxe (Forw) Installation and Maintenance Manual...Marlon Alejandro Arboleda TapiaNo ratings yet

- Oilpump4afe PDFDocument7 pagesOilpump4afe PDFhanzhio elNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 182Document1 pageNissan Almera n16 2001 Electronic Repair Manual 182netifig352No ratings yet

- Flywheel 2 PDFDocument4 pagesFlywheel 2 PDFvictoverNo ratings yet

- Rammer 1655 Service 2015Document52 pagesRammer 1655 Service 2015SerkanAlNo ratings yet

- Engine AssemblyDocument13 pagesEngine AssemblyJacob SilverstielkNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 140Document1 pageNissan Almera n16 2001 Electronic Repair Manual 140netifig352No ratings yet

- Procedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFDocument12 pagesProcedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFirvan hardiansyahNo ratings yet

- Cylinder Head Assembly: Service and RepairDocument6 pagesCylinder Head Assembly: Service and RepairJose PichinteNo ratings yet

- Rear SealDocument9 pagesRear SealHammad Uddin JamilyNo ratings yet

- Reassembly: 1. Assemble Piston and Connecting RodDocument7 pagesReassembly: 1. Assemble Piston and Connecting Roddawitmesfin9No ratings yet

- Bomba Aceite Oil Cooler Carcasa FiltrosDocument15 pagesBomba Aceite Oil Cooler Carcasa FiltrosFredy QuistialNo ratings yet

- Weichai Engine PrintDocument52 pagesWeichai Engine PrintKo ZayNo ratings yet

- Oil PumpDocument4 pagesOil PumpmohanamarasingheNo ratings yet

- ENGINE Timing 4ZZ-FEDocument31 pagesENGINE Timing 4ZZ-FEAriel100% (1)

- Nissan Almera n16 2001 Electronic Repair Manual 197Document1 pageNissan Almera n16 2001 Electronic Repair Manual 197netifig352No ratings yet

- Camry Solara SEV6Document13 pagesCamry Solara SEV6arturmikieNo ratings yet

- MSD 4151Document8 pagesMSD 4151rxhughesNo ratings yet

- Engine Disassembly Assembly 1Document9 pagesEngine Disassembly Assembly 1Moaed KanbarNo ratings yet

- Sistema de TransmisionDocument239 pagesSistema de TransmisionCez Lopez BañezNo ratings yet

- Trooper Mechanic 2Document1 pageTrooper Mechanic 2jose sestayoNo ratings yet

- Clutch ManualDocument16 pagesClutch ManualCO BDNo ratings yet

- Piston: Zoom Sized For PrintDocument8 pagesPiston: Zoom Sized For PrintHillary WoodwardNo ratings yet

- Camry Solara SLEV6Document13 pagesCamry Solara SLEV6arturmikieNo ratings yet

- Cylinder Bloc ReassemblyDocument7 pagesCylinder Bloc ReassemblyYannick de WalqueNo ratings yet

- Torque de Bancada DD15Document6 pagesTorque de Bancada DD15Jhovanny TorresNo ratings yet

- Toyota Haice TDocument42 pagesToyota Haice TEdgar GuzmanNo ratings yet

- Thermal Recirculation Valve Installation InstructionsDocument7 pagesThermal Recirculation Valve Installation InstructionsSean DuncanNo ratings yet

- Volvo D13H Shop Armed Vol1Document33 pagesVolvo D13H Shop Armed Vol1Roberth Sanchez100% (1)

- 4-S - Pump AssyDocument11 pages4-S - Pump AssyDedy hermawanNo ratings yet

- Critical Installation Tips:: Image 2Document2 pagesCritical Installation Tips:: Image 2elpino69No ratings yet

- Reassembly of Basic EngineDocument19 pagesReassembly of Basic EnginePepe AlNo ratings yet

- Installation Procedure: NoticeDocument7 pagesInstallation Procedure: NoticeВиталий ОрловNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 167Document1 pageNissan Almera n16 2001 Electronic Repair Manual 167netifig352No ratings yet

- Inplant Training ReportDocument56 pagesInplant Training Reportsankey11286No ratings yet

- Cummins Ism QSM PDFDocument11 pagesCummins Ism QSM PDFEng-AhmedRashadNo ratings yet

- Timing Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalDocument7 pagesTiming Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalPablo FernandezNo ratings yet

- Power Steering Pump Service and Repair, 1999 Toyota Truck 4 Runner 2WDDocument8 pagesPower Steering Pump Service and Repair, 1999 Toyota Truck 4 Runner 2WDCarlos VillaltaNo ratings yet

- Compressor WabcoDocument6 pagesCompressor Wabcoruben_cruz_34No ratings yet

- Greddy SBD ManualDocument22 pagesGreddy SBD ManualKenneth ChanNo ratings yet

- Sisu Citius Series 44-49-66 74 and 84 Engines Workshop Manual 80 118Document39 pagesSisu Citius Series 44-49-66 74 and 84 Engines Workshop Manual 80 118Сергей ПриймакNo ratings yet

- Connecting Rod Bearings - Install: NoticeDocument3 pagesConnecting Rod Bearings - Install: NoticeqwuLzNo ratings yet

- Figure 1-17 Location of Engine Serial and Model Numbers: Series 60 Service ManualDocument2 pagesFigure 1-17 Location of Engine Serial and Model Numbers: Series 60 Service ManualvictoverNo ratings yet

- Cylinder Head Gasket (Hatchback) - Installation (05 - 2013 - ) (Cylinder Head Assembly) - Yaris HeadDocument9 pagesCylinder Head Gasket (Hatchback) - Installation (05 - 2013 - ) (Cylinder Head Assembly) - Yaris HeadFran SanchezNo ratings yet

- Cylinder Head Assembly: Service and Repair Removal and InstallationDocument2 pagesCylinder Head Assembly: Service and Repair Removal and InstallationJose Pichinte100% (1)

- Timing Belt: Service and Repair Timing Belt Removal and InstallationDocument4 pagesTiming Belt: Service and Repair Timing Belt Removal and InstallationJosé Carlos da silvaNo ratings yet

- 1991 Nissan-Datsun 240SX Cylinder Head RemovalDocument11 pages1991 Nissan-Datsun 240SX Cylinder Head Removalgigabyte3235840No ratings yet

- 1A-112 Engine Mechanical (4Hk1, 6Hk1) : Special Tool Special ToolDocument1 page1A-112 Engine Mechanical (4Hk1, 6Hk1) : Special Tool Special ToolВладимир ШведNo ratings yet

- Sistema de Admision - Mbe900-05aDocument6 pagesSistema de Admision - Mbe900-05aFernando NunezNo ratings yet

- 428f cylinder headDocument1 page428f cylinder headjohnsaad15No ratings yet

- Installation-manual-V-rod-turbo (1)Document17 pagesInstallation-manual-V-rod-turbo (1)bikeleo188No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 140Document1 pageNissan Almera n16 2001 Electronic Repair Manual 140netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 139Document1 pageNissan Almera n16 2001 Electronic Repair Manual 139netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 141Document1 pageNissan Almera n16 2001 Electronic Repair Manual 141netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 137Document1 pageNissan Almera n16 2001 Electronic Repair Manual 137netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 138Document1 pageNissan Almera n16 2001 Electronic Repair Manual 138netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 109Document1 pageNissan Almera n16 2001 Electronic Repair Manual 109netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 177Document1 pageNissan Almera n16 2001 Electronic Repair Manual 177netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 110Document1 pageNissan Almera n16 2001 Electronic Repair Manual 110netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 116Document1 pageNissan Almera n16 2001 Electronic Repair Manual 116netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 115Document1 pageNissan Almera n16 2001 Electronic Repair Manual 115netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 108Document1 pageNissan Almera n16 2001 Electronic Repair Manual 108netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 107Document1 pageNissan Almera n16 2001 Electronic Repair Manual 107netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 114Document1 pageNissan Almera n16 2001 Electronic Repair Manual 114netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 117Document1 pageNissan Almera n16 2001 Electronic Repair Manual 117netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 118Document1 pageNissan Almera n16 2001 Electronic Repair Manual 118netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 195Document1 pageNissan Almera n16 2001 Electronic Repair Manual 195netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 197Document1 pageNissan Almera n16 2001 Electronic Repair Manual 197netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 170Document1 pageNissan Almera n16 2001 Electronic Repair Manual 170netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 182Document1 pageNissan Almera n16 2001 Electronic Repair Manual 182netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 178Document1 pageNissan Almera n16 2001 Electronic Repair Manual 178netifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 176Document1 pageNissan Almera n16 2001 Electronic Repair Manual 176netifig352No ratings yet

- Installation: Drive BeltsDocument1 pageInstallation: Drive Beltsnetifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 166Document1 pageNissan Almera n16 2001 Electronic Repair Manual 166netifig352No ratings yet

- Removal and Installation: Intake ManifoldDocument1 pageRemoval and Installation: Intake Manifoldnetifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 163Document1 pageNissan Almera n16 2001 Electronic Repair Manual 163netifig352No ratings yet

- Changing Air Cleaner FilterDocument1 pageChanging Air Cleaner Filternetifig352No ratings yet

- Timing Chain: JEM147GDocument1 pageTiming Chain: JEM147Gnetifig352No ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 167Document1 pageNissan Almera n16 2001 Electronic Repair Manual 167netifig352No ratings yet